Patents

Literature

38results about How to "Reduce tailings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

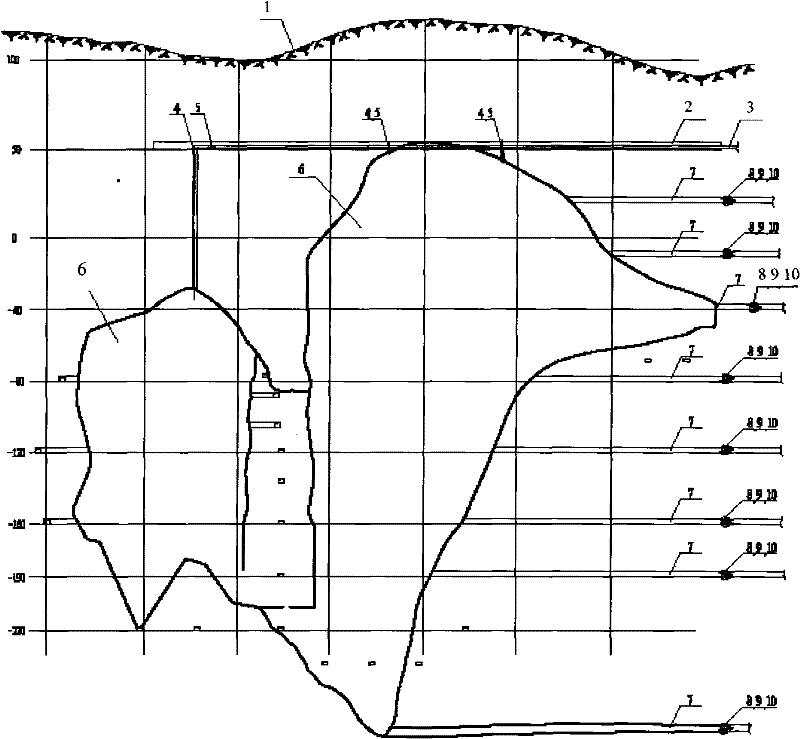

High-yield and low-cost subsequent filling mining method for underground mine

ActiveCN102704934AIncrease mining intensityIncrease production capacityUnderground miningSurface miningEngineeringUltimate tensile strength

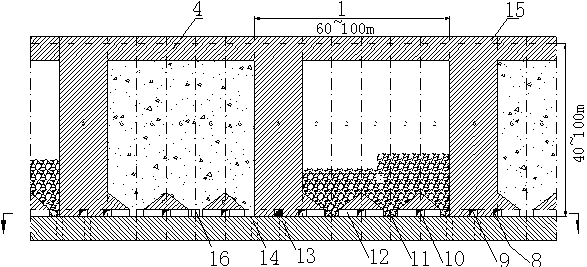

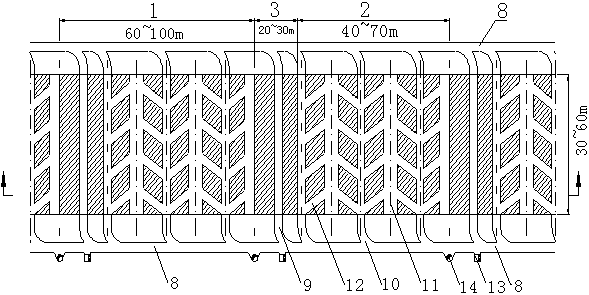

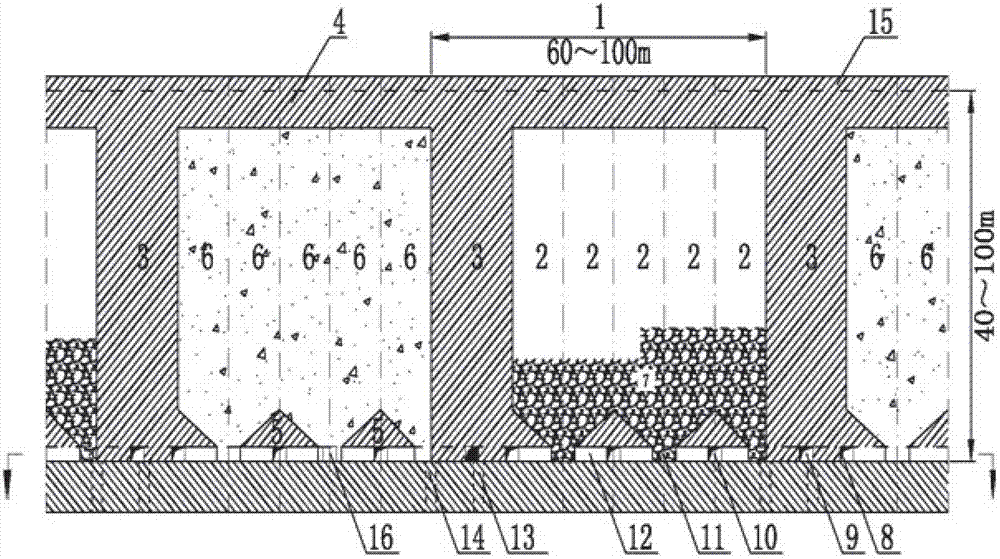

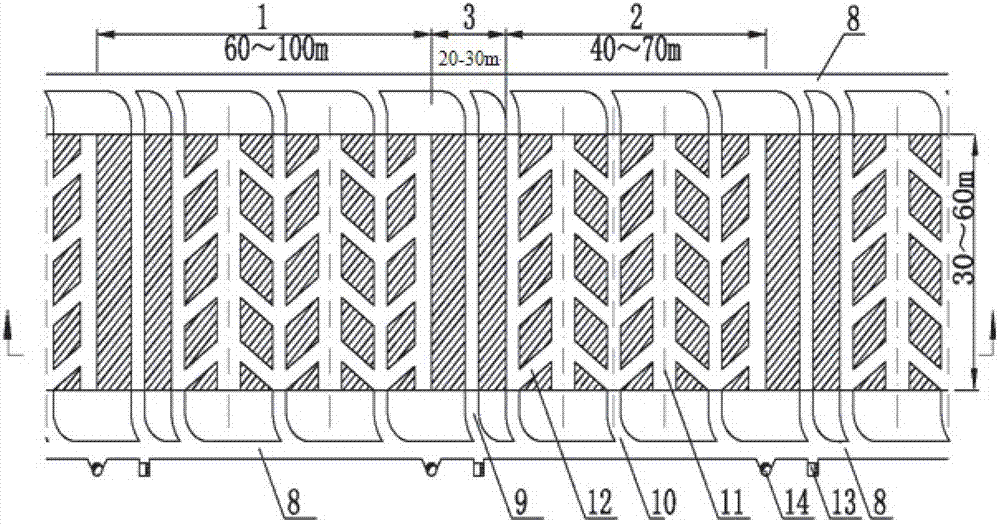

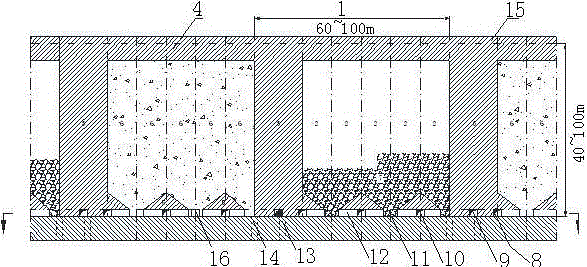

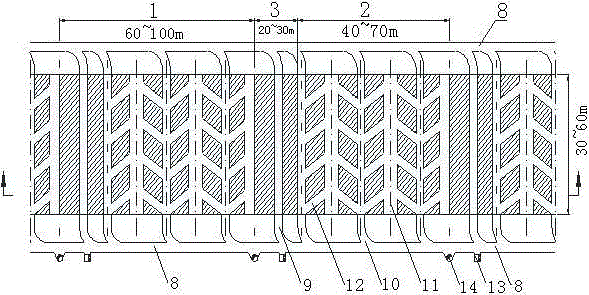

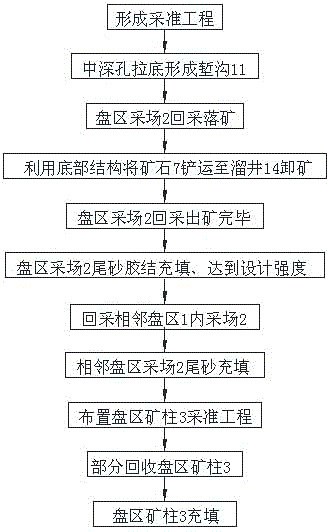

The invention discloses a high-yield and low-cost subsequent filling mining method for an underground mine. An ore section is partitioned into panels (1) underground; each panel is partitioned into 3-6 continuous stopes (2) and a panel barrier (3); a panel top column (4) and a panel bottom column (5) are distributed in the vertical direction; ores (7) in panel stopes (2) fall into a stope trench (11) by blasting; a carry scraper is used for loading ores in an ore outlet feeding channel (12) through an ore outlet laneway (10), transporting the ores to a strike drive (8), and unloading the ores into a pass (14); after stoping and ore discharge are completed, milltailings are filled into a blank region through a filling laneway (15) and a pipeline to form a panel filling body (6); after the filling into the panel stopes (2) is completed, a hollow region formed by subsequent filling in an adjacent panel stope (2) is stoped; and after the adjacent panel stope (2) is filled, a part of the panel barrier (3) is recovered, and a hollow region formed by the panel barrier is filled, so that the hollow region is eliminated finally. According to the method, the mining strength can be enhanced by using limited ore distribution area, the production capacity is increased, and mining production and hollow region filling treatment costs are reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

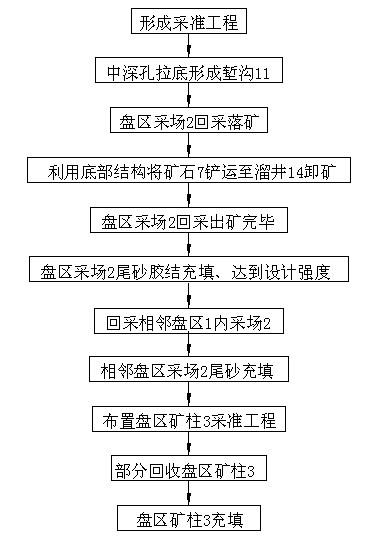

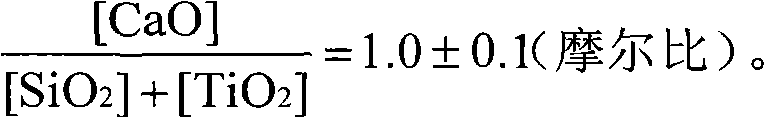

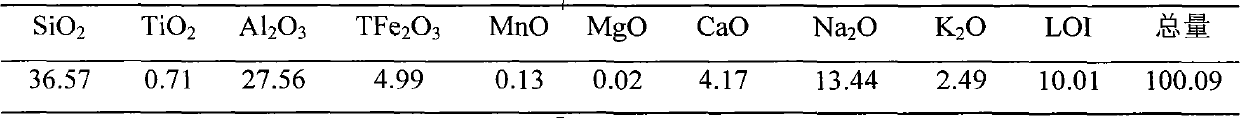

Improved soda lime sintering method for processing aluminum-containing raw material

ActiveCN102107895AExtensive sources of raw materialsReduce manufacturing costAluminium oxides/hydroxidesResource utilizationEnergy consumption

The utility model discloses an improved soda lime sintering method for processing aluminum-containing raw material, and relates to the technical field of aluminum oxide production with a sintering method. The aluminum-containing raw material, limestone and soda ash are evenly mixed in a ball-milling manner according to a raw meal formula of the improved soda lime sintering method, thereby acquiring qualified raw meal; the raw meal is sintered at a high temperature, thereby acquiring sintered clinker; the sintered clinker is dissolved out, desiliconized, resolved and roasted; and an aluminum oxide product can be finally acquired. The raw meal formula of the improved soda lime sintering method is that the sum of the amount of Al2O3, the amount of Fe2O3 and the amount of SiO2 divided by the sum of the amount of Na2O and the amount of K2O is equal to 1.0 plus or minus 0.1 (a molar ratio), and the sum of the amount of SiO2 and the amount of TiO2 divided by CaO is equal to 1.0 plus or minus0.1 (the molar ratio). Compared with the prior art, the improved soda lime sintering method disclosed by the invention has great adaptability to aluminum-containing raw material in various grades, and has the advantages that the addition quantity of burdening lime stone is small, the resource utilization efficiency is high, the sintering temperature is low, the firing energy consumption is low, the firing temperature range is wide, and the industrialization is easy to implement.

Owner:昊青薪材(北京)技术有限公司

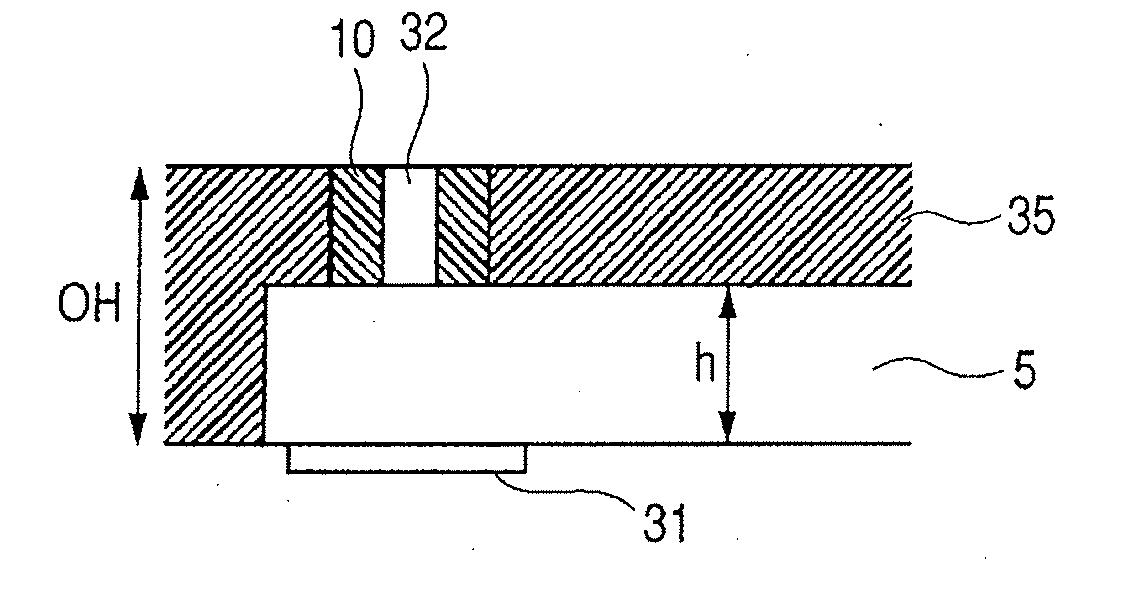

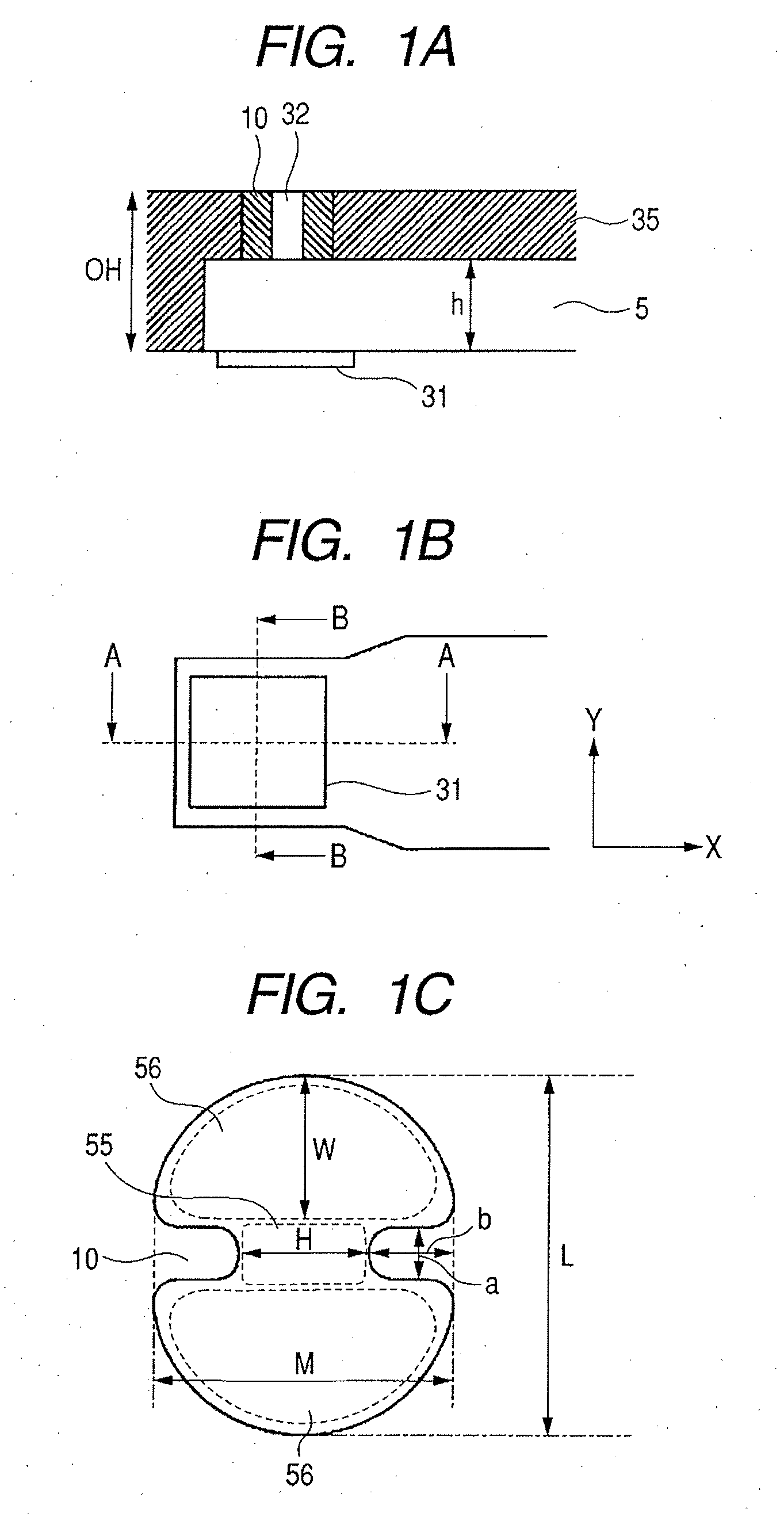

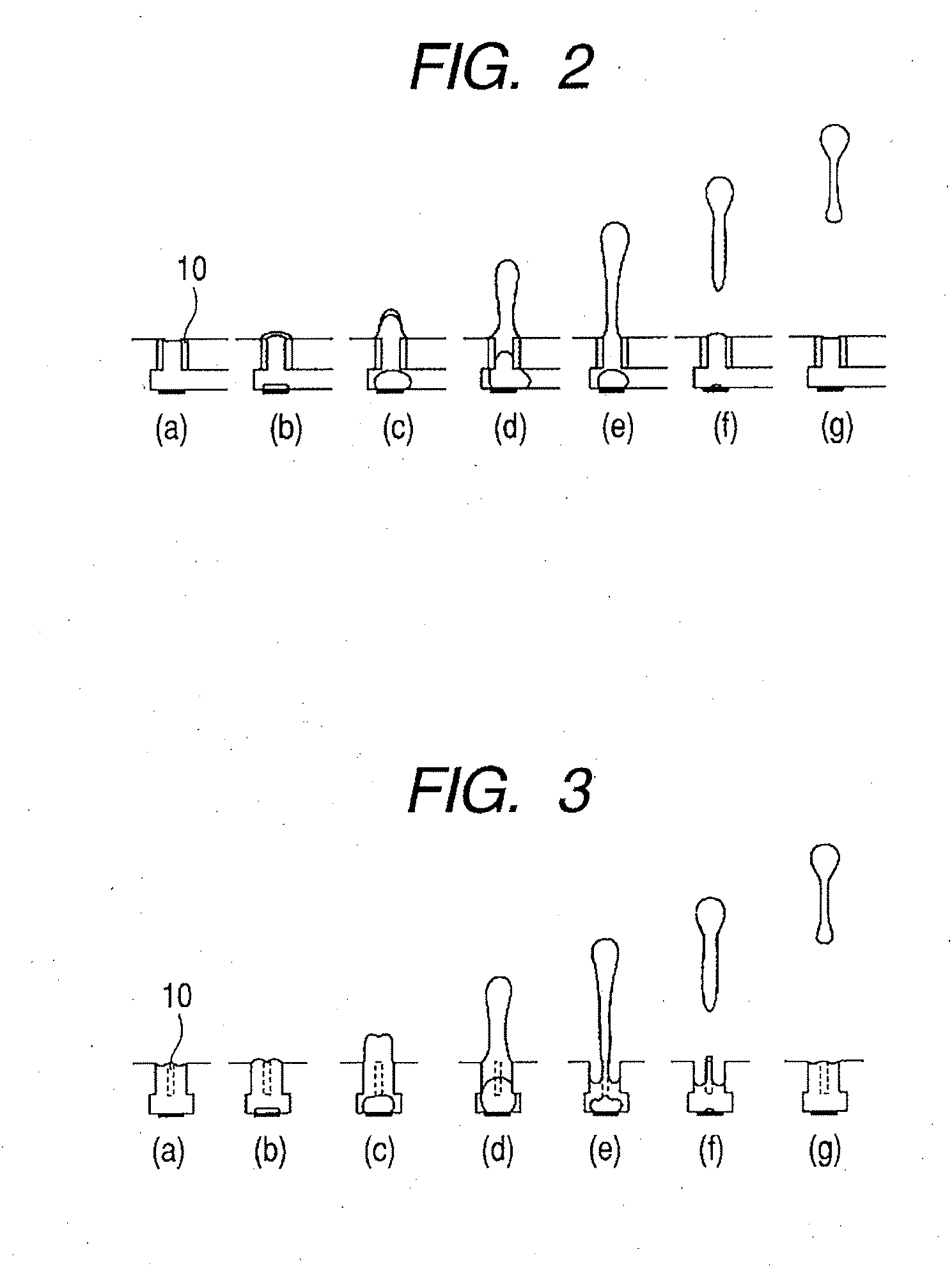

Liquid discharge method, liquid discharge head and liquid discharge apparatus

ActiveUS20070146437A1Reduction in satellite and mistExtension of timePrintingEngineeringLiquid surfaces

A liquid discharge head is arranged in a manner that in the cross section of a discharge port in a liquid discharge direction, the discharge port includes: at least one projection that is convex inside the discharge port; a first area, for holding a liquid surface connecting a pillar-shaped liquid that is elongated outside the discharge port; and second areas where a fluid resistance is lower than that in the first area so as to pull the liquid in the discharge port in a direction opposite to the liquid discharge direction; and the first area is formed in the direction in which the projection is convex, and the second areas are formed on both sides of the projection.

