Patents

Literature

73results about How to "Reduce burning energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

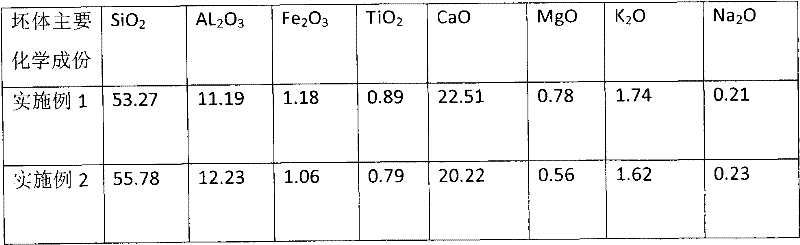

Green body of red soil ceramic and formula of transmutation glaze of red soil ceramic

The invention relates to a green body of red soil ceramic. The green body of the red soil ceramic is prepared from the following raw materials: red soil, quartz, talc, limestone and dolomite; the transmutation glaze of the red soil ceramic is prepared from the following raw materials: potassium feldspar, albite, calcium oxide, barium oxide, kaolin, quartz powder, sodium tripolyphosphate, titaniumoxide, rutile, zinc oxide and a coloring agent. By addition of other mineral raw materials, chemical raw materials and the like, the physical performance and the chemical performance of the green body are changed and the technical problems that the green body glaze of the red soil product is difficult to combine and the product is loose and fragile are solved; the firing temperature of the glaze is reduced from 1,310 DEG C to 1,230 DEG C, so thatthe firing temperature is reduced by 80 DEG C, the using amount of the fuel and the discharge quantity of harmful gas are reduced, environmental protection is contributed and production cost is greatly saved; and by development of the lead-free transmutation glaze, the lead-free transmutation glaze is suitable for being combined with the green body of the red soil ceramic, so that the problem of pollution to the ceramic decorative environment is solved fundamentally.

Owner:FUJIAN JIAMEI GRP +1

Method for producing color blank glaze archaizing brick by using iron mine tailing

The invention discloses a method for preparing an archaizing brick with a colored blank and a glaze surface by using iron tailings, comprising the method for producing regular archaizing brick with the glaze surface; the invention is characterized in that the waste iron tailing material is used to replace part of glaze and blank material of the original archaizing brick, added in the blank material and plus material of the archaizing brick with the glaze surface, and then prepared through a rountine process. The waste iron tailing material takes 20 to 45 percent of the glaze and the blank material. Adopting the method for preparing the archaizing brick with the colored blank and the glaze surface by using the waste iron tailings, the invention has the advantages of reducing production dependence on mineral material resource with excellent quality, improving utilization rate of the resource, diminishing discharge of solid waste, and greatly reducing the production cost of ceramic products; the used tailing replaces not only the ceramic mineral material but also pigments so that pigments only experience one calcining and heating process of ceramic roasting from the mineral to color forming; at the same time, the roasting temperature of the ceramics is decreased and roasting energy consumption of the ceramics is greatly reduced.

