Back chuck with dedusting function

A chuck and functional technology, which is applied in the field of rear chucks with dust removal function, can solve the problems of environmental dust pollution, inability to remove dust and residual tailings of clamping tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following is based on the ideal embodiment of the present invention as an inspiration. Through the following description, relevant workers can make various changes and modifications within the scope of not departing from the technical idea of the present invention. The technical scope of the present invention is not limited to the content in the specification, but must be determined according to the scope of the claims.

[0050] With reference to the following drawings, the present invention is further described:

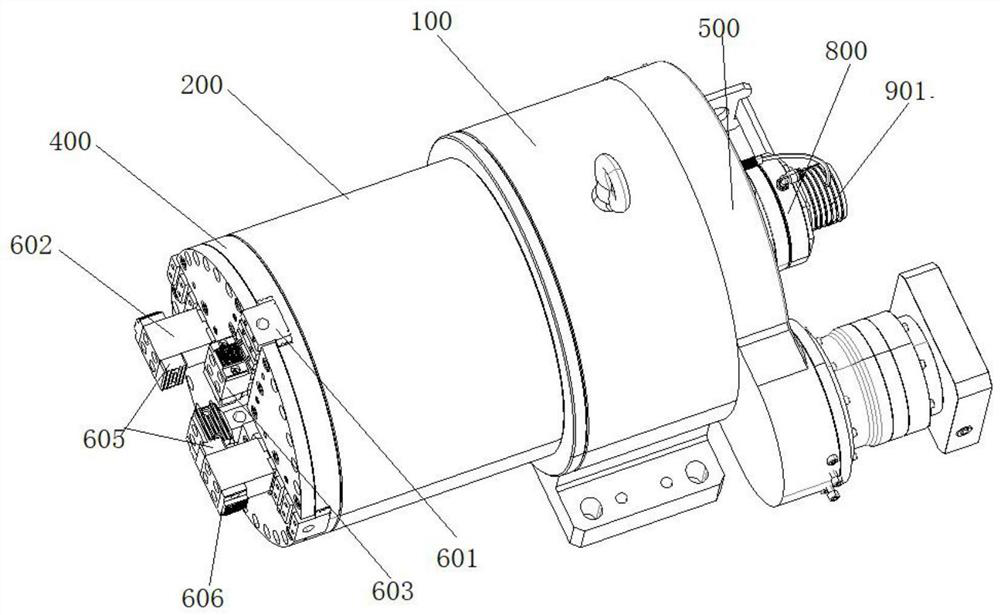

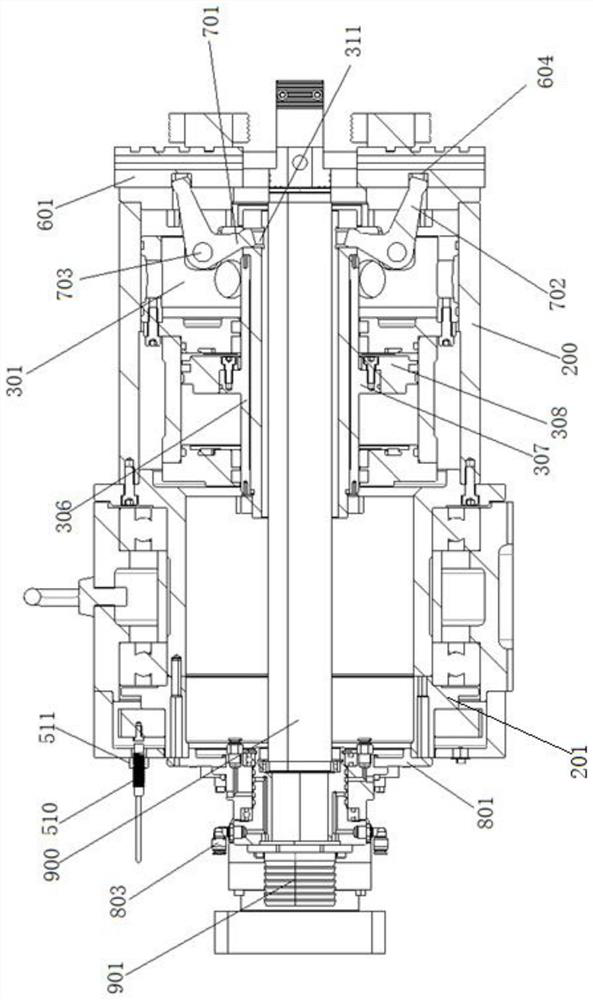

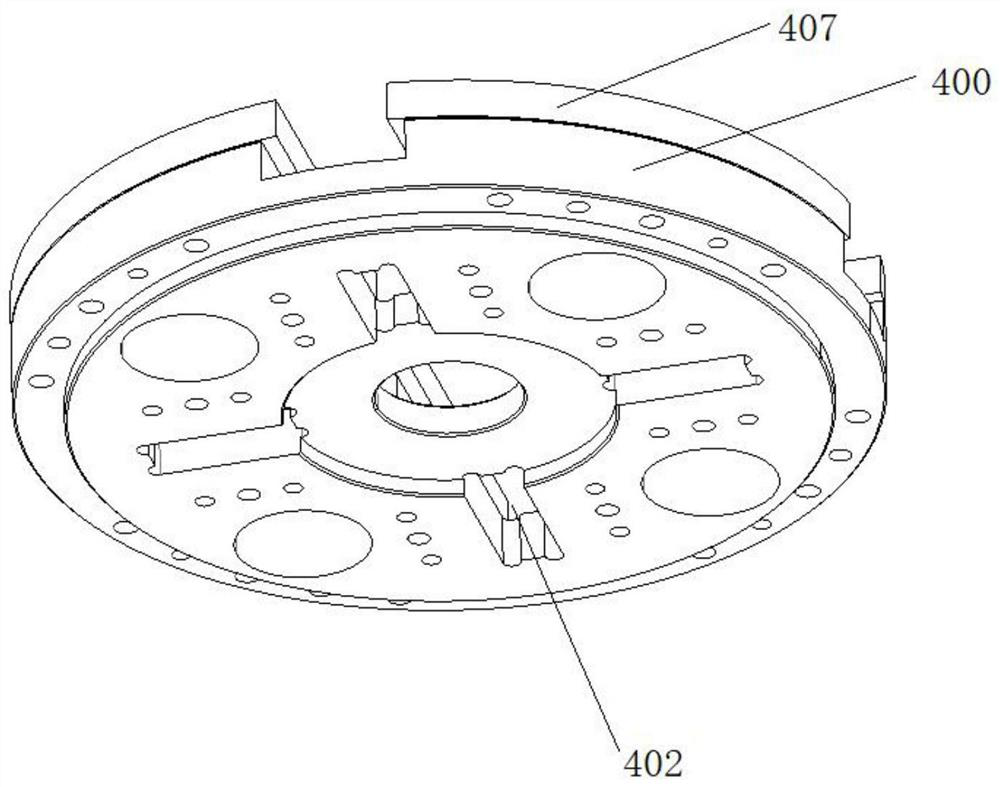

[0051] A rear chuck with a dust removal function has a bearing housing 100, including:

[0052]The front bearing 110 and the rear bearing 120 respectively arranged in the bearing seat 100 are fixedly connected by the spacer 130 between the front bearing 110 and the rear bearing 120 . The guide block cover 200 connected to the front end of the front bearing 110 is fixed by screws, and the guide block cover 200 is provided with a cylinder assembly 300 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com