Owner:CANON KK

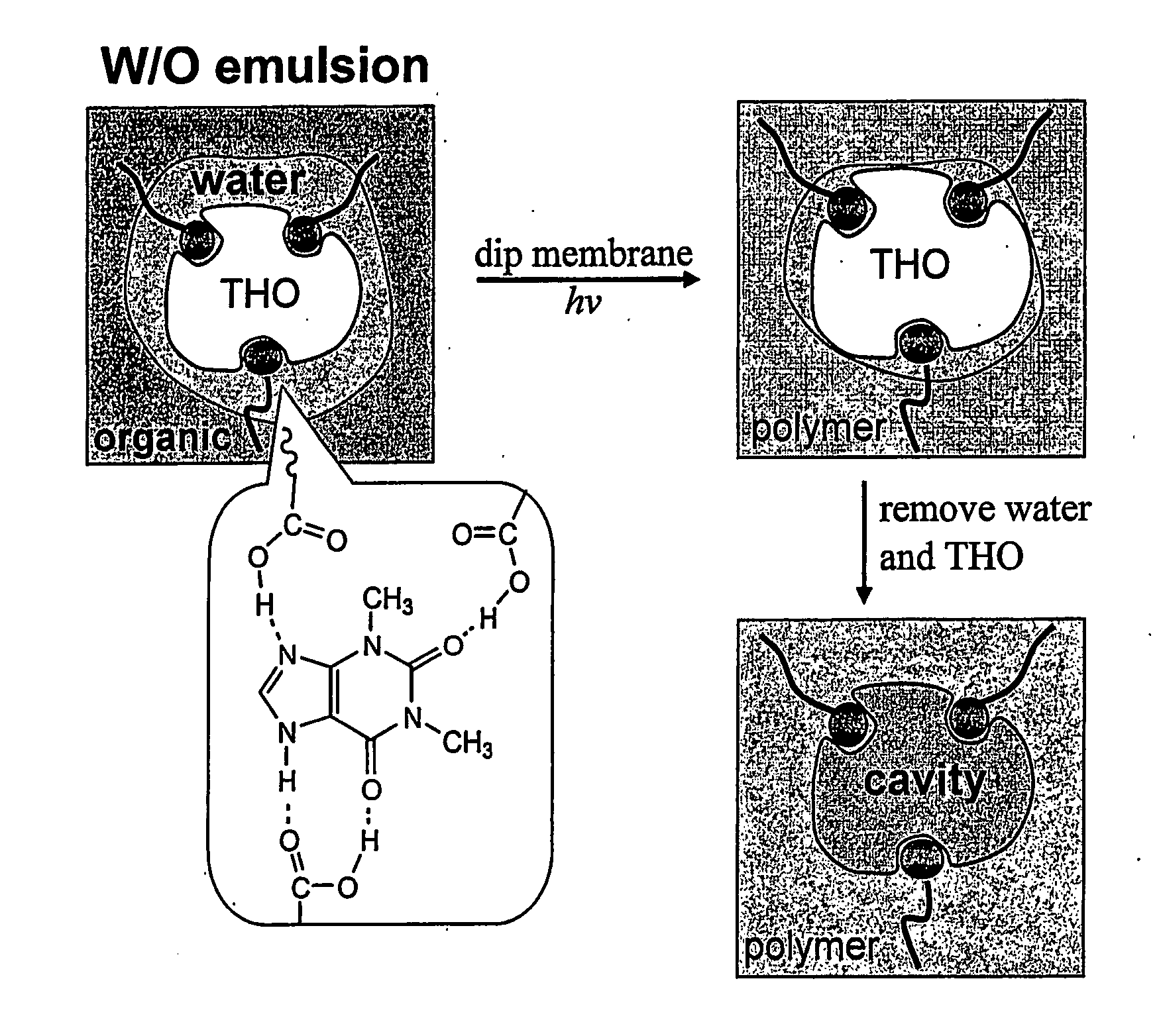

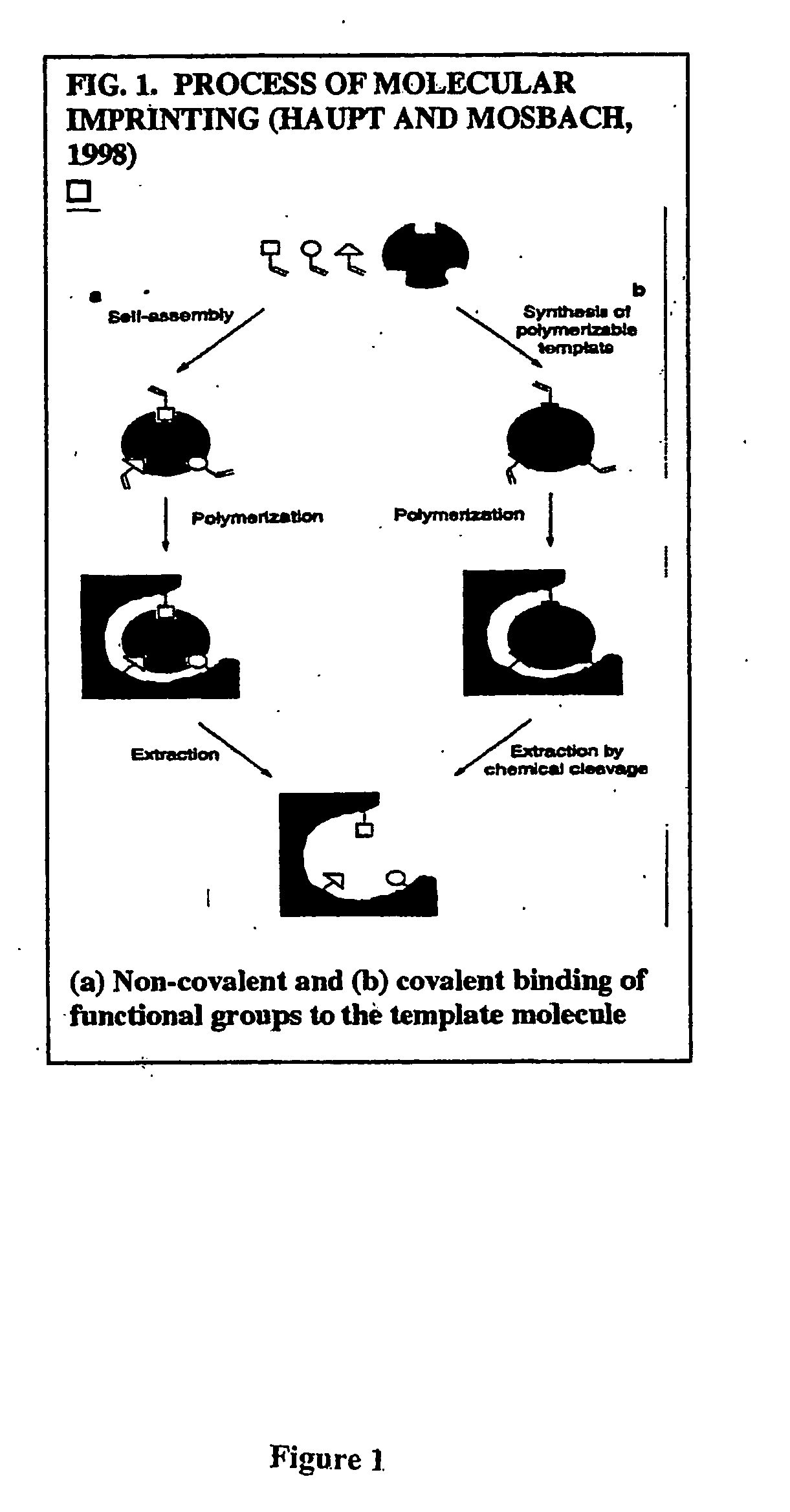

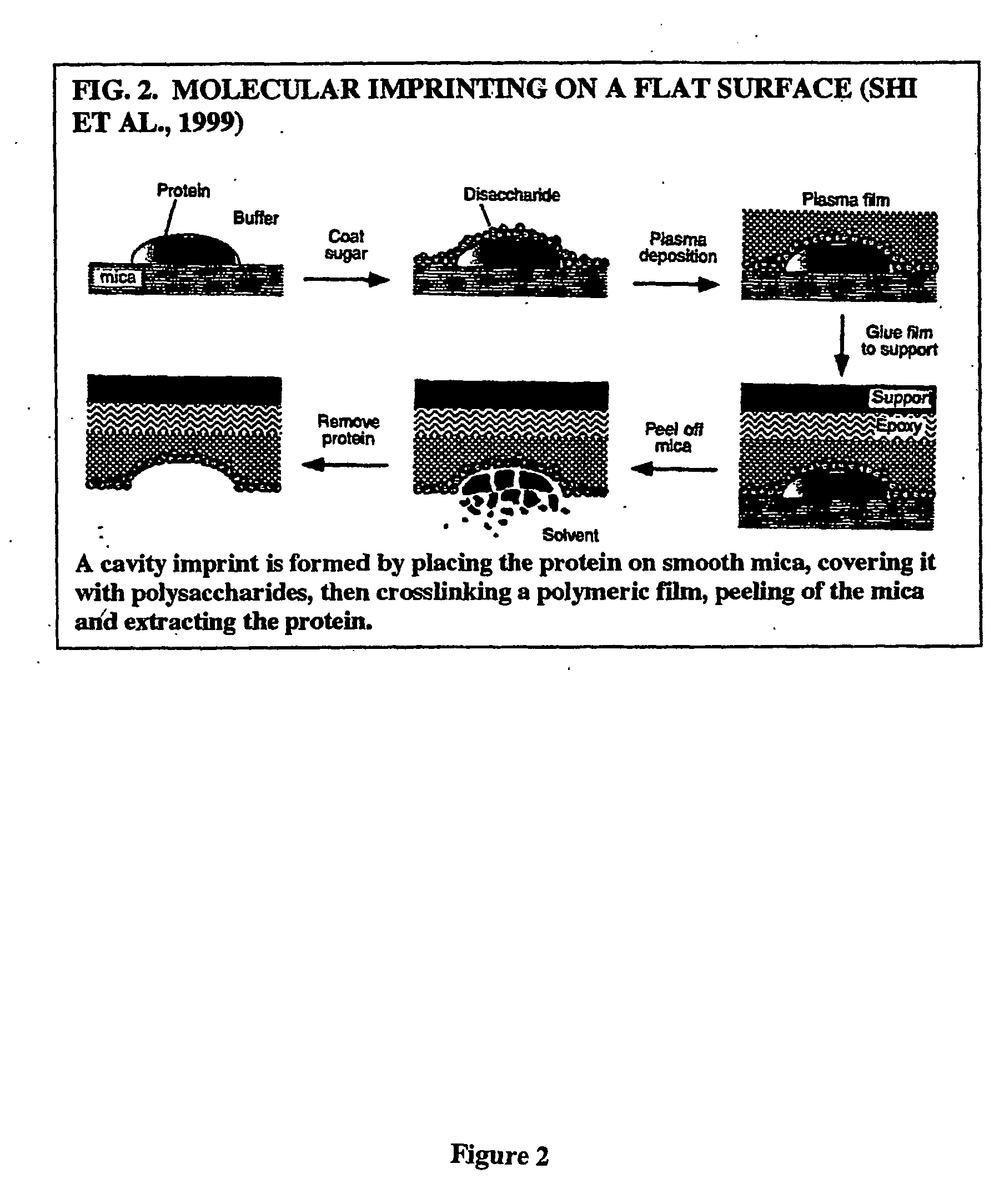

Imprinting a substrate for separation of a target molecule from a fluid medium

InactiveUS20070128423A1Increase tailingReduce restrictionsOther chemical processesLayered productsOil phaseMonomer

The present invention is directed to a method of producing a substrate suitable for separation of a target molecule from a fluid medium. This method includes providing an emulsion comprising a water phase in an oil phase, where the oil phase contains a polymerizable monomer and the water phase contains the target molecule. The substrate, having pores extending from one side of the substrate to another side of the substrate, is coated with the emulsion, and the monomer in the emulsion coated substrate is then polymerized. The water and target molecule are removed from the polymerized, emulsion coated substrate. As a result, the substrate is imprinted with the target molecule and, therefore, is suitable for separation of the target molecule from a fluid medium. The resulting article and its use are also disclosed.

