Medical powered fret saw

A technology of power wire and wire saw, which is applied in the field of medical power wire saw, which can solve problems such as unbalanced force, inaccurate sawing, and unstable direction, so as to achieve stable cutting direction, uniform force on bones, and reduce the pain of patients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

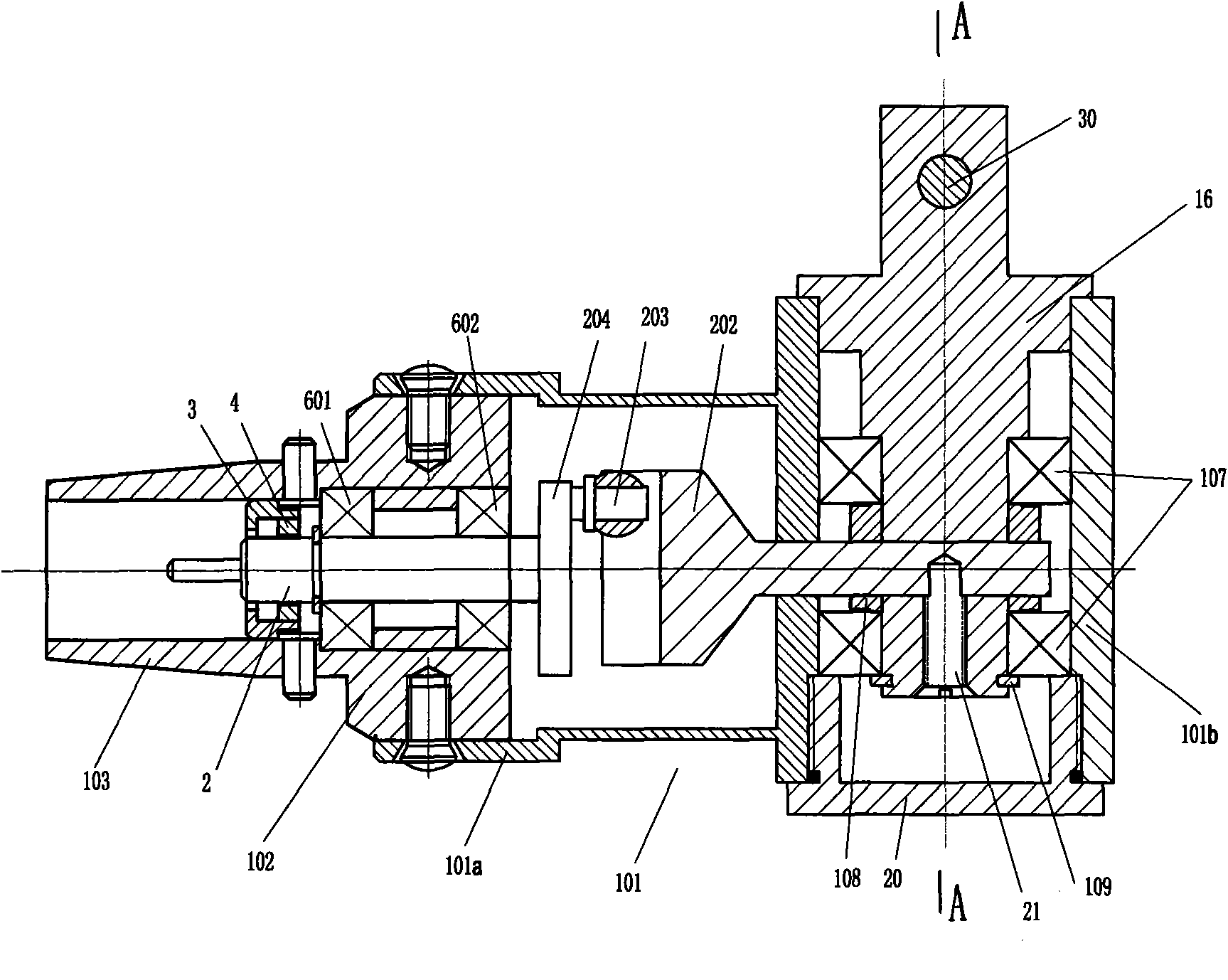

[0022] Such as figure 1 , 1a -1b and figure 2 As shown in , the power jigsaw includes a casing 1, the internal structure of the casing is sequentially, a power input shaft 2, a swing device and a swing head 16, wherein the swing device includes: an eccentric shaft 204 and a swing fork 202, and the position of the swing head is set as front end.

