Feeding device of battery aluminum sheet

A feeding device and aluminum sheet technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems such as the difficulty of using long tails and the deviation of aluminum strip transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

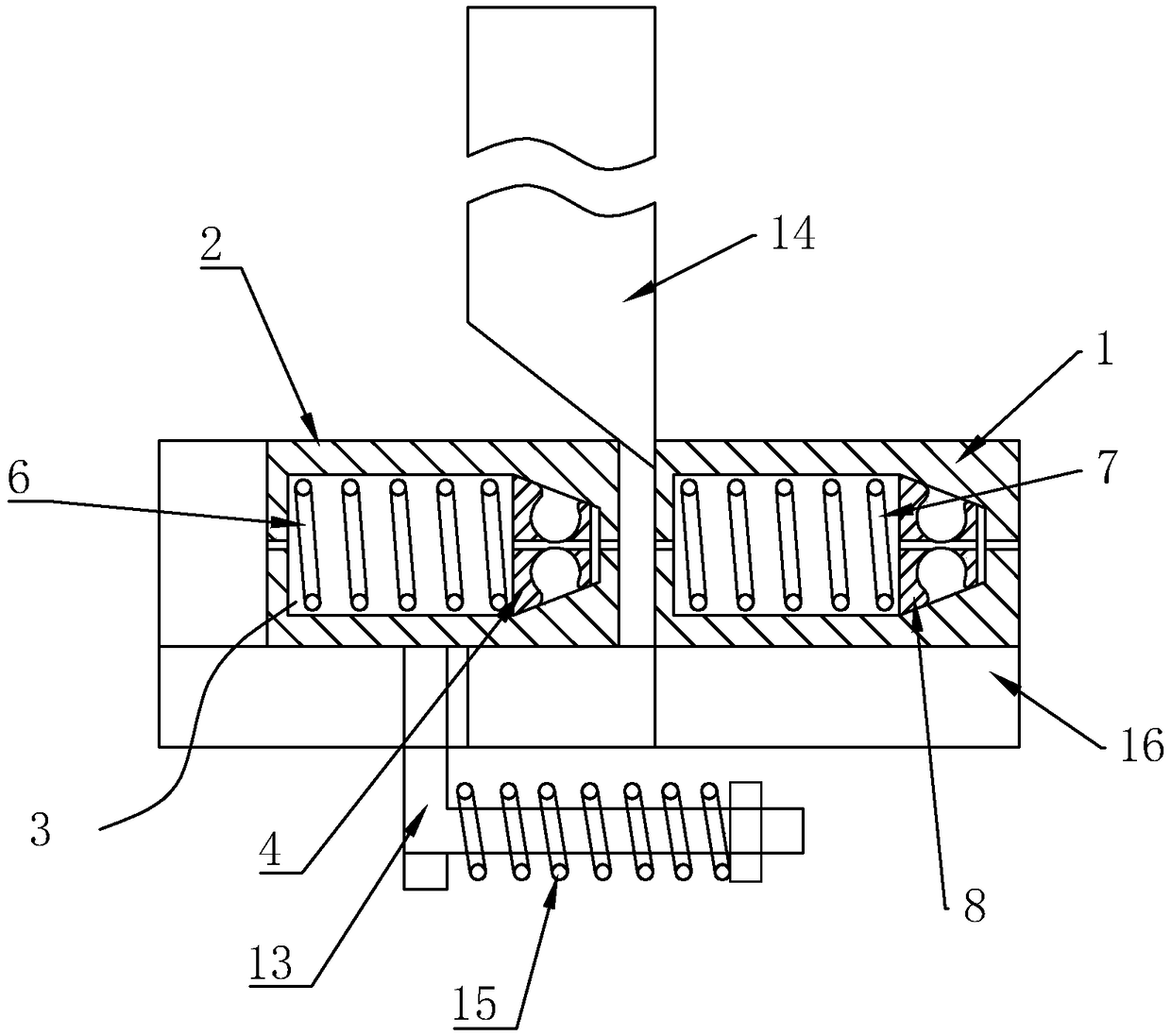

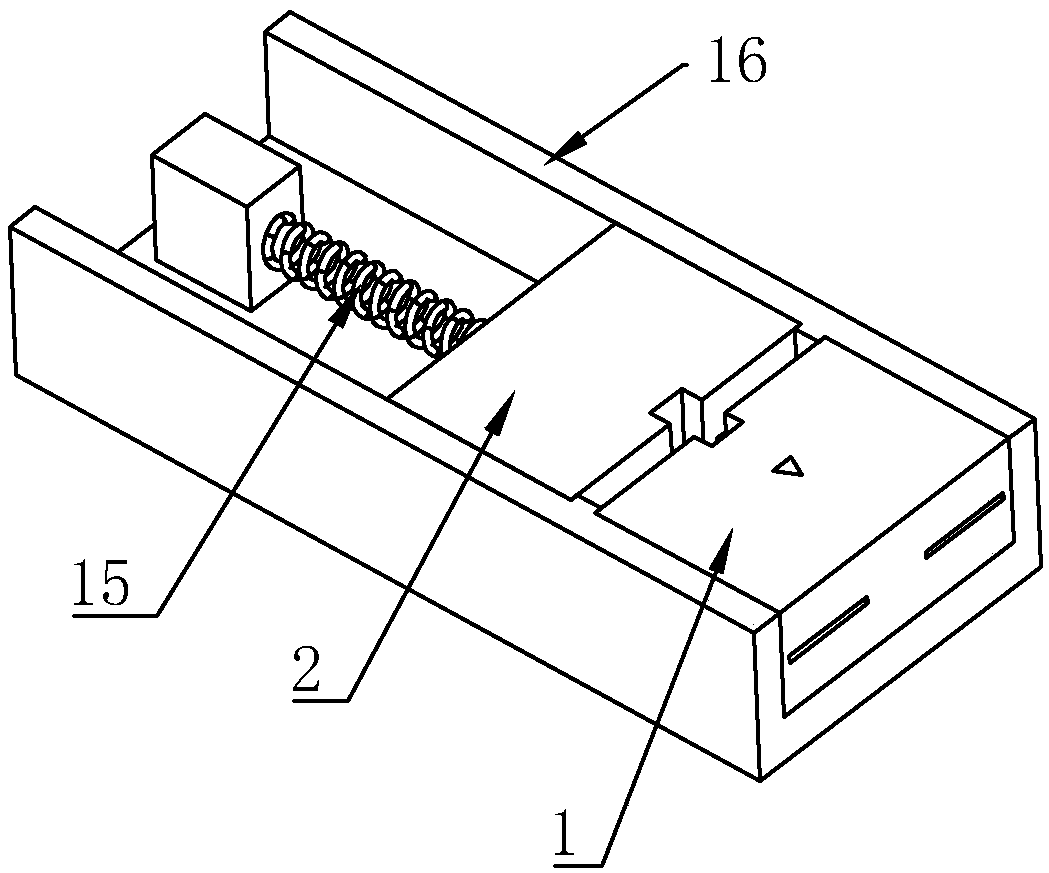

[0028] The return spring 15 is arranged on the other end of the movable slider 2 relative to the static slider 1. One end of the return spring 15 is in conflict with the adjustment plate, and the other end is in conflict with the movable slider 2. The advantage is that the structure is simple and the height of the feeding device can be reduced .

Embodiment 3

[0030] The difference from Embodiment 1 is that the reset spring 15 is set as a tension spring, one end of the tension spring is connected to the reset rod 13 , and the other end is connected to the bottom wall of the base 16 .