Owner:RENESSELAER POLYTECHNIC INST

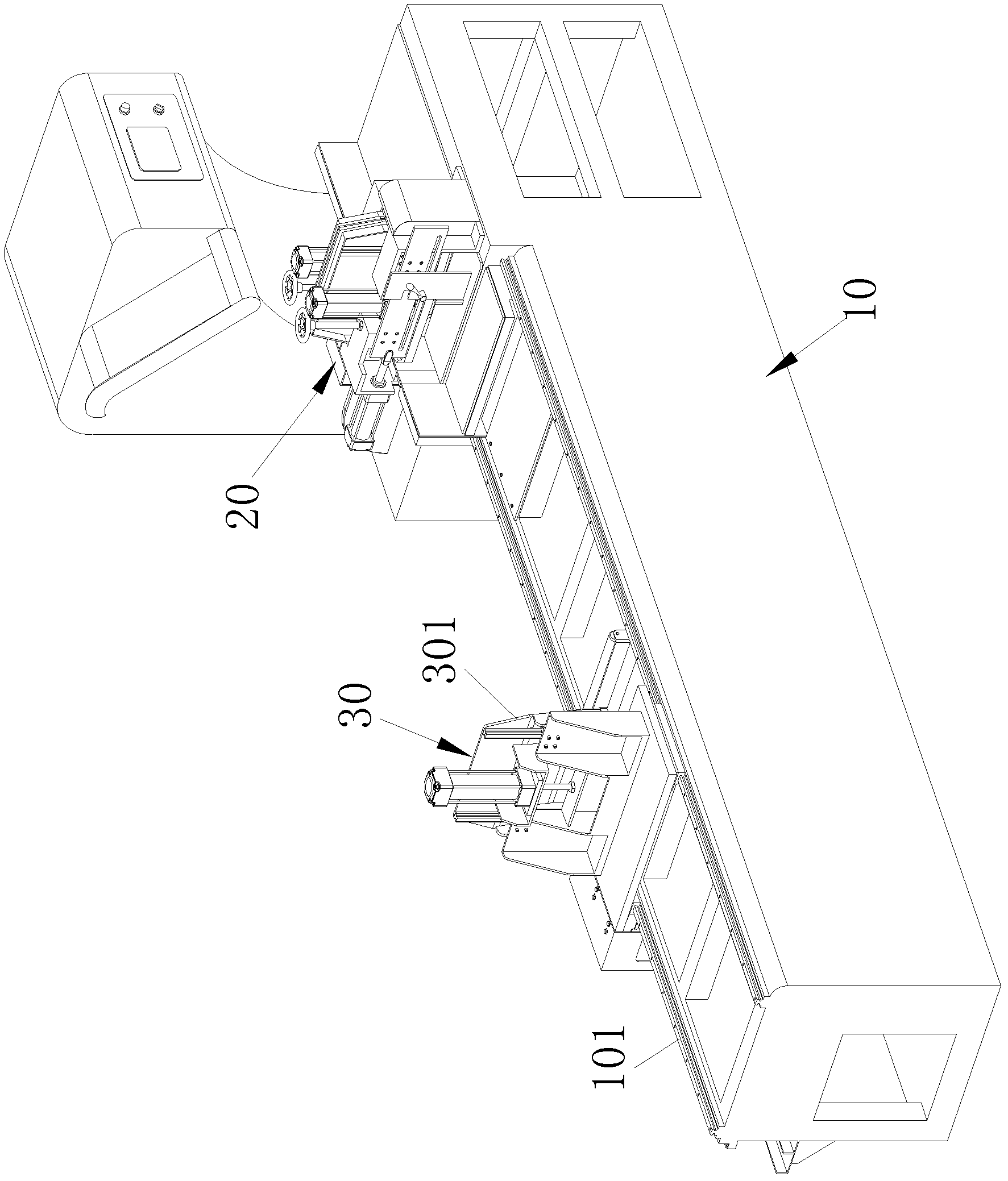

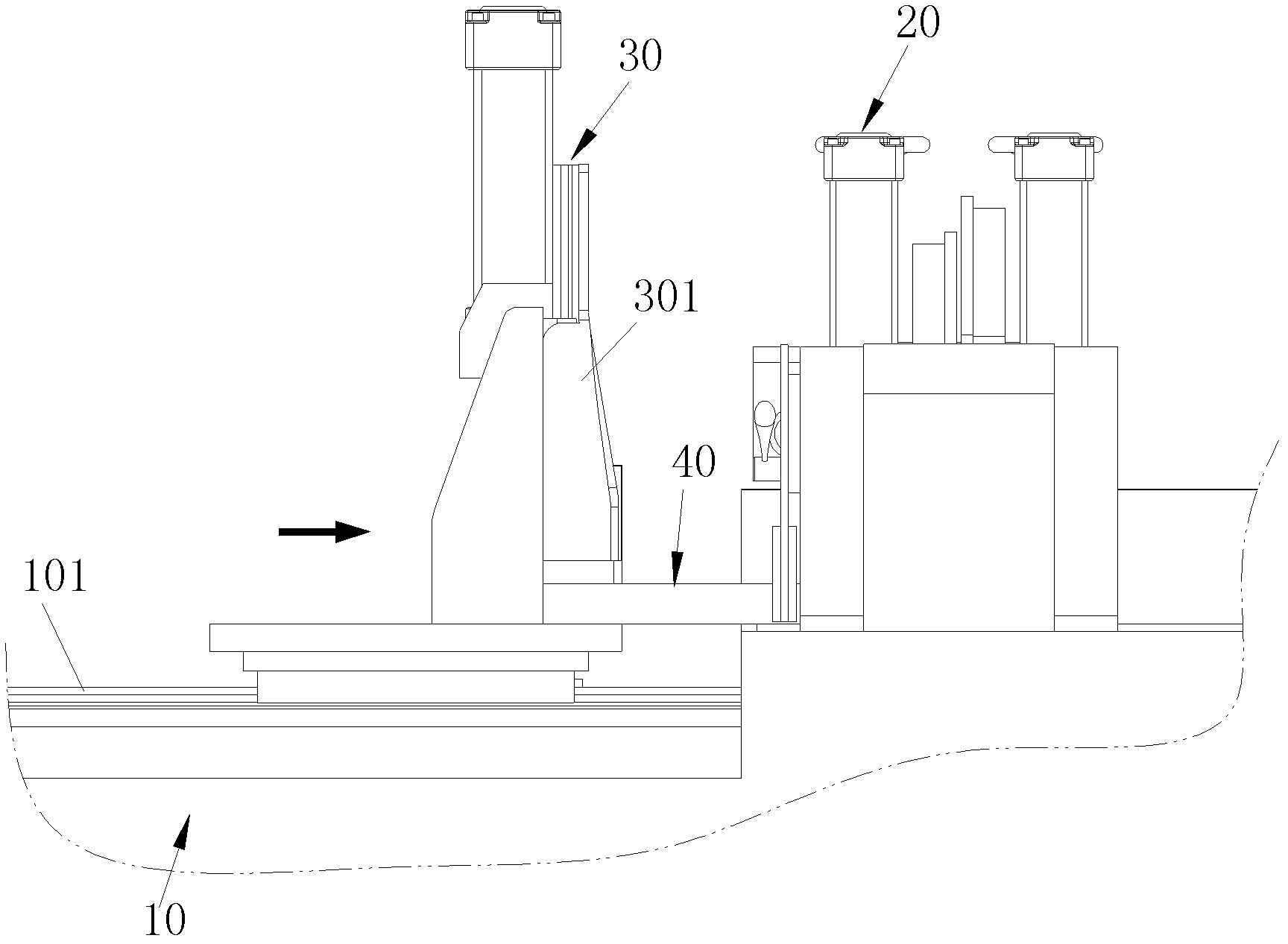

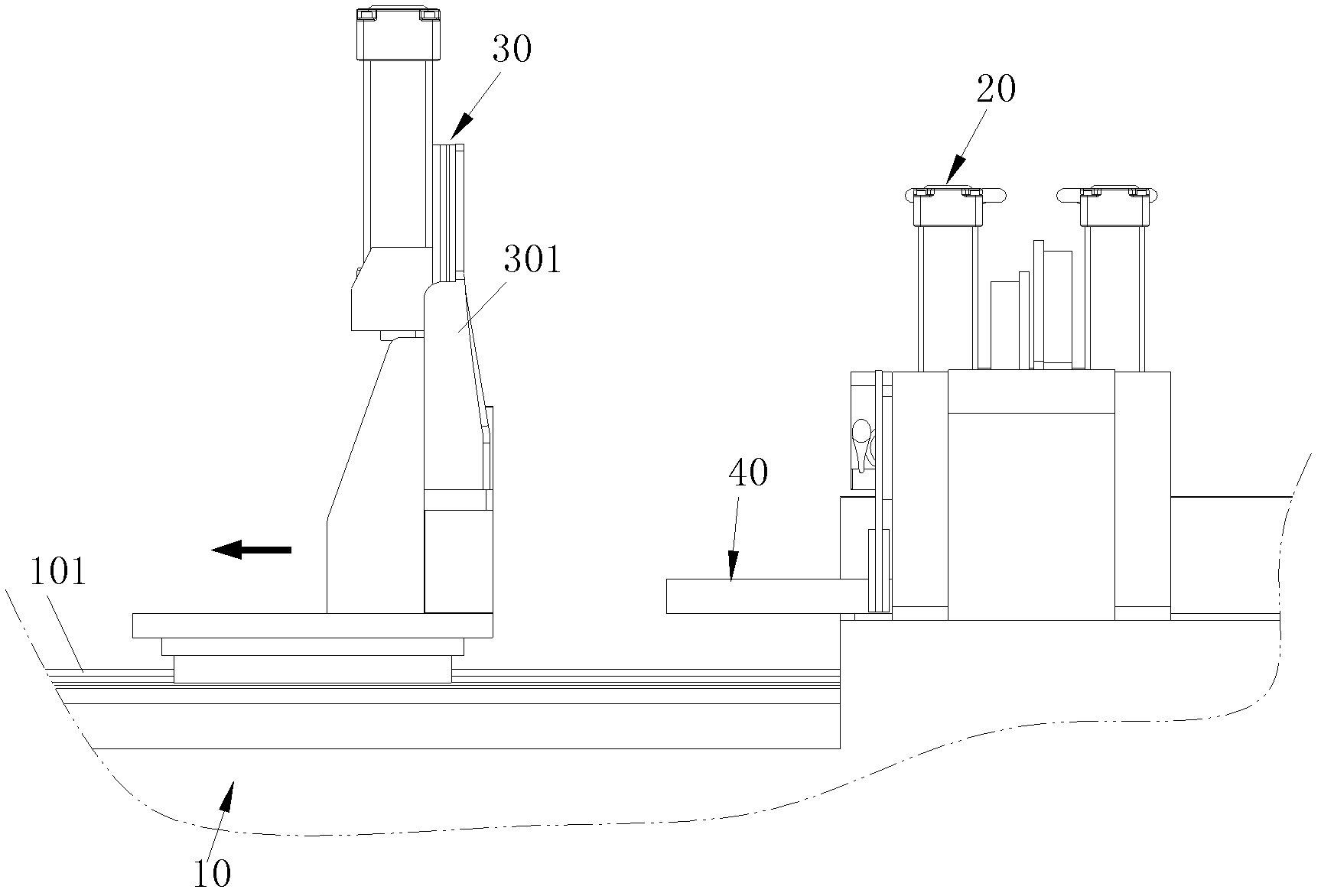

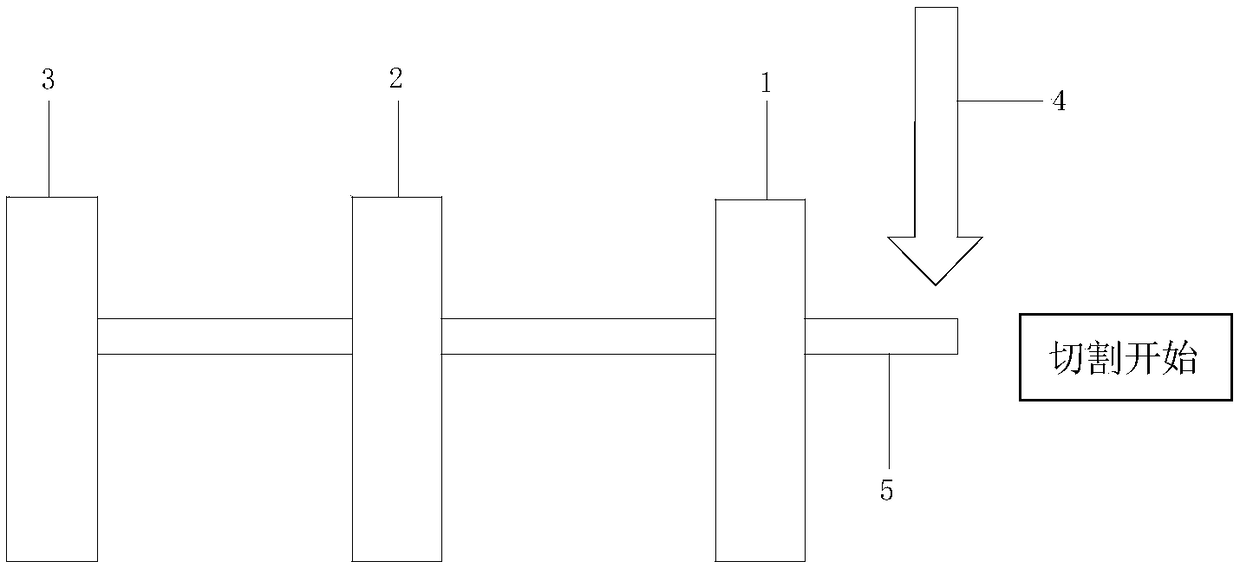

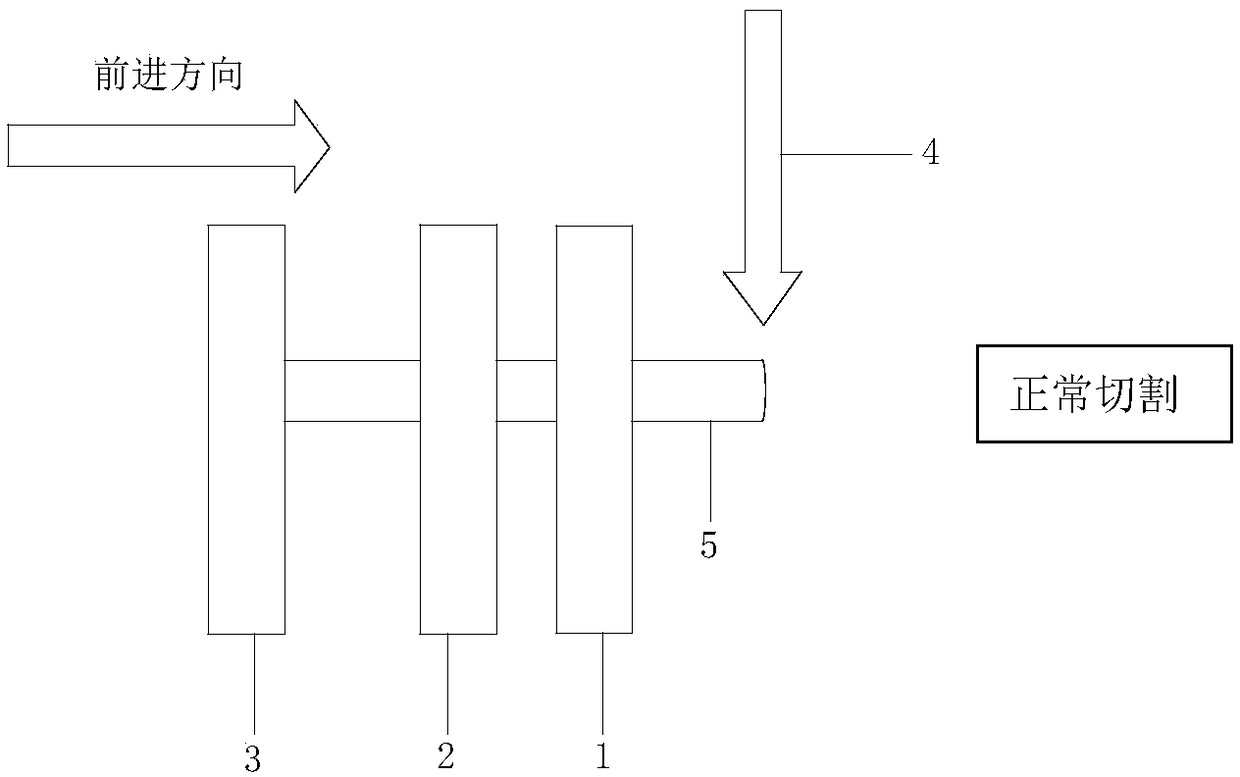

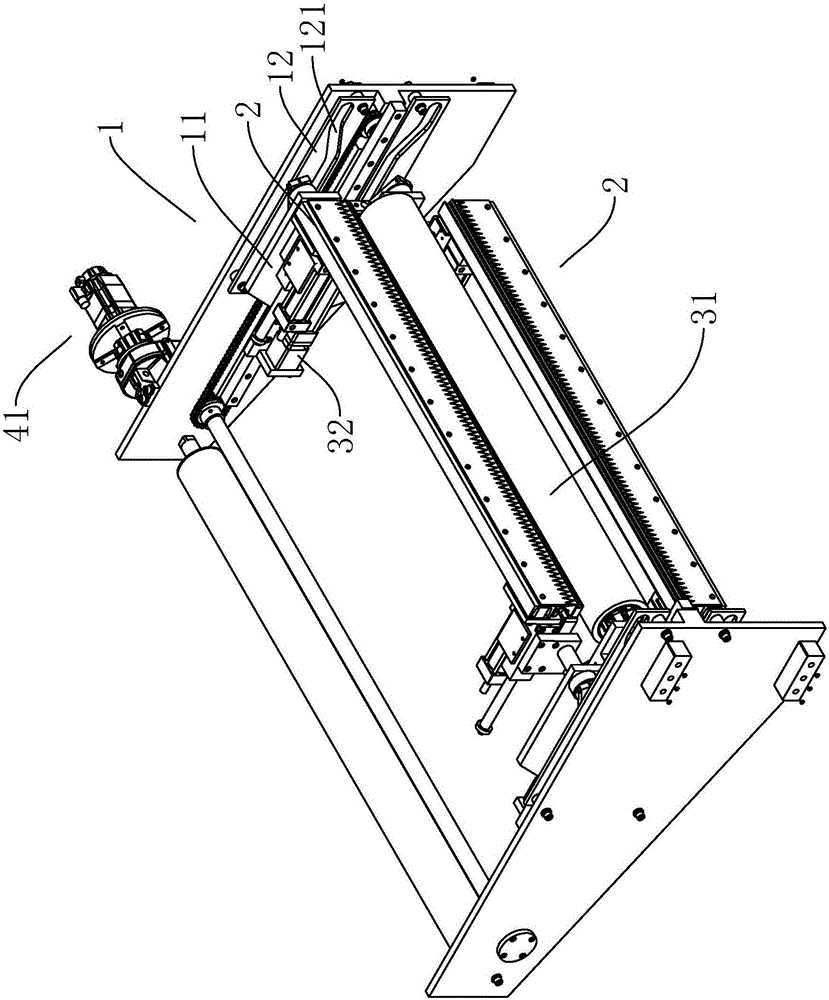

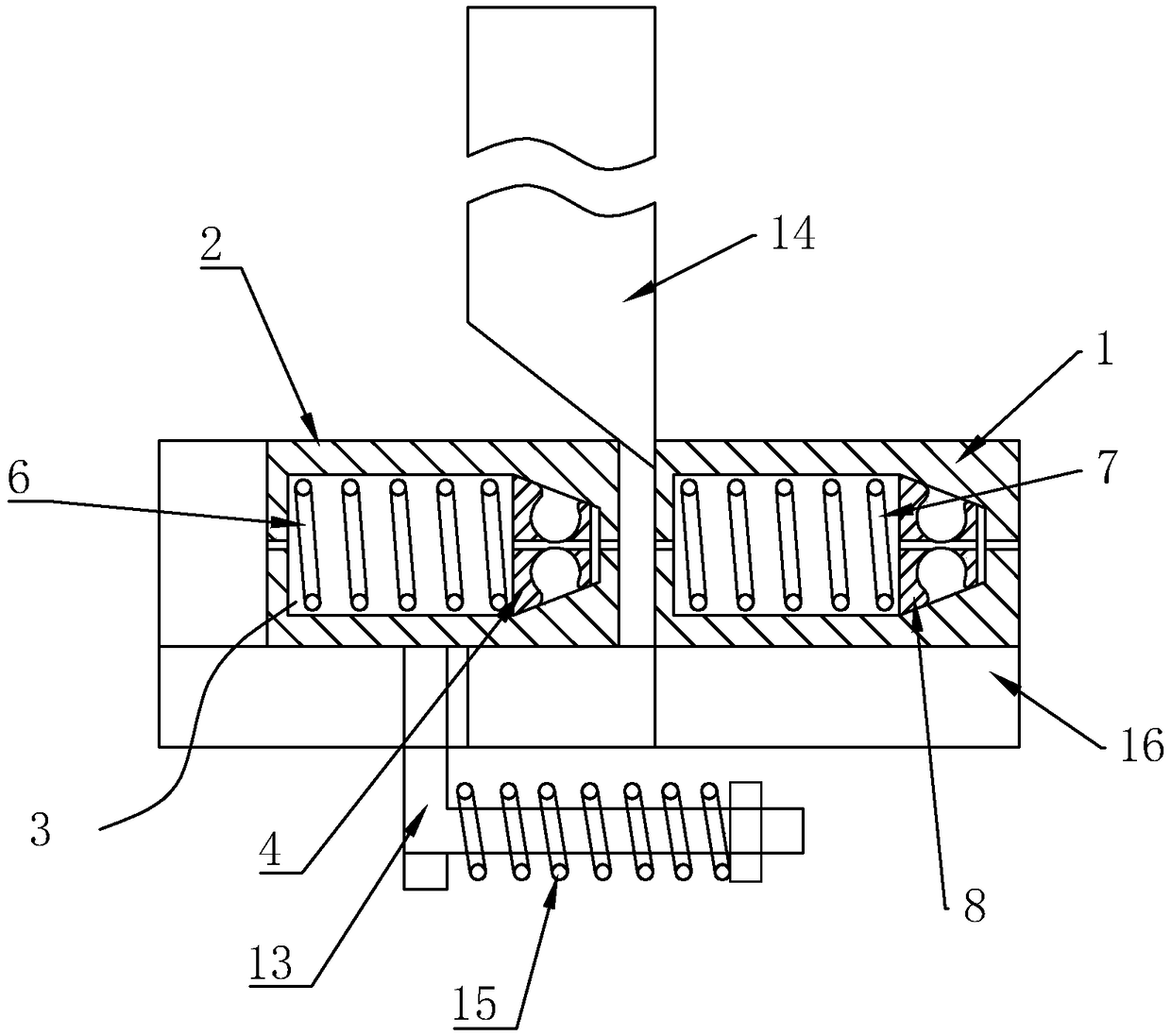

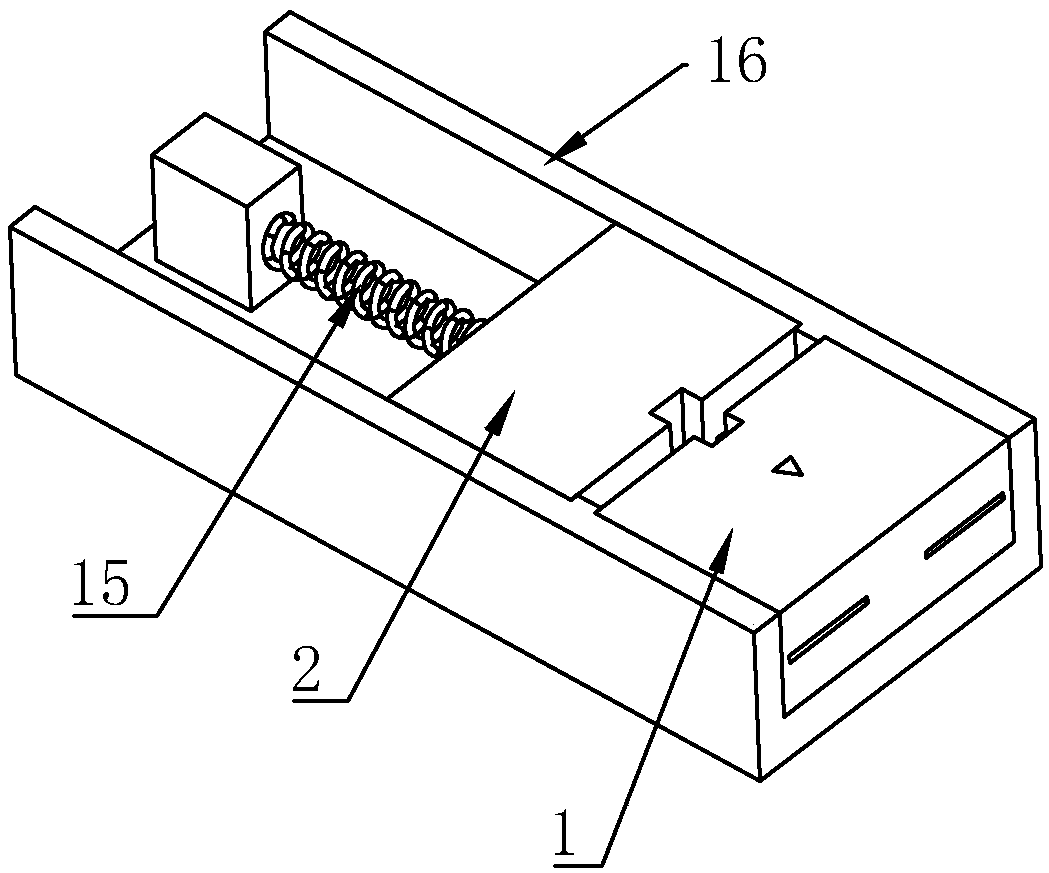

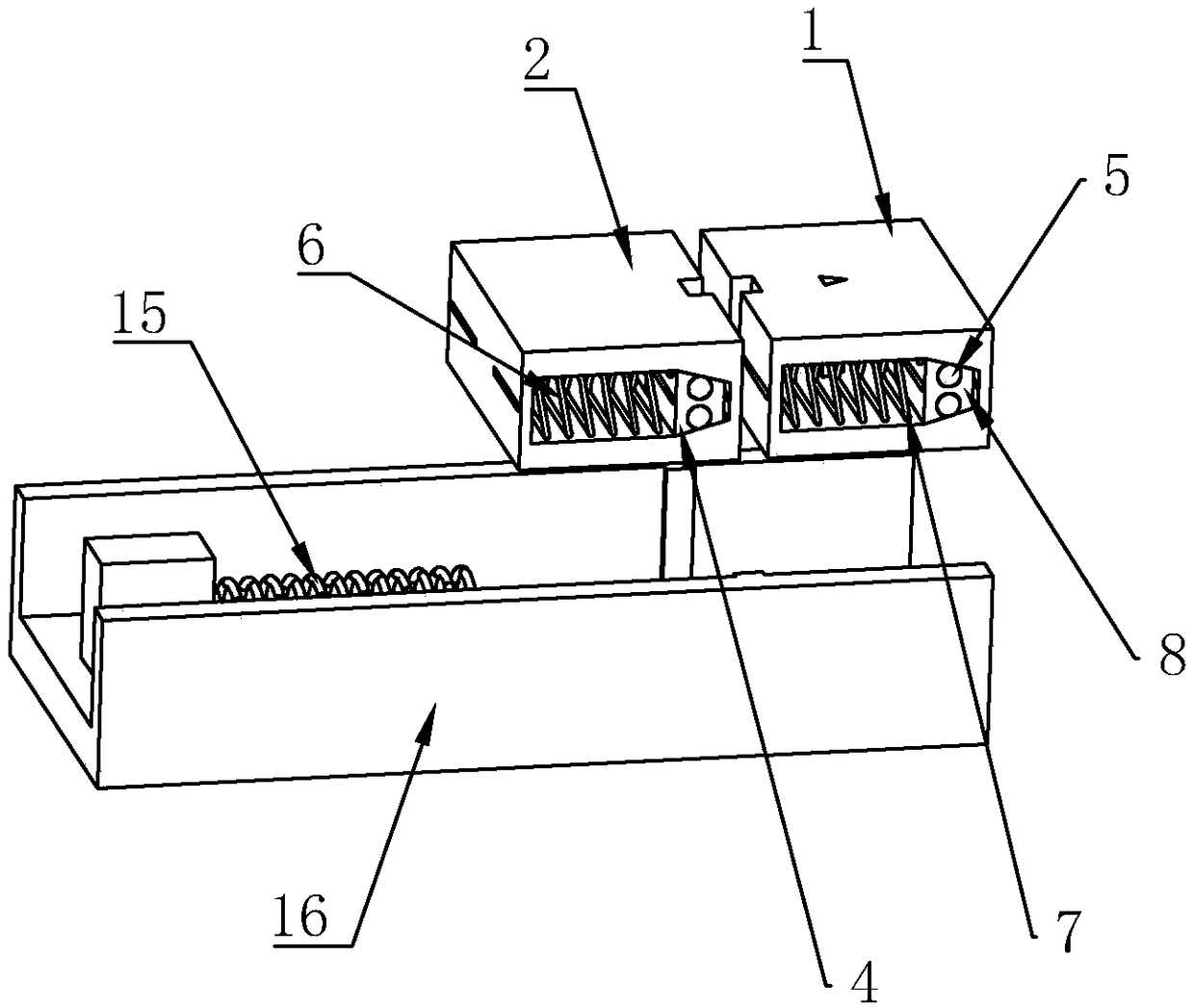

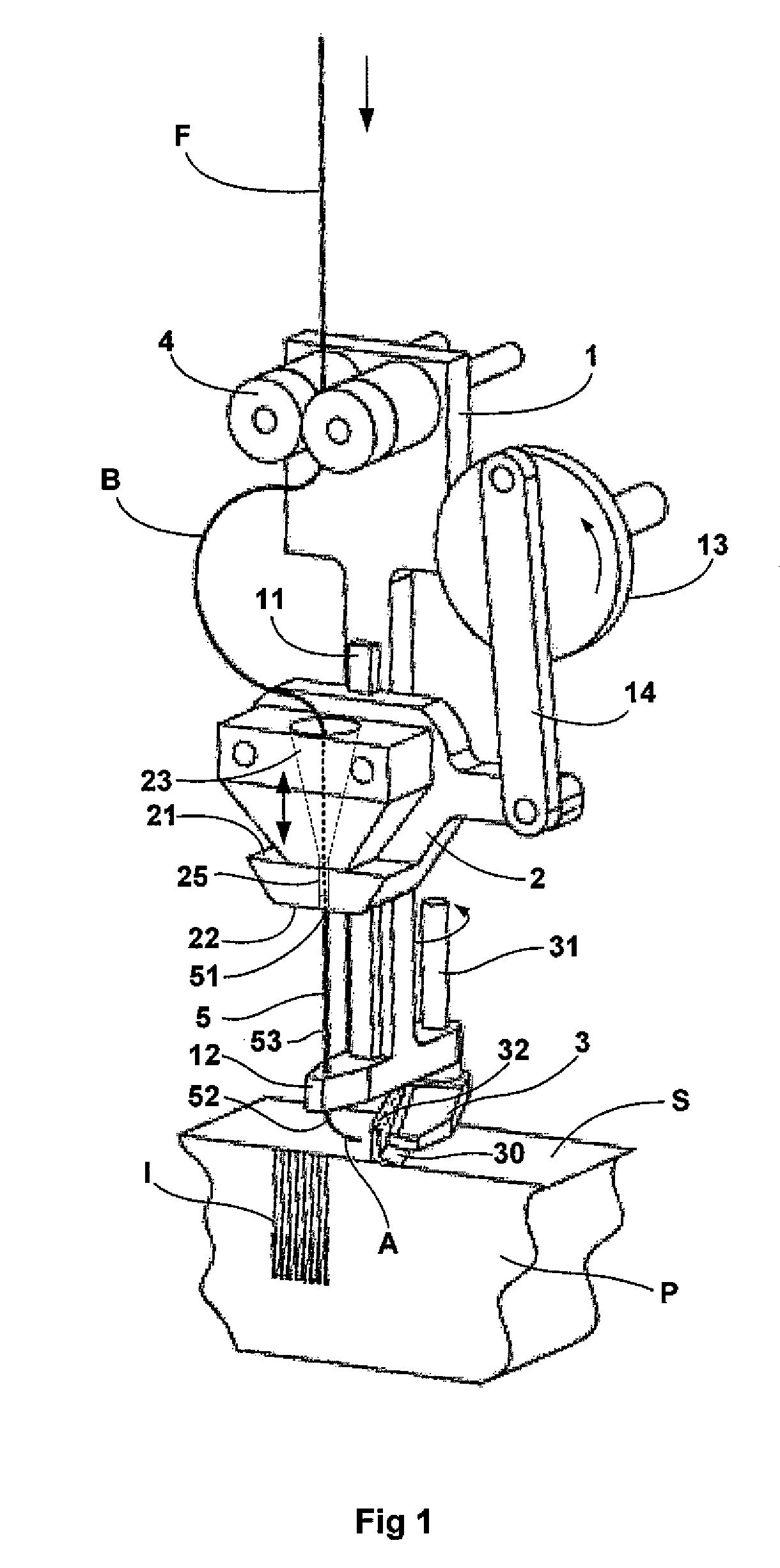

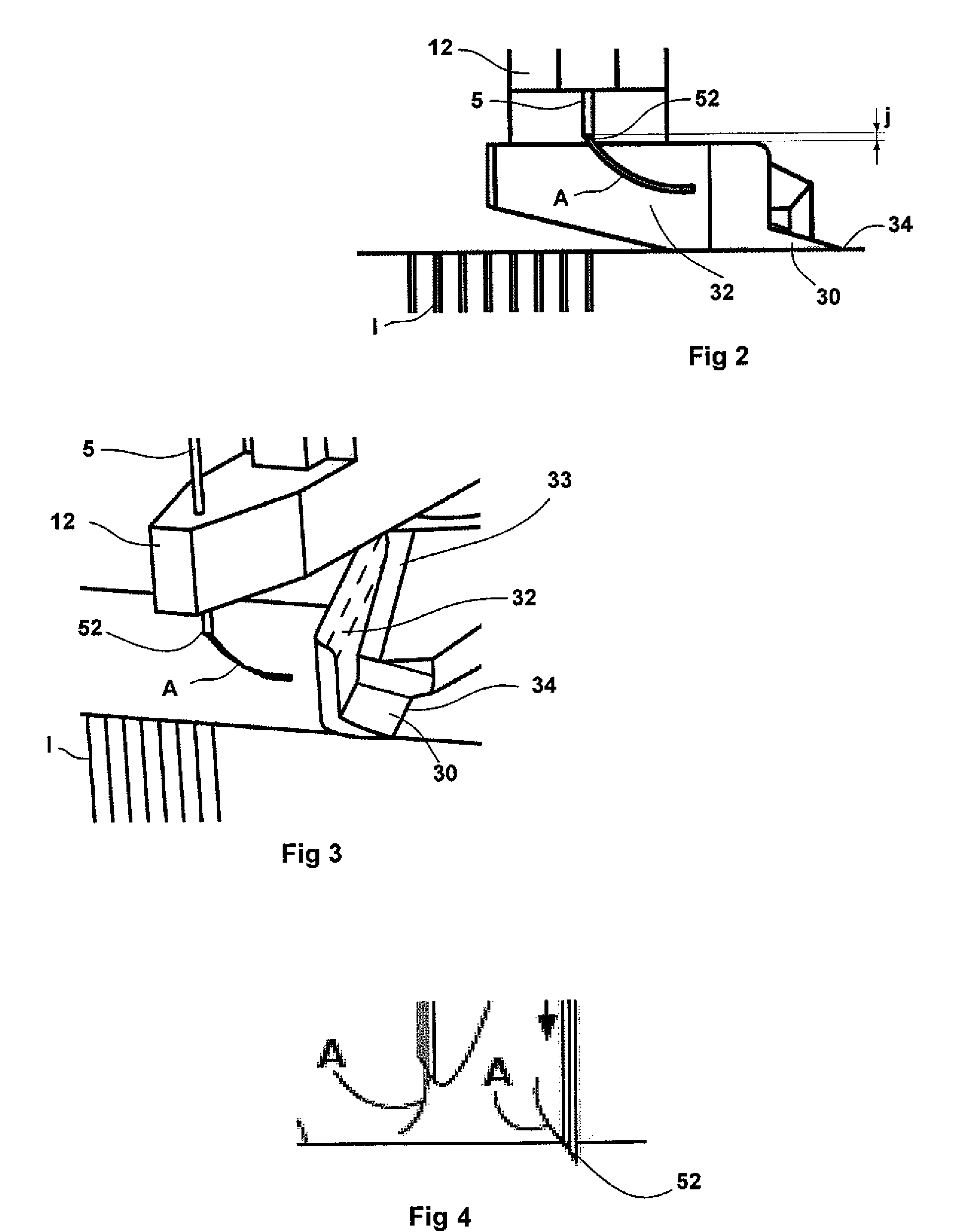

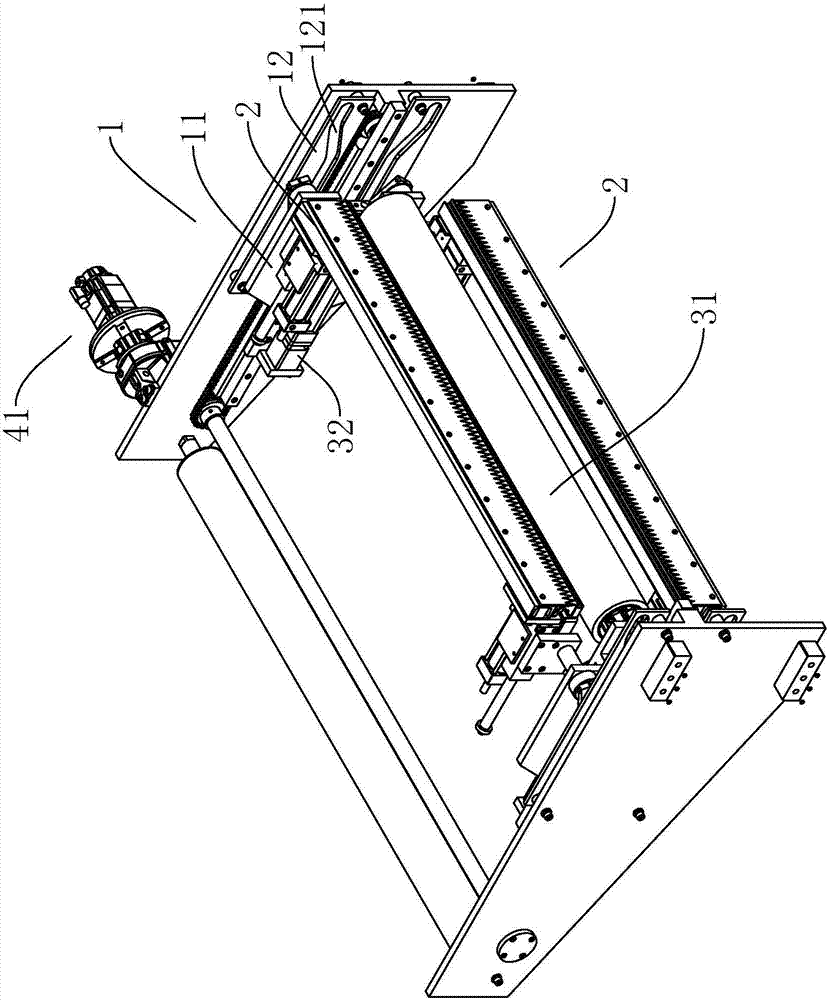

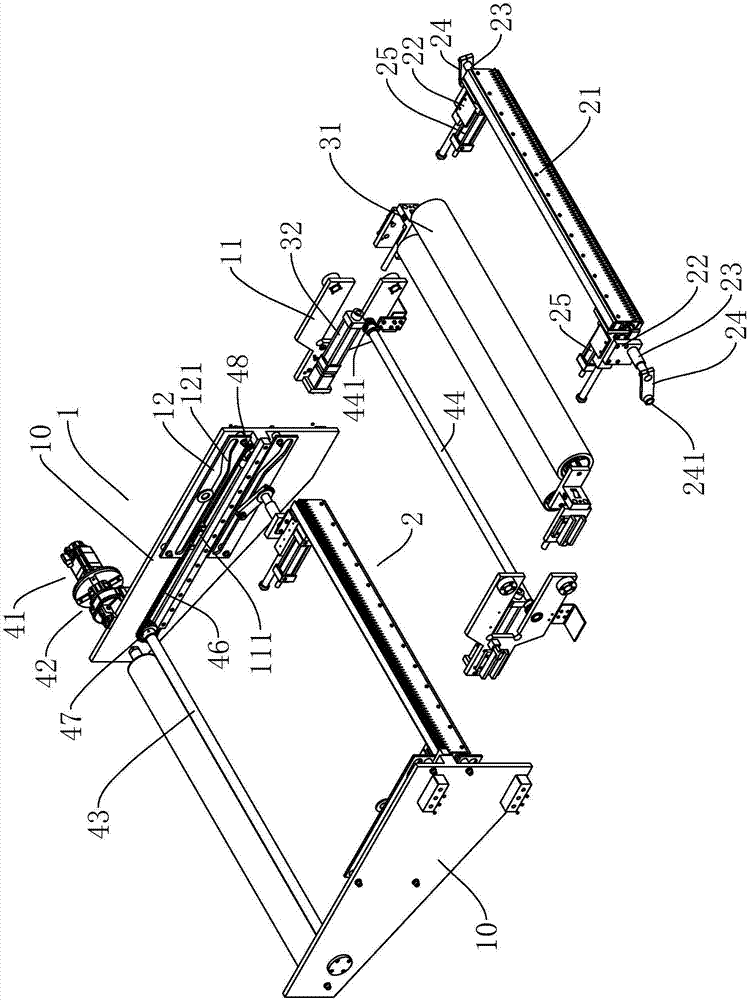

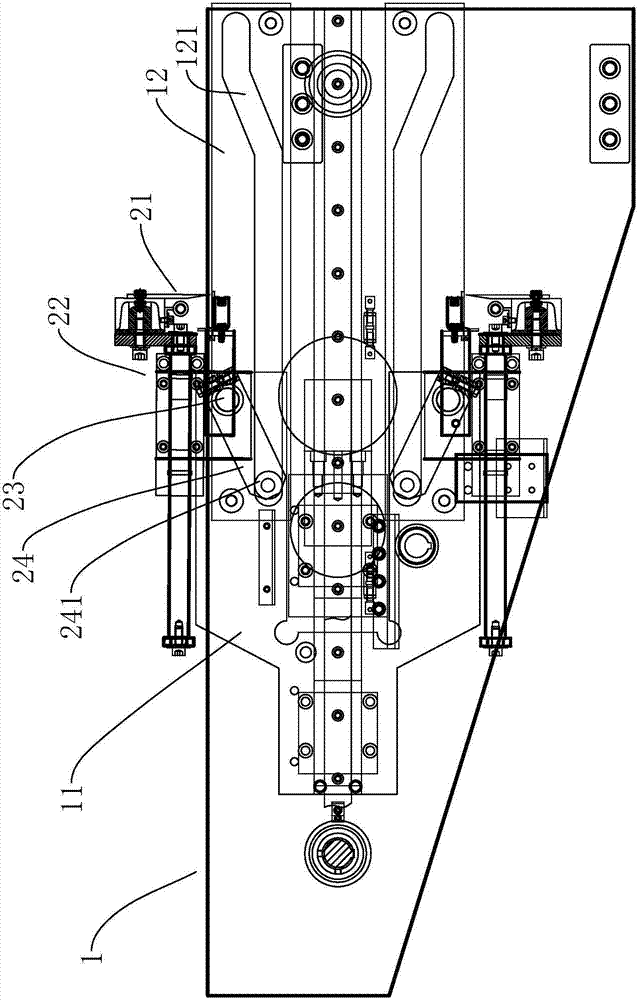

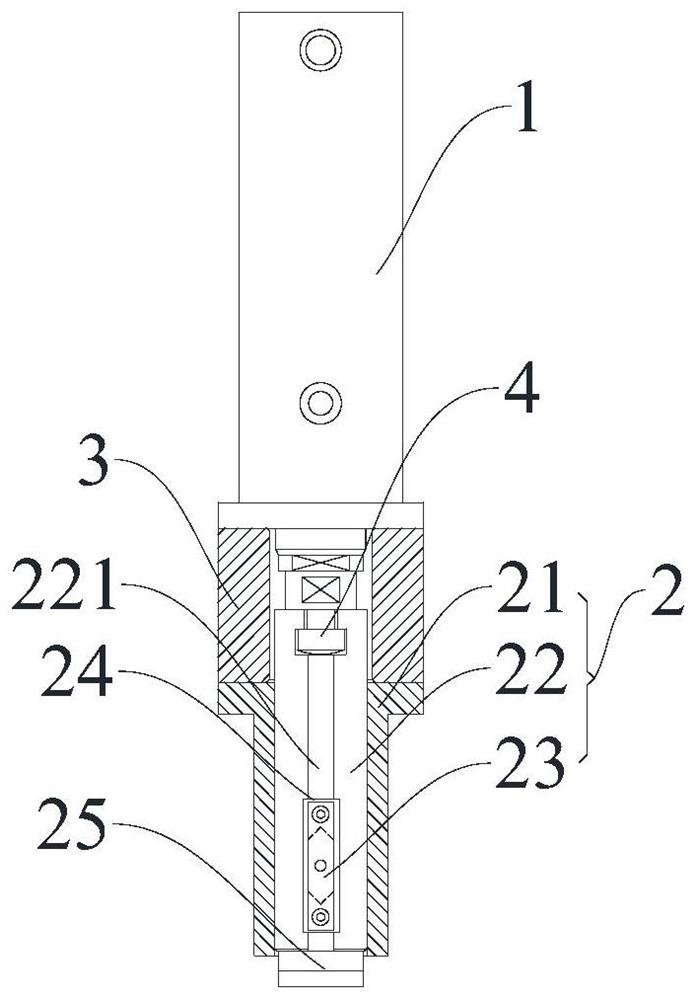

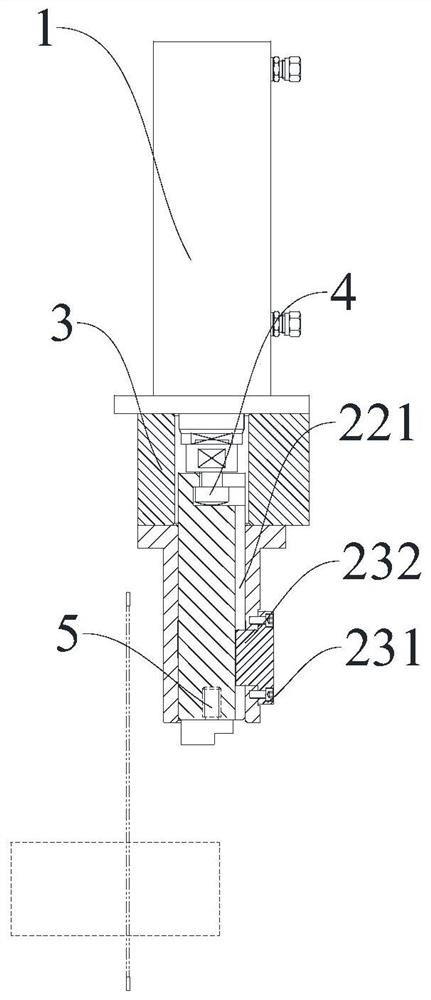

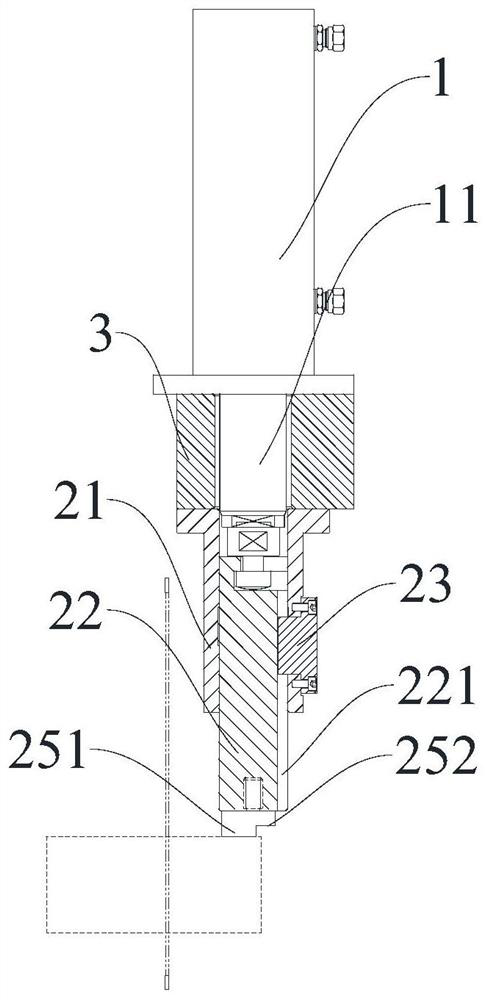

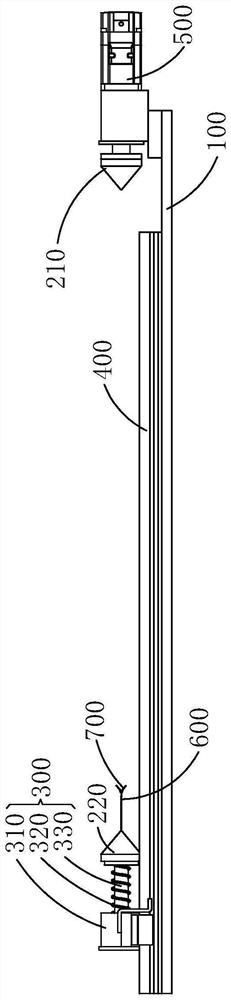

Auxiliary material pushing device of fixed-material cutting machine

InactiveCN102935649AReduce tailingsReduce manufacturing costMetal working apparatusManufacturing cost reductionPiston rod

The invention discloses an auxiliary material pushing device of a fixed-material cutting machine. The auxiliary material pushing device is arranged on a feeding device of the cutting machine and comprises a base plate, a pushing plate and a cylinder, two parallel slide rails are arranged at the top of the base plate, the pushing plate is arranged on the two parallel slide rails of the base plate in a sliding mode through two sliding seats arranged at the bottom of the pushing plate, the cylinder is fixedly arranged on the pushing plate and provided with a piston rod, the end of the piston rod is connected with the feeding device, stretching actions of the piston rod drive the cylinder to slide back and forth together with the pushing rod. According to the auxiliary material pushing device, when the feeding device pushes strip-shaped materials to tail positions, the pushing plate stretches forwards to push the strip-shaped materials to perform cutting actions continuously, residual tailings of the strip-shaped materials are reduced, and the production cost is reduced.

Owner:KUSN WEISHENG PRECISION HARDWARE

Full tailing filling method in large goafs

InactiveCN101892862AEliminate potential safety hazardsGuarantee normal productionMaterial fill-upDrainageLand acquisitionMining engineering

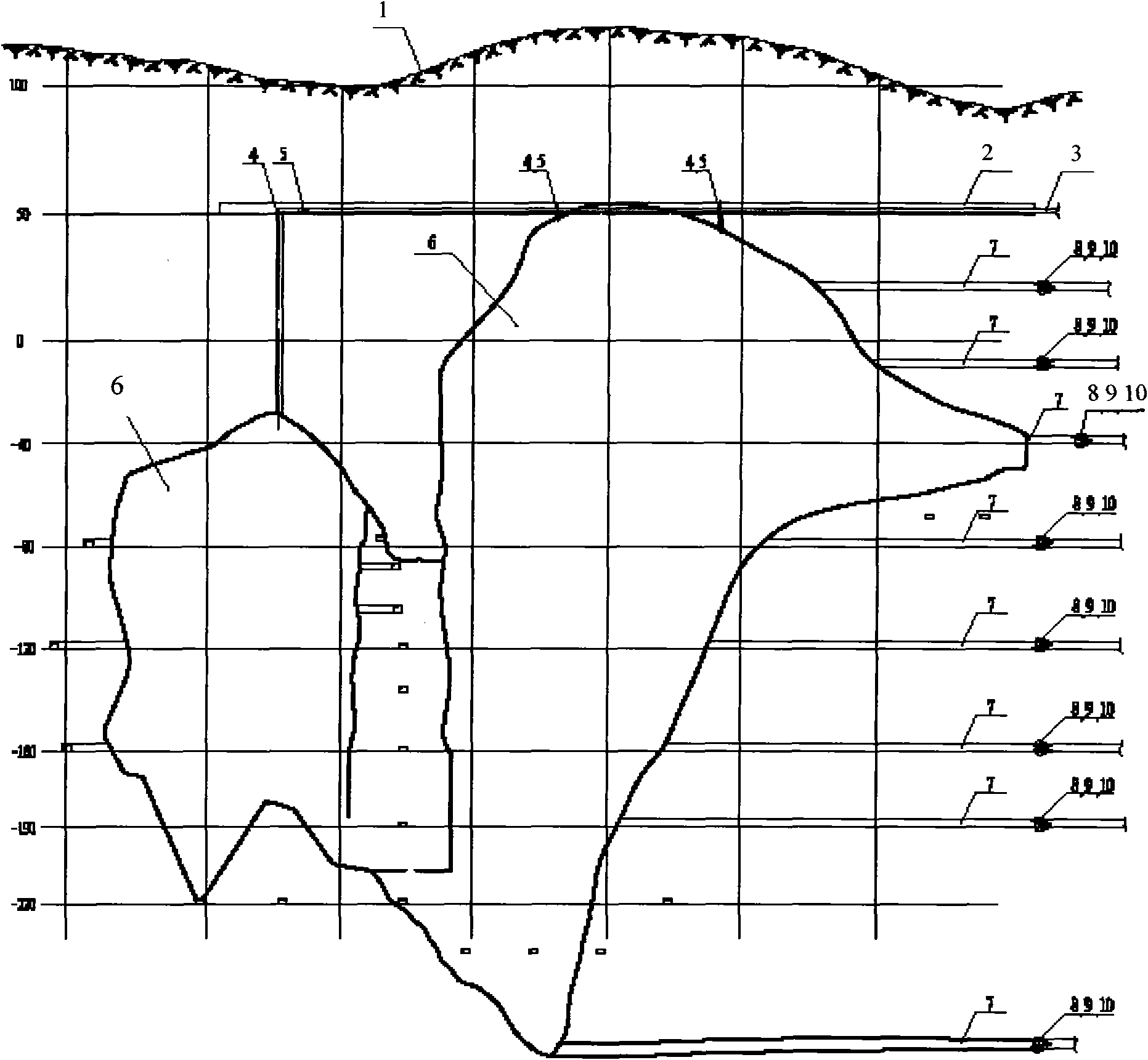

The invention discloses a full tailing filling method in large goafs, which is realized by the technical scheme with the following steps: dividing the combination of relatively independent and adjacent single or a plurality of goafs (6) into a filling unit; building a sealed wall (8) on a tunnel (7) at the periphery of the goafs (6) of the filling unit, arranging a drain pipe (9) in the wall body of the sealed wall (8), and arranging an ore pulp valve (10) on the drain pipe (9); laying a tailing conveying main pipe (3) above the filling unit through an adit (2) above the goafs (6); connecting each upper opening of the filling unit to one or a plurality of hydraulic sand filling pipes (4) through the tailing conveying main pipe (3); and discharging sand at high levels, discharging water in different middle sections, and filling alternately. In the invention, full tailings are used for filling the existing goafs, thereby eliminating the potential safety hazards of the goafs, ensuring the normal production of large deep well mines, saving the treatment cost, the tailing stockpiling and land acquisition cost and the drainage cost of the goafs, realizing the purpose of less-waste and no-waste exploitation, and taking an demonstration effect on constructing ecological mines.