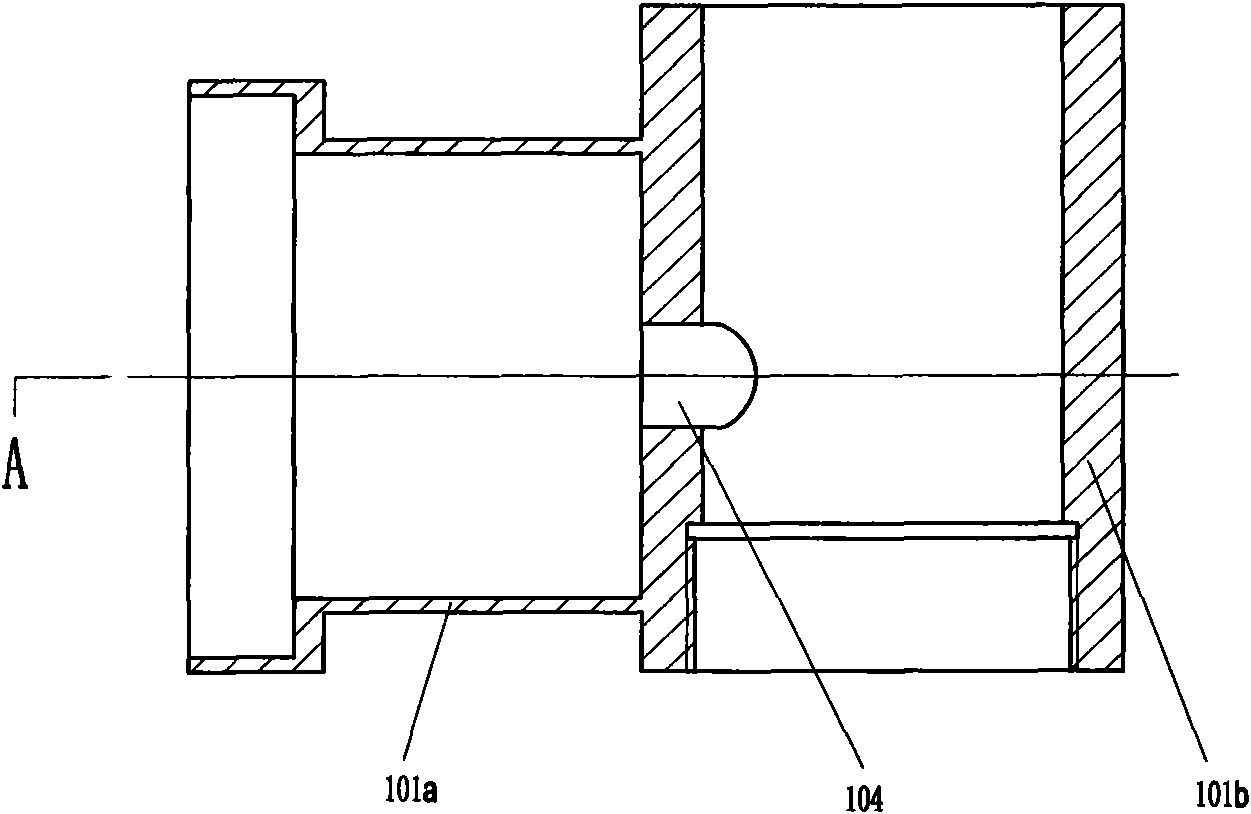

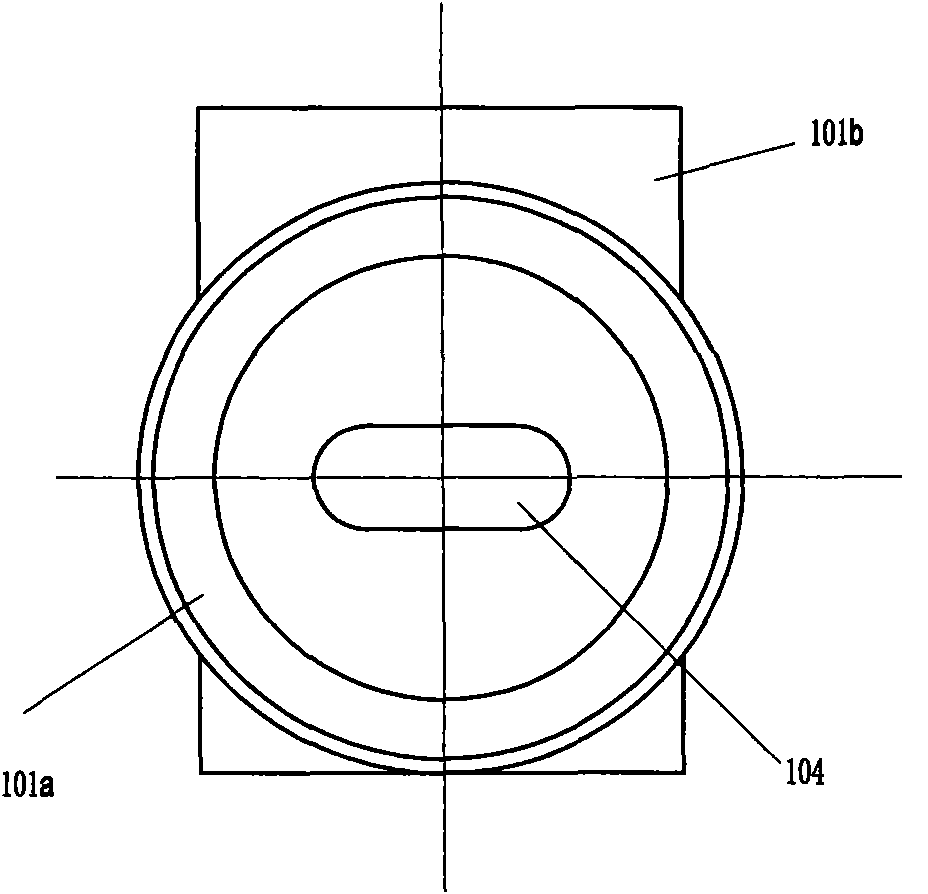

[0023] The casing 1 includes two parts, a connecting sleeve 102 and a housing 101. The rear end of the connecting sleeve 102 has a conical quick-fit joint 103; the power input shaft 2 is installed in the connecting sleeve 102, and the input end of the power input shaft 2 is arranged on the quick-fit Inside the connector 103. The eccentric shaft, the swing fork and the swing head are arranged in the housing 101 . The housing 101 includes two fixedly connected barrel structures 101 a, 101 b. A part of the swing head 16 protrudes from the housing 101 . The connection sleeve 102 and the housing 101 are fixedly connected by screws.

...

Embodiment 2

[0027] Such as image 3 As shown, compared with Embodiment 1, this embodiment adds a speed change mechanism between the power input shaft 2 and the eccentric shaft. a planetary gear 403. The central gear 402 is installed on the front end of the power input shaft, and drives the central gear 402 to rotate through the power input shaft, and then drives the three planetary gears 403 to rotate. In this embodiment, the rear end of the eccentric wheel is connected to the front end of the output shaft 201 , and the rear end of the output shaft 201 is connected to the three planetary gears 403 through three pins 404 .

[0028] When in use, the external power device drives the power input shaft 2 to rotate, and after being decelerated by the speed change mechanism 4, the power output shaft 201 drives the eccentric shaft to rotate.

[0029] In this embodiment, the planetary carrier 401, as a part of the casing, is arranged between the front housing 101 and the connecting sleeve 102, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com