Owner:钟旭东

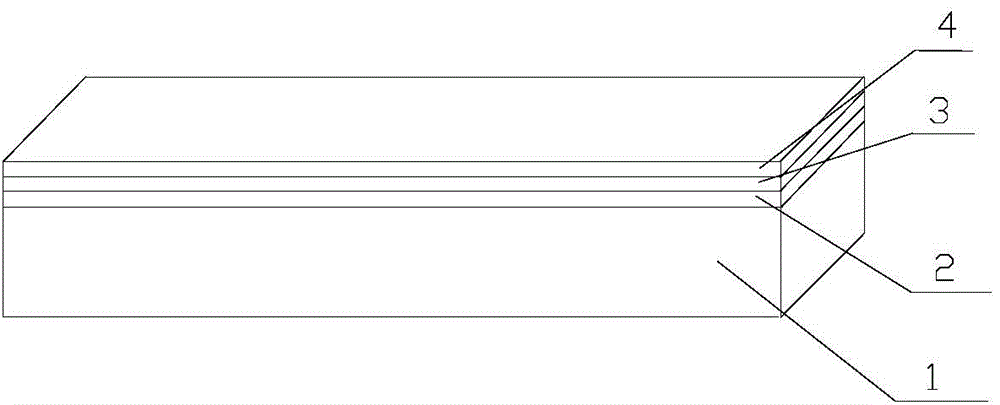

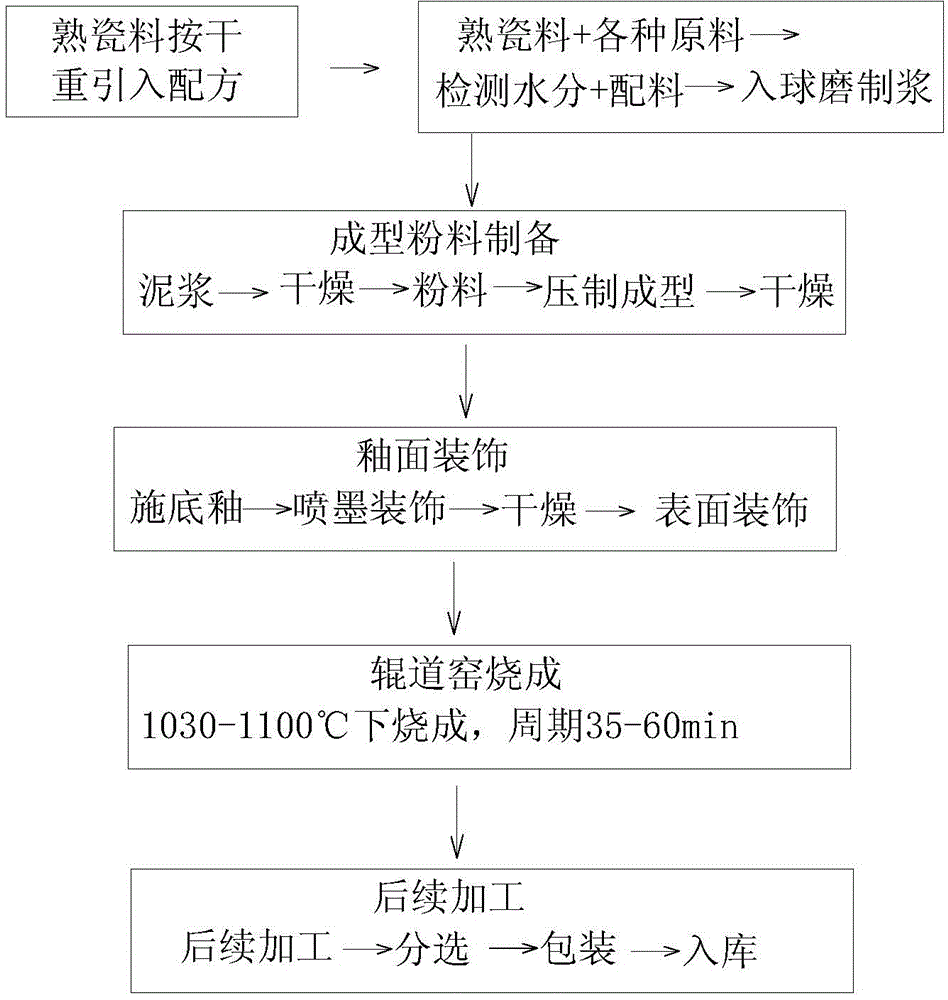

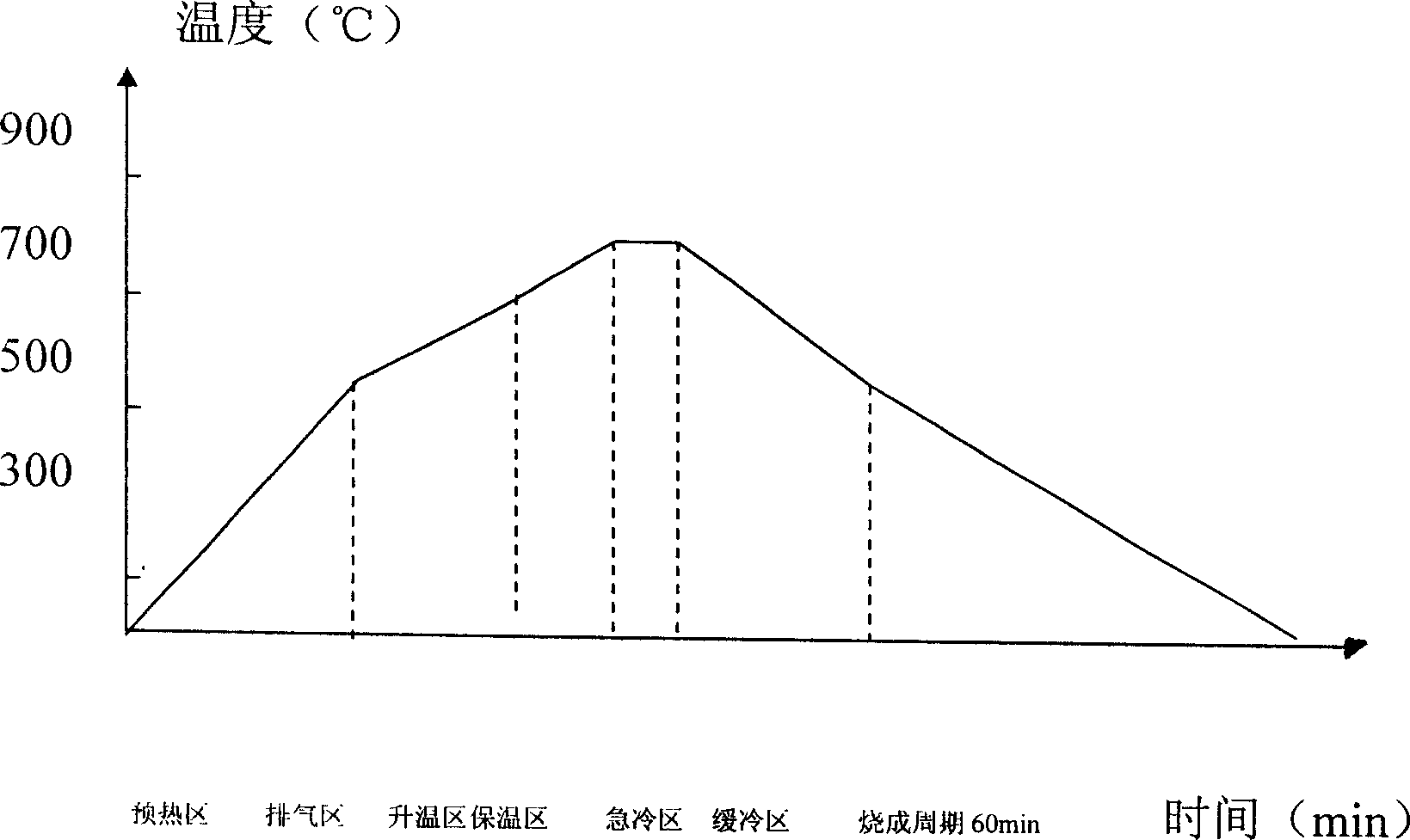

Wide-color-gamut inkjet glaze decorated ceramic floor tile and production process thereof

The invention relates to the technical field of ceramic tiles, and in particular relates to a wide-color-gamut inkjet glaze decorated ceramic floor tile and a production process thereof. A floor tile billet comprises the following components in parts by weight: 40-75 parts of a cooked porcelain material, 0-38 parts of porcelain stone, 20-30 parts of clay and 0-5 parts of a mineralizing agent; and a production method comprises the following steps: firstly performing conventional processes such as wet-process ball-milling, spray drying and dry-pressing molding on architectural ceramics to prepare a billet, by taking titanium series engobe as a ground glaze, combining engobe with a low-temperature ink-jet ink composition of interior wall tiles to perform inkjet decoration, and performing firing in a roller hearth kiln under the conditions that the firing temperature is 1030-1100 DEG C and the firing cycle is 35-60min to prepare a finished product, wherein the water absorption rate of the finished product is 0-3%, and the quality of the product can meet the national standard requirements. The wide-color-gamut inkjet glaze decorated ceramic floor tile disclosed by the invention has the beneficial effects that energy conservation and emission reduction can be achieved, and the firing temperature can be reduced by 50-100 DEG C compared with that of the same category of products; the technology bottleneck that titanium series opacified engobe can be yellowed when being applied in the floor tiles in a conventional high-temperature process can be effectively solved; and the color gamut range of an inkjet decorative layer of a glaze decorated ceramic tile can be significantly broadened.

Owner:JIANGXI HEMEI CERAMICS +1

Method for preparing ceramic material by virtue of copper tailings

ActiveCN105541296ARealize resource utilizationGood environmental benefitsCeramic materials productionClaywaresSocial benefitsSlag

The invention discloses a method for preparing a ceramic material by virtue of copper tailings, and belongs to the fields of industrial solid waste resource comprehensive utilization and environmental protection. The method comprises the following steps of ball-milling and mixing 35 to 55 parts by weight of copper tailings, 25 to 40 parts by weight of steel slag, 10 to 25 parts by weight of clay, 0 to 15 parts by weight of feldspar, 0 to 10 parts by weight of talc and the like, and executing the procedures of sieving, drying, pressing or extrusion molding, sintering and the like to obtain the ceramic material, wherein the firing temperature is 1,080 to 1,160 DEG C. According to the method, the ceramic material is synergistically prepared from the copper tailings and the steel slag, and the ratio of the using amount of industrial solid waste to the total weight of the raw materials in the ceramic material reaches 65 to 85 percent, so that the industrial solid waste can be resourcefully utilized in large scale, and obvious social benefits and environmental benefits can be achieved; the copper tailings and the steel slag are small in granularity, so that ball-milling energy consumption in a ceramic material production process can be reduced; the sintering temperature is lower, so that the sintering energy consumption of the ceramic material can be reduced, and economic benefits are achieved; the method is relatively simple in process and easy to popularize and use.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI

Method for manufacturing glazed brick by utilizing silico-calcium slag

InactiveCN102173740AEmission reductionReduce production energy consumptionClaywaresCalcium silicateBrick

The invention relates to a method for manufacturing a glazed brick by utilizing silico-calcium slag, belonging to the technical field of ceramic manufacture. The glazed brick comprises the following raw materials in percentage by weight: 5%-40% of the silico-calcium slag, 0%-10% of Dongsheng clays and 50%-95% of bamboo partridge tower clays. Due to the adoption of the invention, the shortage crisis of raw mineral materials is weakened and the discharge of the silico-calcium slag is reduced, and an energy-saving type ceramic product is produced; the production energy consumption of ceramics can be reduced and the utilization efficiency of resources is enhanced by preparing low-temperature glaze materials adapted to calcium silicate because the firing temperature of a blank body is reduced through the calcium silicate contained in the silico-calcium slag; the invention not only reduces the pollution, but also increases a new member for building materials; and in addition, the novel glazed brick prepared by using the method has various properties which all accord with or surpass the national standard.

Owner:ORDOS CITY TAOERSI CERAMIC

Preparation method for clinker of alumina produced by sintering process

InactiveCN105540627AQuality improvementReduce burning energy consumptionAluminium oxides/hydroxidesRed mudEnergy consumption

The invention discloses a preparation method for a clinker of alumina produced by a sintering process, and relates to an improvement on the process of producing alumina by the sintering process. The preparation method is characterized in that according to the preparation process of the preparation method, Bayer alkali red mud powder, lime, bauxite, soda ash and pulverized coal are mixed uniformly to be raw material pellets, and the raw material pellets are sintered to obtain the clinker of the alumina produced by the sintering process. A dry-process sintering method of the sintering process disclosed by the invention can be used in the process of producing alumina by a mixed combination process and a series process, the process disclosed by the invention has stable clinker quality, reduced clinker sintering energy consumption by more than 40%, and increased clinker kiln production capacity by more than 60% in comparison with the existing alumina production process, thereby having the effect of saving energy and reducing consumption in a large extent.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