Owner:HUAWEI METAL MINERAL RESOURCE EFFICIENT RECYCLING UTILIZATION NAT ENG RES CENT CO LTD

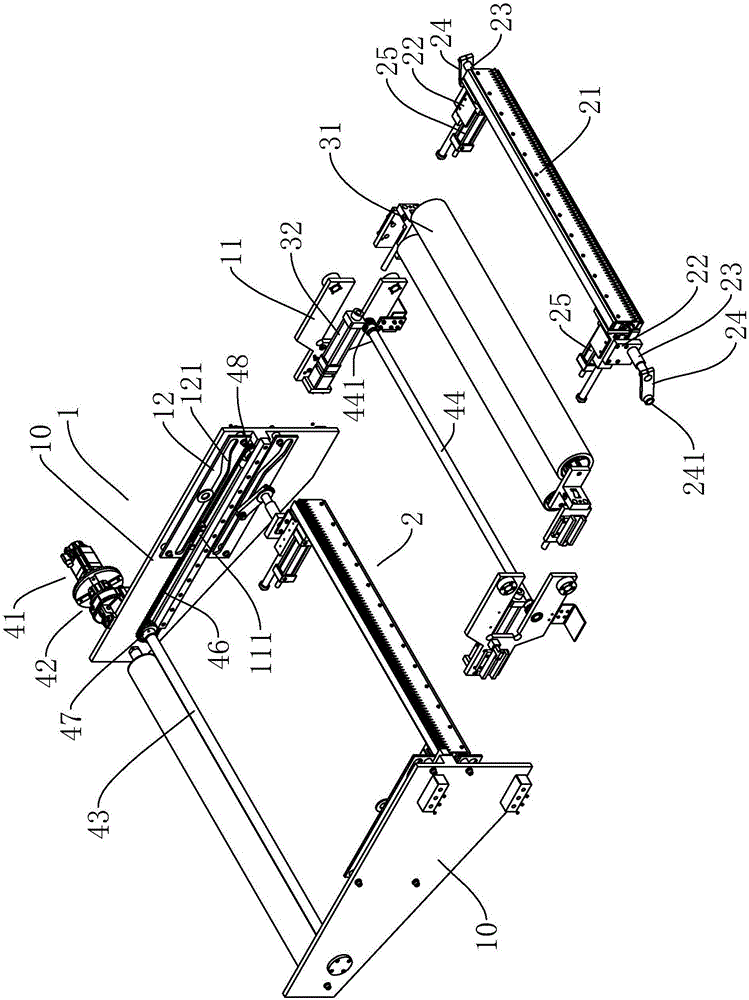

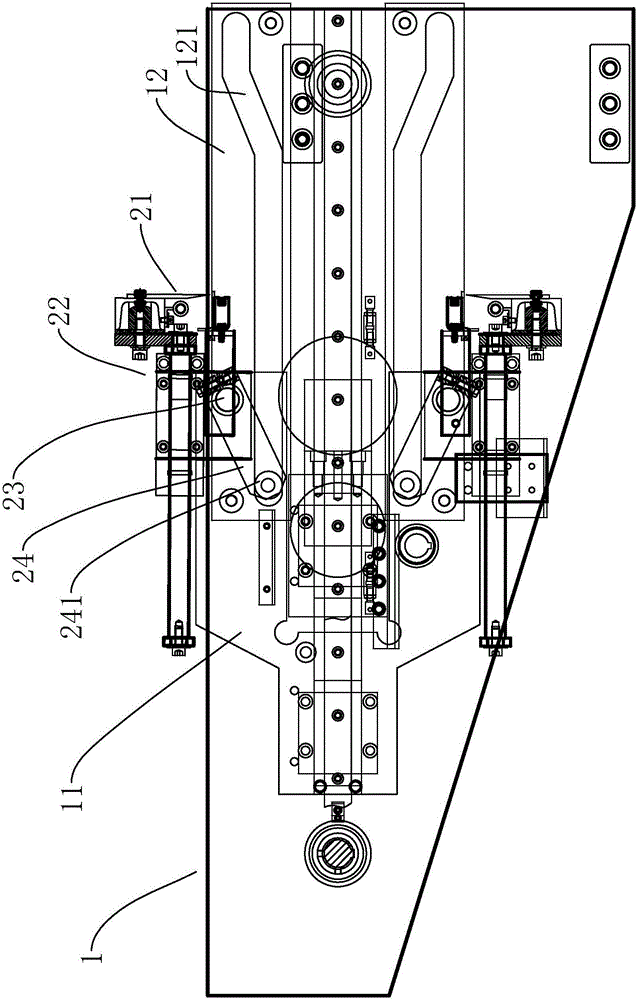

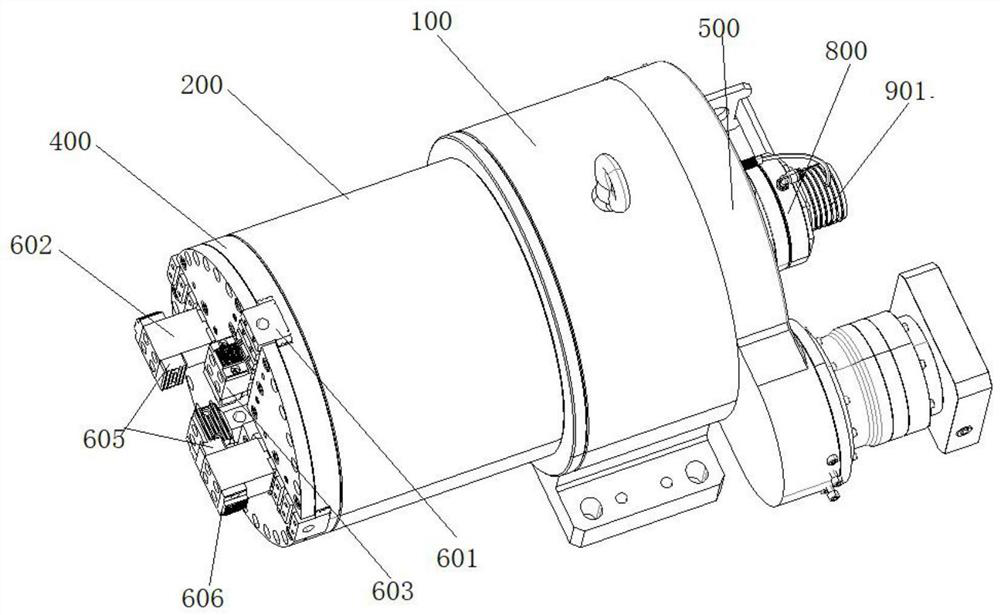

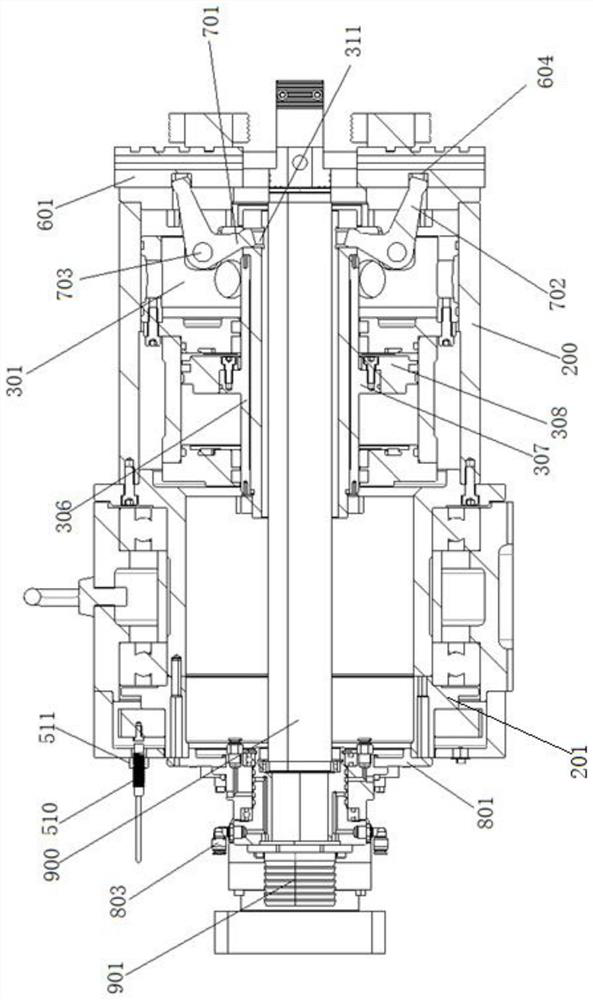

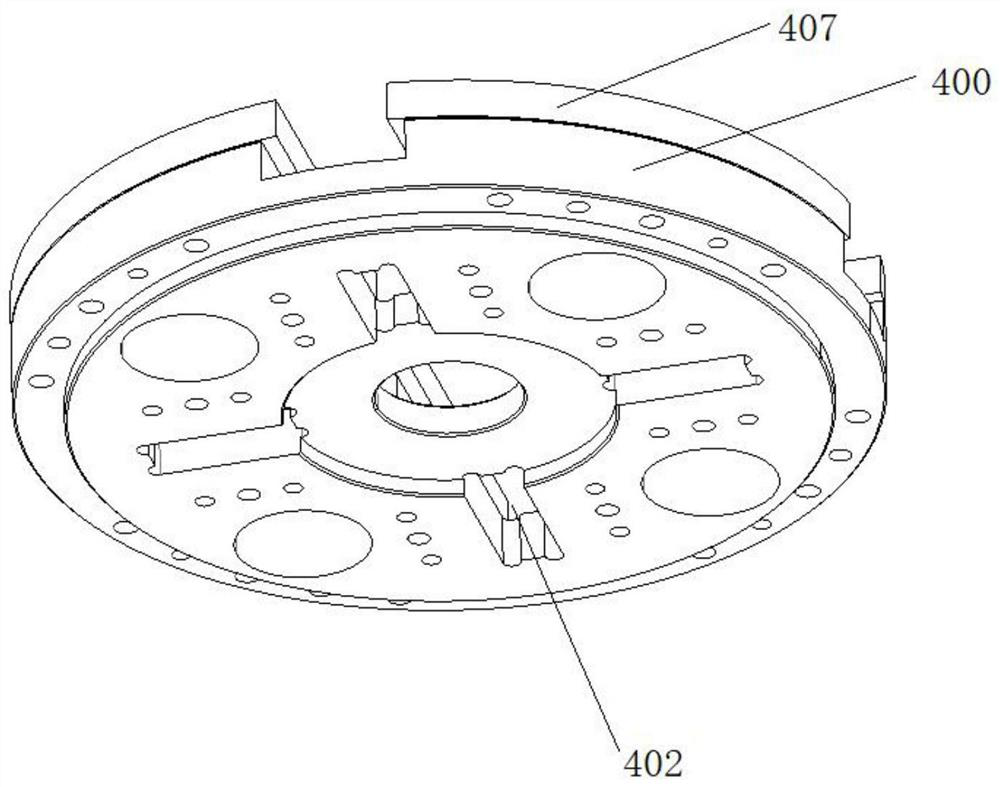

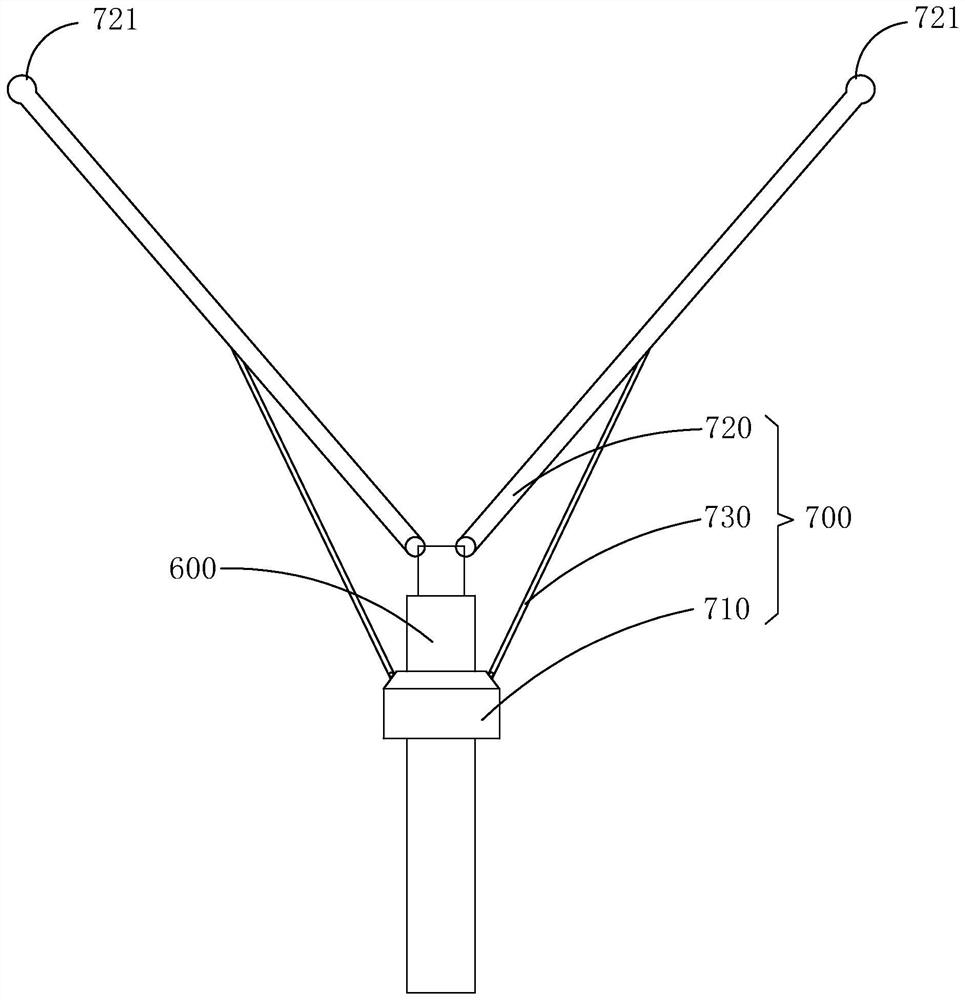

Claw-free chuck for clamping pipes

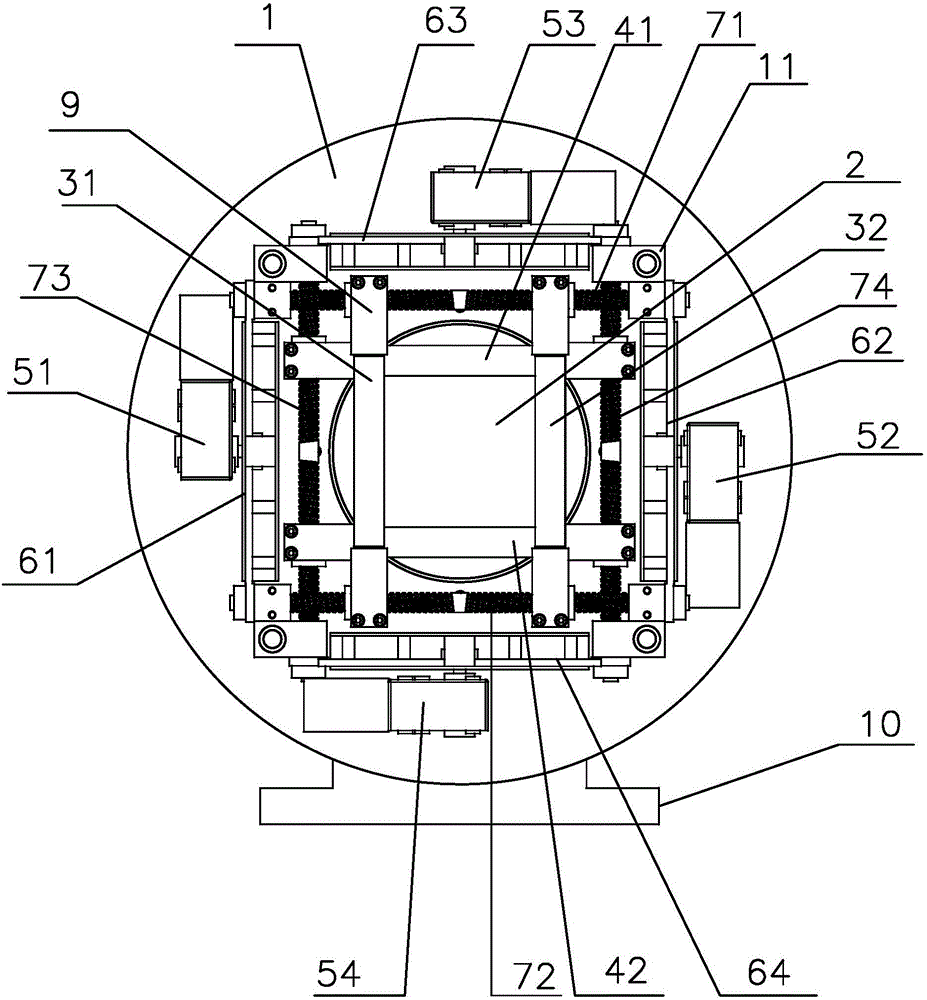

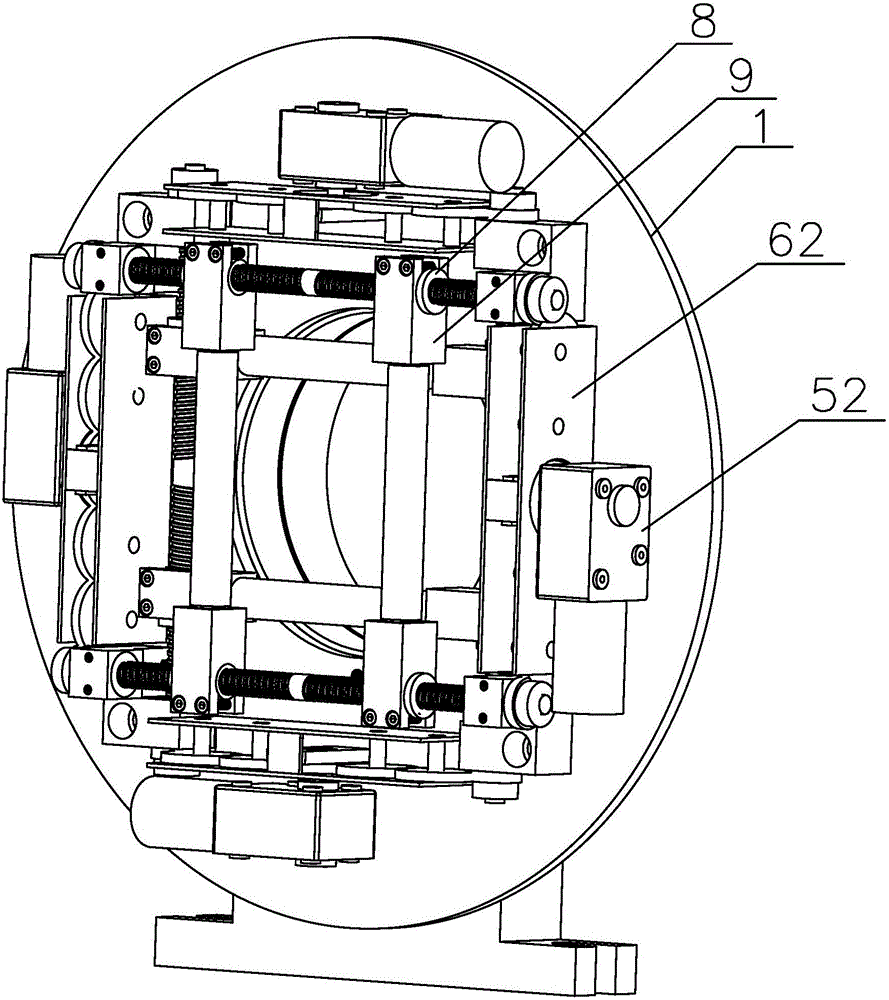

ActiveCN105710592AOmit the jawsConsistent centering accuracyWelding/cutting auxillary devicesAuxillary welding devicesMaximum diameterEngineering

The invention relates to the technical field of pipe clamps, in particular to a claw-free chuck for clamping pipes. A through hole accepting penetration of the pipes is formed in the middle of a main plate, and the main plate is provided with a claw-free clamp capable of clamping the pipes and enabling the pipes to slide in the through hole in the axial direction of the center of the main plate. According to the claw-free chuck for clamping the pipes, claws and clamping bases pushing the claws are eliminated, and therefore the thickness of the claw-free chuck for clamping the pipes is reduced, the self weight of the chuck is lowered, and feeding waste of the pipes is reduced; because the claws are eliminated, the problem that claw handles extend out of the maximum diameter part of the chuck (namely the main plate) is avoided, the installation space of the chuck is greatly reduced, the manufacturing cost of the chuck is greatly reduced, and the stability is high; pipe loads are retained by screw rods firstly, worm motors just need to bear small retaining force, and gearboxes of the worm motors are protected against damage caused by overload due to the two-stage retaining function. In addition, the claw-free chuck is simple in structure, small in size and light in self weight and has full stroke.

Owner:常州市力源恒机械有限公司

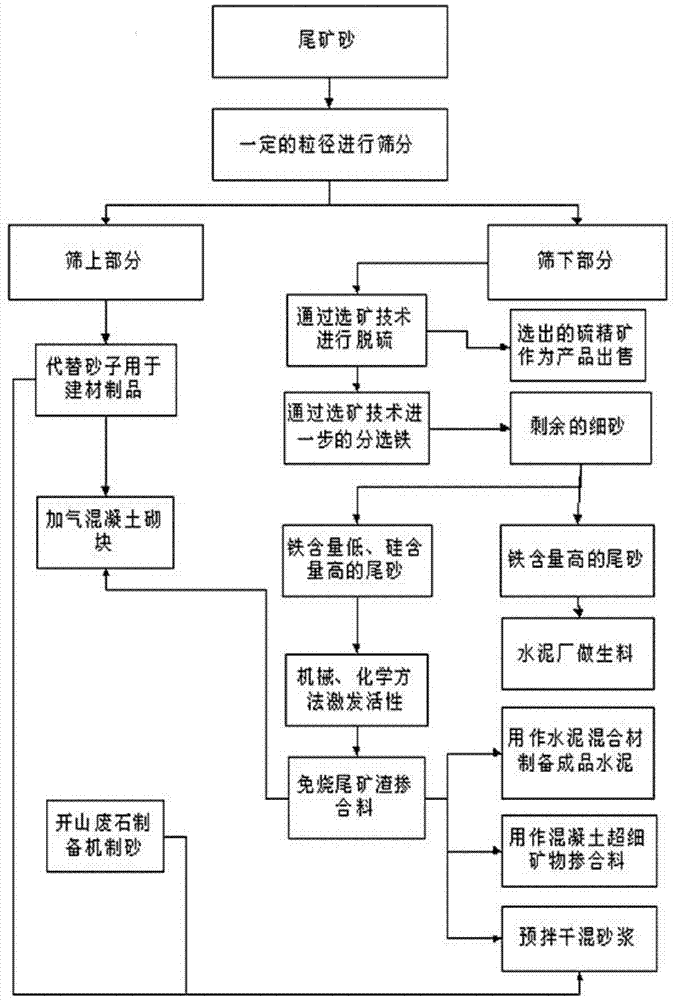

Gradient utilization method of high-sulfur low-silicon iron tailings

ActiveCN103801548AEfficient use ofReduce tailingsSolid waste managementSolid waste disposalSlagHigh activity

The invention relates to a gradient utilization method of high-sulfur low-silicon iron tailings. The gradient utilization method comprises the following steps: (1) sieving by utilizing a 60-80-mesh sieve, wherein about 70% of tailings are remained on the sieve, and about 30% of tailings are sieved; (2) preparing a standard cement mortar product from the about 70% of rough tail sand on the sieve instead of 50-60% of river sand; and (3) separating 6.14% of sulfur ore concentrate from the about 30% of sieved fine tailings by virtue of flotation desulfurization so as to prepare sulfuric acid, carrying out iron separation on 24.6% of fine sand by utilizing a strong magnetic separation technique after the sulfur separation, preparing a high-activity tailing slag admixture by utilizing the residual 7.14% of high-silicon-content tail sand after the iron separation, and directly utilizing 17.47% of high-iron-content tail sand separated through the strong magnetic separation as a raw material to sinter cement in a cement plant, wherein the sulfur grade of the sulfur ore concentrate reaches 44.65%, and the iron grade of high-content iron slag remained after the sulfuric acid preparation reaches 63%. According to the gradient utilization method, the utilization range of the iron tailings is extended from barren rock and iron tailing sand obtained in a mountain cutting process to the tailing slag admixture, so that 100% gradient utilization of mine waste is realized.

