Heat treating method for large-scale device integral anneal

A heat treatment method and large-scale equipment technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as narrow application areas and inability to solve large-scale equipment heat treatment problems, and achieve the effect of reducing welding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

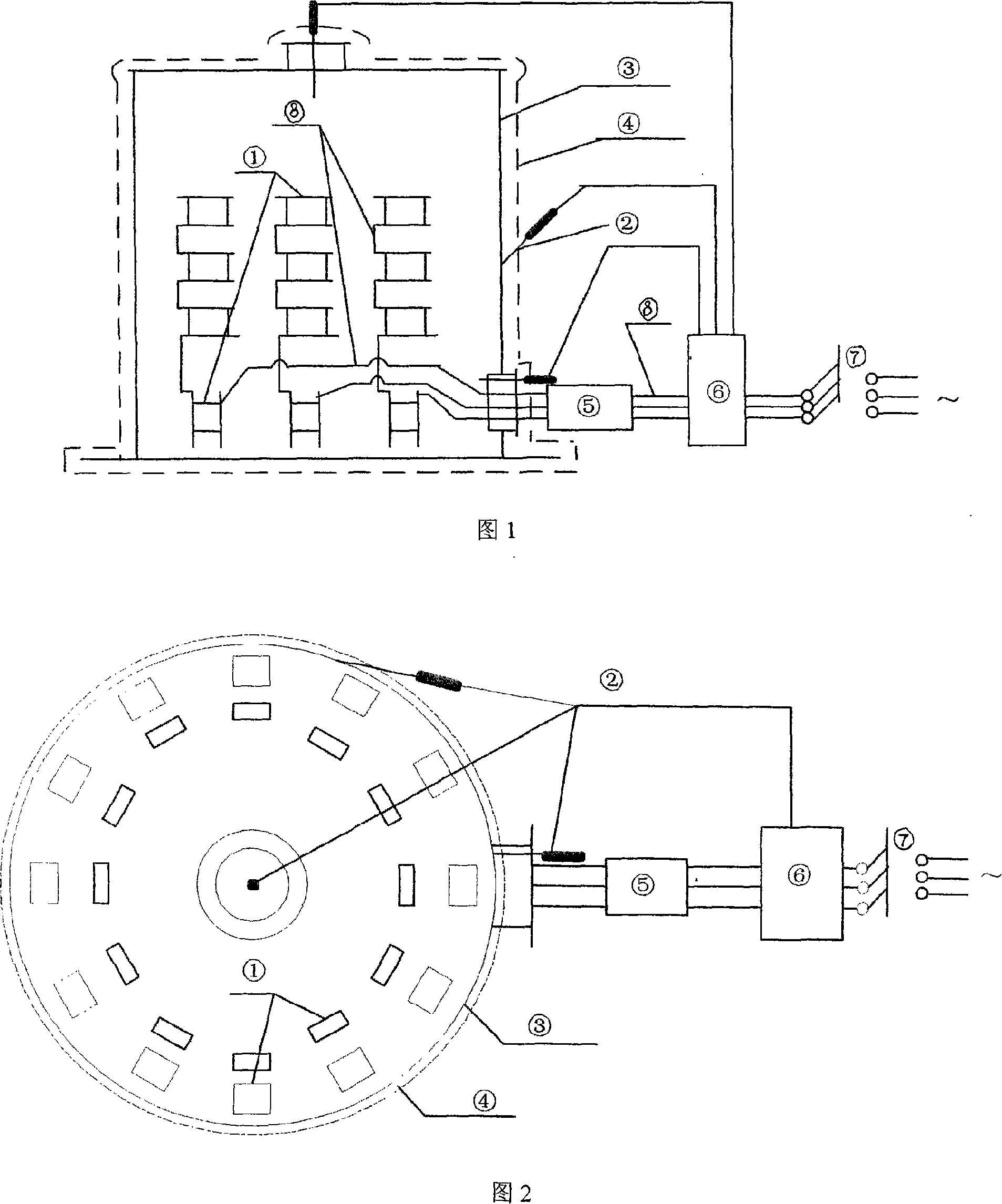

[0015] Embodiment 1: In July 2007, the self-evaporator of ф4000×9000mm manufactured by Guiyang Baiyun Aluminum Industrial Equipment Manufacturing Plant was subjected to overall annealing treatment by the method of the present invention, as shown in Figure 1. The process is as follows:

[0016] The first step is to arrange the electric heating plate: inside the evaporator shell 3, the electric heating plate 1 is arranged in a stepwise manner according to its shape,

[0017] The second step is to establish a temperature control system: connect the electric heating plate 1 arranged in the previous step with the connecting wire 8, first connect it inside the device separately, and then connect it outside the device after checking it is correct, and finally connect it to the temperature control system through the interface converter 5 Box 6; then arrange the thermocouple thermometer 2, and connect it to the temperature control box 6 with a data line to build a temperature control sy...

Embodiment 2

[0020] Example 2 In April 2007, the on-site assembled chemical cleaning tank with a volume of ф6000×6000 was subjected to overall annealing heat treatment in the alumina plant of Chalco Guizhou Branch, as shown in Figure 2, and the process was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com