Steel plate combined shear wall capable of achieving connection through crossed bending type partition board and preparing method

A combined shear wall and partition technology, applied in the direction of walls, building materials, building components, etc., can solve the problems affecting the overall strength of the steel plate combined shear wall, the difficulty in ensuring the quality of concrete pouring, and the long welding seam between the partition and the outer steel plate. and other problems, to achieve the effect of reducing welding residual stress, improving the quality of pouring and tamping, and improving the overall mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

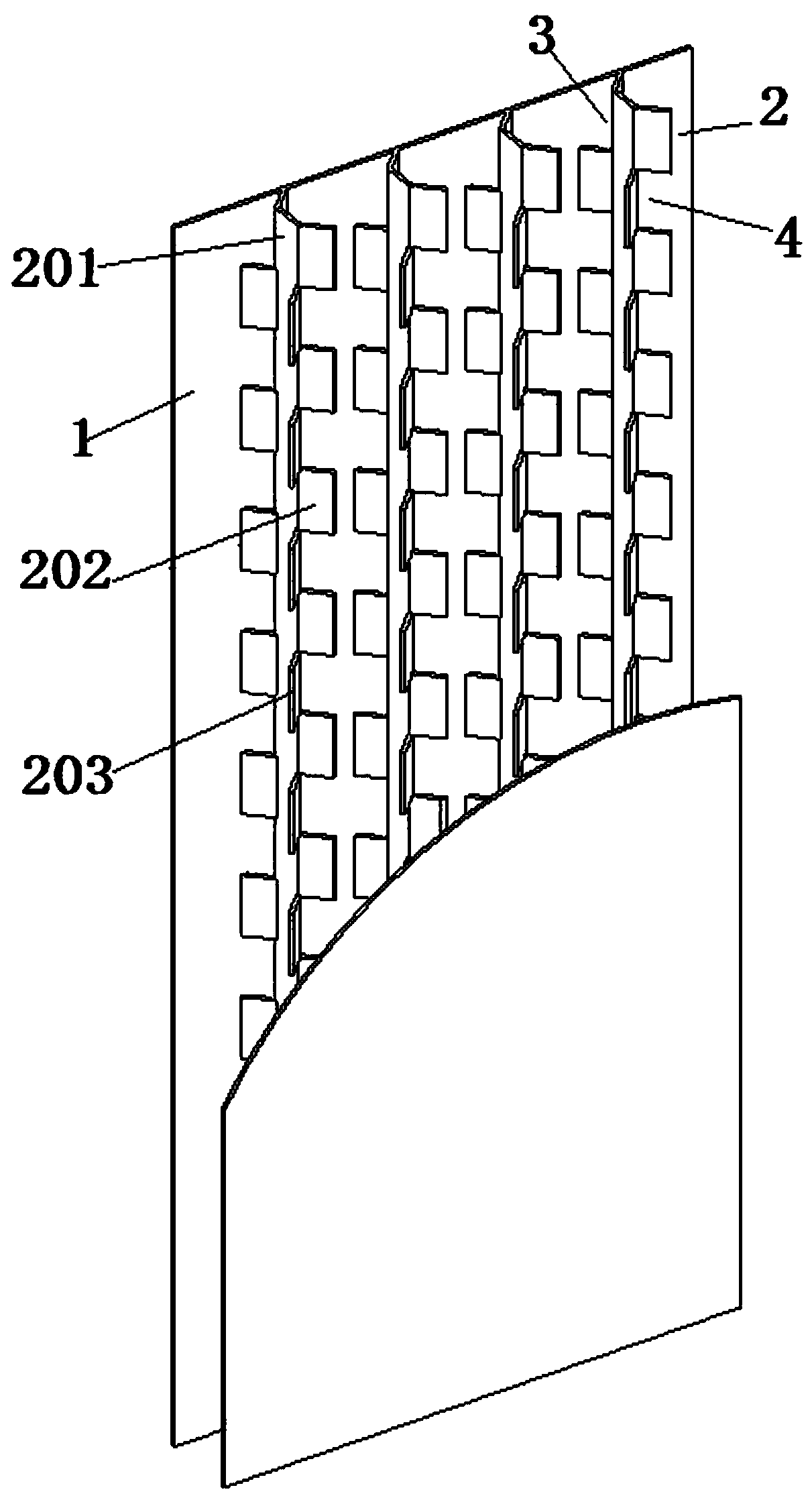

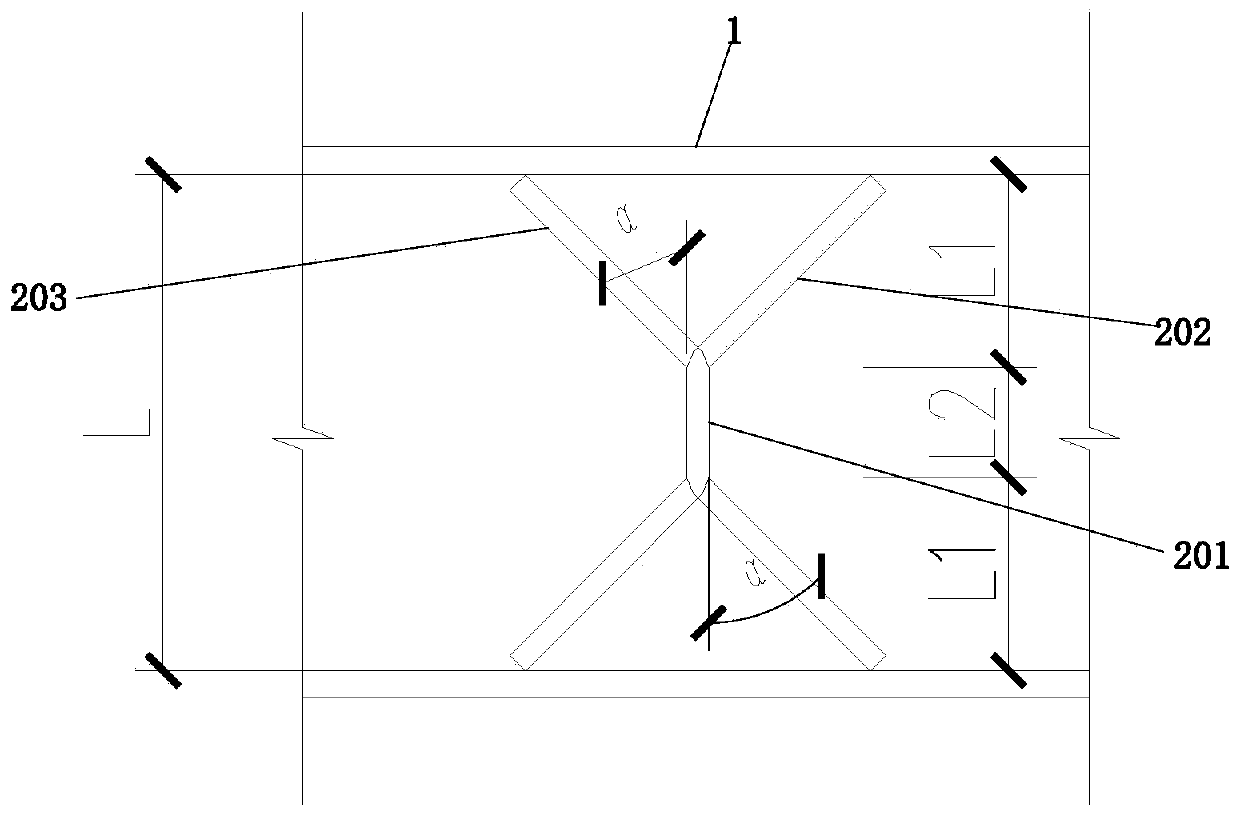

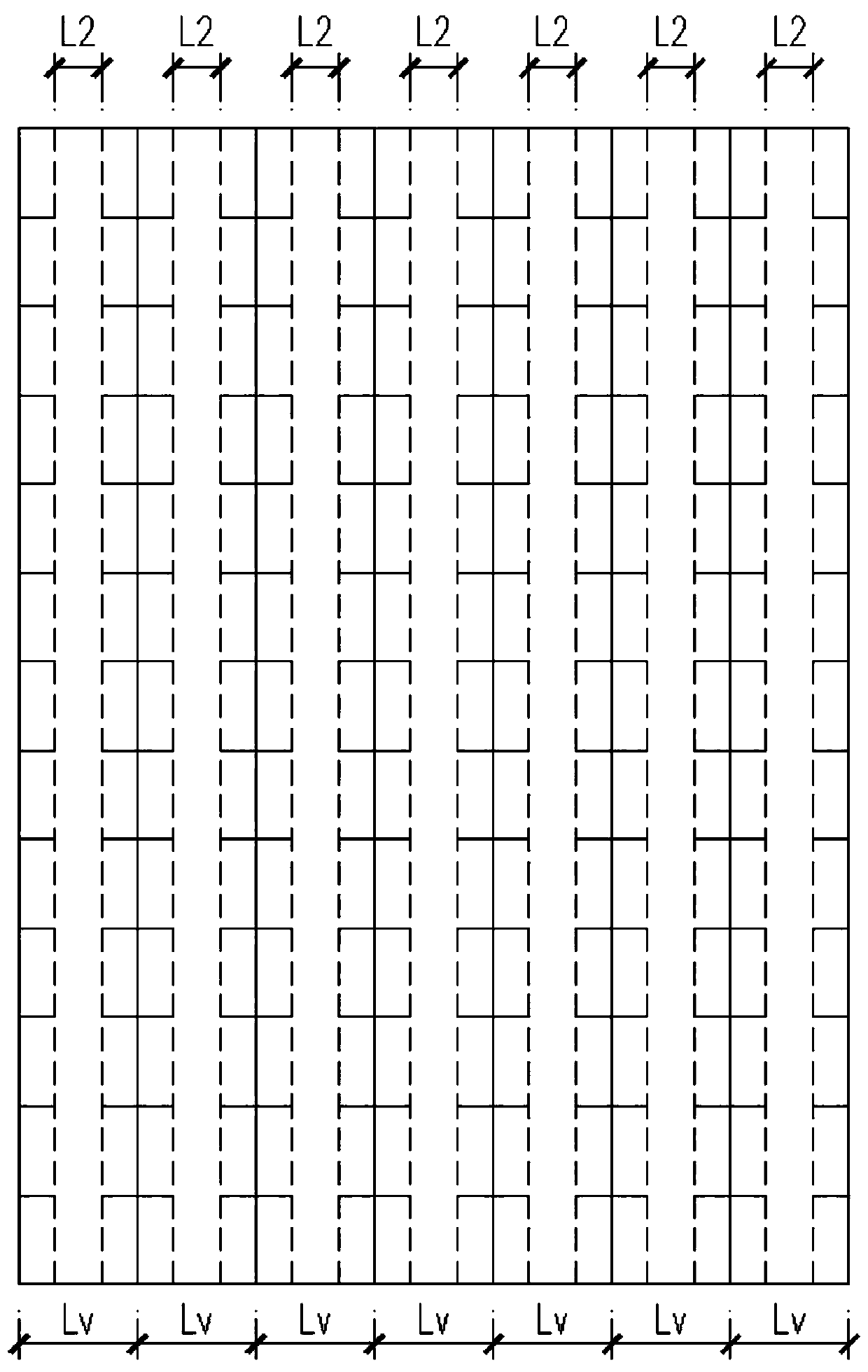

[0028] Example 1. A steel plate composite shear wall connected by cross-bending partitions, which is composed of Figure 1 to Figure 5 As shown, it includes two outsourcing steel plates 1 arranged in parallel, and a cross-bending partition plate 2 is arranged between the two outsourcing steel plates 1; between the cross-bending type partition plate 2 and the outsourcing steel plate 1, there are upper and lower alternately distributed first An opening 3 and a second opening 4 .