Owner:中钢集团武汉安全环保研究院有限公司 +3

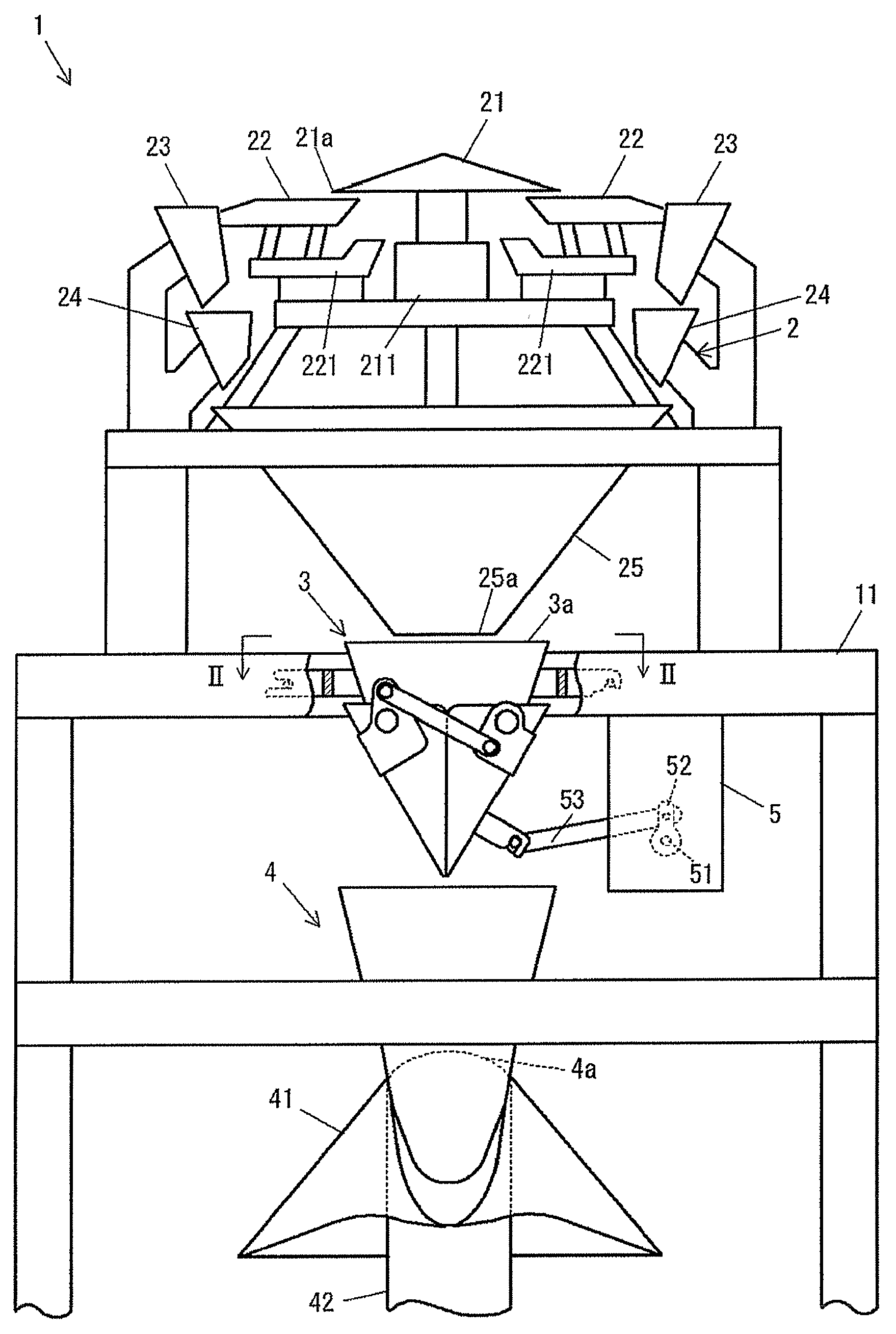

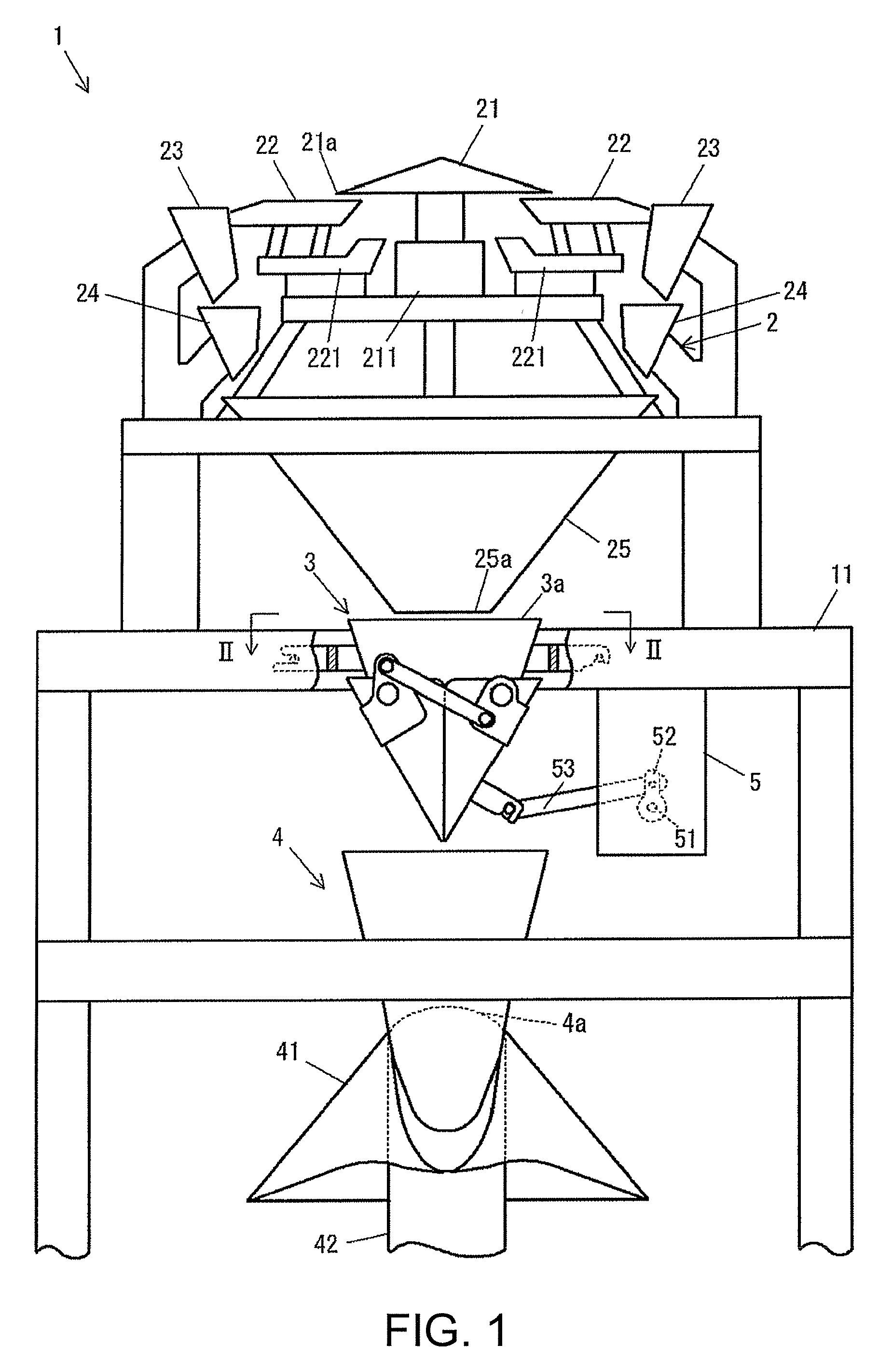

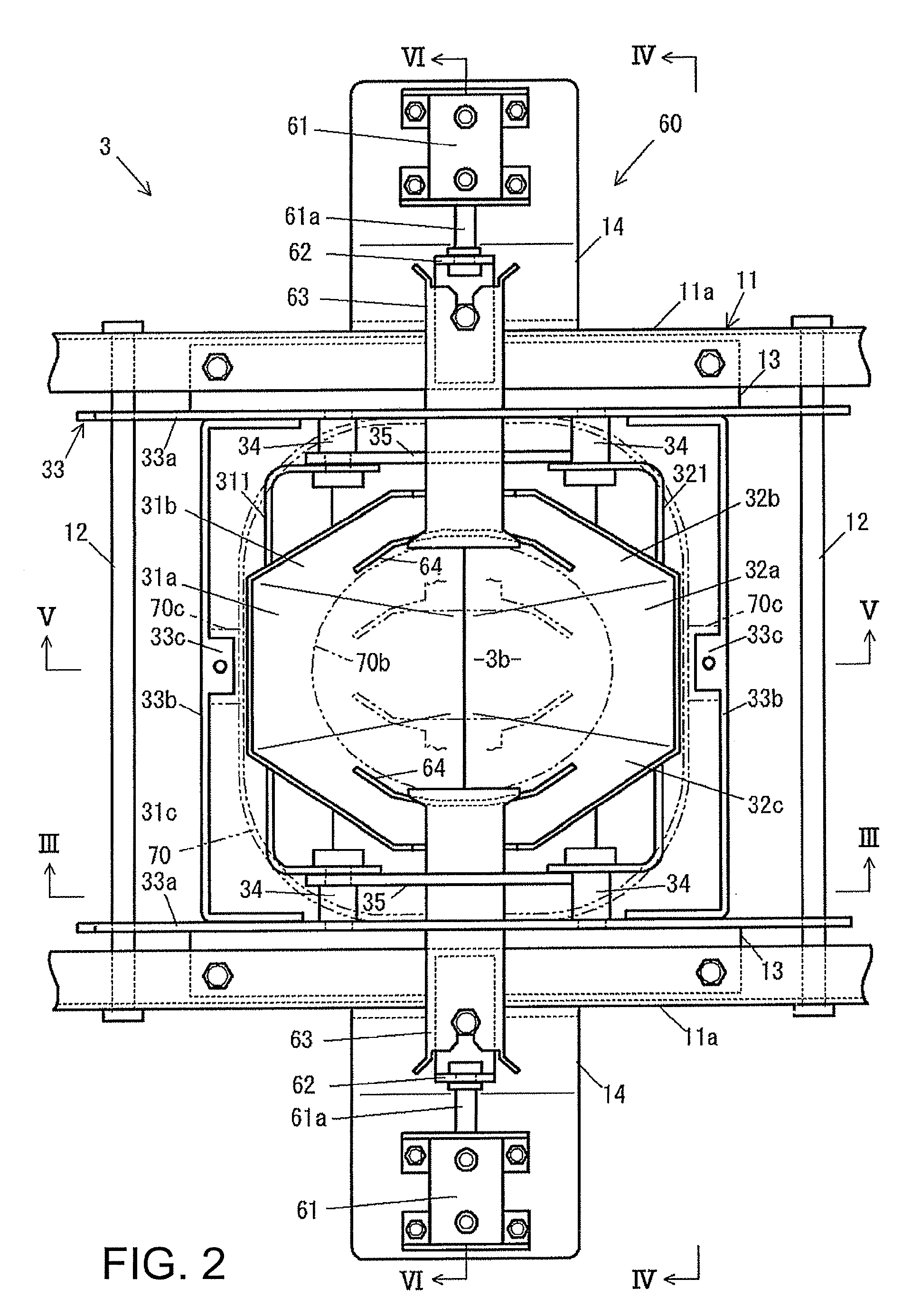

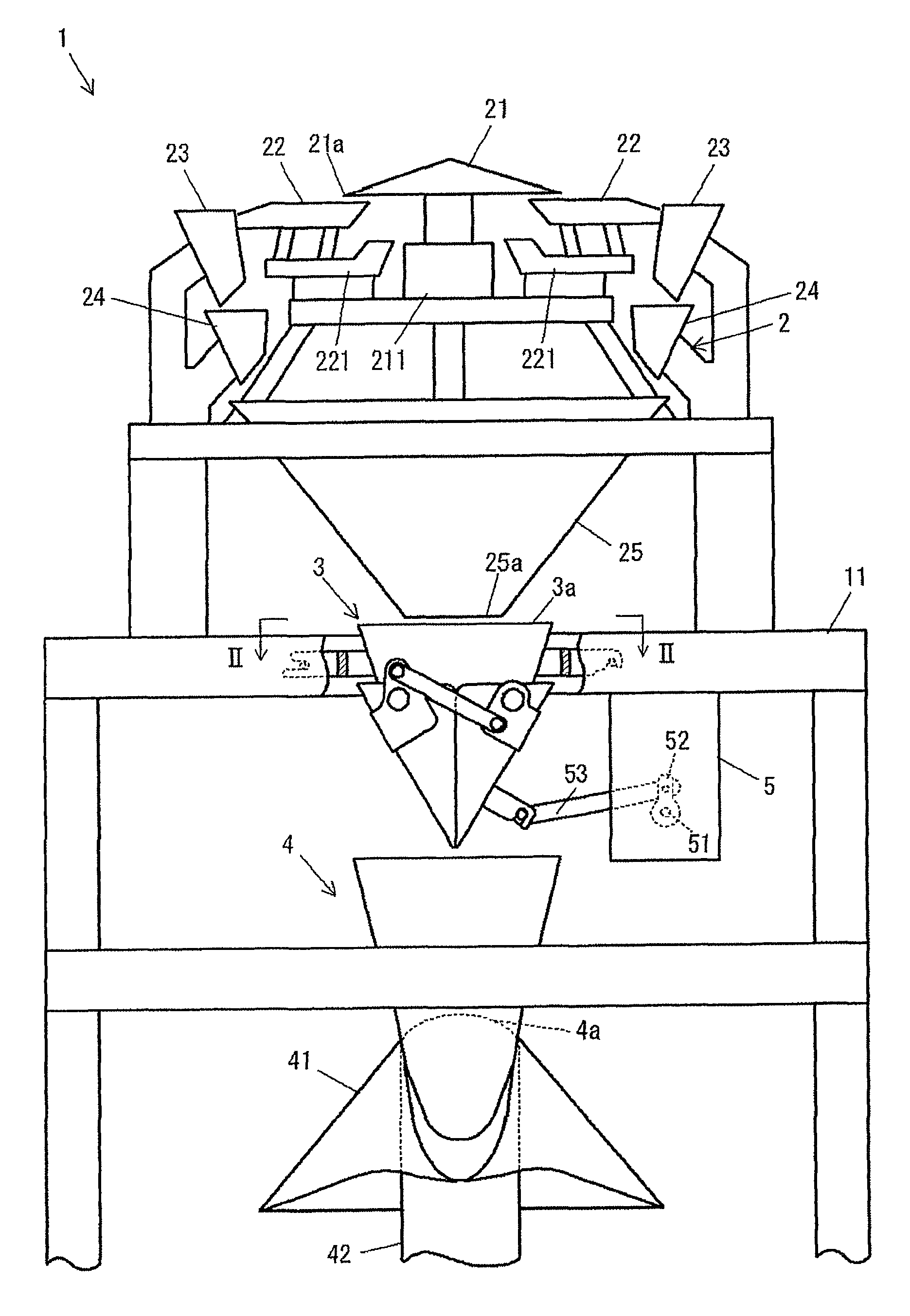

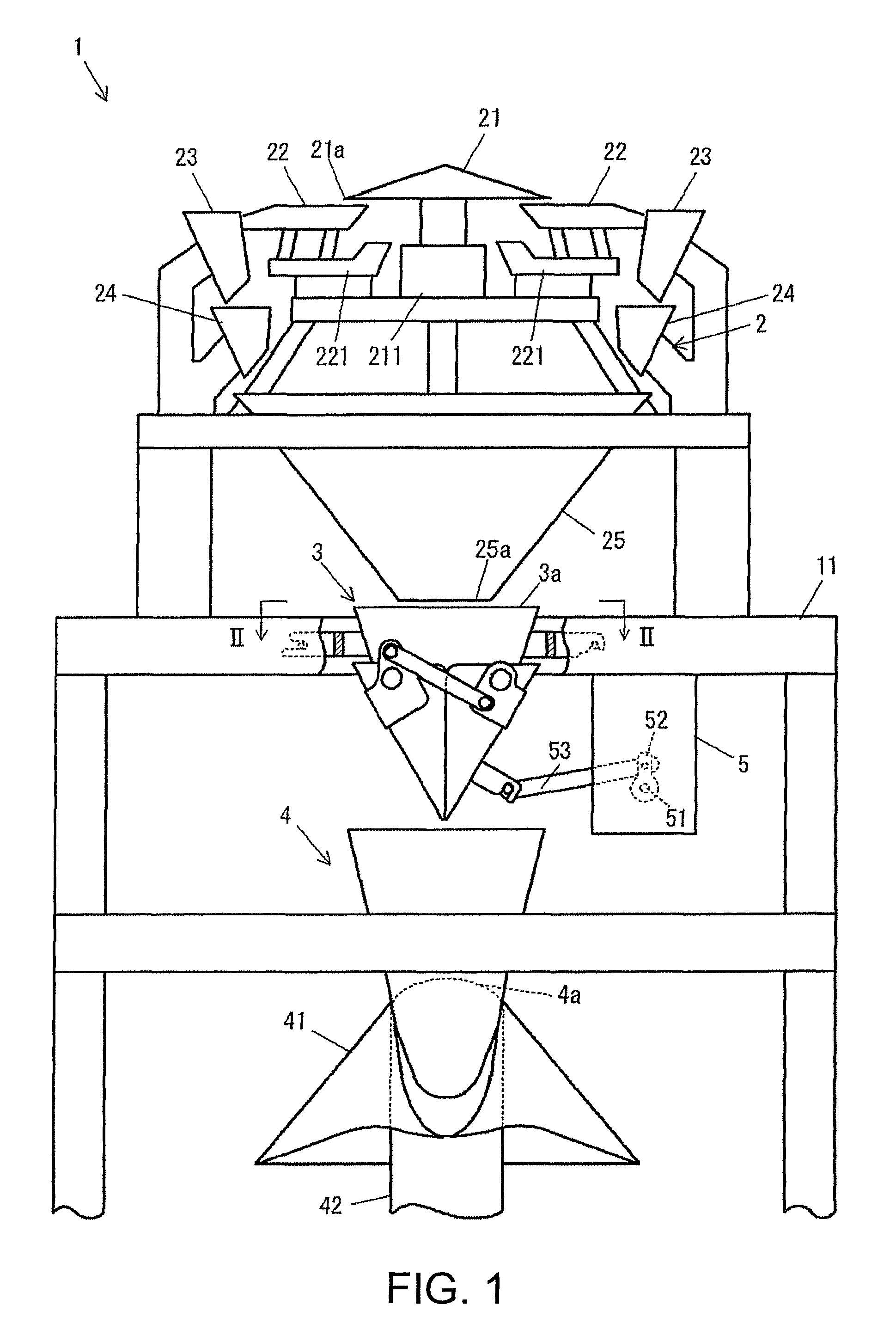

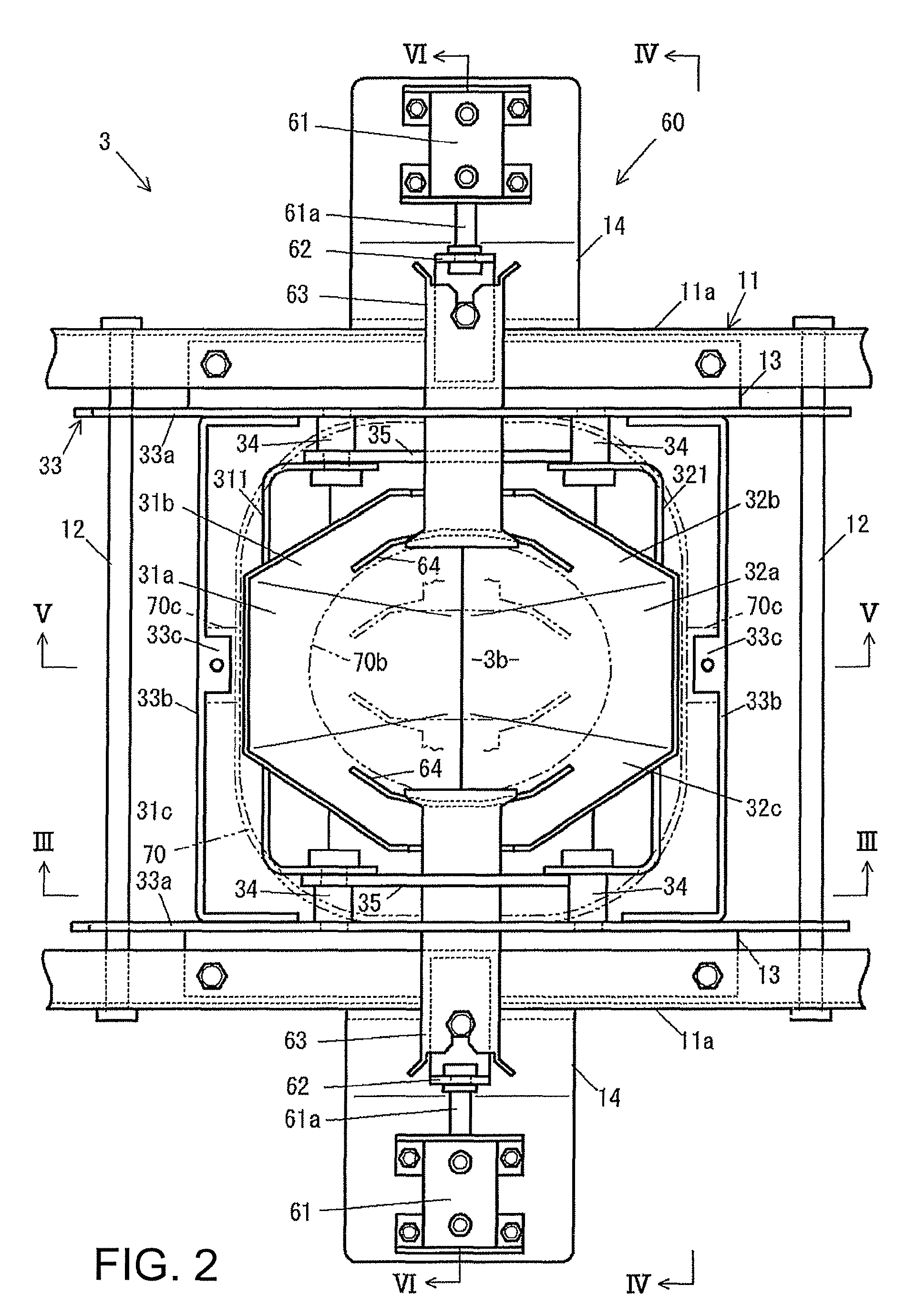

Storage hopper, and combination weighing device and packaging device provided with the same

InactiveUS20090194558A1Reduce the overall heightReduce tailingsDispensing apparatusLarge containersEngineering

Owner:ISHIDA CO LTD

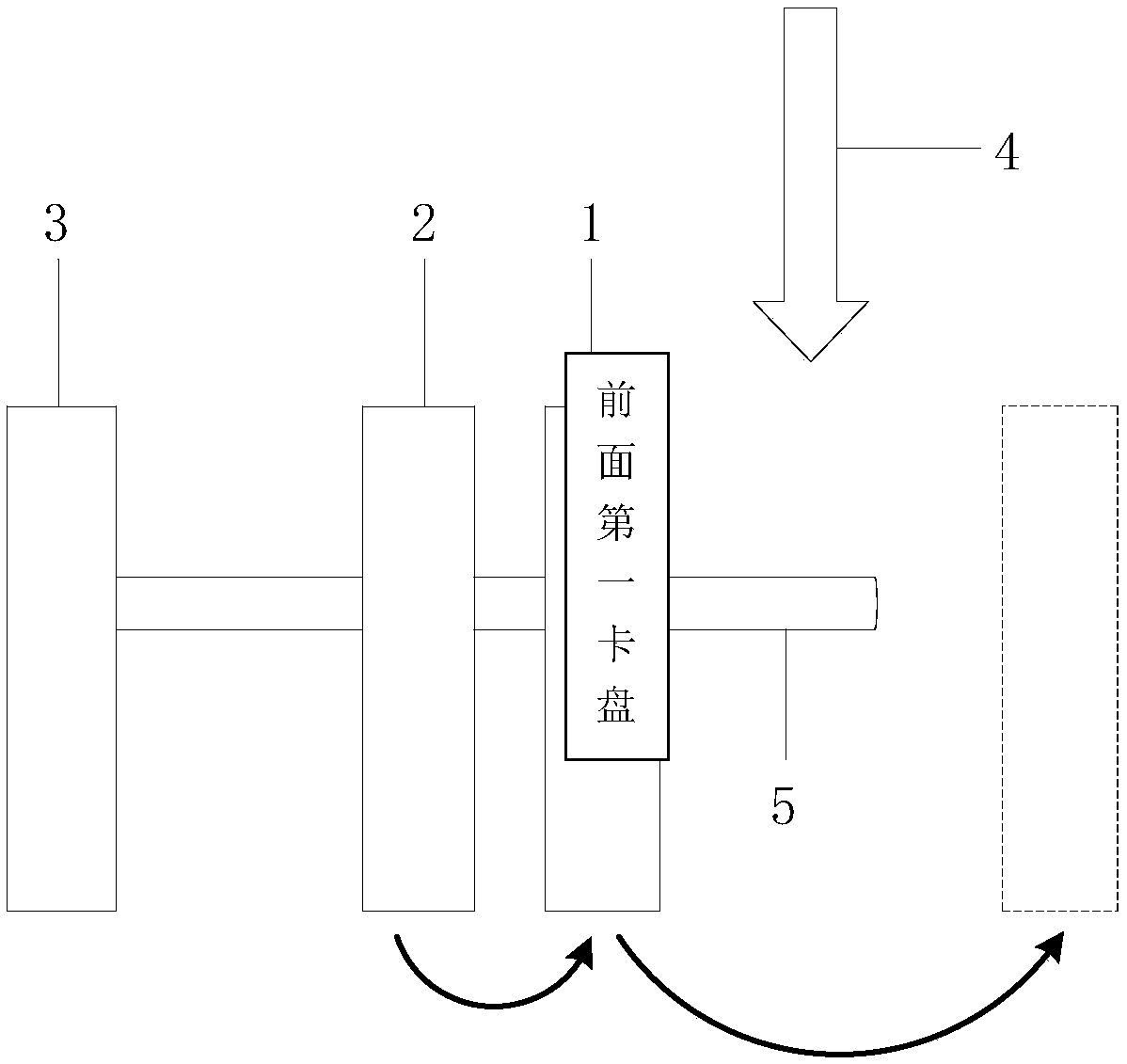

Full-moving type multi-chuck cutting device and method

PendingCN109175730AReduce swingPrevent forward and backward displacementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a full-moving type multi-chuck cutting device and method. The full-moving type multi-chuck cutting device comprises at least three chucks capable of moving left and right and synchronously rotating, and when a pipe is cut, the pipe is clamped in the three chucks, so that the rotation of the pipe is reduced; and during normal cutting, the chucks drive the pipe to move forwards and backwards and rotate, a cutting head is used for cutting, and the cutting head is lifted when the last section is cut; and the first chuck loosens a claw and moves forwards to exceed a certain distance of the cutting head, the position of the first chuck before the middle chuck moves forwards is replaced, the last chuck and the middle chuck jointly clamp the pipe to move forwards and backwards and synchronously rotate, and after the head end part of the last material is cut completely, the second chuck moves forwards by a certain distance over a laser head, the third chuck feeds the pipeforwards and moves to the position of the second chuck before moving to the position of the previous second chuck, the first chuck grasps the pipe, and the cutting head is used for cutting the last section of the pipe. The last section of pipe can be fully utilized, the tail material is reduced, and the cost is saved.

Owner:SHANDONG TAIPENG INTELLIGENT HOUSEHOLD PROD

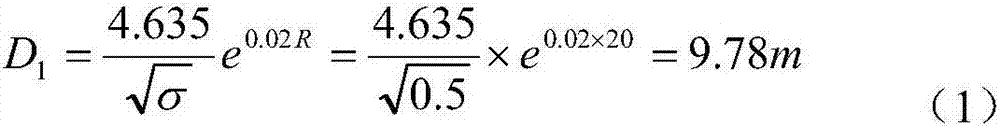

Method for backfilling land collapse pit of mine subjected to caving mining by utilizing tailings

ActiveCN107975044AEliminate geohazard problemsSave management feeEmbankmentsSingle pointMining engineering

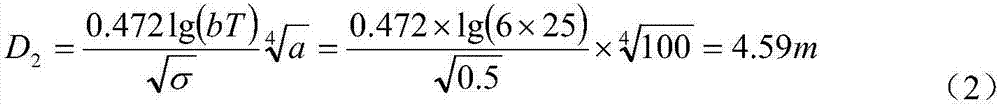

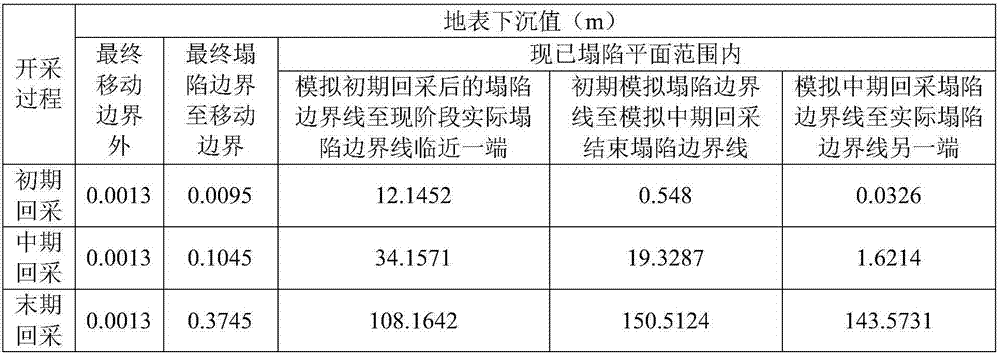

The invention provides a method for backfilling a land collapse pit of a mine subjected to caving mining by utilizing tailings. The method comprises the steps that (1) a collapse pit mill tailing backfill material is prepared, specifically, binding materials and mill tailings are mixed and stirred at the proportion of (1:6)-(1:8), and the concentration of backfill slurry can reach over 65%; (2) backfill zoning is conducted on the mine land collapse pit; (3) a solidified tailing slurry single-point piling and discharging flowing average expansion radius is determined, specifically, the solidified tailing slurry single-point piling and discharging flowing average expansion radius is determined to be 20 m; and (4) backfill material solidifying is conducted, specifically, tailing solidifying and backfilling units are arranged along the boundary arc length of a piled and discharged position of a semi-secure area at intervals of 20 m when on-site piling and discharging are conducted, the prepared backfill material is directly discharged into the designated backfilling units, the one-time piled and discharged thickness is (4.59-4.59 m)-9.78 m, the solidifying time lasts for 14 days, and circulation backfilling is conducted. According to the method, potential safety hazards of a tailing pond can be avoided, a lot of lands can be saved, meanwhile the problem of safety of a land collapsearea is solved, and the engineering amount and the cost of mine terminal-stage management of geological disasters are greatly reduced.

