Beneficiation process of high-sulfur composite iron ore and pre-selection production system thereof

A production system, iron ore technology, applied in the beneficiation process of high-sulfur composite iron ore and its pre-selection production system, can solve the problem of cost reduction and efficiency increase, reduction of iron element, sulfur element and copper element recovery rate, and impact on sales Price and other issues, to achieve the effect of low investment and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

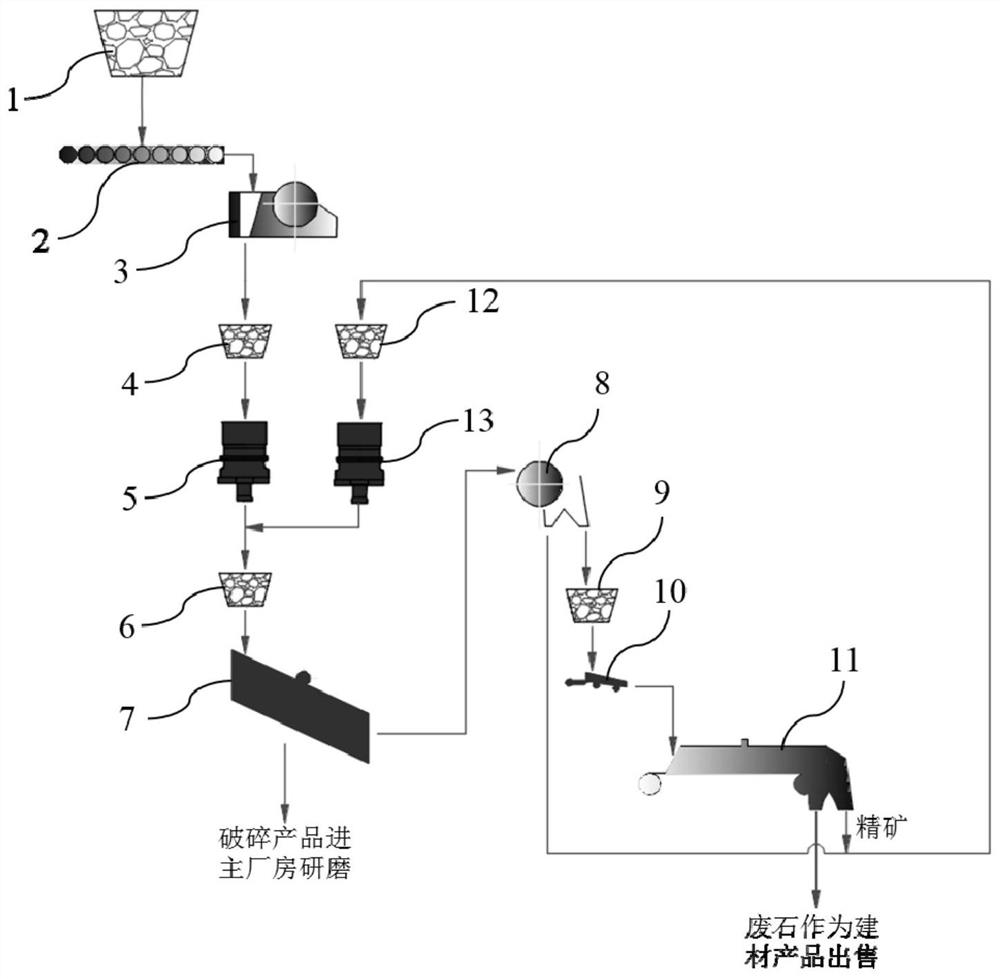

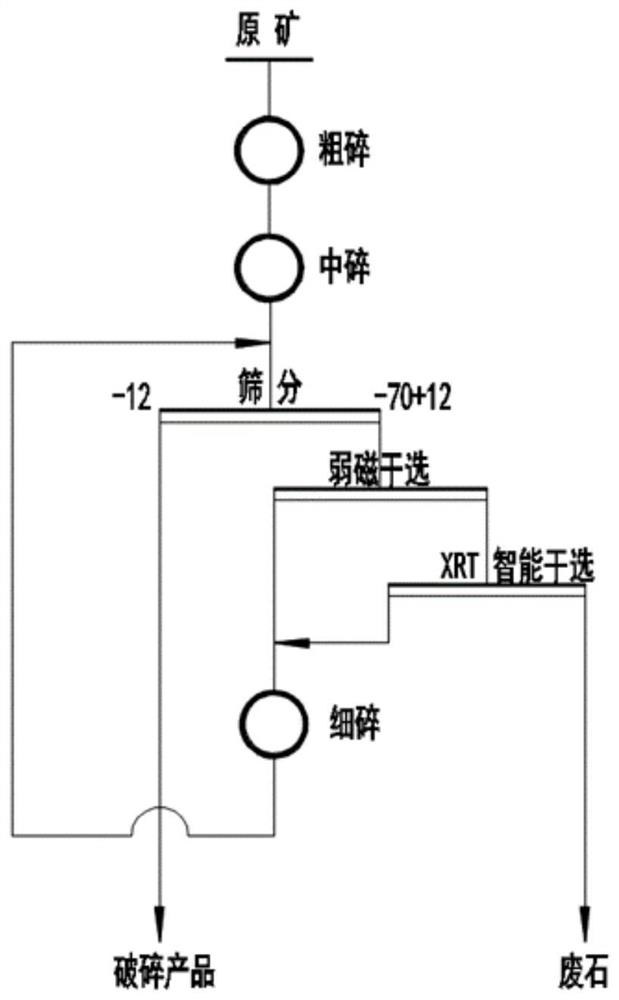

[0038] A kind of beneficiation process of high-sulfur composite iron ore of the present embodiment, such as figure 2 shown, including the following steps:

[0039] Step 1. Crushing: two-stage open-circuit crushing is used to crush the raw ore to -70mm, the first-stage crushing adopts the jaw crusher 3 for primary crushing, and the second-stage crushing selects the secondary crushing cone crusher 5 for secondary crushing;

[0040] Step 2. Screening: The products under the screen enter the grinding operation of the main plant as the final product of crushing, and the products on the screen enter the weak magnetic dry separation operation;

[0041] Step 3, weak magnetic dry separation: carry out weak magnetic dry separation on the screened product of the vibrating screen 7, the weak magnetic dry separation tailings enter the XRT intelligent dry separation operation, and the weak magnetic dry separation concentrate enters the fine crushing operation;

[0042] Step 4, XRT intelli...

Embodiment 2

[0047] A kind of beneficiation process of high-sulfur composite iron ore of the present embodiment, basic structure is the same as embodiment 1, difference and improvement are: comprise the following steps:

