Gradient utilization method of high-sulfur low-silicon iron tailings

A technology for iron tailings and ferrosilicon is applied in the field of cascade resource utilization of high-sulfur and low-silicon ferrosilicon tailings to achieve the effects of reducing costs and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

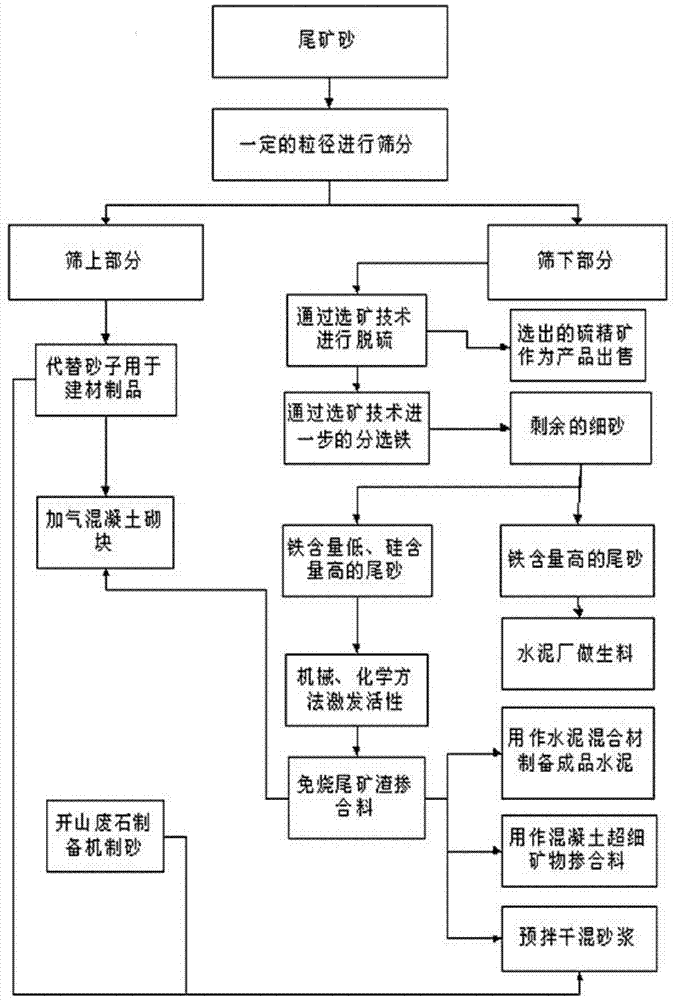

Image

Examples

Embodiment Construction

[0023] Below in conjunction with example the present invention will be further described.

[0024] This embodiment takes Nanshan Mine in Ma'anshan City, Anhui Province as an example. Nanshan Mine in Ma'anshan City, Anhui Province is the largest iron ore base in East China, located in Xiangshan Town, Ma'anshan City. In 2010, the iron ore resources in the mining area were 788 million tons, but the grade of iron ore was very low. The mining of low-grade iron ore will produce a large amount of iron tailings, which is estimated to be more than 500 million tons. More than 100 million tons of iron tailings, Nanshan Mine will have the problem of a large number of tailings without land.

[0025] Aiming at the problem of stockpiling iron tailings in Nanshan Mine, the present invention provides a cascade utilization method, which is carried out according to the following steps.

[0026] 1. The composition and radioactivity detection of Nanshan iron tailings. The main components of Nansh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com