Bell type full-argon protective annealing method of titanium coil rod wire

A technology for wire rods and wires, applied in the field of heat treatment of titanium metal materials, can solve the problems of annealing without inert gas and protective atmosphere for titanium wire rods and wires, and achieve the effect of solving the problem of annealing heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

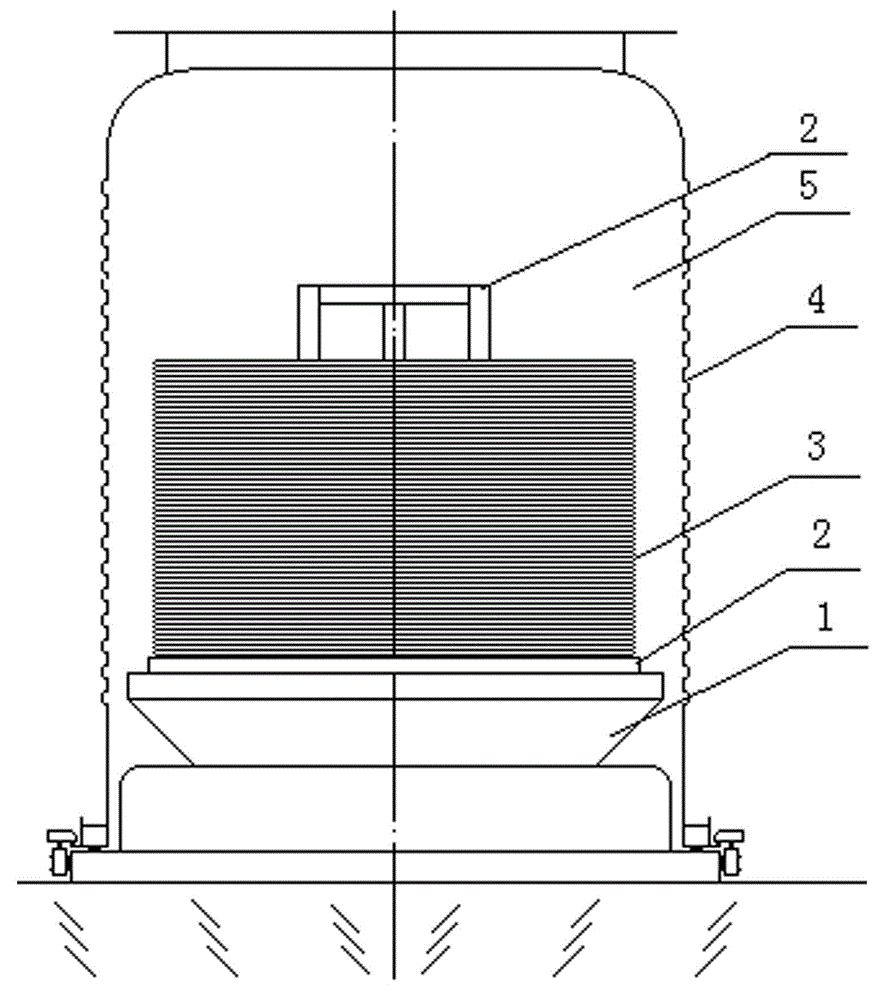

[0019] Titanium wire rod cover type full argon protection annealing method, the present invention adopts the following process steps:

[0020] A. Put 2235kg titanium wire rod into the bell furnace;

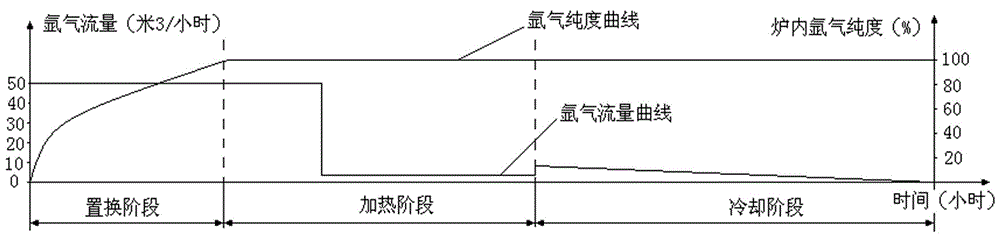

[0021] B. Purging and replacing the furnace with argon with a purity of 99.999%. The time for purging and replacing is 60 minutes. After the replacement, the purity of the argon atmosphere in the bell-type furnace is 98.95%. 3 / Hour;

[0022] C. Use a heating mantle to ignite and heat up and keep warm, and use argon gas with a purity of 99.999% to purge and maintain pressure during the heating up and keeping warm; the purity of the argon atmosphere in the furnace during the heating up and keeping warm is 99.98%. Argon purge flow rate is 45 m 3 / hour, the time is 2.5 hours, and the argon pressure holding flow rate is 3 m 3 / hour, the time is 4.5 hours, and the purity of the argon atmosphere in the furnace is 99.91%;

[0023] D. After heating, use a heating hood to cool with a...

Embodiment 2

[0027] A. Put 1587kg titanium wire rod into the bell furnace;

[0028] B. Purging and replacing the furnace with argon with a purity of 99.999%. The time for purging and replacing is 62 minutes. After the replacement, the purity of the argon atmosphere in the bell-type furnace is 98.99%. m 3 / Hour;

[0029] C. Use a heating mantle to ignite and heat up and keep warm, and use argon gas with a purity of 99.999% to purge and maintain pressure during the heating up and keeping warm; the purity of the argon atmosphere in the furnace during the heating up and keeping warm is 99.98%. Argon purge flow rate is 45 m 3 / hour, the time is 2.0 hours, the argon pressure holding flow is 4 m 3 / hour, the time is 4.0 hours, and the purity of the argon atmosphere in the furnace is 99.85%;

[0030] D. After heating, use a heating hood to cool with a heating hood. During the cooling process with a heating hood, use argon gas with a purity of 99.999% for supplementary pressure maintenance. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com