Incoming cable restraining device on box-type transformer

A box-type transformer and restraint device technology, which is applied to the transformer/inductor casing, transformer/inductor parts, circuits, etc., can solve the problems of reducing equipment safety, large swing range, and easy to fall off, etc., to reduce Oscillation range, effective sealing, and the effect of reducing springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

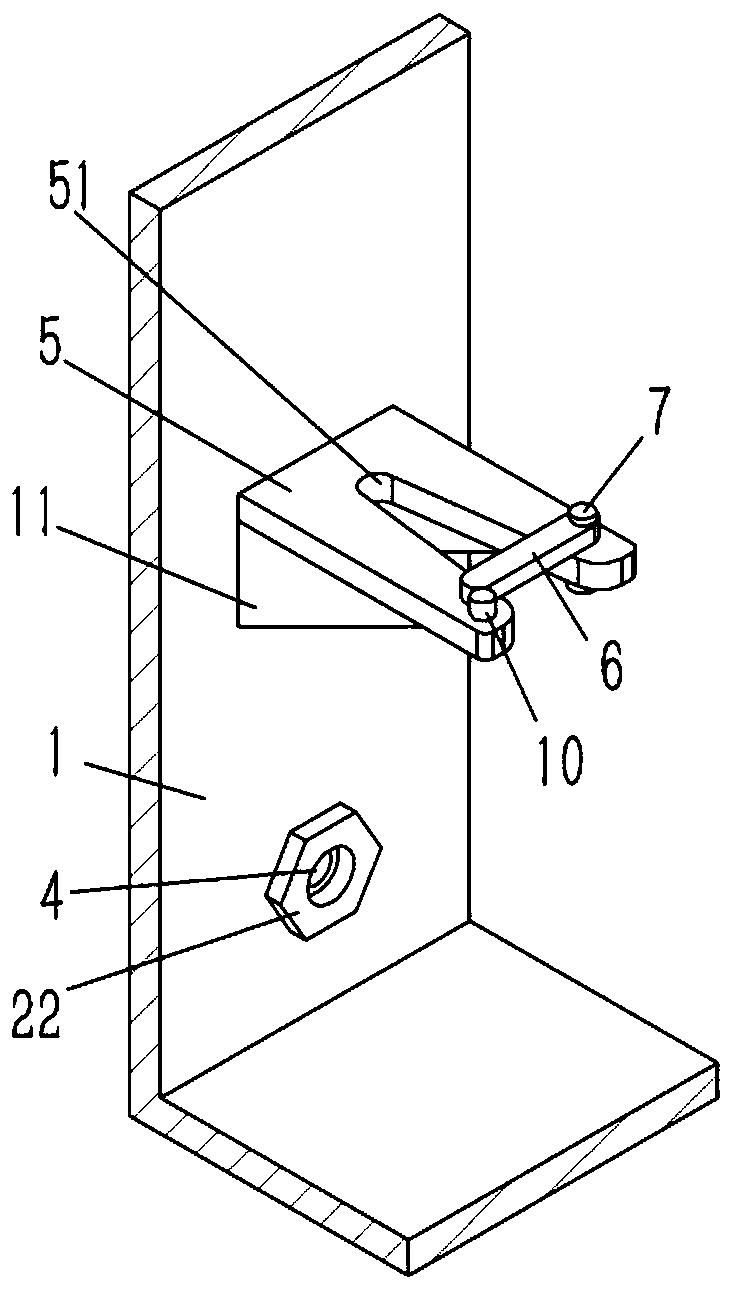

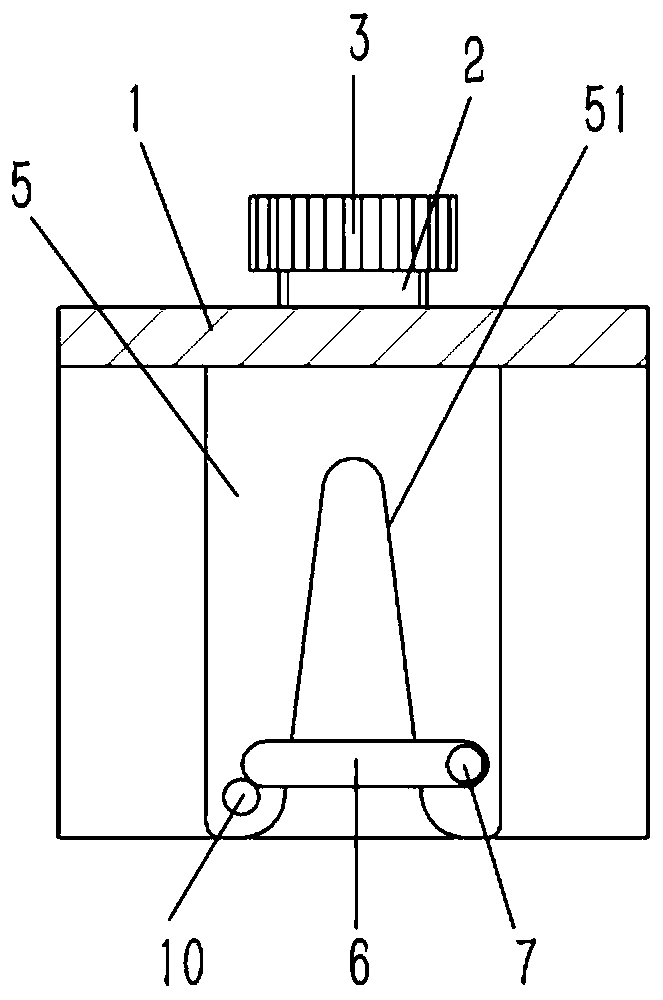

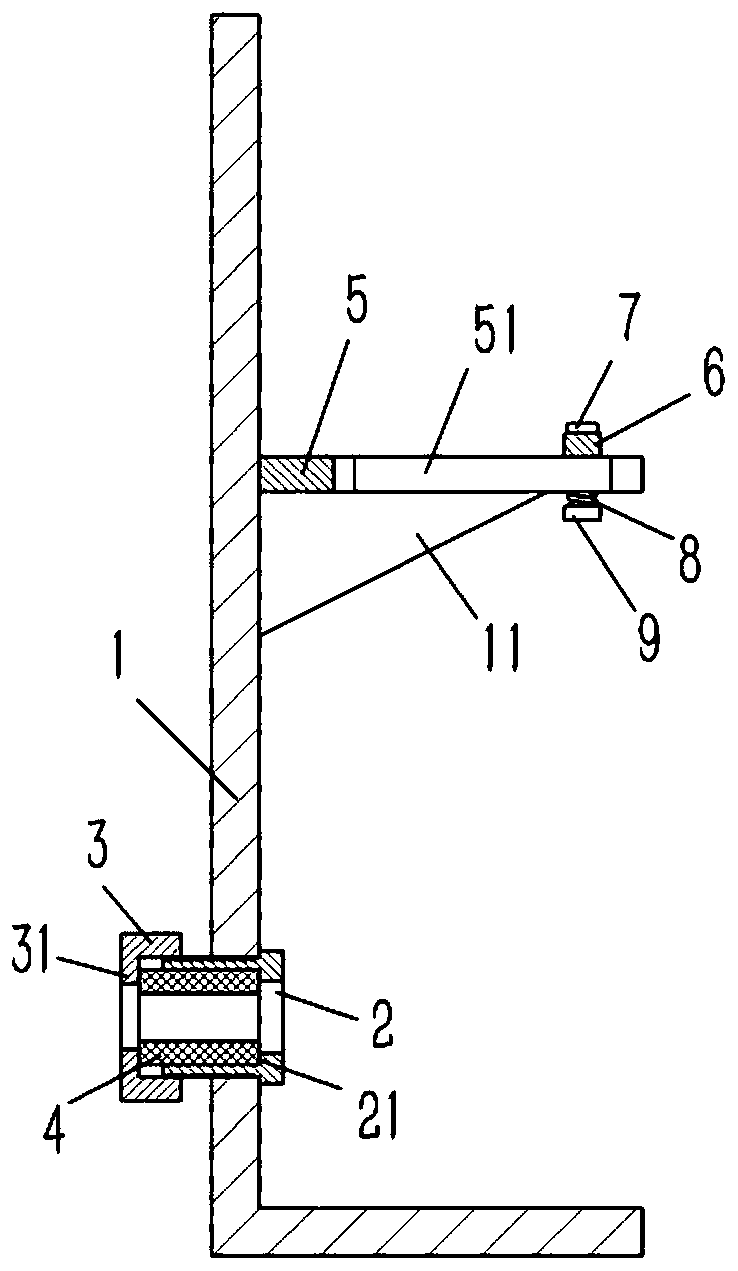

[0017] Example: see figure 1 , 2 , 3, an incoming cable restraint device on a box-type transformer, including a box body 1 on the box-type transformer, the bottom of the side wall of the box body 1 is formed with an inlet hole, and the inner screw of the wire inlet hole of the box body 1 Connected with an external thread sleeve 2, the inner end of the external thread sleeve 2 is formed with a flange 22, the flange 22 is against the inner wall of the box body 1, and the outer end of the external thread sleeve 2 is exposed to the outer wall of the box body 1 and is screwed with an inner A threaded sleeve 3, the inner wall of the externally threaded sleeve 2 is formed with an annular groove 21 that runs through the outer end surface of the externally threaded sleeve 2, and an annular rubber sleeve 4 is inserted into the annular groove 21 of the externally threaded sleeve 2. The outer end of the threaded sleeve 3 is formed with an annular end cap 31, and the end cap 31 abuts agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com