[0029] The cross-bending separator 2 includes a separator body 201, and a set of bending edge groups are arranged on both sides of the separator body 201; Two bent edges 203 .

[0030] Both sides of the partition body 201 are provided with groups of bent edges symmetrically distributed with each other.

[0031] The two sides of the partition body 201 are provided with groups of bent edges that are mutually offset. The first bending edges 202 on both sides of the partition body 201 are vertically st...

Embodiment 2

[0047] Example 2. A steel plate composite shear wall connected by cross-bending partitions, which is composed of Figure 2 to Figure 6 As shown, it includes two outsourcing steel plates 1 arranged in parallel, and a cross-bending partition plate 2 is arranged between the two outsourcing steel plates 1; between the cross-bending type partition plate 2 and the outsourcing steel plate 1, there are upper and lower alternately distributed first An opening 3 and a second opening 4 .

[0048]The cross-bending separator 2 includes a separator body 201, and a set of bending edge groups are arranged on both sides of the separator body 201; Two bent edges 203 .

[0049] Both sides of the partition body 201 are provided with groups of bent edges symmetrically distributed with each other.

[0050] The two sides of the partition body 201 are provided with groups of bent edges that are mutually offset. The first bending edges 202 on both sides of the partition body 201 are vertically sta...

Embodiment 3

[0065] Example 3. A steel plate composite shear wall connected by cross-bending partitions, which is composed of Figure 7 to Figure 8 As shown, it includes two outsourcing steel plates 1 arranged in parallel, and two cross-bending partitions 2 arranged side by side are arranged between the two outsourcing steel plates 1; The first openings 3 and the second openings 4 are distributed alternately up and down.

[0066] The cross-bending separator 2 includes a separator body 201, and a set of bending edge groups are arranged on both sides of the separator body 201; Two bent edges 203 .

[0067] Both sides of the partition body 201 are provided with groups of bent edges symmetrically distributed with each other.

[0068] The two sides of the partition body 201 are provided with groups of bent edges that are mutually offset. The first bending edges 202 on both sides of the partition body 201 are vertically staggered, and the opposite second bending edges 203 on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com