Owner:NANJING MEISHAN METALLURGY DEV

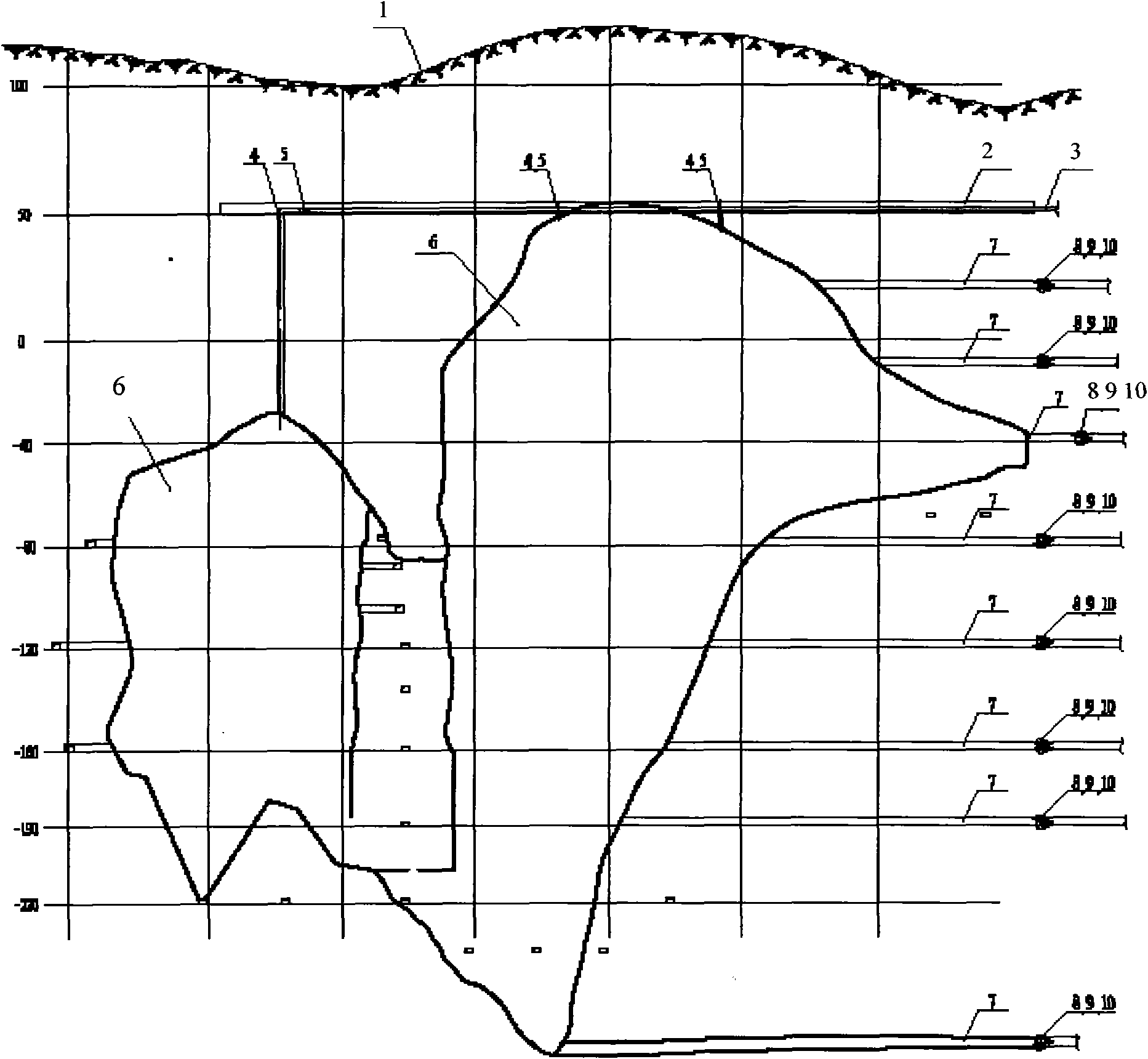

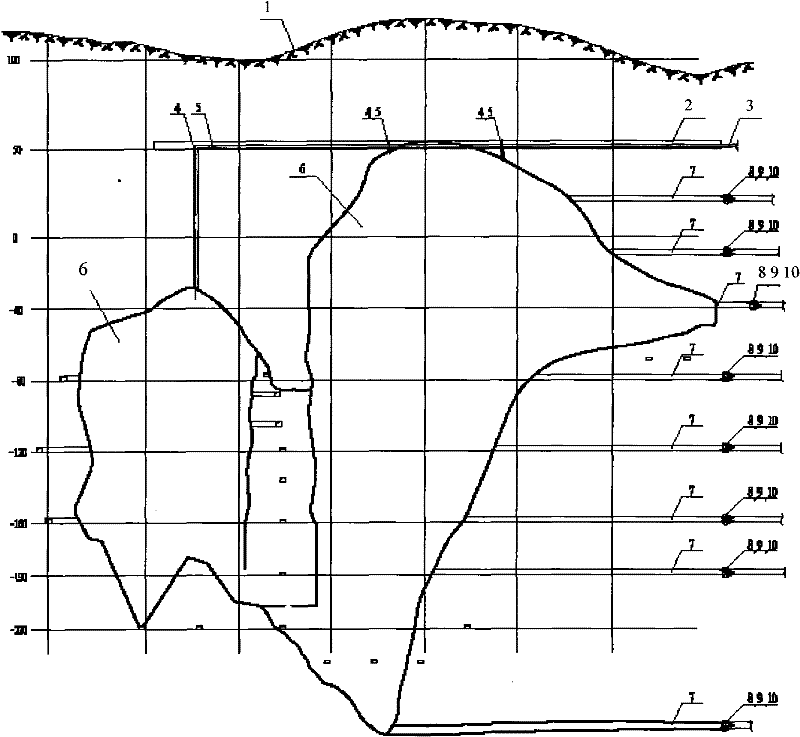

Stope structure arrangement mode suitable for underground mine high productivity and low cost subsequent filling

ActiveCN102817614ASolve the contradiction of low mining production capacitySimple processUnderground miningSurface miningEngineeringUltimate tensile strength

The invention discloses a stope structure arrangement mode suitable for underground mine high productivity and low cost subsequent filling. Underground ore block is divided into panels (1), the interior of each panel (1) is divided into 3-6 continuous stopes (2) and a panel stud (3), a panel crown pillar (4) and a panel sill pillar (5) are arranged in a vertical direction, ores (7) in the stopes (2) drop into a stope trenches (11) through blasting, a carry-scraper passes through an ore removal roadway (10), ore loading is performed in ore removal access road (12), ores are transported to drift roadway (8) and are discharged into an orepass (14). After the stope ore removal, tailings pass through a filling roadway (15) and are subjected to pipeline filling to a dead zone to form a panel filling body (6). After the filling of the panel stopes (2) is finished, adjacent panel stopes (2) are stoped, and subsequently the formed dead zones are filled. After the filling of the adjacent panel stopes (2) is fihished, a part of the panel studs (3) is recovered, dead zone formed by the panel studs are filled, and finally the dead zones are eliminated. The stope structure arrangement mode has the advantages that the mining intensity can be improved by utilizing limited ore body distribution area, the production capacity is increased, and mining production and dead zone filling treatment costs are reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Arbidol granular formulation and fluidized-bed coating preparation thereof

InactiveCN101249076ASimple processReduce spillageOrganic active ingredientsPharmaceutical product form changeFluidized bedEngineering

The invention discloses an arbidole granule preparation and a fluidized-bed coating preparation method thereof. The direct granulation of powder in a fluidized bed improves fluidity and reduces fly ash. The fluidized bed equipment is provided with discharge holes to eliminate explosion hazards. The coating process is performed in a closed system without leakage risk. The equipment has no dead angles, rapid discharge, easy cleaning, and compliance to the GMP standards. Compared with the prior art, the preparation method has simple process, high product quality, short production cycle and low production cost.

Owner:徐向兵

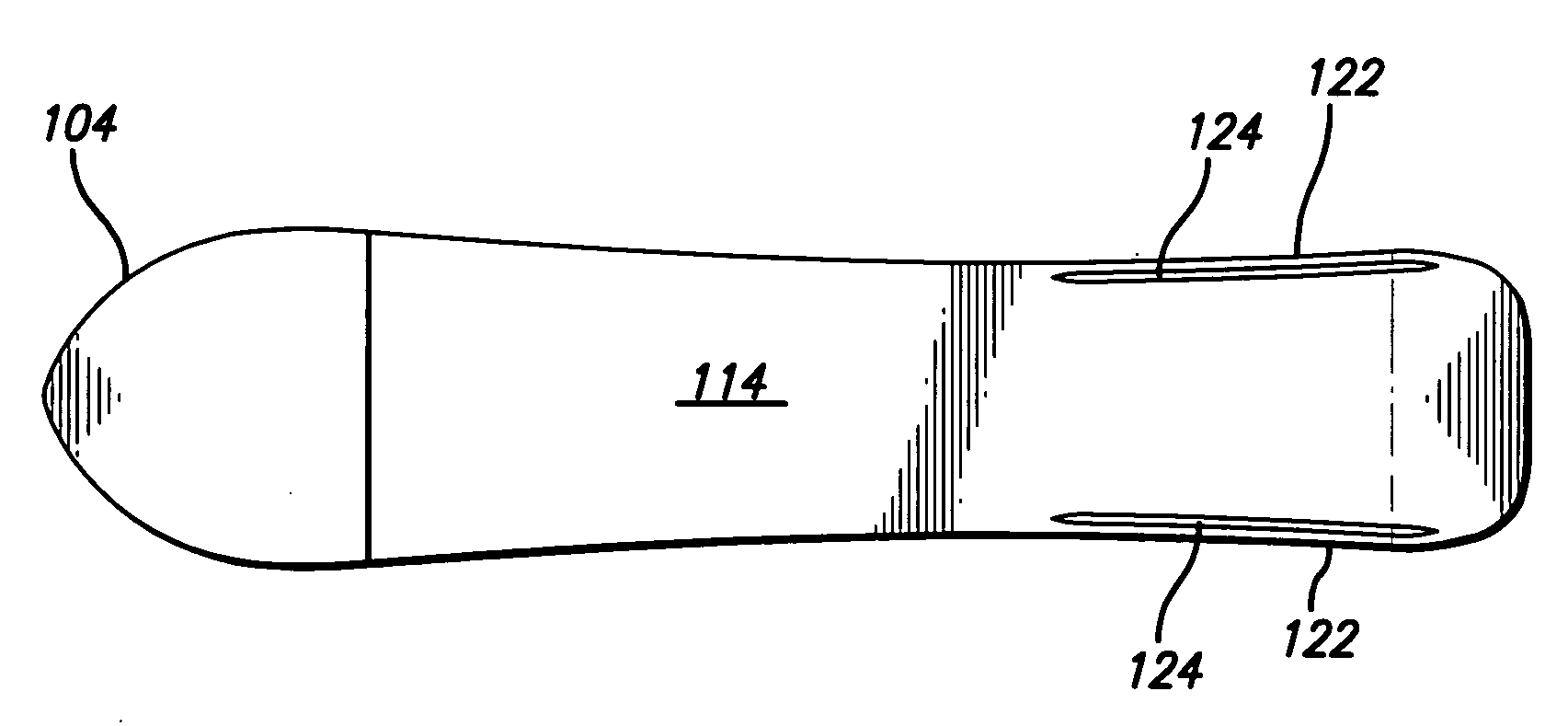

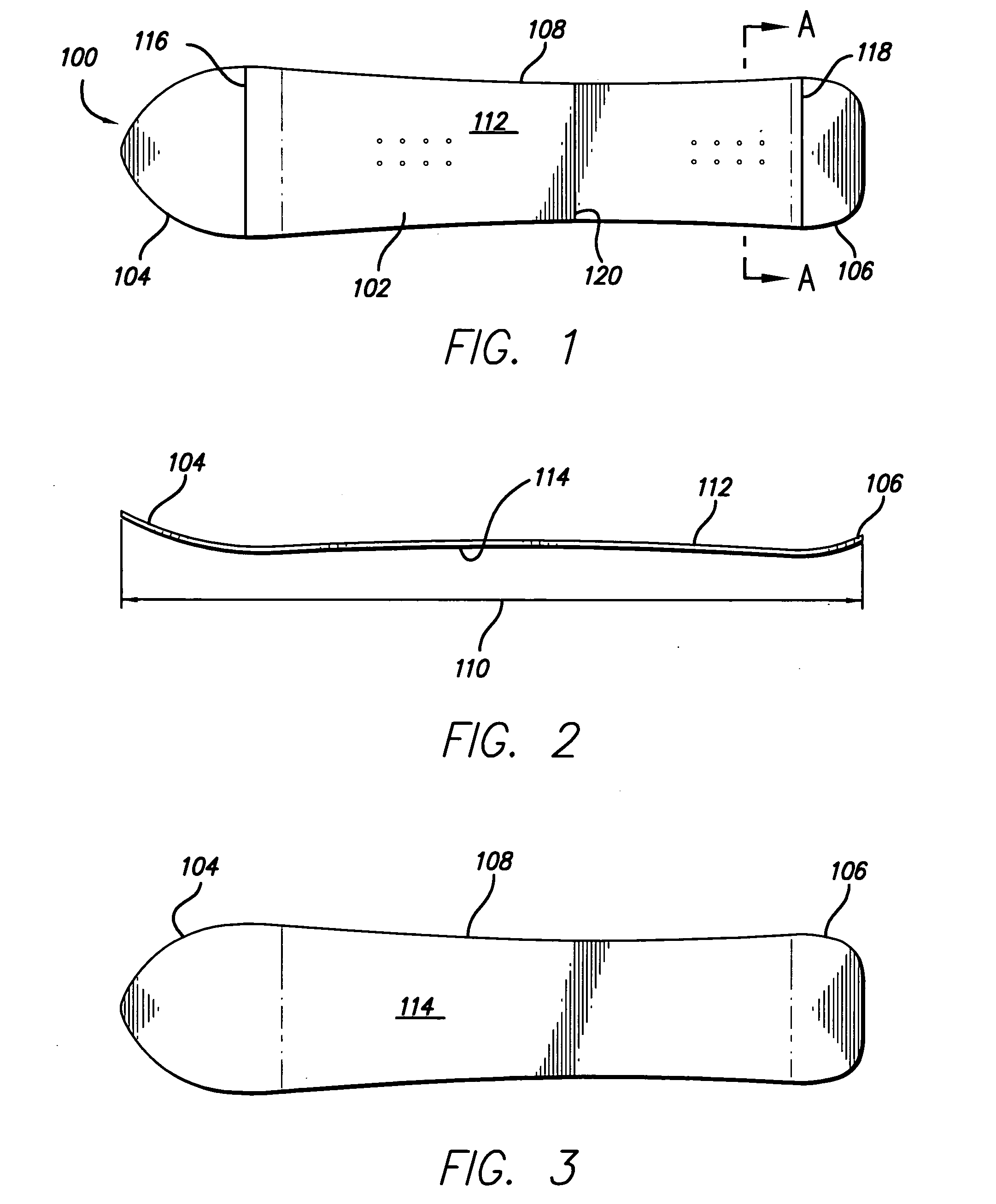

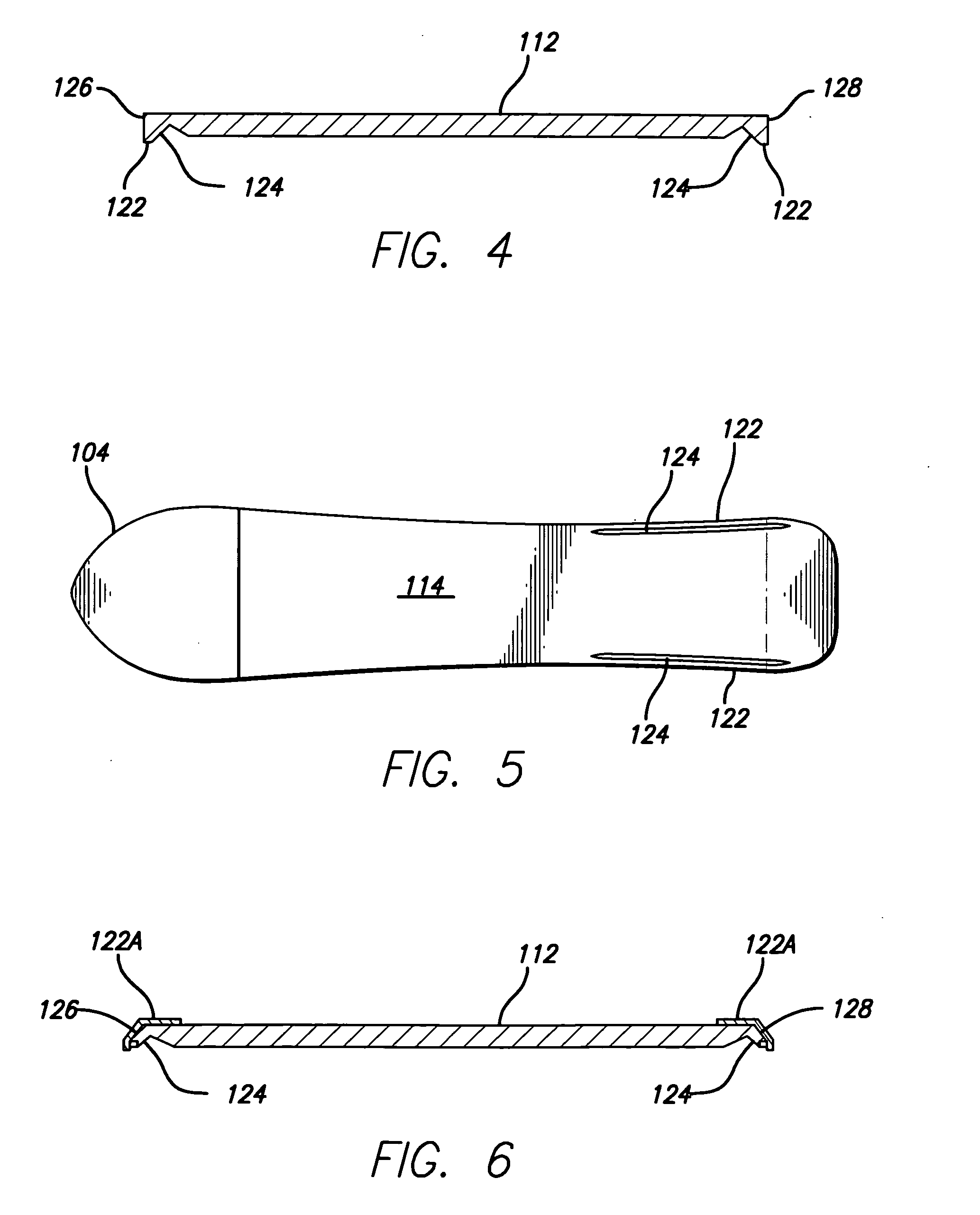

Performance enhanced snowboard

InactiveUS20100013191A1Effectively floatIncrease frictionSki bindingsSki-brakesNinetieth percentileEngineering

A performance enhanced snowboard having an extended, generally planar deck with a nose, a tail, and a central section. The deck also has an overall length, a top surface, and a bottom surface. The nose has a widest portion that defines a nose chord line having a nose chord length. The tail has a widest portion that defines a tail chord line having a tail chord length, and the central section has a narrowest portion that defines a central chord line having a central chord length. The nose chord length is greater than the central chord length, and the nose chord length is between about fifteen and thirty-five percent of the overall length of the deck. The tail chord length is between about one percent and ten percent greater than the central chord length, while the distance between the tail chord line and the central chord line is between about forty to ninety percent of the distance between the nose chord line and the central chord line. The structure permits the invented board to function like a surfboard or skateboard while also sliding like a conventional snowboard.

Owner:MCKEEVER NATHANIEL W

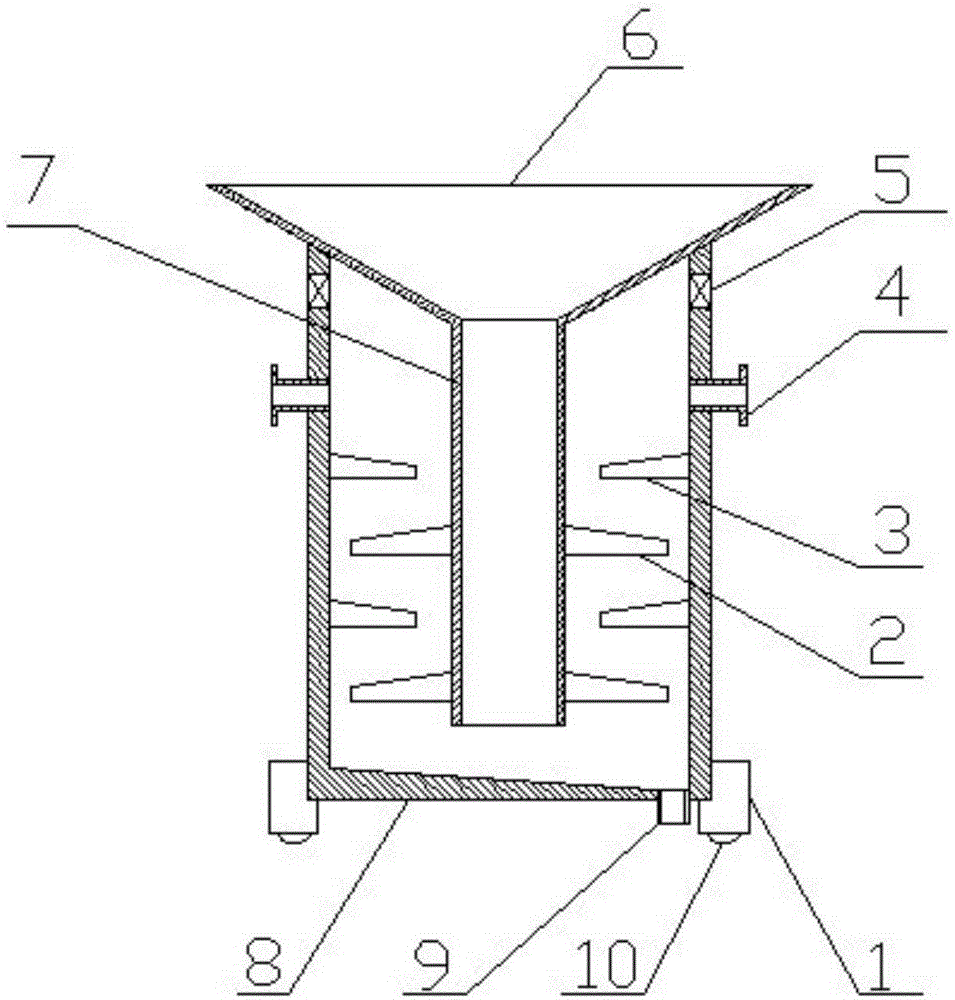

Sedimentation device for sewage treatment

InactiveCN105233531AEasy dischargeReduce tailingsSettling tanks feed/dischargeSedimentation settling tanksParticulatesParticle adhesion

The invention discloses a sedimentation device for sewage treatment. The sedimentation device includes a supporting pedestal, a sedimentation chamber, a material guiding pipe, a feeding hopper and discharge pipes; the sedimentation chamber is mounted on the supporting pedestal and has a cylindrical cavity body structure having the bottom tilted to a sewage draining port; the inner wall of the sedimentation chamber is provided with guide plates A in an tilting manner; guide plates B are arranged between the guide plates A and are mounted on the material guiding pipe in an tilting manner; the material guiding pipe is mounted on the feeding hopper; the feeding hopper is mounted at the upper edge opening of the sedimentation chamber; the discharging pipes are mounted below the upper edge opening of the sedimentation chamber; the sedimentation chamber is provided with exhaust ports; the exhaust ports are located above the discharging pipes. A tank body and the material guiding pipe are adopted, and the guide plates A and the guide plates B are respectively mounted on the tank body and the material guiding pipe in the titling manner, so that the sewage flow rate is reduced, the particle adhesion area is increased, the sedimentation time and the drug use amount are reduced, the production cost is lowered, and the production efficiency is improved.

Owner:广西大美节能设备有限公司

Novel winding cutting knife device

The invention discloses a novel winding cutting knife device. The novel winding cutting knife device comprises a machine frame, a flat pushing pressing roller device, and a cutting knife assembly, wherein moving plates are arranged on two sides of the machine frame; the flat pushing pressing roller device and the cutting knife assembly are arranged on the moving plates; the cutting knife assembly comprises two groups of cutting knife mechanisms which are oppositely arranged above the flat pushing pressing roller device and under the flat pushing pressing roller device; each of the cutting knife mechanism comprises a cutting knife and cutting knife bases positioned at two ends of the cutting knife; a pushing mechanism is arranged on the cutting knife bases; two groups of guiding plates corresponding with the cutting knife mechanisms are arranged on the machine frame, and are oppositely arranged. When a printing material needs to be cut, the moving plates are moved forward; the guiding plates guide the cutting knife bases and the cutting knives to rotate around a rotating shaft; the cutting knives of the two groups of the cutting knife mechanisms relatively rotate in a closing manner; the flat pushing pressing roller device is in contact with an air bulking shaft; the two groups of the cutting knives are relatively oblique and close to the printing material, and then the two groups of the cutting knifes are pushed to move forward and fit cut, so that the printing material can be cut off. According to the novel cutting knife device disclosed by the invention, the swinging range of each of the cutting knifes is small, tail materials are shortened, the waste is reduced, besides, the cutting knifes stably move, the positioning accuracy is high, the tensile force fluctuation of a film is small, and the printing material is not liable to wrinkle.

Owner:ZHONGSHAN SOTECH PRINTING MACHINERY CO LTD

Storage hopper, and combination weighing device and packaging device provided with the same

InactiveUS7770713B2Reduce tailingsReduce the overall heightLarge containersLiquid materialEngineering

Owner:ISHIDA CO LTD

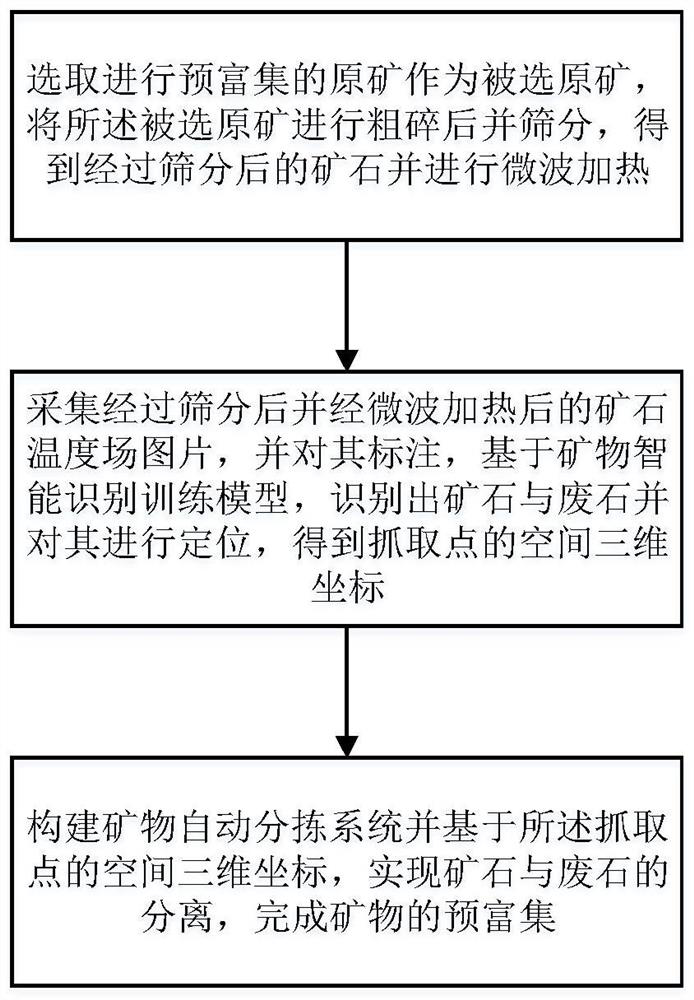

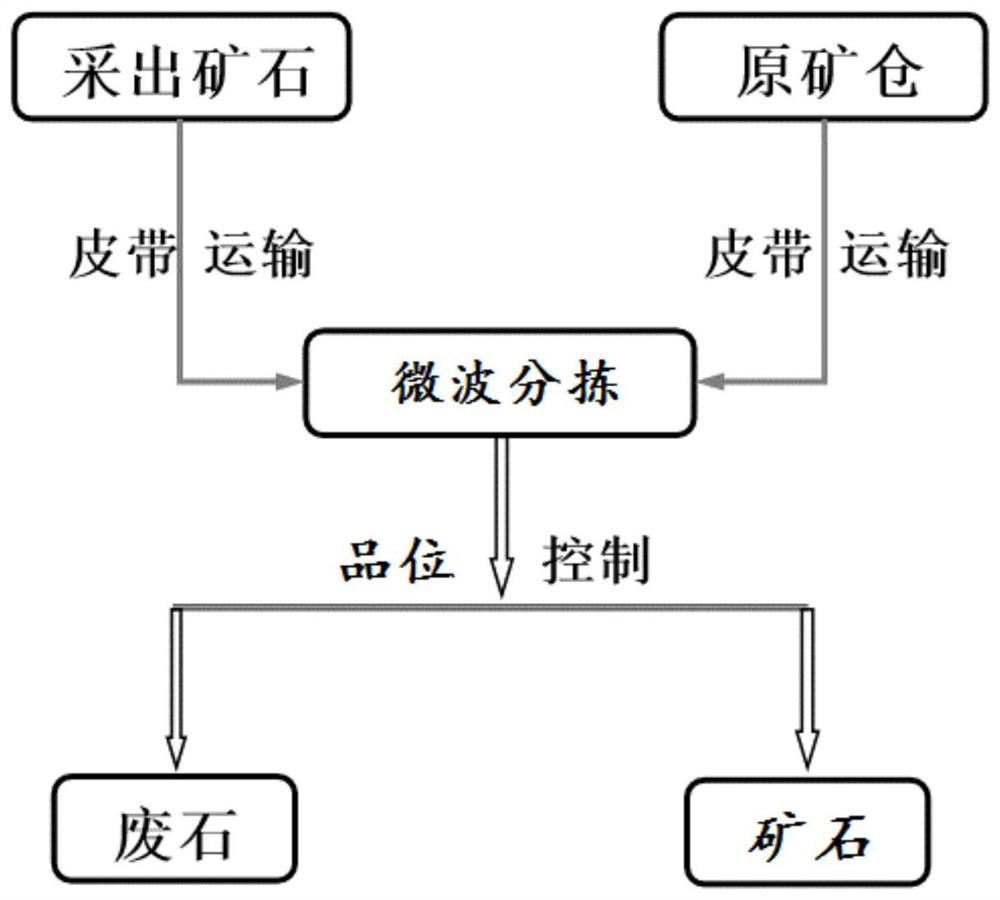

Mineral pre-enrichment method based on solid microwaves

ActiveCN113953067AHigh resolutionShort detection timeProcess efficiency improvementGrain treatmentsImage resolutionMaceral

The invention relates to a mineral pre-enrichment method based on solid microwaves, which comprises the following steps: selecting pre-enriched raw ores as selected raw ores, carrying out coarse crushing on the selected raw ores, screening to obtain screened ores, and carrying out microwave heating on the screened ores; acquiring temperature field pictures obtained after screening and microwave heating, making minerals and barren rocks in the pictures, on the basis of a large number of experiments, constructing an intelligent mineral recognition training model based on deep learning, recognizing and positioning the minerals and the barren rocks, and obtaining spatial three-dimensional coordinates of grabbing points; and constructing an automatic mineral sorting system, achieving separation of the ores and the barren rocks based on the spatial three-dimensional coordinates of the grabbing points, and completing pre-enrichment of the minerals. The method can be used for directly detecting whether the target mineral exists in a certain volume of mineral or not, can be used for quantitatively detecting the content of the mineral in the ore, and has a relatively high resolution ratio.