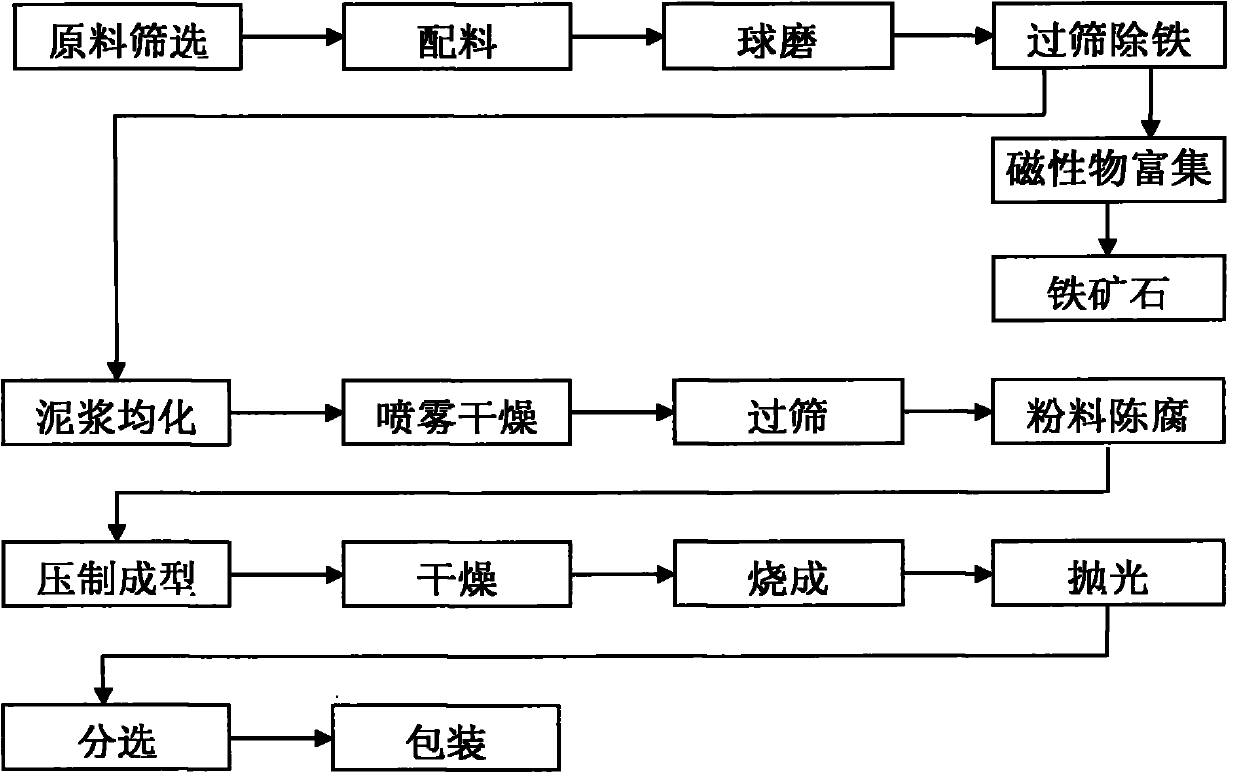

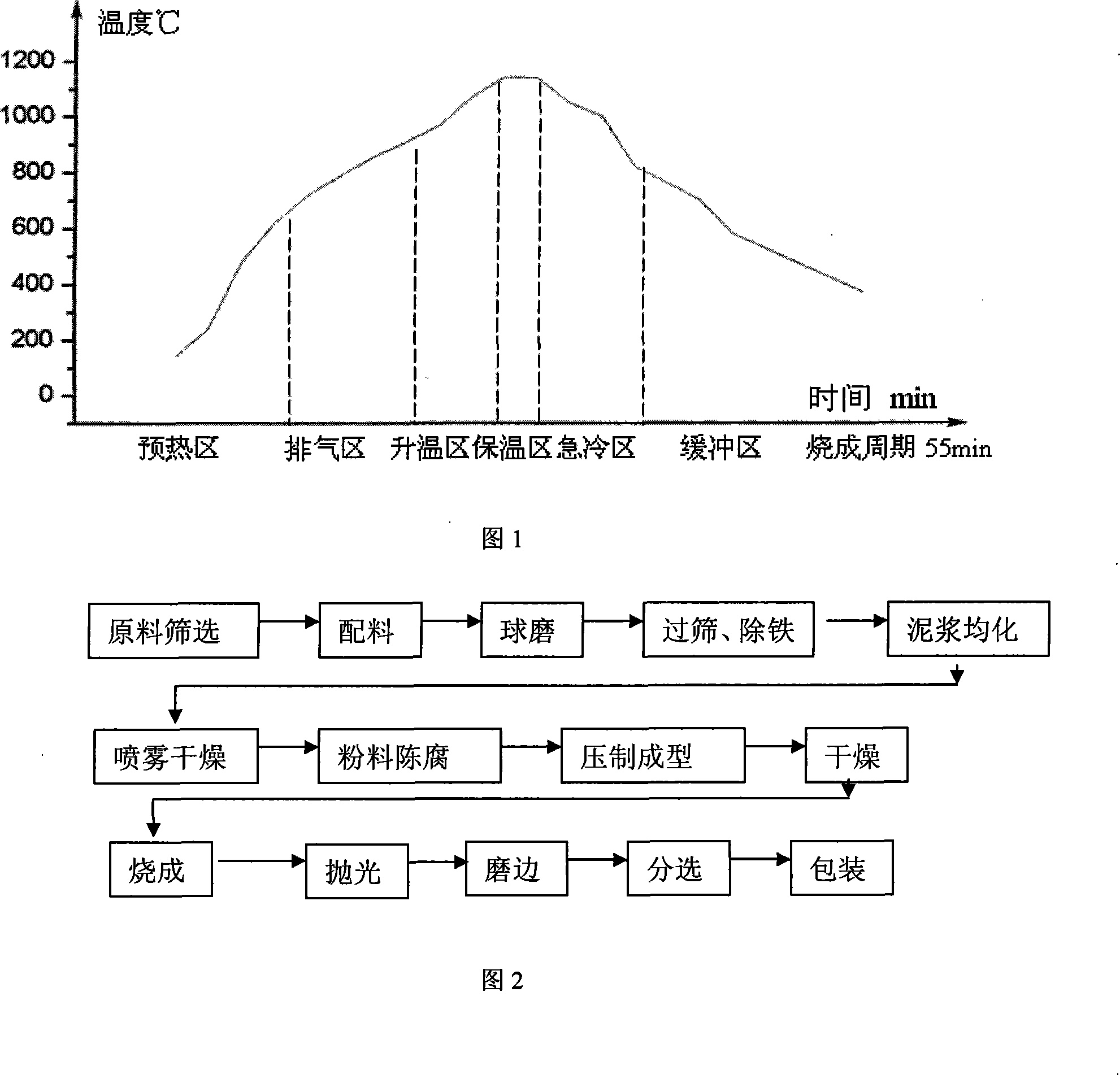

Method of producing polishing brick by low-temperature sintering

The invention discloses a production method for archaizing bricks by low-temperature sintering. The method comprises using cullet as a major raw material, sodium tripolyphosphate (Na3P5O10) as a secondary raw material, and other other low-priced ceramic raw materials, and producing archaizing bricks suitable for one rapid firing (burning time of 55 minutes and firing temperature <= 900DEG C). The raw materials comprise: waste glass 42-60%, cooked bauxite 18-25%, white mud 15-2%, bentonite 3-8%, sodium tripolyphosphate 5-8%, and pigment 3-4%. Prescription referred to the specific chemical composition, Al2O3 52-60%, SiO2 23-26%, Fe2O3 0-1%, CaO 6-8, MgO 0.5-1.0%, KNaO 8-10%, and others 3-4%. The formula can also include various plasticizers and electrolytes. The invention has the advantages of low energy consumption and simple process.

Owner:钟旭东

Method of preparing ceria by mixed precipitant

A method of preparing ceria by a mixed precipitant mainly comprises the steps of enabling a mixed solution of ammonium bicarbonate and ammonia as the precipitant to perform combined action with inoculating crystals, precipitating rare earth ions in a rare earth chloride solution to obtain a mixture with primary alkali type cerous carbonate and subsidiary cerous carbonate and cerium hydroxide, and further firing to prepare a rare earth ceria product. The prepared ceria accords with industry standards; reaction conditions of the method are mild; energy consumption during preparing process is obviously reduced, and the cost is low; meanwhile, the carbon dioxide emission is greatly reduced, and obvious social benefit and environmental benefit are achieved.

