Method for backfilling land collapse pit of mine subjected to caving mining by utilizing tailings

A technology of surface subsidence and caving method, which is applied in the field of mining tailings utilization, to achieve significant direct economic benefits, save treatment costs, and eliminate geological disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

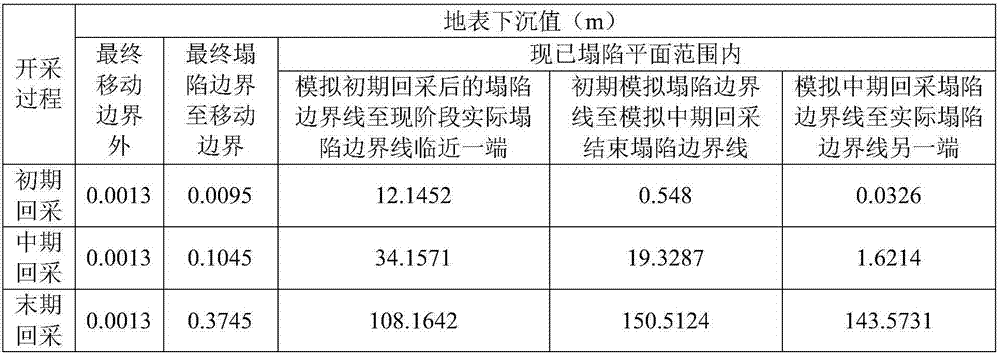

[0046] A method for backfilling a subsidence pit on the surface of tailings in a caving mine, the method comprising:

[0047] (1) Preparation of tailings backfill in subsidence pit

[0048] According to the fluidity characteristics of the overlying rock in the collapse pit, it is not suitable to produce fine-grained debris after the tailings are backfilled into the collapse pit. It is necessary to classify the tailings and make a cementitious material according to the characteristics of the tailings. The cementitious material consists of 17.5% activator and 82.5% % of water-quenched slag, in which the activator includes 21.3% of gypsum, 19.4% of water glass and 59.3% of cement clinker, and then the cementitious material and tailings are mixed in a ratio of 1:6 to 1:8 Stir to make the concentration of the backfill slurry reach more than 65%, so that it is not easy to enter the underground working face through the cracks in the overlying rock when it is just backfilled into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com