[0048] Step 1. Two-stage open-circuit crushing: the raw ore is ore mined underground, and its maximum ore particle size is 750mm. Two-stage open-circuit crushing is used to crush the raw ore to -70mm. One-stage crushing uses CJ612 jaw crusher, and the ore discharge particle size is 300mm; The second stage adopts CH870 cone crusher, and its ore discharge particle size is -70mm.

[0049] Step 2. Screening: The sieve hole size of the vibrating screen is 12mm, and the product under the screen -12mm enters the grinding operation as a finely crushed product; the product on the screen -70+12mm is dry-selected with a weak magnetic magnetic roller, and the magnetic induction intensity on the surface of the magnetic roller tape It is 0.3T, the yield of tailings in weak magnetic dry...

Embodiment 3

[0053] A kind of beneficiation process of high-sulfur composite iron ore of the present embodiment, basic structure is the same as embodiment 2, difference and improvement are: comprise the following steps:

[0054] Step 1. Two-stage open-circuit crushing: the raw ore is ore mined underground, and its maximum ore particle size is 750mm. Two-stage open-circuit crushing is used to crush the raw ore to -70mm. One-stage crushing uses CJ612 jaw crusher, and the ore discharge particle size is 300mm; The second stage adopts CH870 cone crusher, and its ore discharge particle size is -70mm.

[0055] Step 2. Screening: The sieve hole size of the vibrating screen is 12mm, and the product under the screen -12mm enters the grinding operation as a finely crushed product; the product on the screen -70+12mm is dry-selected with a weak magnetic magnetic roller, and the magnetic induction intensity on the surface of the magnetic roller tape It is 0.3T, the yield of tailings in weak magnetic dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com