Owner:CENT SOUTH UNIV +1

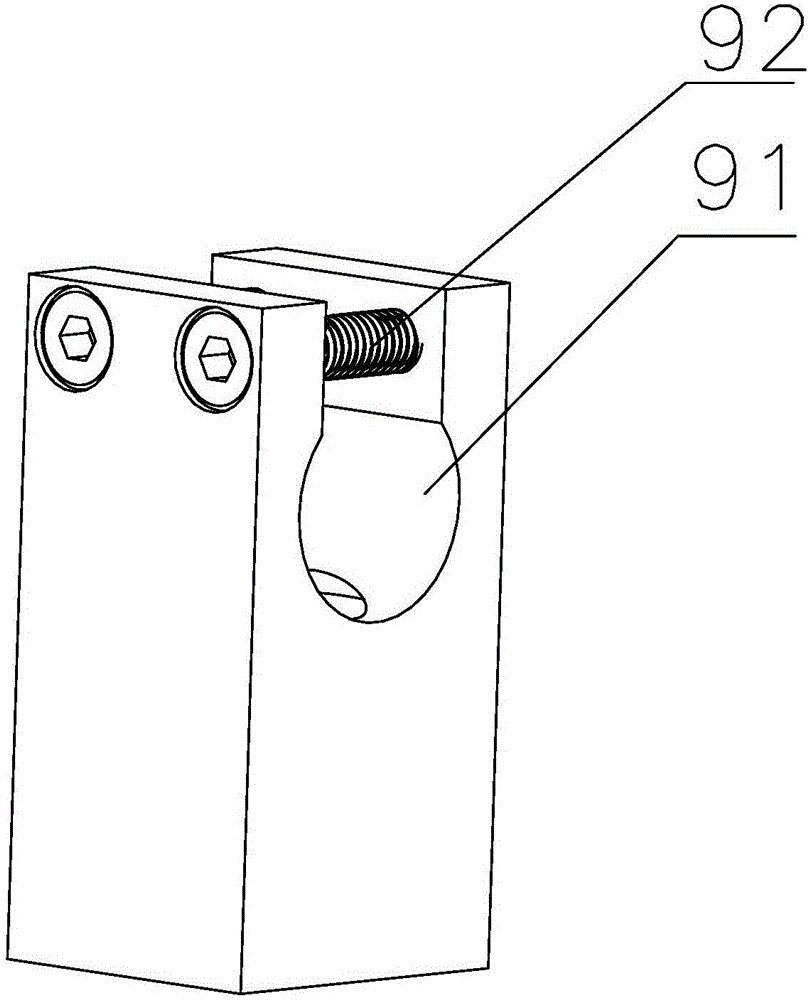

Back chuck with dedusting function

PendingCN111822895AShort overhang lengthReduce tailingsWelding/cutting auxillary devicesAuxillary welding devicesDust controlEngineering

The invention relates to the field of clamping equipment, in particular to a back chuck with a dedusting function. The back chuck is provided with a bearing pedestal and comprises a front bearing anda back bearing arranged in the bearing pedestal, separately, a guide block hood, a chuck body, a connecting rod bracket, an air pumping assembly and an air outlet pipe, wherein the guide block hood isfixedly connected to the front end of the front bearing through a screw; an air cylinder assembly is arranged in the guide block hood; the chuck body is fixed to the front ends of a guide block assembly and the air cylinder assembly, and a clamping jaw assembly is driven by the air cylinder assembly; the connecting rod bracket is arranged between the chuck body and the air cylinder assembly, andthe connecting bracket is movably connected to the air cylinder assembly through a connecting rod; the air pumping assembly is arranged at the back end of a reducer assembly, and the air pumping assembly is supplied with gas by an external gas source and drives the air cylinder assembly; and the air outlet pipe penetrates the reducer assembly, the bearing pedestal, the air cylinder assembly and the chuck body. The clamping jaw provided by the invention is simple in structure and communicates to the external gas source by means of the air outlet pipe, so that fragments and dust are blown away / extracted during processing, and therefore, dust pollution of the environment is avoided.

Owner:常州市润渊精密机械科技有限公司

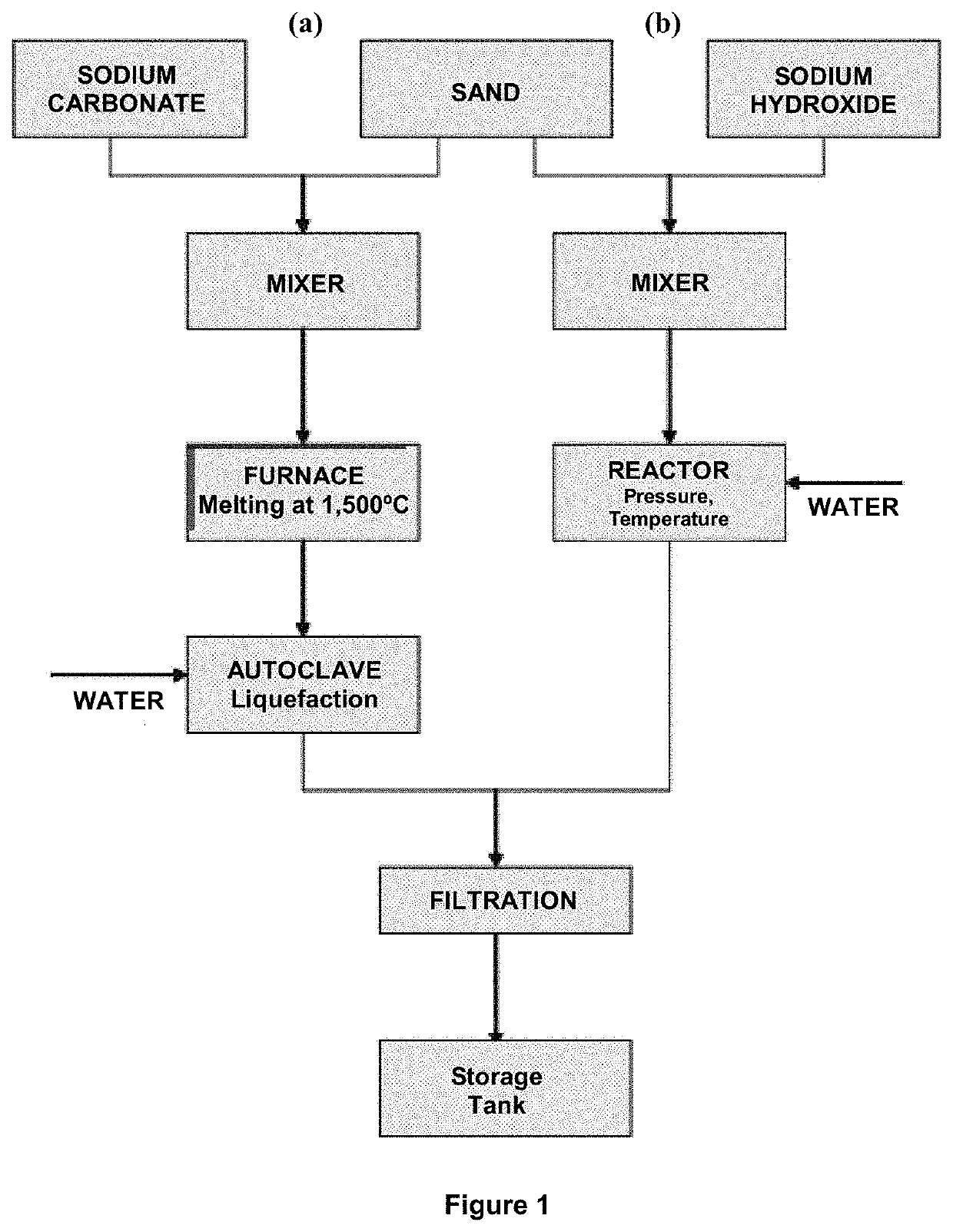

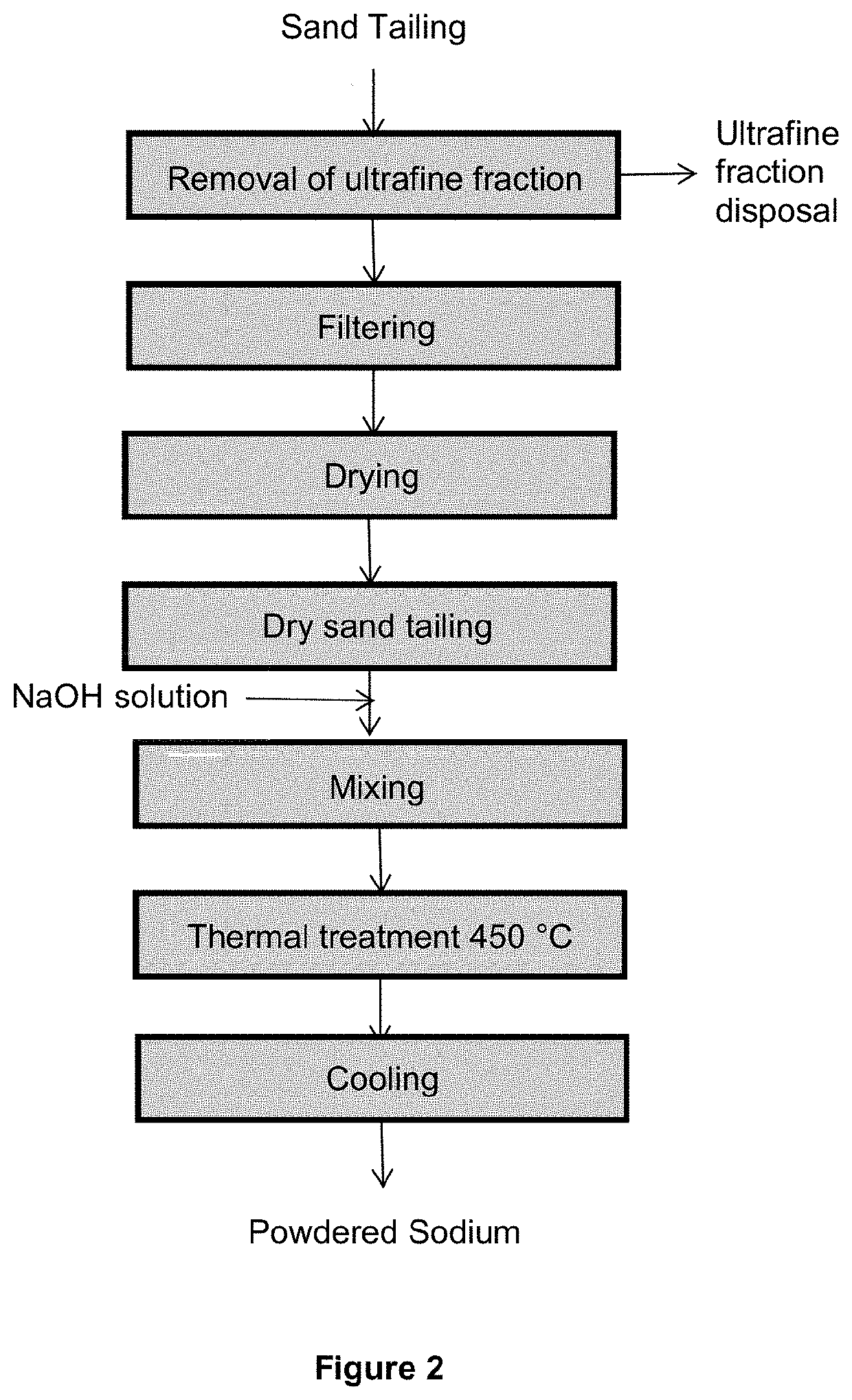

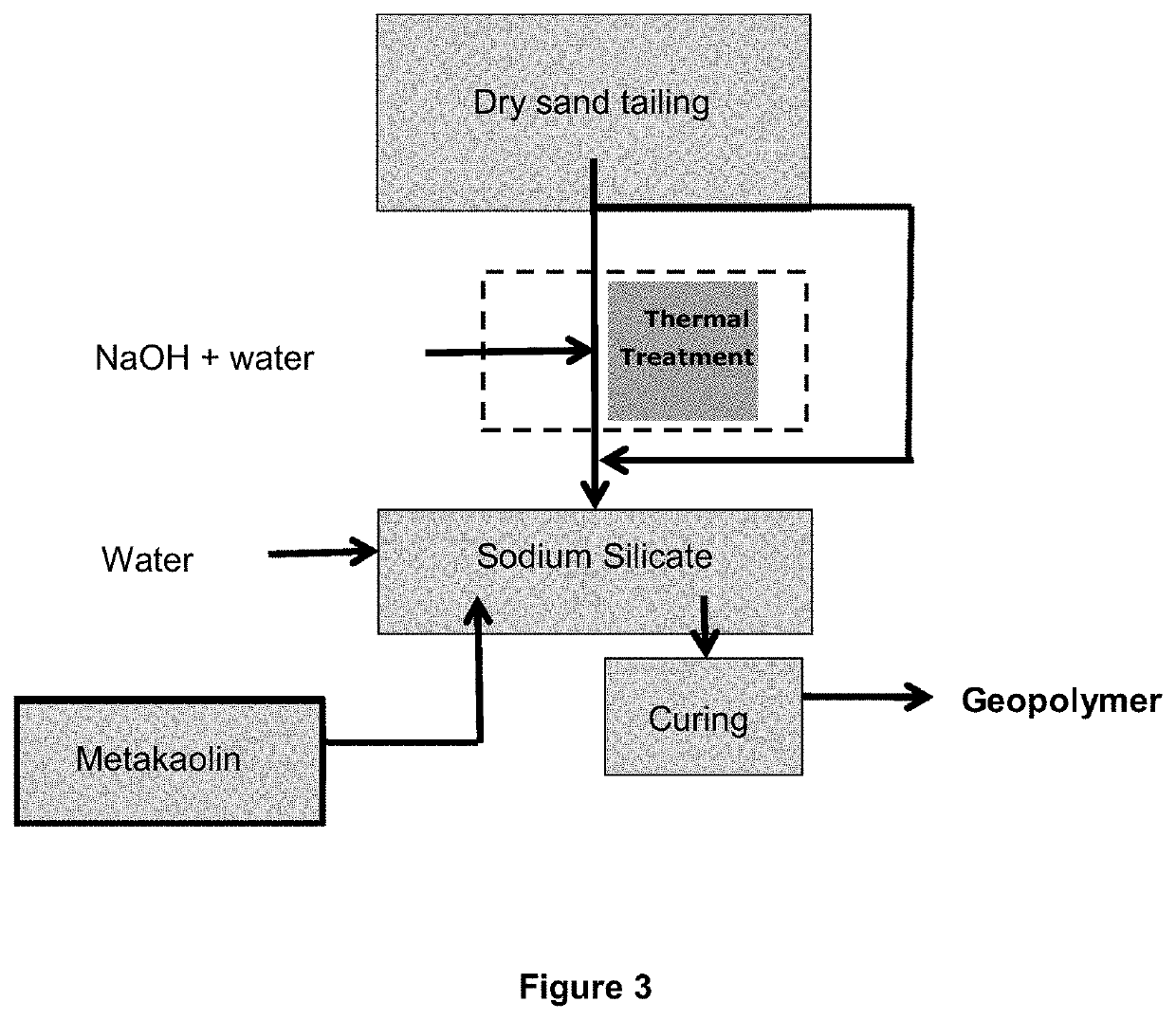

Process of obtaining powdered sodium silicate from sand tailings originated from the iron ore concentration process

PendingUS20220250923A1Avoid absorptionReduce tailingsTransportation and packagingAlkali metal silicatesMining engineeringGeopolymer

A process of obtaining powdered sodium silicate from sand tailings generated from iron ore processing addresses the production of raw materials used in the manufacturing of geopolymers to be employed mainly by the construction industry and in road paving. The utilization of this tailing reduces environmental impact generated by the disposal in large dams, as well as enabling addition of value to a tailing by obtaining a commercially applicable product.

Owner:VALE LIMITED

High-yield and low-cost subsequent filling mining method for underground mine

ActiveCN102704934BSolve the contradiction of low mining production capacitySimple processUnderground miningSurface miningMining engineeringMechanical engineering

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

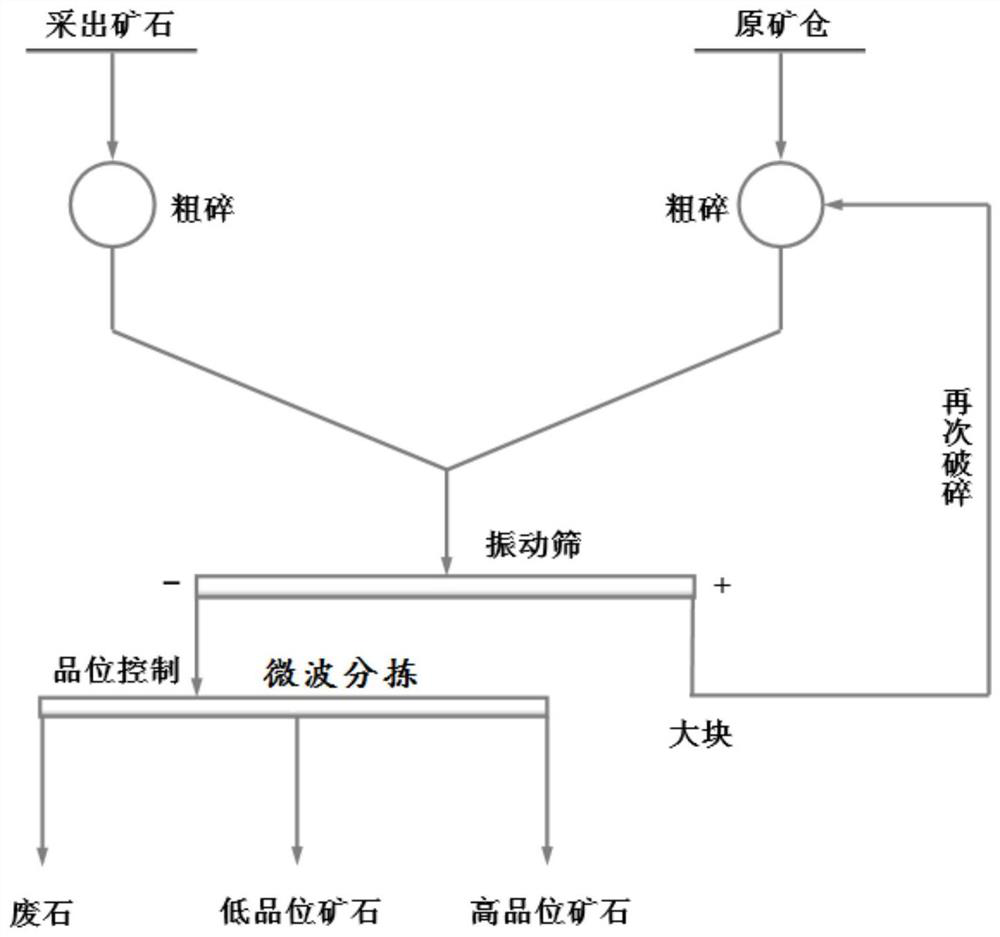

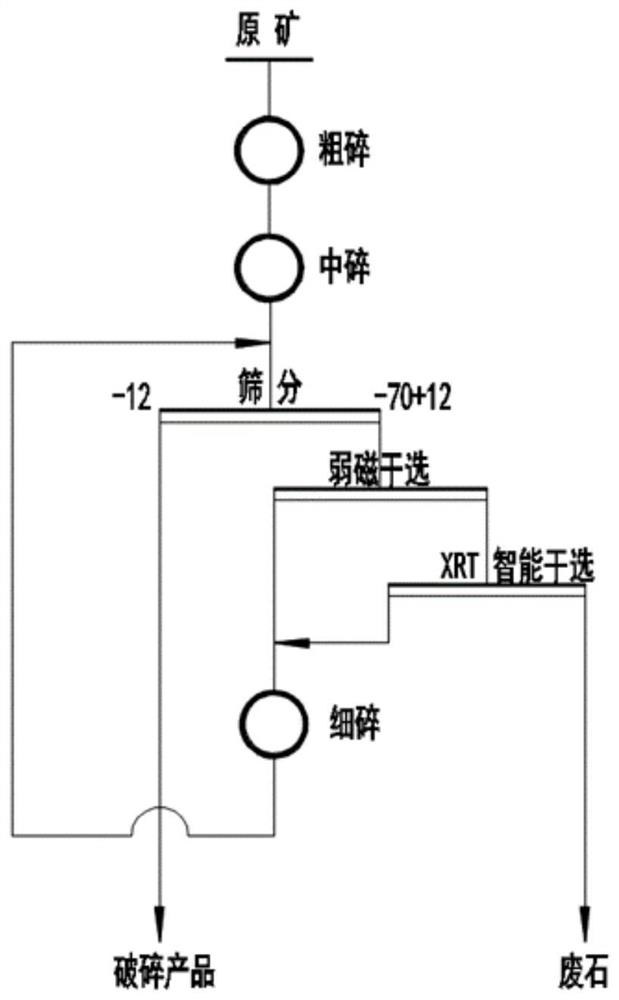

Beneficiation process of high-sulfur composite iron ore and pre-selection production system thereof

The invention discloses a beneficiation process of high-sulfur composite iron ore and a pre-selection production system thereof, and relates to the technical field of iron ore beneficiation. According to the beneficiation process of the high-sulfur composite iron ore and the pre-selection production system thereof, a weak magnetic dry separation process and an XRT intelligent dry separation combined separation process are adopted according to different physicochemical properties of different iron ore in the iron ore, the weak magnetic dry separation process is firstly adopted, magnetite is recycled from raw ore, and hematite weak magnetic minerals enter tailings; and then intelligent dry separation is conducted on the tailings through the XRT intelligent dry separation, sulfur-containing iron ore and the like obtained through dry separation of an XRT intelligent dry separation machine and weak magnetic concentrate of a weak magnetic dry separation machine are combined and enter a fine crushing buffer ore bin, ore in the fine crushing buffer ore bin is fed into a fine crushing cone crusher through a rubber belt feeder, and fine crushing products and intermediate crushing products are combined and fed into a screening buffer ore bin, so that the particle size of crushed products is ensured to be-12 mm, all crushed-70+12mm products are effectively pre-selected, gangue minerals are removed, and the ore grinding and sorting cost is reduced.

Owner:马钢集团设计研究院有限责任公司

Feeding device of battery aluminum sheet

InactiveCN109013939ACorrect deviations in the delivery processImprove utilizationMetal-working feeding devicesPositioning devicesMechanical engineeringEngineering

The invention discloses a feeding device of a battery aluminum sheet. The feeding device comprises a base, a movable sliding block and a static sliding block, wherein the movable sliding block is in sliding connection with the base; a feeding hole, a discharging hole and a mounting groove body are formed in the mounting groove, and a spring, a movable clamp head and two round rods are arranged inthe mounting groove; the movable clamp head is matched with a trapezoid-shaped groove in shape, a feeding through hole and two clamping grooves are formed in the movable clamp head, and the movable sliding block and the static sliding block are the same in structure; an aluminum belt penetrates into the feeding hole of the static sliding block, and penetrates out from the discharging hole in the movable sliding block, a groove is formed between the movable sliding block and the static sliding block, and allows a push rod to be inserted to push the movable sliding block to move; and when a movable template moves upwards, the movable sliding block returns to an initial state under the action of a reset spring. The two round rods clamp the aluminum belt to move together with the movable sliding block, and the length of the movement of the aluminum belt is the width of the push rod; when the movable sliding block is restored to the initial position, the movable sliding block moves relativeto the aluminum belt because the base is arranged close to a stamping die, the deviation of the aluminum belt in a transmission process can be corrected, tail material is less, and the utilization ofthe material is improved.

Owner:许建

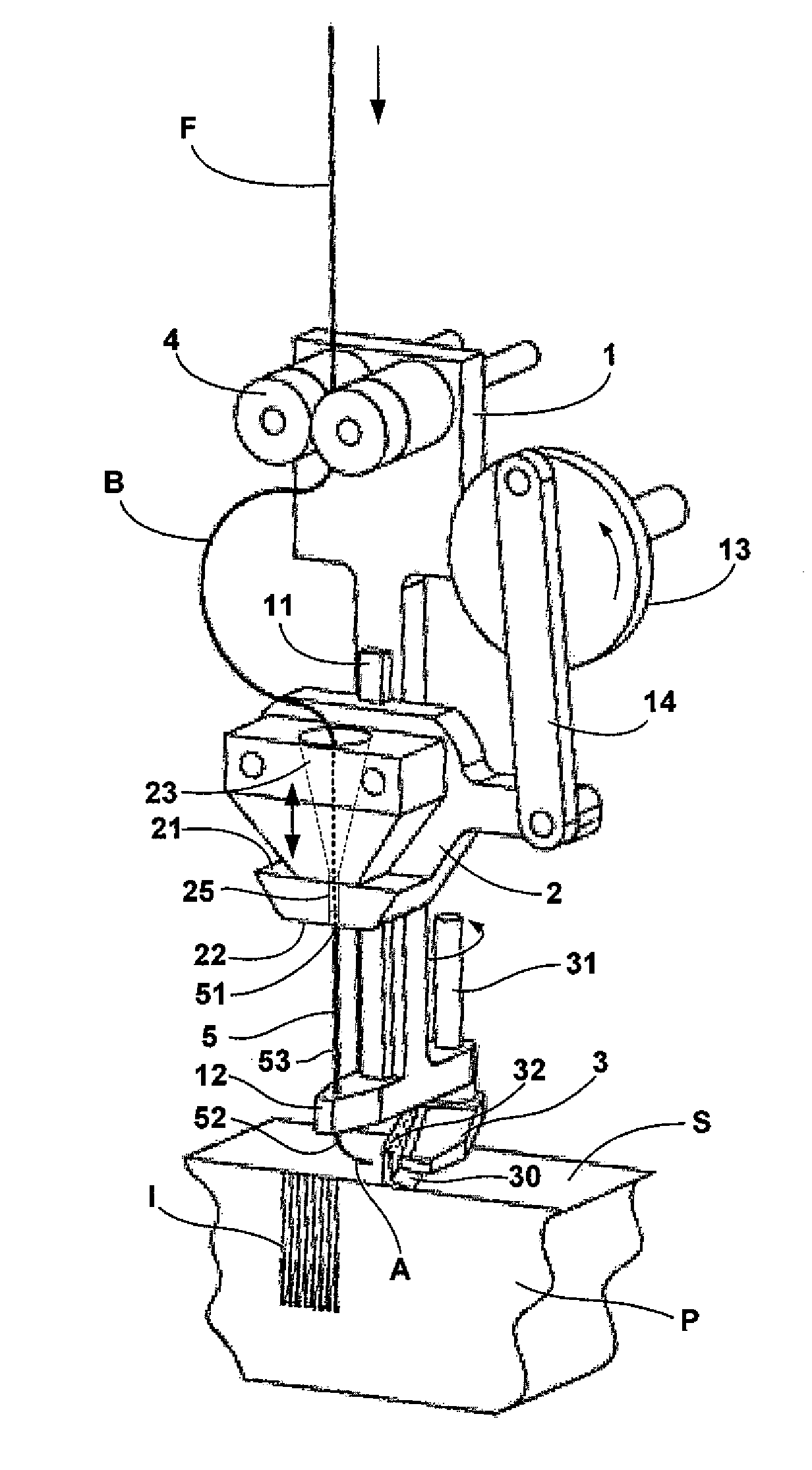

Device and method for embedding threads in a rubber profiled element

ActiveUS8986477B2Shorten tailLengthen tailLamination ancillary operationsBristleKnife bladesReciprocating motion

Device for embedding a thread in a rubber profiled element comprising: a continuous thread feeder arranged on a structure, a moving support able to run along the structure between a raised and a lowered position. A hollow needle, comprising a canal in which the thread runs is fixed by one of its ends to the base of the moving support in the duct, and a tip at its other end capable of penetrating the rubber profiled element, a cutter arranged on the structure, comprising a rotary blade able to cut off the thread at a given distance from the tip of the needle upon each cycle of reciprocating movement of the needle. The cutter comprises a paddle arranged behind the cutting wire of the blade and intended to fold the tail around the tip of the needle just after the thread has been cut by the blade.

