Method for preparing bio-carrier by porous foam polymer modification

A porous foam, polymer technology, applied in the direction of fixing on/in organic carriers, separation methods, sustainable biological treatment, etc., to achieve the effect of high proportion of components and lower modification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

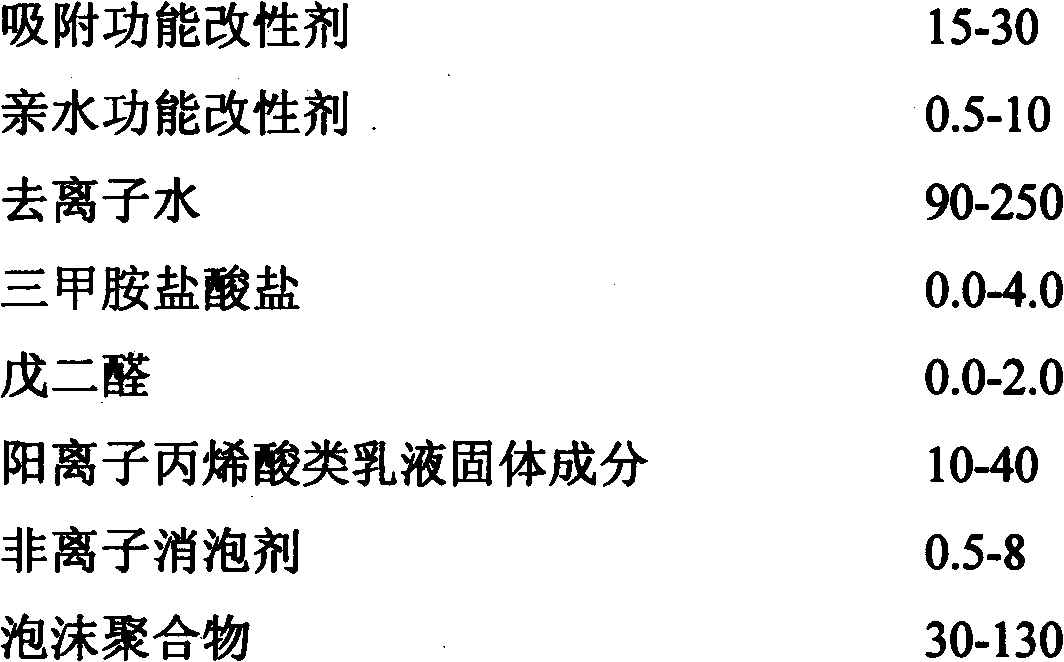

Method used

Image

Examples

Embodiment 1

[0047] Weigh 18 g of 300-mesh powdered activated carbon and 4 g of 300-mesh hydroxyapatite and mix them for use. Measure 180 ml of deionized water, add 0.2 g of trimethylamine hydrochloride, stir rapidly for 10 minutes, and completely dissolve trimethylamine hydrochloride in deionized water. Then deionized water containing trimethylamine hydrochloride was poured into activated carbon and hydroxyapatite, and stirred rapidly to mix. Then add 0.2 ml of alkylaryl polyether alcohol wetting and dispersing agent, and stir for 60 minutes. After the modifier is fully wetted, add 50ml of cationic acrylic emulsion with a solid content of 40%, 0.2ml of silicone defoamer, stir rapidly for 20 minutes to fully mix various components, and complete the preparation of the modified coating solution.

[0048] A commercially available common polyether polyurethane foam (pore size 10PPI, density 26kg / m3) was cut into small pieces of 40*40*20mm as the modified coated foam polymer. The method of so...

Embodiment 2

[0051] Weigh 25 g of 300 mesh powdered activated carbon to prepare 20 ml of 10% PVA117 aqueous solution. Measure 180 ml of deionized water, add 0.18 g of trimethylamine hydrochloride, stir rapidly for 10 minutes, and completely dissolve trimethylamine hydrochloride in deionized water. Then pour the deionized water containing trimethylamine hydrochloride into the activated carbon, then add the dissolved PVA117, stir and mix quickly. Then add 0.2 ml of alkylaryl polyether alcohol wetting and dispersing agent, and stir for 60 minutes. After the modifier is fully wetted, add 65ml of cationic fluoropropylene emulsion with a solid content of 40%, 0.2ml of silicone defoamer and 2ml of cross-linking agent glutaraldehyde, stir rapidly for 20 minutes to fully mix the various ingredients, The preparation of the modified coating solution is completed.

[0052] A commercially available common polyether polyurethane foam (pore diameter 20PPI, density 30kg / m3) was cut into small pieces of ...

Embodiment 3

[0055] Weigh 22g of nano-scale attapulgite powder, 5g of 200 mesh chitosan (chitin), mix well and set aside. Measure 180 ml of deionized water, add 0.18 g of trimethylamine hydrochloride, stir rapidly for 10 minutes, and completely dissolve trimethylamine hydrochloride in deionized water. Then pour deionized water containing trimethylamine hydrochloride into the nano-attapulgite powder and chitosan powder, and stir rapidly for 10 minutes. Then add 0.2 ml of alkylaryl polyether alcohol wetting and dispersing agent, and stir for 90 minutes. After the modifier is fully wetted, add 60ml of cationic styrene-acrylic emulsion with a solid content of 40%, 0.2ml of silicone defoamer, stir rapidly for 20 minutes to fully mix various ingredients, and complete the preparation of the modified coating solution .

[0056] A commercially available common polyether polyurethane foam (pore size 8PPI, density 23kg / m3) was cut into small pieces of 40*40*40mm as the modified coated foam polymer....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com