Mineral pre-enrichment method based on solid microwaves

A pre-enrichment and mineral technology, applied in grain processing, etc., can solve the problems of large waste generation, high energy consumption and high cost of beneficiation, and achieve the effects of short detection time, broad application prospects and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

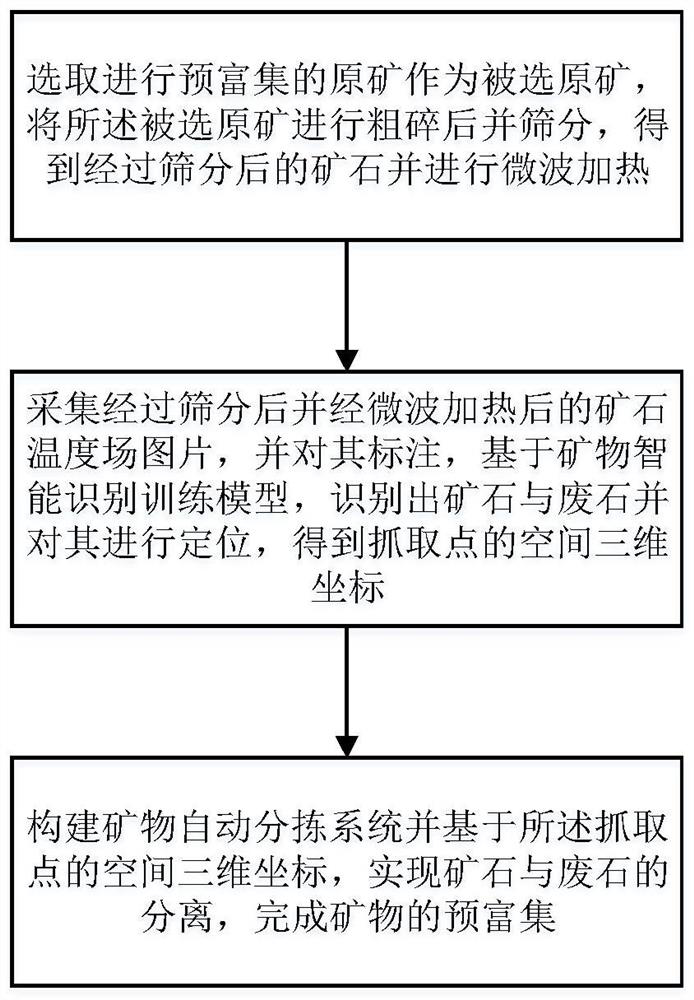

Method used

Image

Examples

Embodiment 1

[0050] The mineralization of a copper deposit is mainly composed of plagioclase and orthoclase, and a small amount of hornblende, quartz and other minerals. The main sulfide minerals are bornite, chalcopyrite and pyrite.

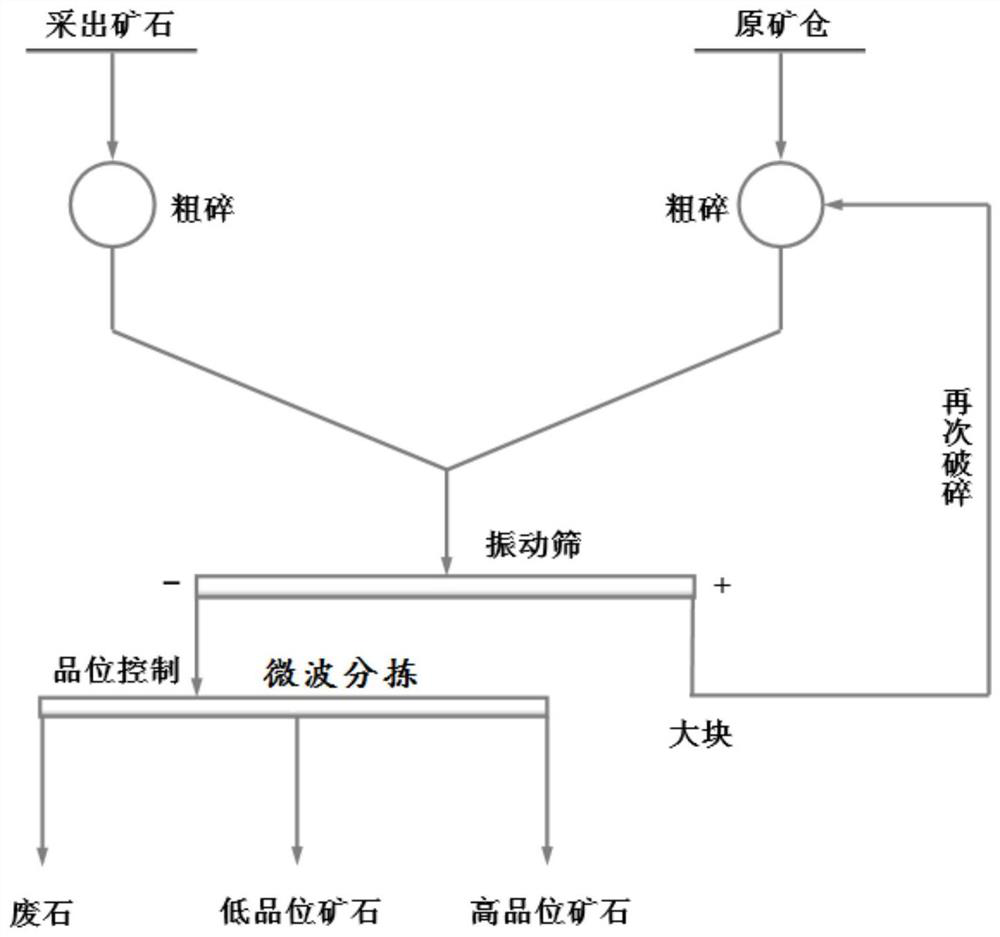

[0051] see figure 2 , a process flow chart of an ore pre-enrichment method based on solid-state microwave.

