Novel winding cutting knife device

A cutting knife, a new type of technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of large up and down swing range, large equipment vibration, long tailings, etc., to achieve small swing range, film tension The effect of small fluctuation and shortening tailing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

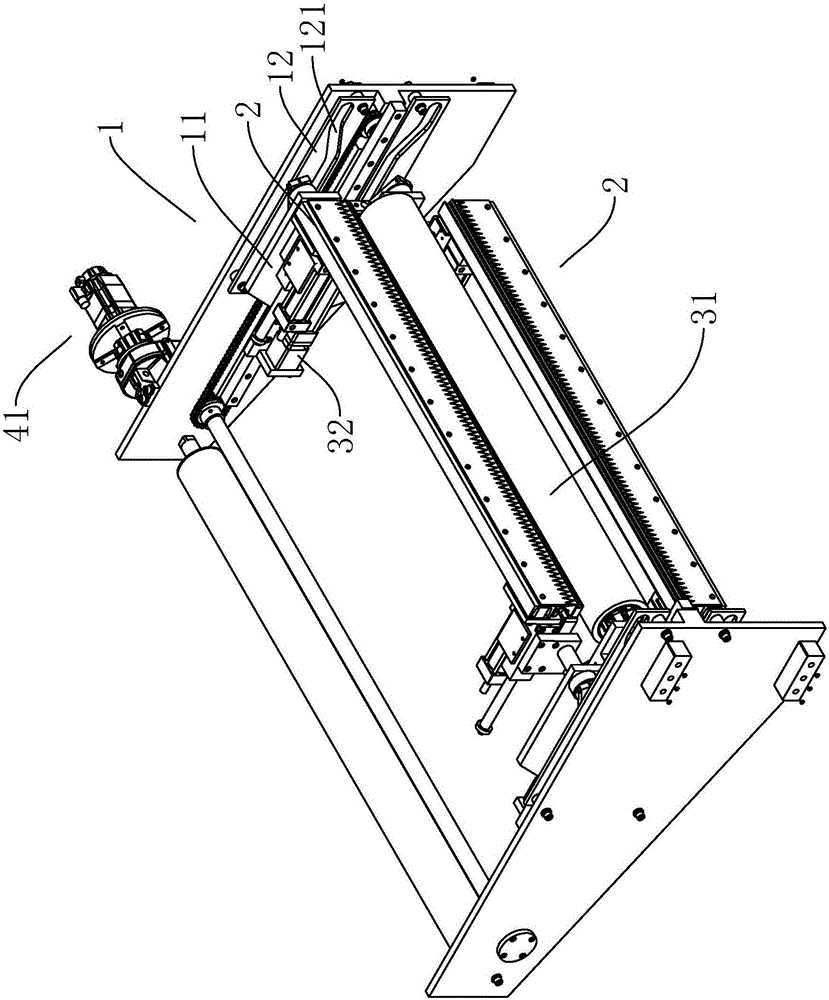

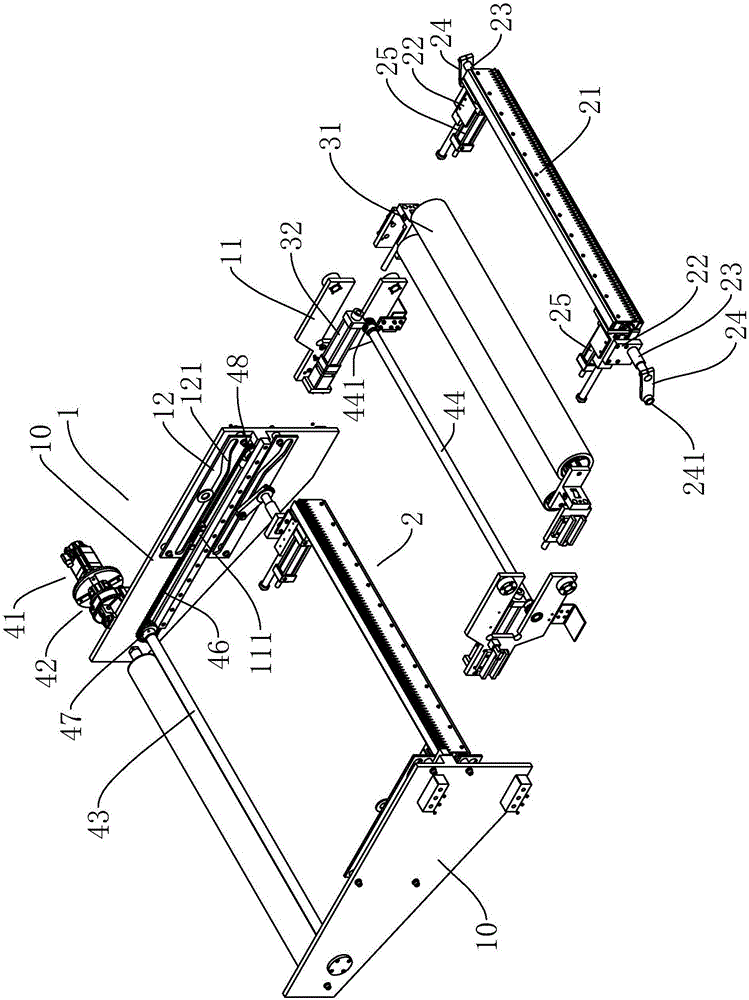

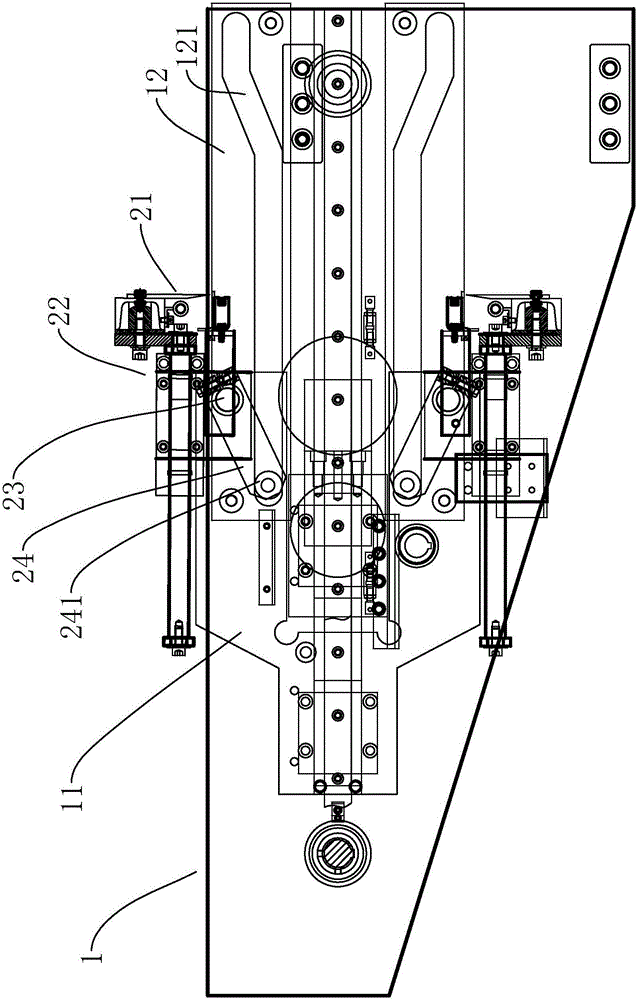

[0018] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a new type of winding cutter device includes a frame 1, a flat push roller device, and a cutter assembly. The two sides of the frame 1 pass a translation The drive devices are respectively provided with moving plates 11. Preferably, in this embodiment, the frame 1 includes two sets of oppositely arranged base plates 10, the translation drive device is a sprocket drive device, and the sprocket drive device Including a motor 41, a reducer 42, and a transmission shaft 43, the two ends of the transmission shaft 43 are respectively rotated and arranged on the base plate 10, the motor 41 is fixed on the frame 1 and connected to the transmission shaft 43 through the reducer 42, the The transmission shaft 43 is located at one end of the base plate 10 and the two ends of the transmission shaft 43 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com