Owner:MICHELIN RECH & TECH SA +1

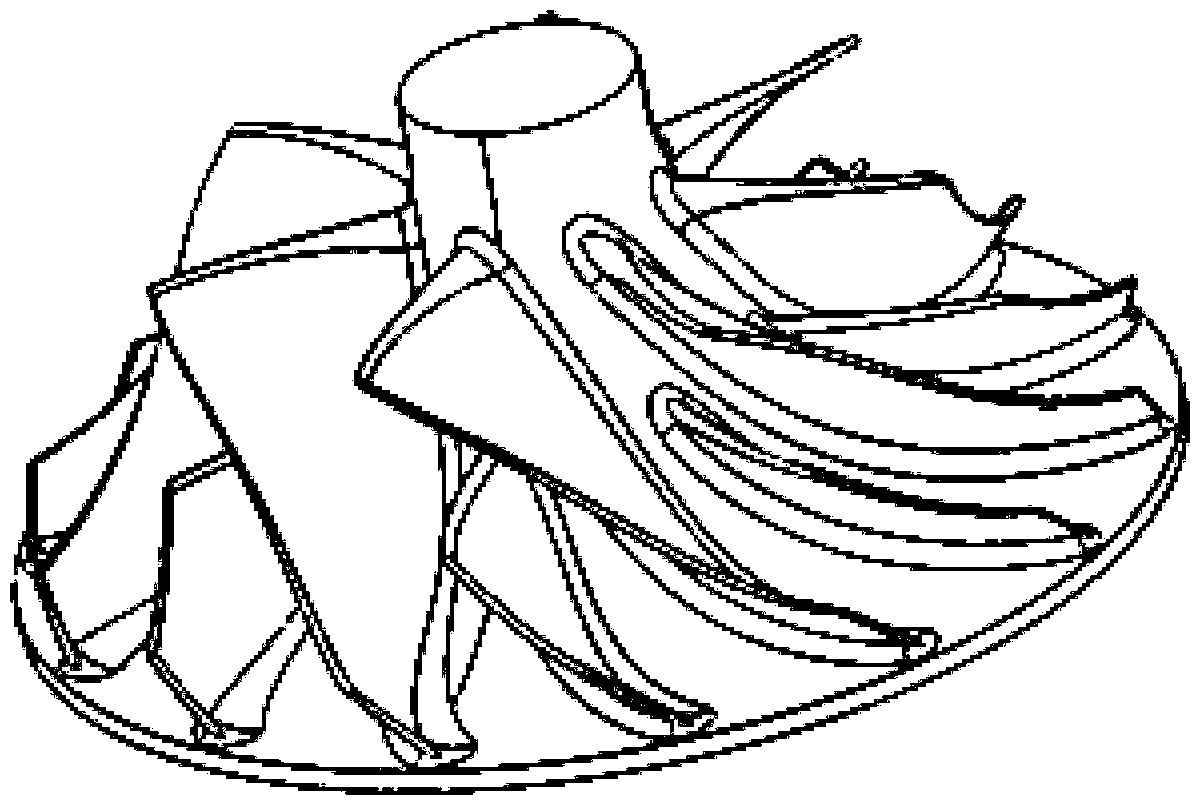

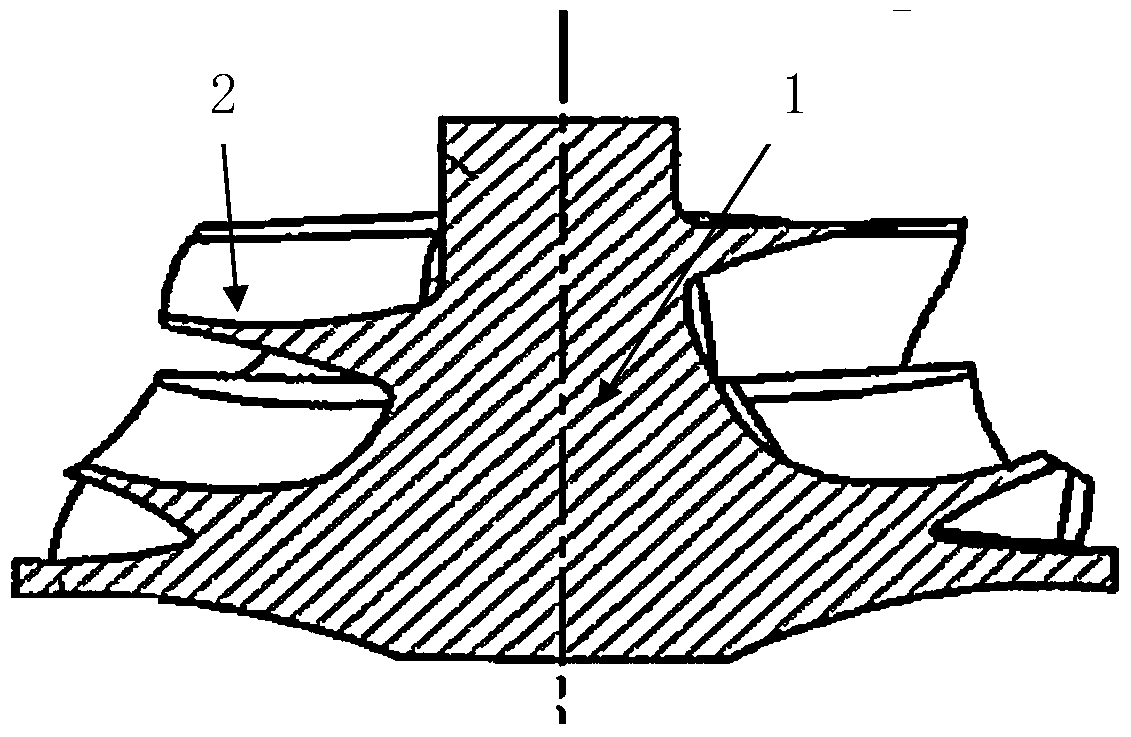

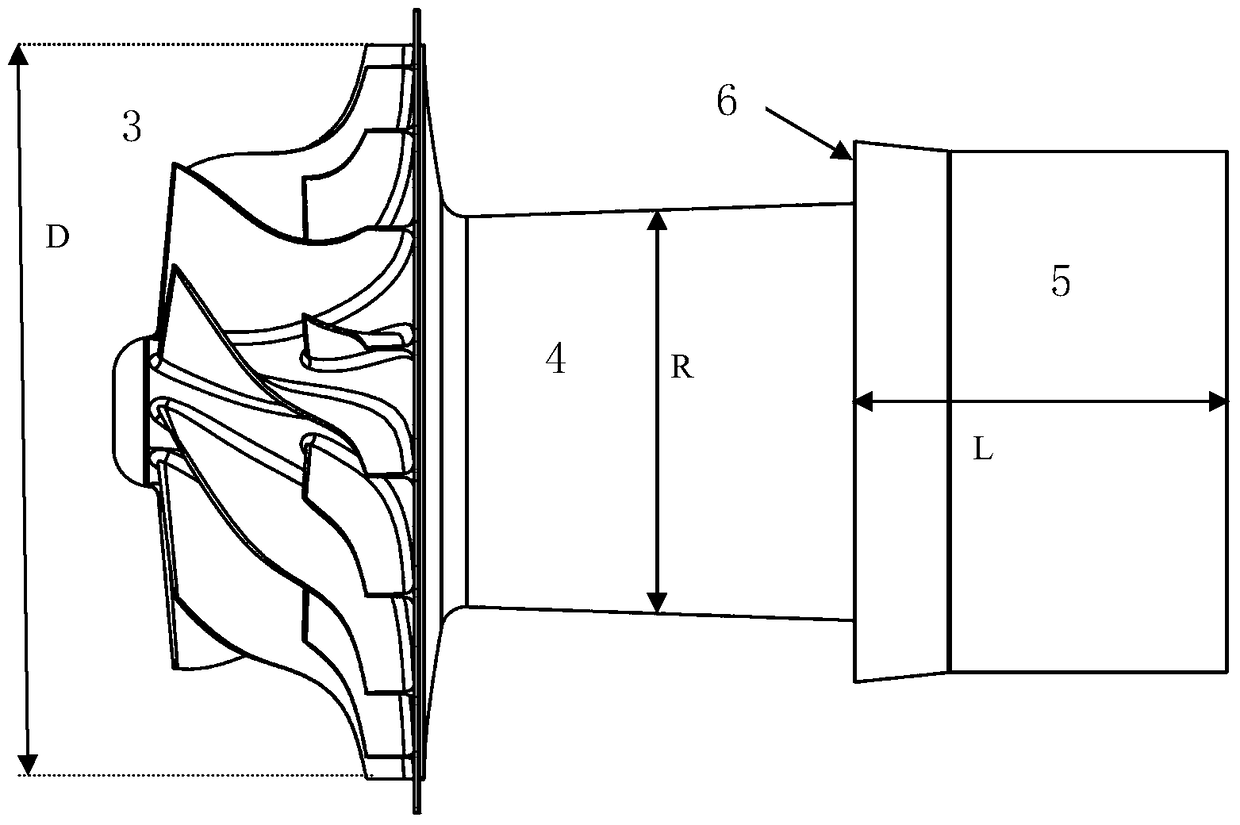

A semi-solid die-casting method for impeller of turbocharger

Owner:GRIMAT ENG INST CO LTD

A new type of winding and cutting knife device

The invention discloses a novel winding cutting knife device. The novel winding cutting knife device comprises a machine frame, a flat pushing pressing roller device, and a cutting knife assembly, wherein moving plates are arranged on two sides of the machine frame; the flat pushing pressing roller device and the cutting knife assembly are arranged on the moving plates; the cutting knife assembly comprises two groups of cutting knife mechanisms which are oppositely arranged above the flat pushing pressing roller device and under the flat pushing pressing roller device; each of the cutting knife mechanism comprises a cutting knife and cutting knife bases positioned at two ends of the cutting knife; a pushing mechanism is arranged on the cutting knife bases; two groups of guiding plates corresponding with the cutting knife mechanisms are arranged on the machine frame, and are oppositely arranged. When a printing material needs to be cut, the moving plates are moved forward; the guiding plates guide the cutting knife bases and the cutting knives to rotate around a rotating shaft; the cutting knives of the two groups of the cutting knife mechanisms relatively rotate in a closing manner; the flat pushing pressing roller device is in contact with an air bulking shaft; the two groups of the cutting knives are relatively oblique and close to the printing material, and then the two groups of the cutting knifes are pushed to move forward and fit cut, so that the printing material can be cut off. According to the novel cutting knife device disclosed by the invention, the swinging range of each of the cutting knifes is small, tail materials are shortened, the waste is reduced, besides, the cutting knifes stably move, the positioning accuracy is high, the tensile force fluctuation of a film is small, and the printing material is not liable to wrinkle.

Owner:ZHONGSHAN SOTECH PRINTING MACHINERY CO LTD

Oil cylinder pressing guide reinforcing structure

PendingCN111941119AReduced clamping distanceReduce tailingsPositioning apparatusMetal-working holdersStructural engineeringReciprocating motion

The invention discloses an oil cylinder pressing guide reinforcing structure. The oil cylinder pressing guide reinforcing structure comprises a clamping oil cylinder and a guide mechanism arranged onthe clamping oil cylinder, wherein the guide mechanism comprises a guide sleeve, a guide bar and a guide key; the guide sleeve is connected to a piston rod of the clamping oil cylinder in a sleeved mode; the bottom end of the guide sleeve is connected to the clamping oil cylinder; a through hole is arranged in the guide sleeve; the guide bar is inserted into the guide sleeve and connected to the piston rod; a chute is arranged in the guide bar; a pressing block is arranged at the top end of the guide bar; the guide key is arranged in the through hole and fixedly connected to the guide sleeve;and one end of the guide key penetrates through the through hole, extends into the guide sleeve and abuts against the chute in order to drive the guide bar and the pressing block to do linear reciprocating motion in the guide sleeve through the piston rod under the limit of the guide key. The oil cylinder pressing guide reinforcing structure is easy to operate, small in horizontal area and capableof effectively increasing the clamping rigidity, improving the machining precision, shortening the clamping distance, reducing tailings and improving the production benefit.

Owner:江苏宁兴恒力智能设备有限公司

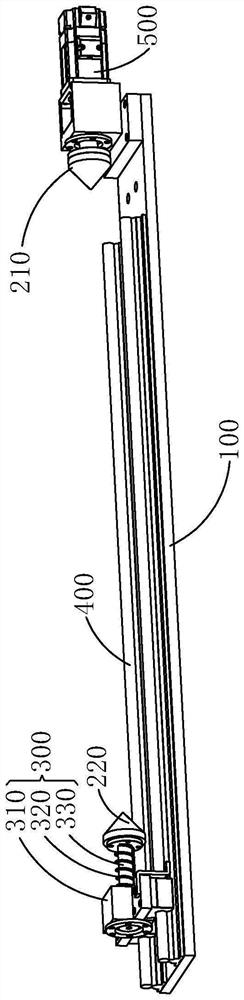

Pipe clamping device and pipe cutting machine

PendingCN113909707AReduce wasteSmooth rotationMetal working apparatusLaser beam welding apparatusEngineeringStructural engineering

The invention discloses a pipe clamping device and a pipe cutting machine. The pipe clamping device comprises a base frame, a first clamping structure, a second clamping structure, a telescopic mechanism and a supporting and fixing mechanism, and a long-strip pipe to be machined is placed between the first clamping structure and the second clamping structure; the first clamping structure and the second clamping structure can abut against the inner side edges of the two ends of the pipe correspondingly, so that the pipe is clamped and fixed, the telescopic mechanism drives the supporting and fixing mechanism to move and stretch into the pipe, and the supporting and fixing mechanism abuts against the inner wall of the pipe so that supporting and bearing can be provided for the middle position of the pipe; therefore, shaking of the pipe is reduced, more stable clamping of the whole to-be-machined pipe is achieved, the cutting machining precision is guaranteed, the first clamping structure, the second clamping structure and the supporting and fixing mechanism all act on the inner side of the pipe, the pipe clamping and supporting occupy few pipe positions, the appearance of the pipe can be prevented from being damaged, tailings can be reduced, and the cost is saved.

Owner:大展智能装备(广东)有限责任公司

Full tailing filling method in large goafs

InactiveCN101892862BEliminate potential safety hazardsGuarantee normal productionMaterial fill-upDrainageLand acquisitionAdit

The invention discloses a full tailing filling method in large goafs, which is realized by the technical scheme with the following steps: dividing the combination of relatively independent and adjacent single or a plurality of goafs (6) into a filling unit; building a sealed wall (8) on a tunnel (7) at the periphery of the goafs (6) of the filling unit, arranging a drain pipe (9) in the wall bodyof the sealed wall (8), and arranging an ore pulp valve (10) on the drain pipe (9); laying a tailing conveying main pipe (3) above the filling unit through an adit (2) above the goafs (6); connectingeach upper opening of the filling unit to one or a plurality of hydraulic sand filling pipes (4) through the tailing conveying main pipe (3); and discharging sand at high levels, discharging water indifferent middle sections, and filling alternately. In the invention, full tailings are used for filling the existing goafs, thereby eliminating the potential safety hazards of the goafs, ensuring the normal production of large deep well mines, saving the treatment cost, the tailing stockpiling and land acquisition cost and the drainage cost of the goafs, realizing the purpose of less-waste and no-waste exploitation, and taking an demonstration effect on constructing ecological mines.

Owner:HUAWEI METAL MINERAL RESOURCE EFFICIENT RECYCLING UTILIZATION NAT ENG RES CENT CO LTD

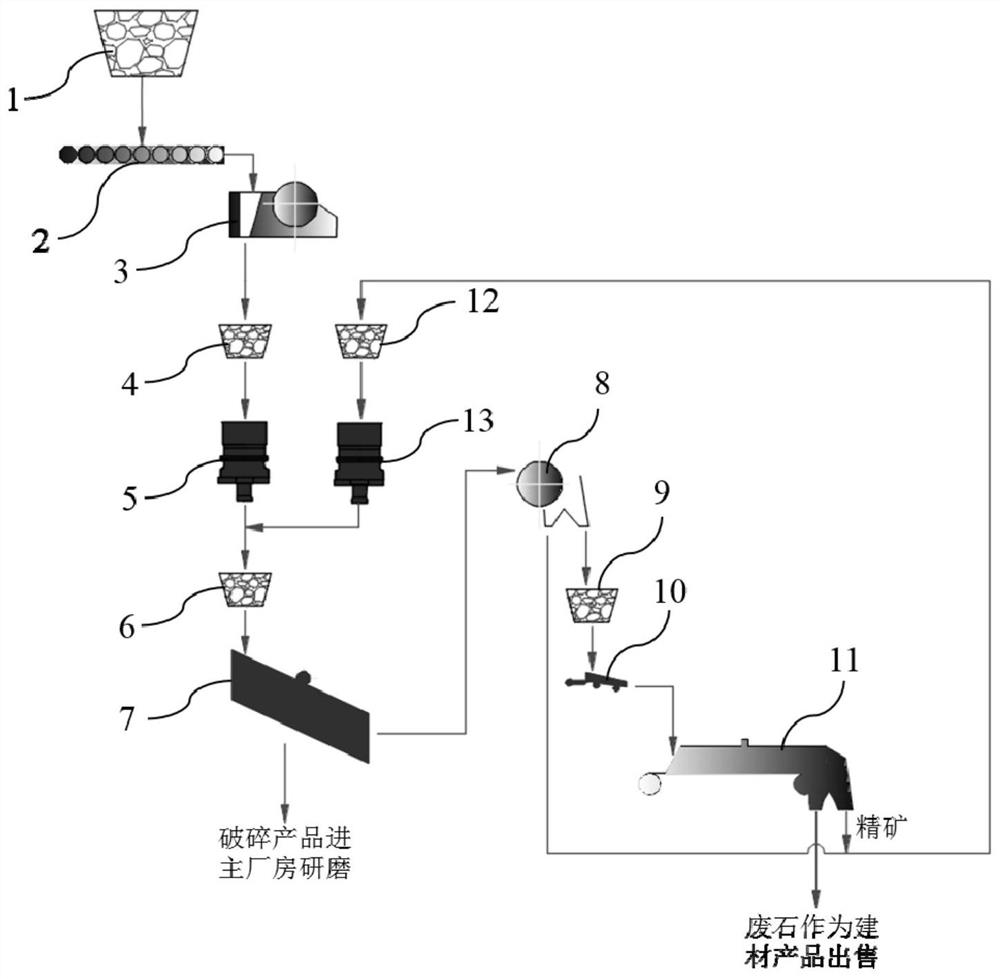

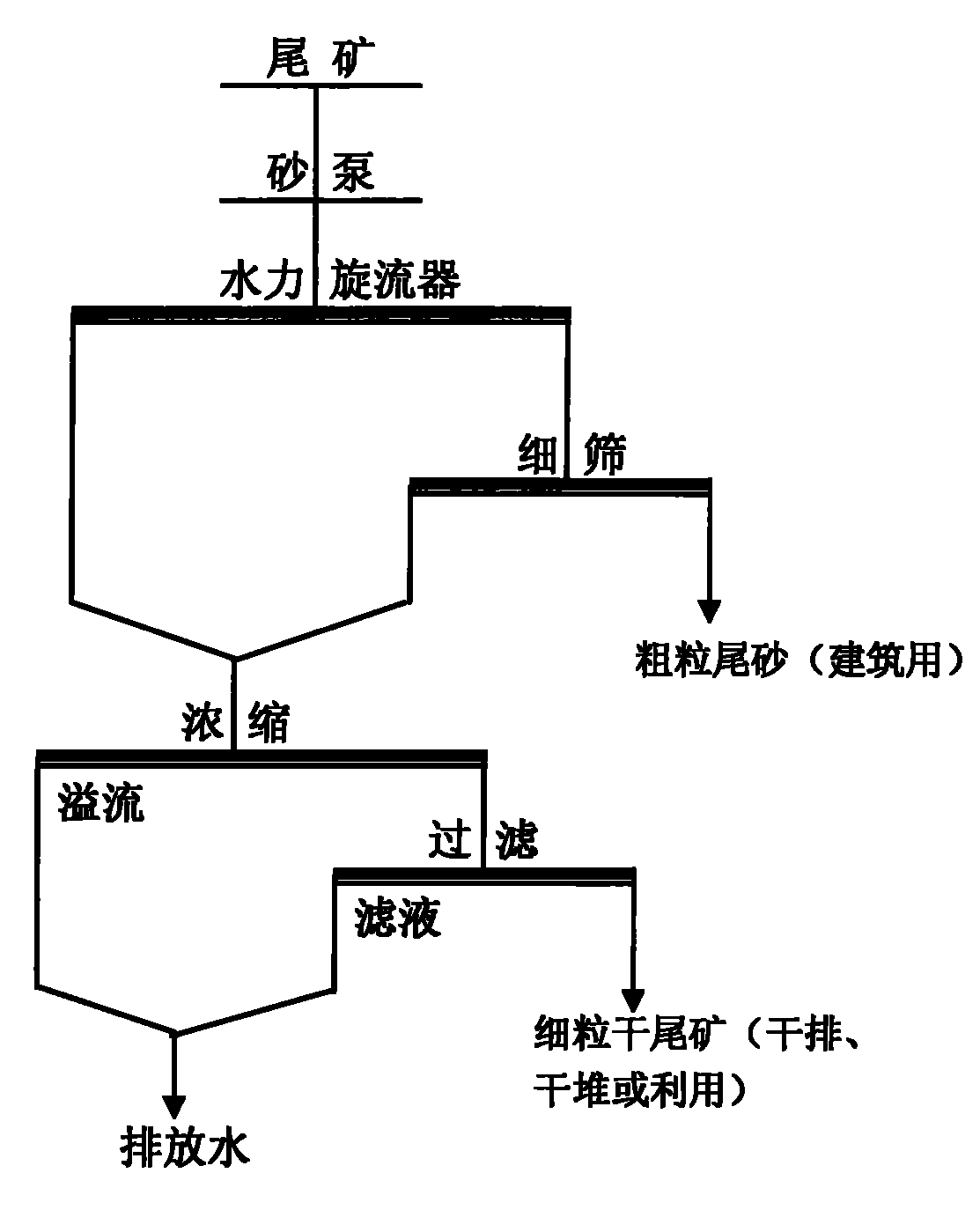

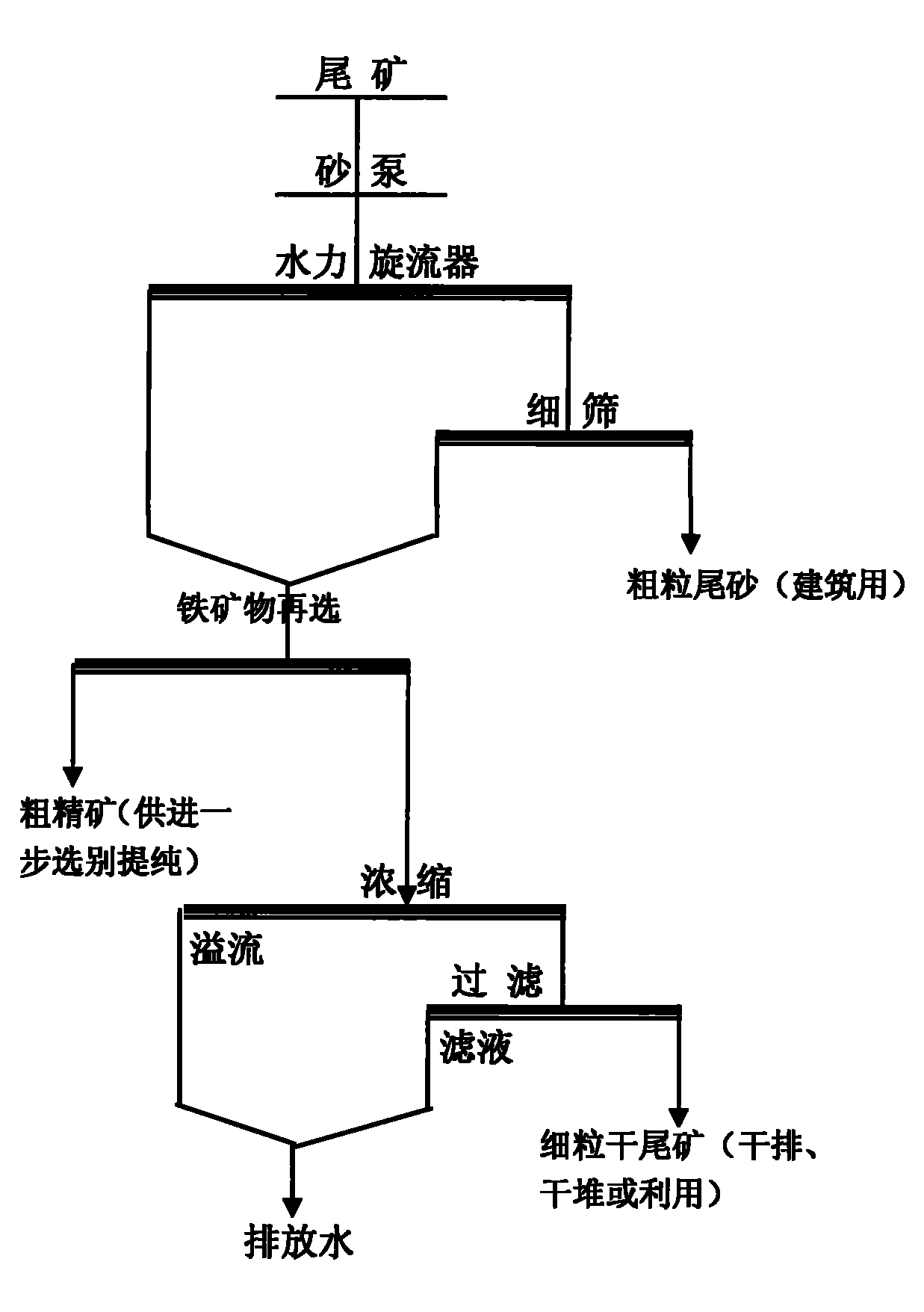

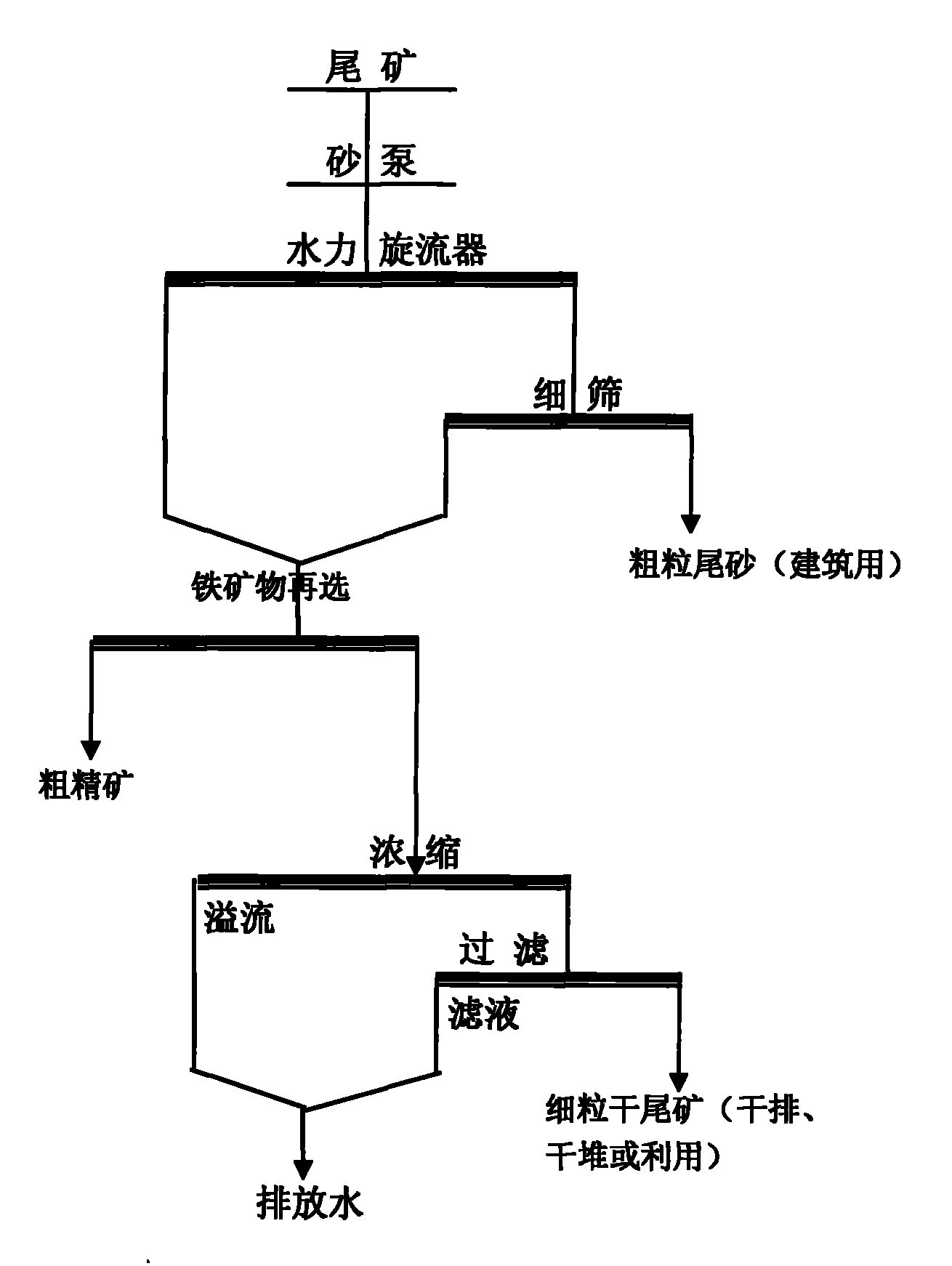

Overall utilization and treating process of iron ore mine

InactiveCN101513625BRealize the comprehensive utilization of a large amountReduce tailingsSievingVortex flow apparatusYardMaterials science

The invention discloses an overall utilization and treating process of iron ore mine, which comprises the following steps: (1) according to a grading process, separating coarse grain ore mine from the iron ore mine, in which SiO2 is not less than 40%, wherein, the content of 0.16mm grade in the coarse grain ore mine is not more than 10%; (2) according to a magnetic separation method, recovering the iron mine from the fine grain ore mine separated by the grading process, thus obtaining a rough concentrate and a fine new ore mine; (3) performing the dehydration onto the fine grain ore mine or the fine new ore mine via a densifier and a filter to obtain a fine dry ore mine, wherein, the water content is not more than 20%; (4) discharging the fine dry ore mine to a dry ore mine storage yard or using the fine dry ore mine as industrial raw material. The invention has advantages that: valuable component can be overall recovered, the ore mine can be greatly utilized, meanwhile, zero ore discharge in the ore mine base can be achieved. Accordingly, the invention is widely used for overall utilization and safety treatment of magnetic iron ore and hematite ore mine.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com