Ore dressing method of high-muddy high-alkalinity gangue low-grade refractory copper oxide ores

A copper oxide ore, low-grade technology, applied in the direction of chemical instruments and methods, flotation, wet separation, etc., can solve the problems of unproposed solutions, high production costs, complicated process flow, etc., and achieve the best mineral processing technology Parameters, the best beneficiation index, and the effect of overcoming low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

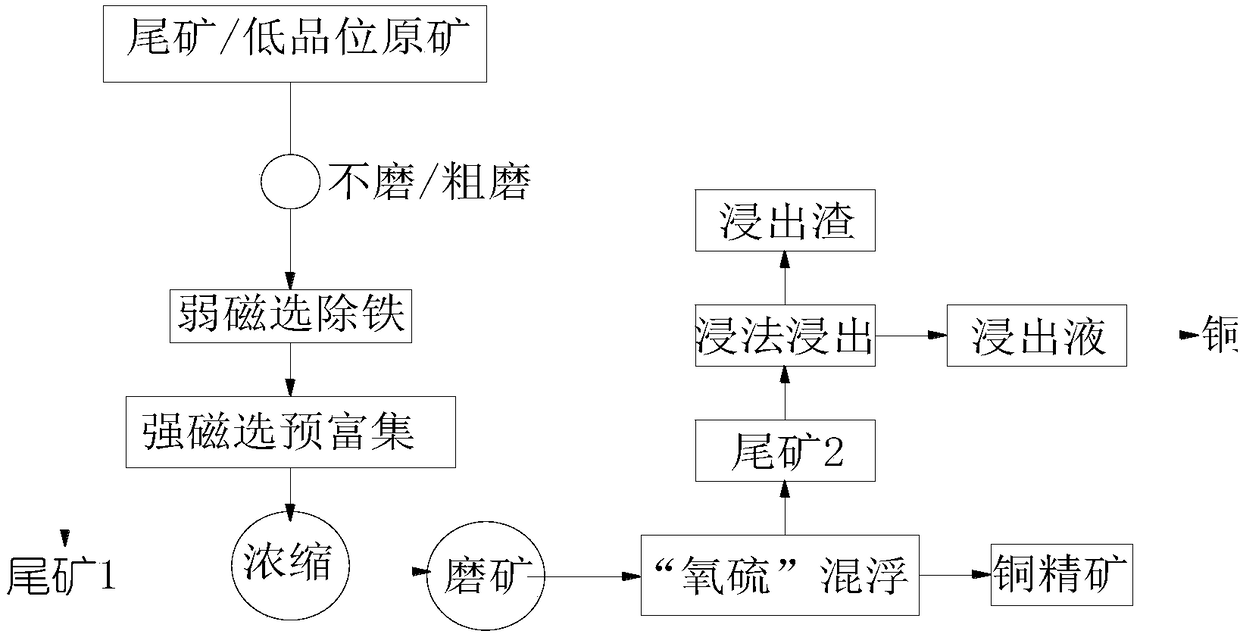

Image

Examples

Embodiment 1

[0029] The flotation tailings of a copper oxide ore containing high muddy and highly alkaline gangue, the ore contains about 0.26% copper, and the copper minerals are mainly bornite, chalcopyrite, chalcocite, and blue chalcocite , Malachite, Chloratackite, etc., the particle size is relatively small, about 1-10μm, the degree of dissociation is low, and the intergenerational relationship is more complicated. The gangue minerals are mainly calcite, feldspar, quartz, chlorite and mica. It is a low-grade refractory copper oxide ore with high shale and high alkaline gangue.

[0030] The ore dressing recovery method of the flotation tailings comprises the following steps:

[0031] (1) Flotation tailings pulping: the concentration of flotation tailings pulp is 20-24%;

[0032] (2) Magnetic separation: the pulp is subjected to weak magnetic separation to remove strong magnetic ore minerals to obtain weak magnetic separation tailings, and the weak magnetic separation tailings are sub...

Embodiment 2

[0038] The valuable element that can be recovered in a stockpile ore is copper, with a grade of 0.4-0.6%. The copper sulfide minerals in the ore are mainly blue chalcocite and chalcocite, followed by copper blue, and a small amount of chalcopyrite and bornite. ore, natural copper, etc.; the main copper oxide minerals are azurite and malachite; other metal minerals are mainly limonite, followed by ilmenite, pyrite, rutile, and a small amount of pyrrhotite and galena Wait. Gangue minerals are mainly calcite, quartz and plagioclase, followed by muscovite, chlorite, dolomite and potassium feldspar, and a small amount of apatite and barite can also be seen. It is a low-grade refractory copper oxide ore with high shale and high alkaline gangue.

[0039] This ore recovery copper method comprises the following steps:

[0040] (1) Raw ore pulping: raw ore grinding fineness -0.074mm accounts for about 60%, and the pulp concentration is 24-28%;

[0041](2) Magnetic separation: the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com