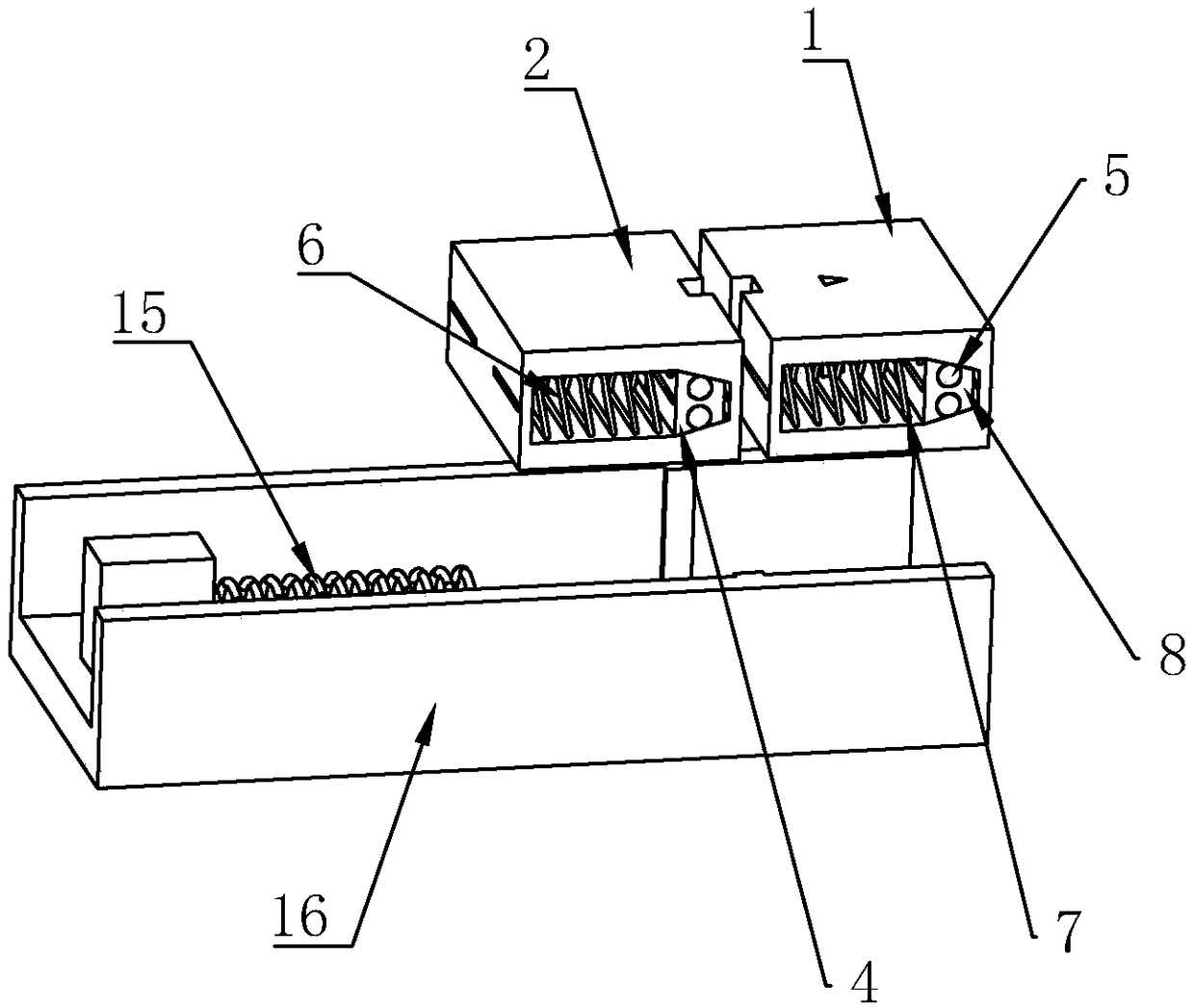

[0031] The movable slider 2 is processed and formed as a whole metal block or is formed by riveting the upper slider and the lower slider through pins, and the static slider 1 and the movable slider 2 have the same structure and size. The round rod 5 made of brass material has less damage to the aluminum strip. The aluminum strip is in rolling friction with the round rod 5 during the movement. When the aluminum strip is stationary, the round rod 5 is in linear contact with the aluminum strip. The clamping aluminum strip is more stable and firm.

[0032] Both the moving slider 2 and the static sliding are provided with two mounting grooves 3 . It can improve the efficiency of feeding and can process two aluminum sheets at the same time.

[0033] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com