Owner:YANSHAN UNIV

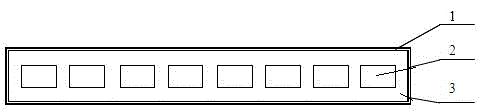

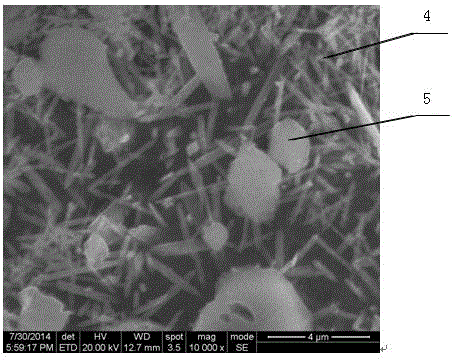

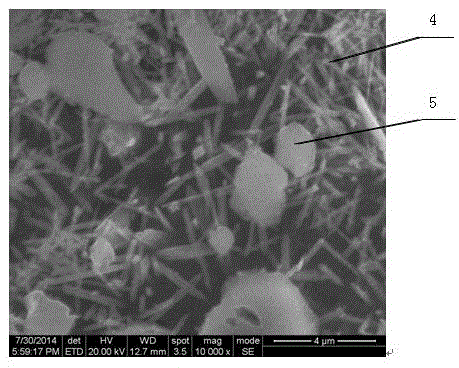

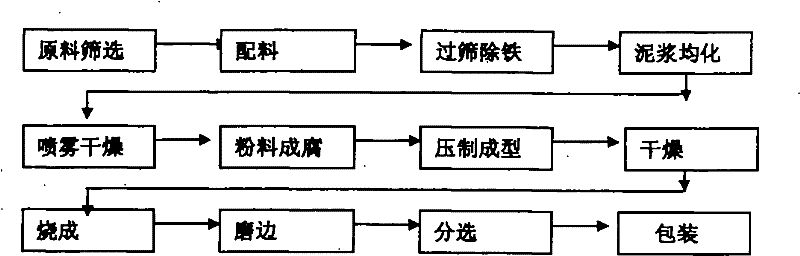

Method for preparing high-strength ceramic membrane by cofiring once

The invention provides a method for preparing a high-strength ceramic membrane by cofiring once. The method comprises the following steps: fully mixing ceramic body paste by taking calcined bauxite and high-plasticity clay as main raw materials with a plant pore-forming material; fabricating a ceramic membrane support body green body in a vacuum extrusion manner; drying and then spraying ceramic membrane slurry on the surface of the green body; and then cofiring once in a roller kiln. The strength of a support body of the ceramic membrane is provided by a composite ceramic material which is highly densified and takes alundum particle and mullite whiskers generated in situ as strengthening phases; and the aperture and the porosity are regulated and controlled by the plant pore-forming material which is in a fibrous or flaky structure and is completely burnt at high temperature, and therefore, the ceramic membrane has the relatively good pore connectivity characteristics, the support body of the ceramic membrane, with high strength and a high connected pore structure, is obtained; the bonding strength of a ceramic membrane layer and the support body is high by the cofiring once; the service life is long; and meanwhile, the ceramic membrane has the characteristics of low preparation cost, energy conservation and the like.

Owner:湖南科一环保科技股份有限公司

Method using titanium gypsum and acetylene sludge to prepare high-calcium sulphoaluminate or high-sulfur clinkers

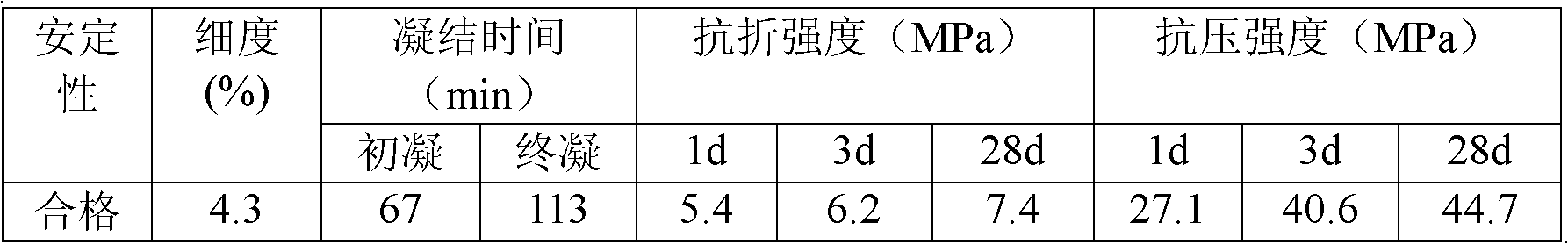

A method using titanium gypsum and acetylene sludge to prepare high-calcium sulphoaluminate or high-sulfur clinkers includes the steps: (1) compounding; (2) homogenizing; and (3) calcining. According to the method using the titanium gypsum and the acetylene sludge to prepare the high-calcium sulphoaluminate or the high-sulfur clinkers, drying and grinding of wet sludge titanium gypsum and the acetylene sludge are omitted, energy consumption in drying and grinding is reduced, the firing temperature is low, firing energy consumption is low, production cost of the clinkers is low, and waste recycling benefits are good.

Owner:长沙紫宸科技开发有限公司

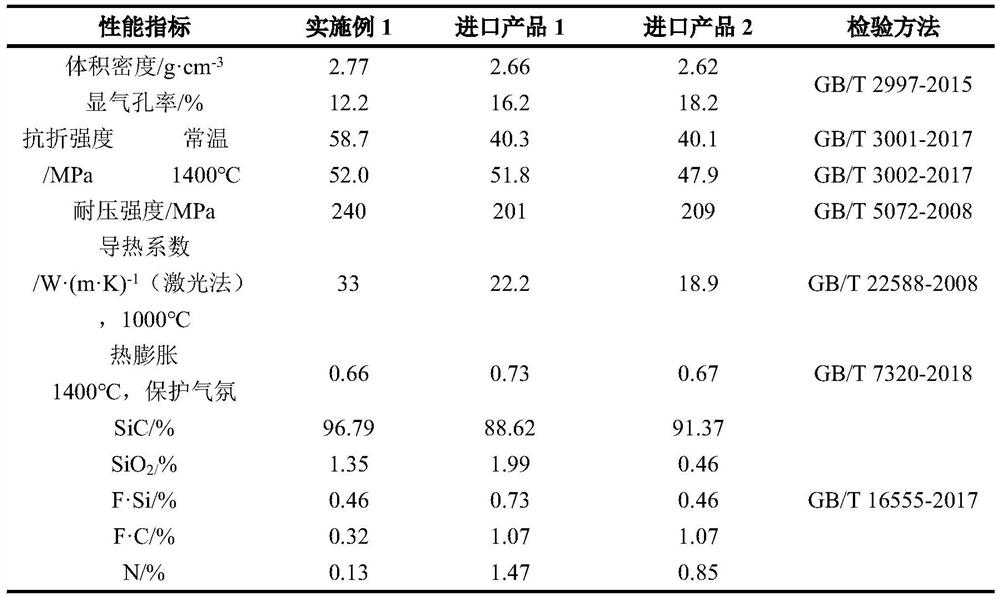

Method for preparing high performance silicon oxide combining silicon carbide refractory by low-temperature sintering

ActiveCN101423412ALower firing temperatureReduce burning energy consumptionVolume densitySilicon oxide

The invention belongs to a refractory material technology, and provides a method for preparing a high-performance silica bonded silicon carbide refractory material through low temperature calcination. The method comprises the following steps: SiC particles, fine powder, fine SiO2 powder, and Si powder are taken as raw materials, the raw materials and a bonding agent are calendered, molded and dried, and then a silica sol solution is adopted to perform at least one time of vacuum infiltration treatment on a green body; the final calcination temperature range of the green body is between 1,100 and 1,250 DEG C, and the high-performance silica bonded silicon carbide refractory material can be prepared. The highest calcination temperature of the refractory material is between 100 and 500 DEG C lower than that of the prior SiO2 bonded silicon carbide material, which can apparently reduce the calcination energy consumption of the material. The material has good physical and chemical performance: the content of SiC is between 85 and 95 percent, the volume density is between 2.65 and 2.82g / cm<3>, the high temperature rupture strength at a temperature of 1,400 DEG C reaches between 40 and 52 MPa, and the highest service temperature of the material can reach 1,550 DEG C; and the refractory material can be used as ceramic kiln furniture and kiln linings of various industrial kilns such as zinc smelters, garbage incinerators, and has good application effect.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