[0052] Ore pre-enrichment method based on magnetic resonance technology, including:

[0053] Step 1: Selected raw ore. The selected raw ore comes from the ore extracted from the stope or the raw ore warehouse.

[0054] Step 2: The raw ore is broken. The raw ore from the stope or the raw ore bin is coarsely crushed by the crusher.

[0055] Step 3: Sieve the bulk. The coarsely crushed raw ore is screened by a 50mm×50mm vibrating screen to remove large ore in the raw ore, and the large ore is discharged into the crusher for further crushing.

[0056] Step 4: Solid state microwave pre-enrichment. Different picture data of bornite, chalcopyrite and...

Embodiment 2

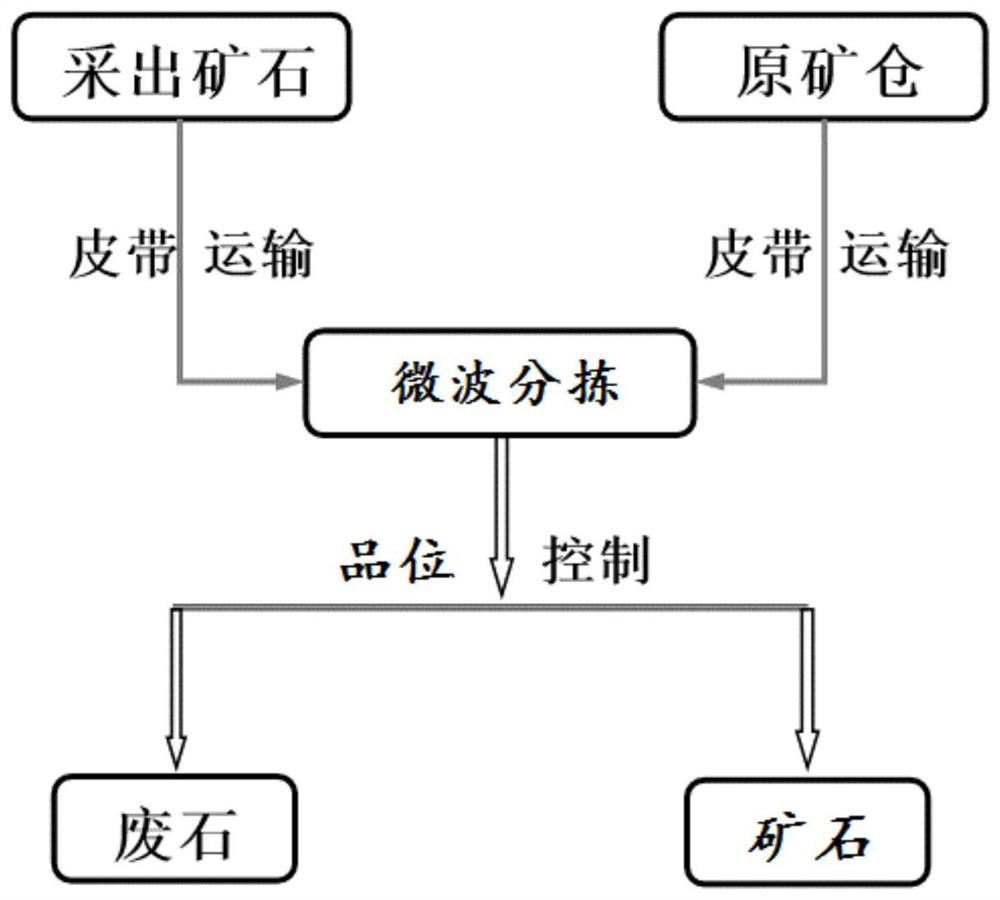

[0058] see image 3 , a flow chart of an ore pre-enrichment method based on solid-state microwave technology. The difference between Embodiment 2 and Embodiment 1 is that the crushing in step 2 and the vibration screening in step 3 are not required. For the selected raw ore without large pieces, the ore pre-enrichment can be directly carried out through the solid-state microwave pre-enrichment system in step 4 without crushing.

Embodiment 3

[0060] see Figure 4 , a process flow chart of an ore pre-concentration method based on solid-state microwave technology. The difference between embodiment three and embodiment one is that step 4 in embodiment three can control the concentration of certain minerals in the solid-state microwave pre-concentration system. In the case of fixed microwave frequency and fixed microwave heating time, according to the temperature rise and temperature field difference of mixed minerals, the raw ore can be pre-enriched into three types: waste rock, low-grade ore and high-grade ore.

[0061] The invention uses microwave technology to heat minerals at a set frequency, measures mineral-related parameters, and uses infrared sensors to collect mineral temperature field pictures. On this basis, it develops a microwave intelligent sorting algorithm based on computer vision and deep learning, combined with Intelligent sorting of ore materials can be realized by other means such as manipulator te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com