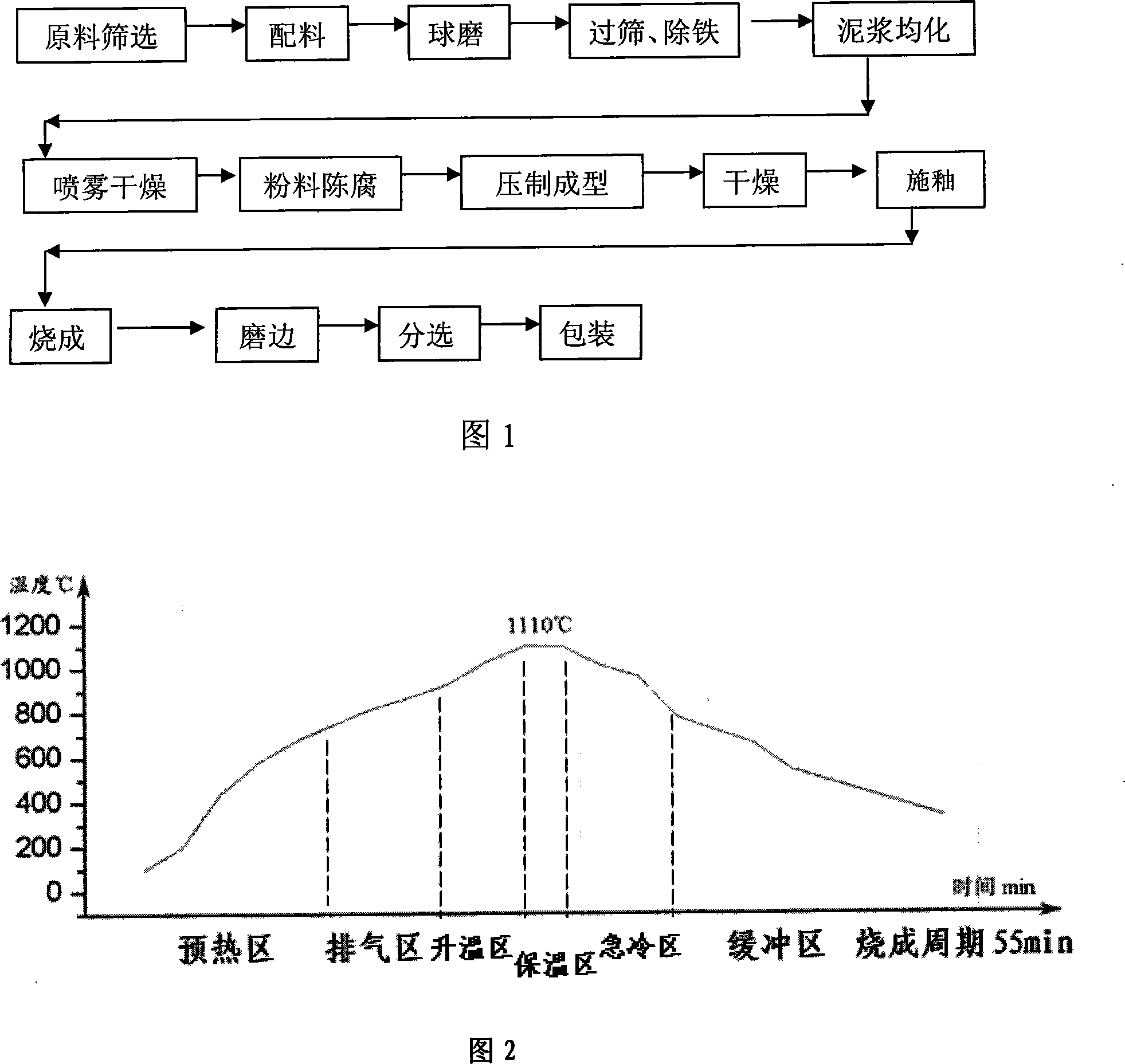

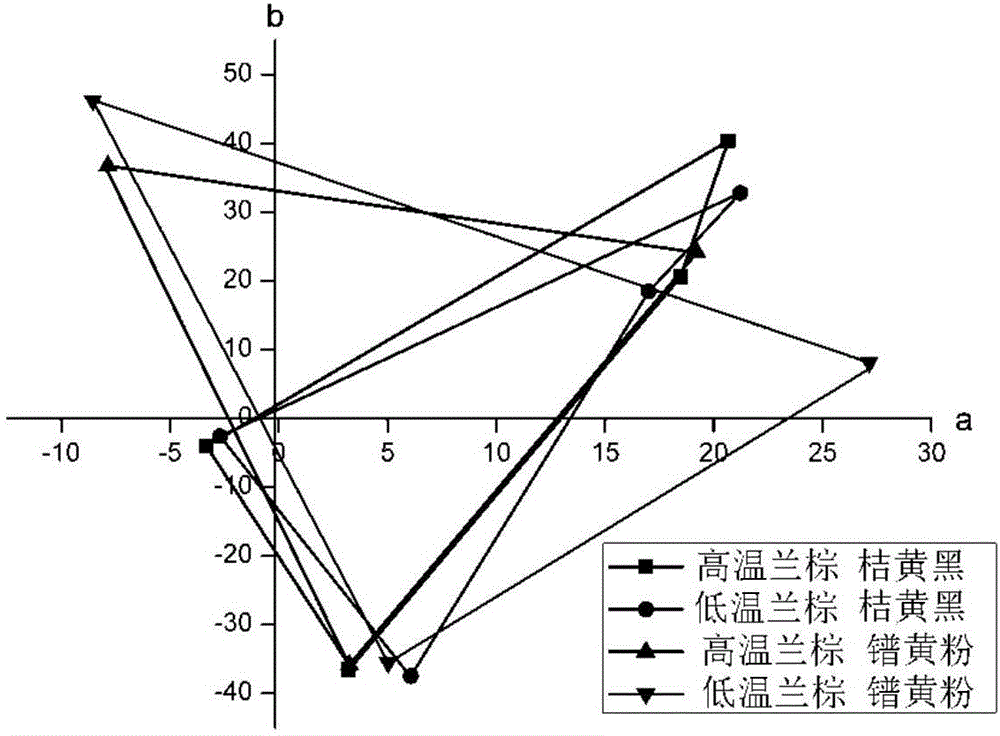

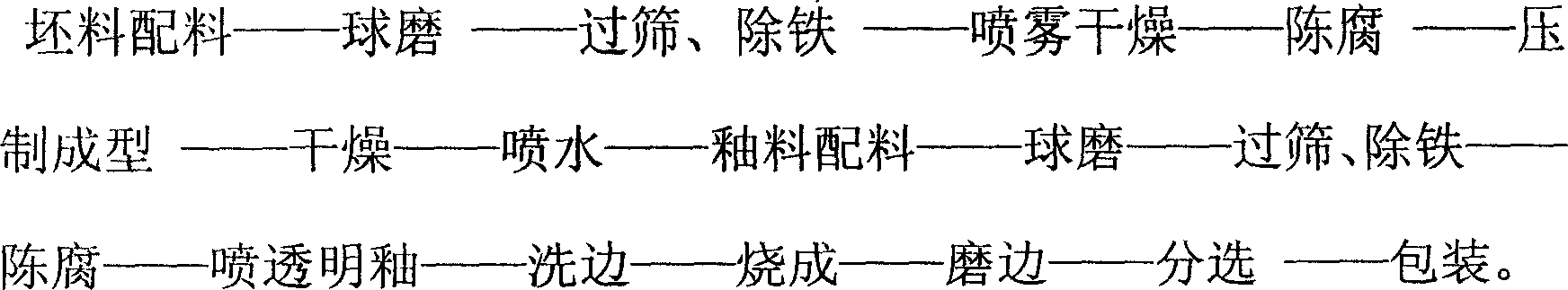

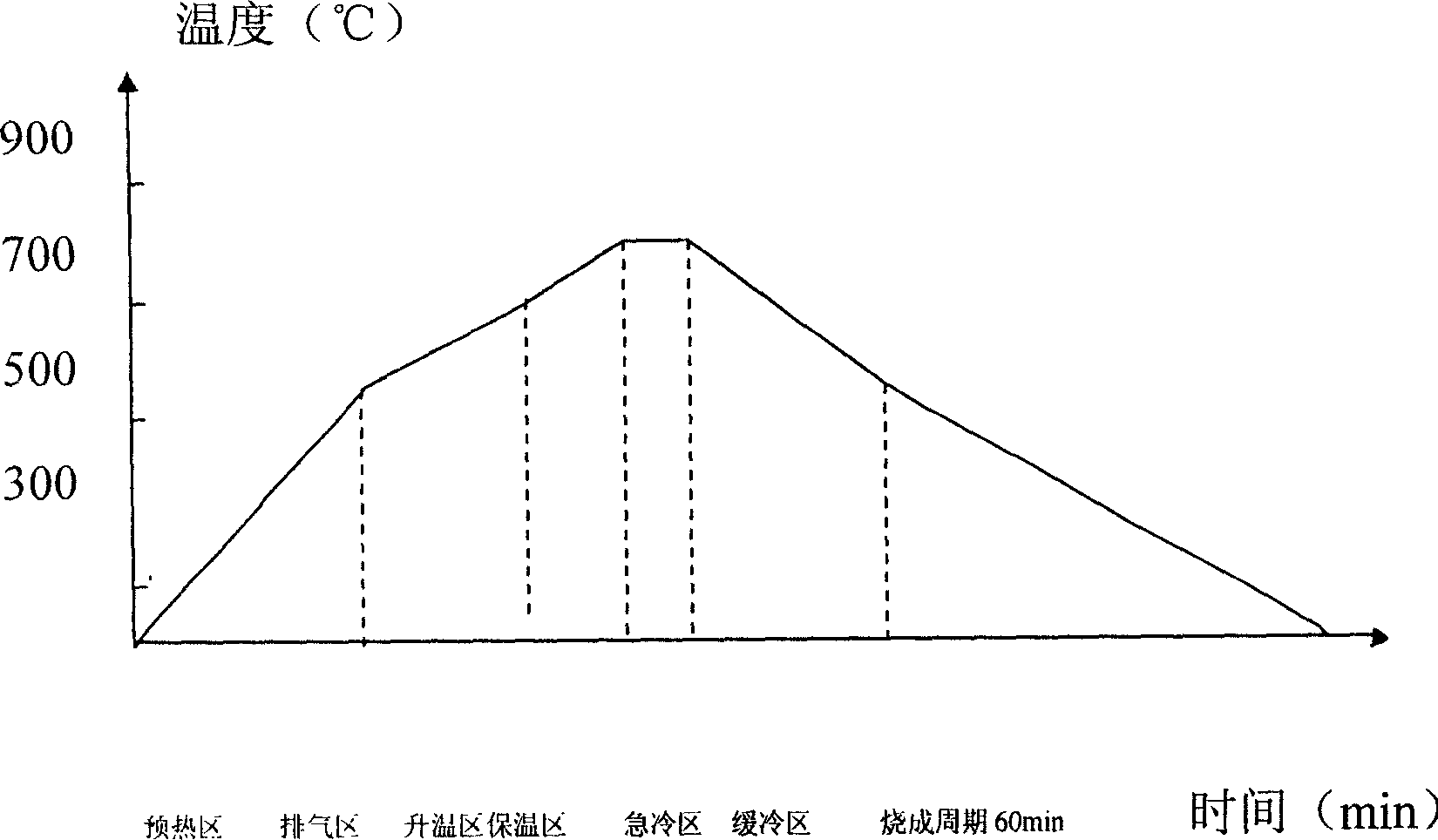

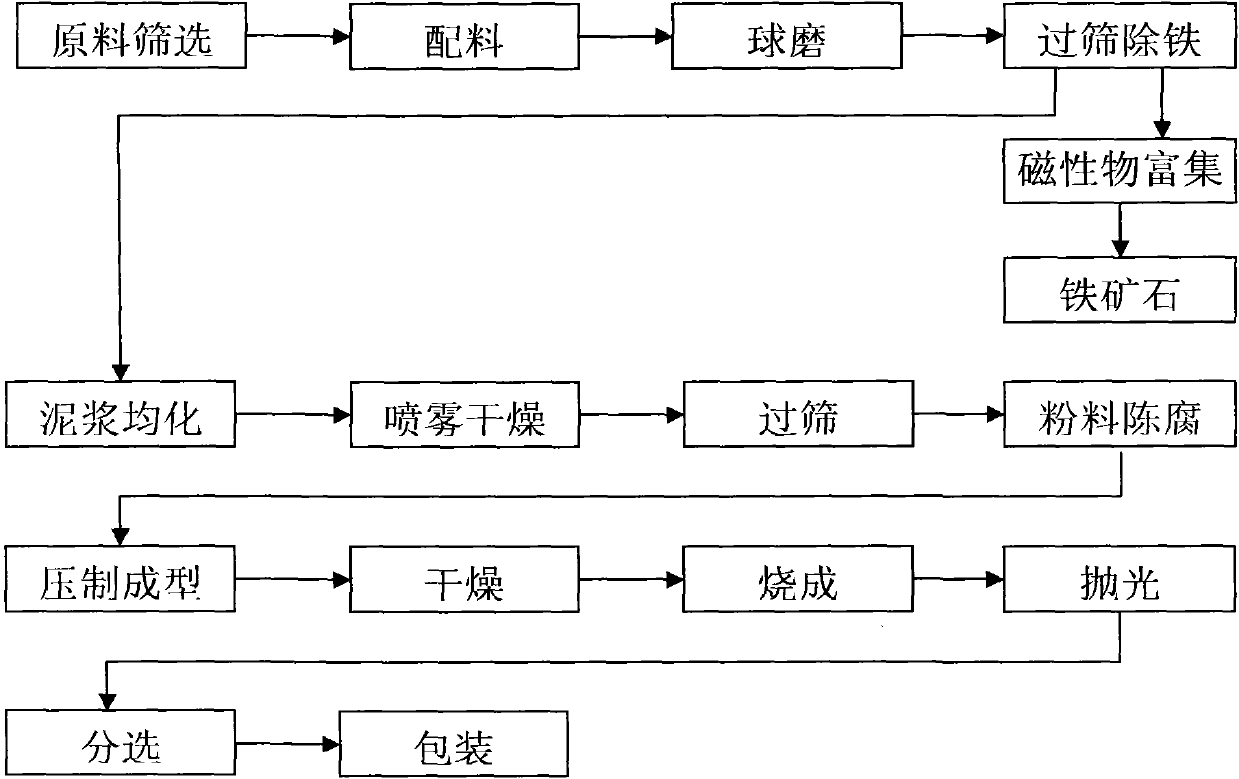

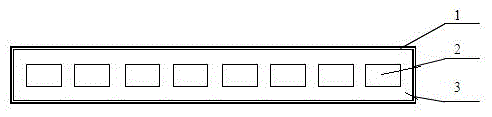

Method of producing archaistic brick by low-temperature sintering

The invention discloses a production method for archaizing bricks by low-temperature sintering. The method comprises using cullet as a major raw material, sodium tripolyphosphate (Na3P5O10) as a secondary raw material, and other other low-priced ceramic raw materials, and producing archaizing bricks suitable for one rapid firing (burning time of 55 minutes and firing temperature <= 900DEG C). The raw materials comprise: waste glass 42-60%, cooked bauxite 18-25%, white mud 15-2%, bentonite 3-8%, sodium tripolyphosphate 5-8%, and pigment 3-4%. The method comprises proportioning the ingredients, ball-milling, sifting, removing iron, spray-drying, pressing and molding, drying, spraying water, proportioning glaze ingredients, ball-milling, sifting and removing iron, aging, spraying transparent glaze, washing edge, sintering, grinding edge, separating, and packaging. The invention has the advantages of low energy consumption and low cost.

Owner:钟旭东

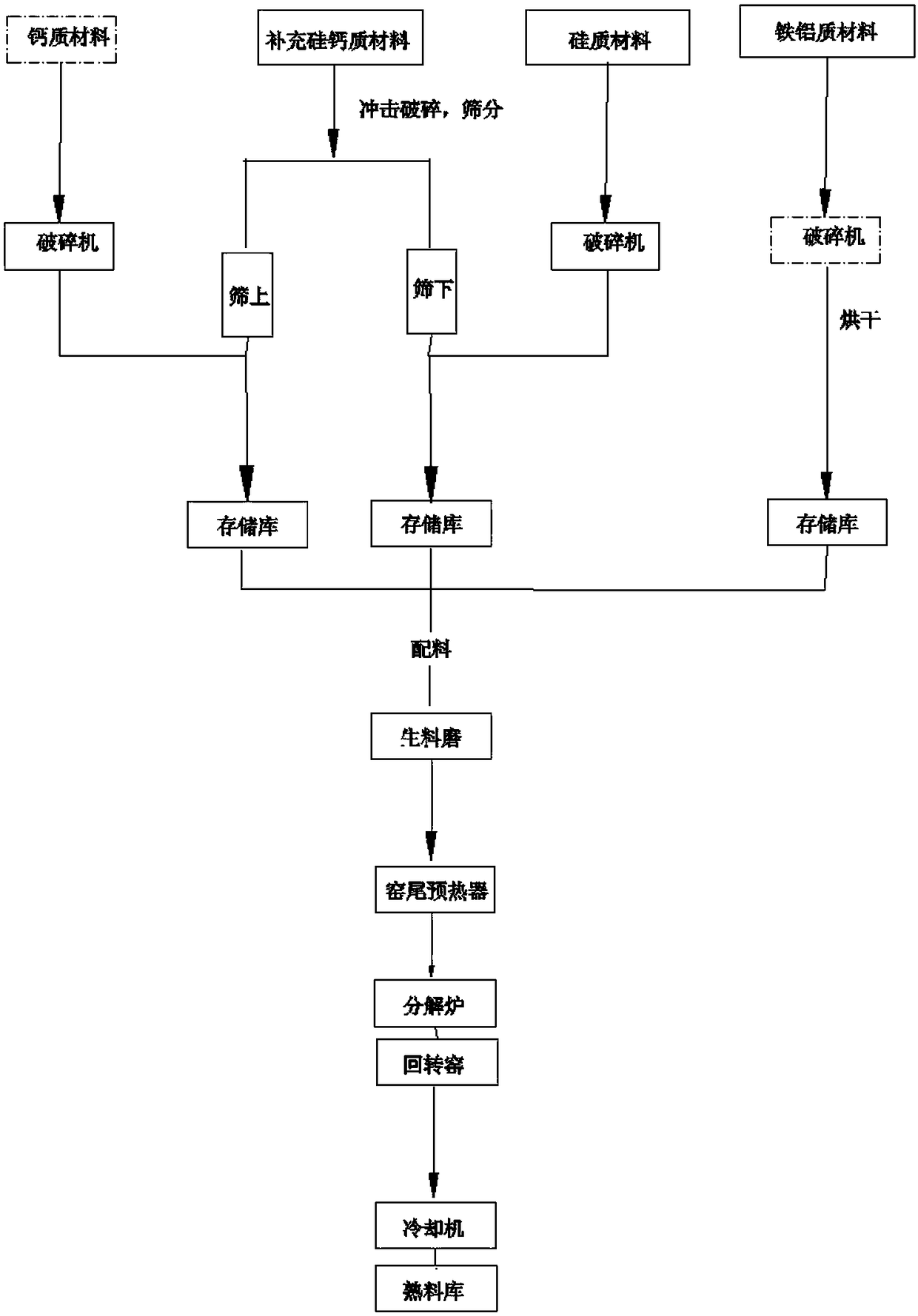

Method for producing belite-gypsum material by using sludge and waste gypsum through dry-process rotary kiln

The invention discloses a method for producing a belite-gypsum material by using sludge and waste gypsum through a dry-process rotary kiln. The method comprises the following steps of (1) melting a sludge ridge grain seed crystal with high water content into modified sludge residues; (2) proportioning raw materials of the modified sludge residues, the waste gypsum and a correcting material according to a certain ratio, and grinding the raw materials by using a vertical mill to form raw material powder; (3) delivering the raw material powder obtained in the step (2) into a dry-process rotary kiln system, and calcining the raw material powder to form clinker; and (4) grinding the obtained clinker to obtain powder with the fineness of 0.08mm and the screen residue content of less than 20%. The method disclosed by the invention is simple, low in investment and cost, free of other secondary pollution and capable of absorbing the sludge and the waste gypsum on a large scale and in a recycling way, greatly reducing the energy consumption and relieving the environment pollution.

Owner:长沙紫宸科技开发有限公司

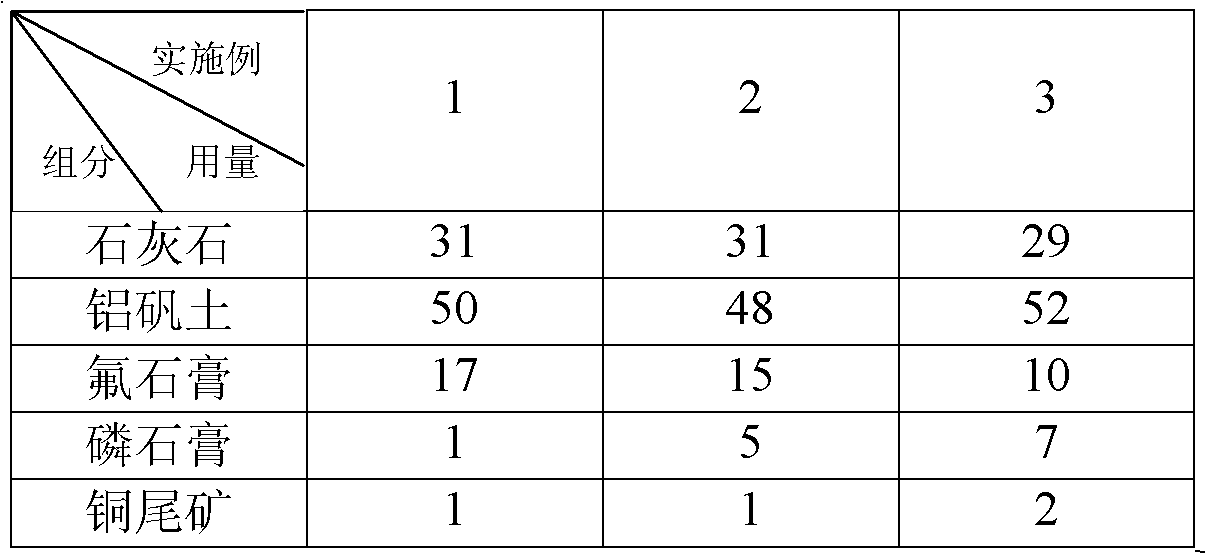

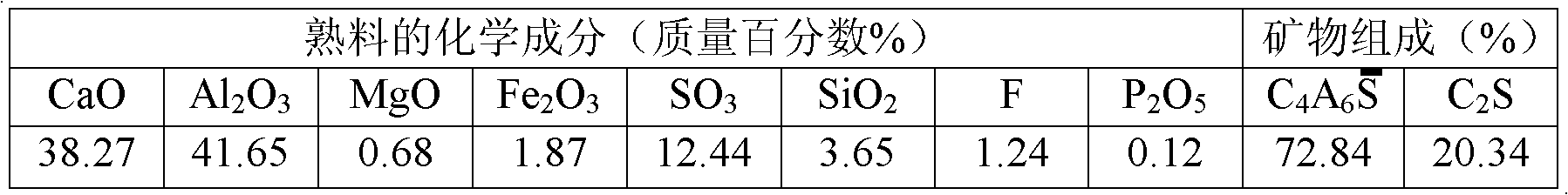

Method for preparing sulphoaluminate cement clinker with fluorgypsum, phosphogypsum and copper tailings

The invention belongs to the filed of building materials, and relates to a method for preparing sulphoaluminate cement clinker with fluorgypsum, phosphogypsum and copper tailings, which is characterized by comprising the following steps: uniformly mixing limestone, bauxite, fluorgypsum, phosphogypsum and copper tailings, grinding together and then obtaining the sulphoaluminate cement clinker by firing in a precalcining kiln system, wherein the sulphoaluminate cement clinker comprises the following raw materials by weight percent: 29-35% limestone, 45-55% of bauxite, 5-20% of fluorgypsum, 1-10% of phosphogypsum and 0.5-3% of copper tailings. The preparation method adopts industrial solid waste as a raw material, and has low cost, less environmental pollution, low burning temperature of the clinker, low energy consumption per unit of the clinker, and high strength of the obtained clinker.

Owner:WUHAN UNIV OF TECH

Method to prepare full-body tiles by iron tailings

InactiveCN101993236AImprove utilization efficiencyReduce manufacturing costSolid waste managementBrickRaw material

The invention relates to a method to prepare full-body tiles by iron tailings, which belongs to the field of comprehensive utilization of building materials and resources. The method is characterized in that during the preparation of full-body tiles, partial iron resources in iron tailings are recycled, iron contents in raw materials of the full-body tiles are reduced, and amount of the iron tailings used in the full-body tiles is increased and accounts for up to 98.4% of the raw materials of the full-body tiles; a composite dyeing formulation is formed by adding a certain amount of metallic oxide or substances containing metallic oxide used as dyeing assistants to metal in the iron tailings to prepare the full-body tiles with good performance, and the dyeing assistants are a certain amount of MnO2, Cr2O3, NiO and CuO or are raw mineral materials containing one or a plurality of Mn, Co, Ni and Cu. The invention achieves the double effect of increasing recycling rate of resources and producing high value added products, reduces dependence of ceramics production on high-quality raw mineral materials, needs no colorant, and reduces production cost of full-body tiles.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for producing belite-gypsum material by calcining sludge and waste gypsum through vertical kiln

The invention discloses a method for producing a belite-gypsum material by calcining sludge and waste gypsum through a vertical kiln. The method comprises the following steps of (1) melting a sludge ridge grain seed crystal with high water content into modified sludge residues; (2) carrying out two-stage proportioning on raw materials of the modified sludge residues, the waste gypsum and a correcting material according to a certain ratio, homogenizing, adding a proper proportion of fire coal in the proportioning and homogenizing processes, and molding grains or charging bars to obtain a black raw material molding material; (3) delivering the obtained black raw material molding material into the vertical kiln, and calcining the black raw material molding material at the temperature of 1250-1400 DEG C to form clinker; and (4) grinding the obtained clinker to obtain powder. The method disclosed by the invention is simple, low in investment and cost, free of other secondary pollution and capable of absorbing the sludge and the waste gypsum on a large scale and in a recycling way, greatly reducing the energy consumption and relieving the environment pollution.

Owner:长沙紫宸科技开发有限公司

Preparation method for cement clinker

InactiveCN104692679ASimple processing methodRaw materials are easy to obtainCement productionFly ashCalcination

The invention discloses a preparation method for cement clinker. The method comprises the following steps: (1) preparation of raw materials: a step of compounding residues obtained after extraction of aluminum from fly ash, limestone and iron ores according to a weight ratio of 65-85: 40-15: 1-3; (2) refinement of the raw materials: a step of placing the above-mentioned raw materials into a grinding machine for fine grinding; (3) homogenization of the raw materials: a step of homogenizing the ground raw materials; and (4) calcination of the raw materials: a step of calcining the homogenized raw materials so as to obtain the cement clinker. The preparation method for the cement clinker provided by the invention employs simple and easily-available raw materials, is simple, has low energy consumption and can be conveniently implemented and popularized.

Owner:青岛昊河水泥制品有限责任公司

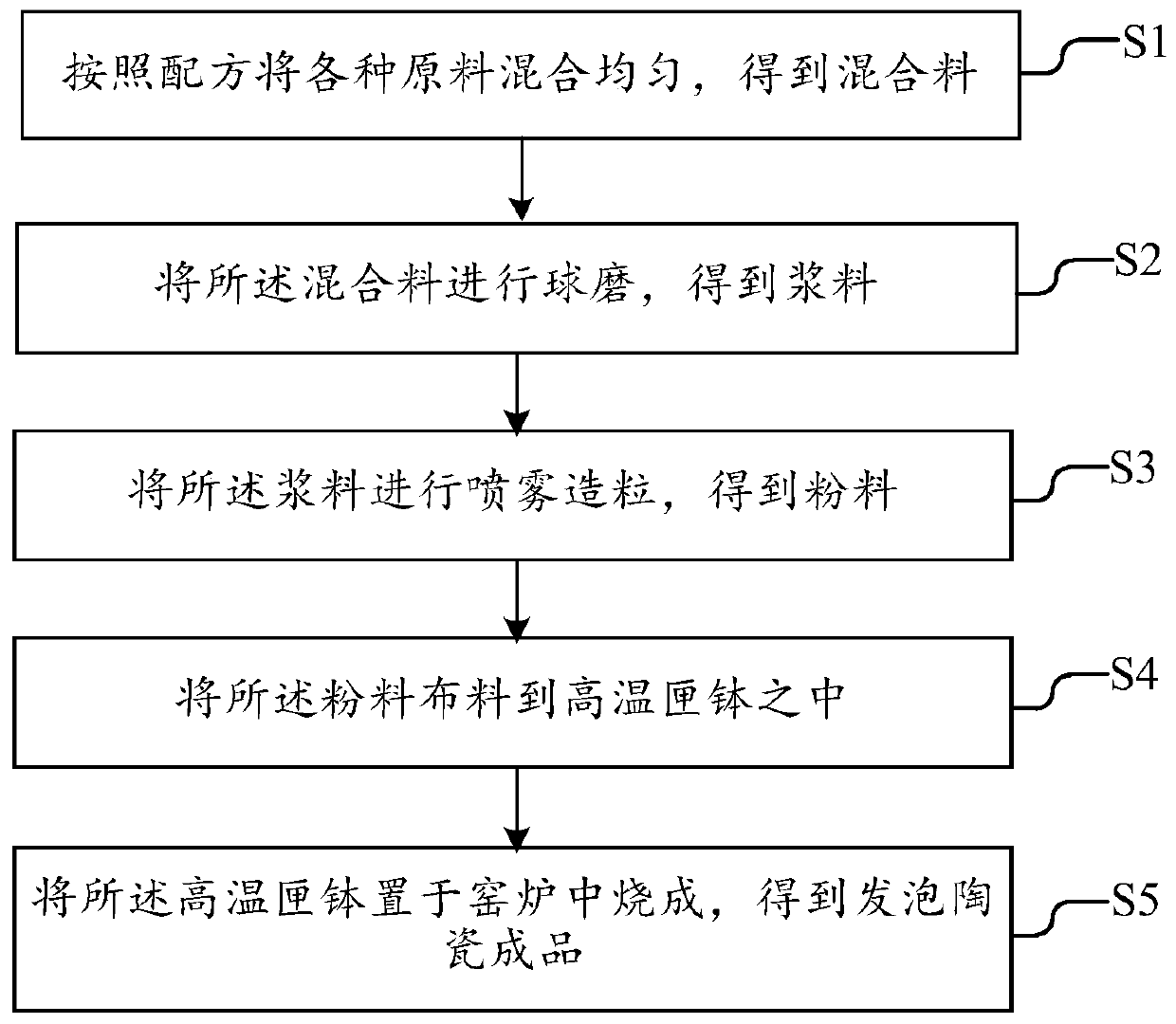

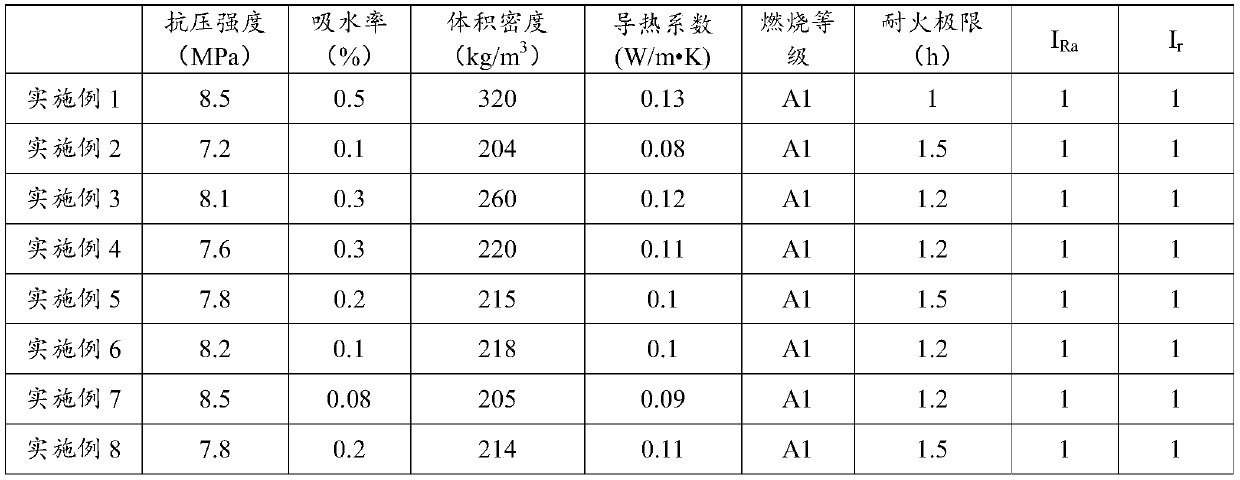

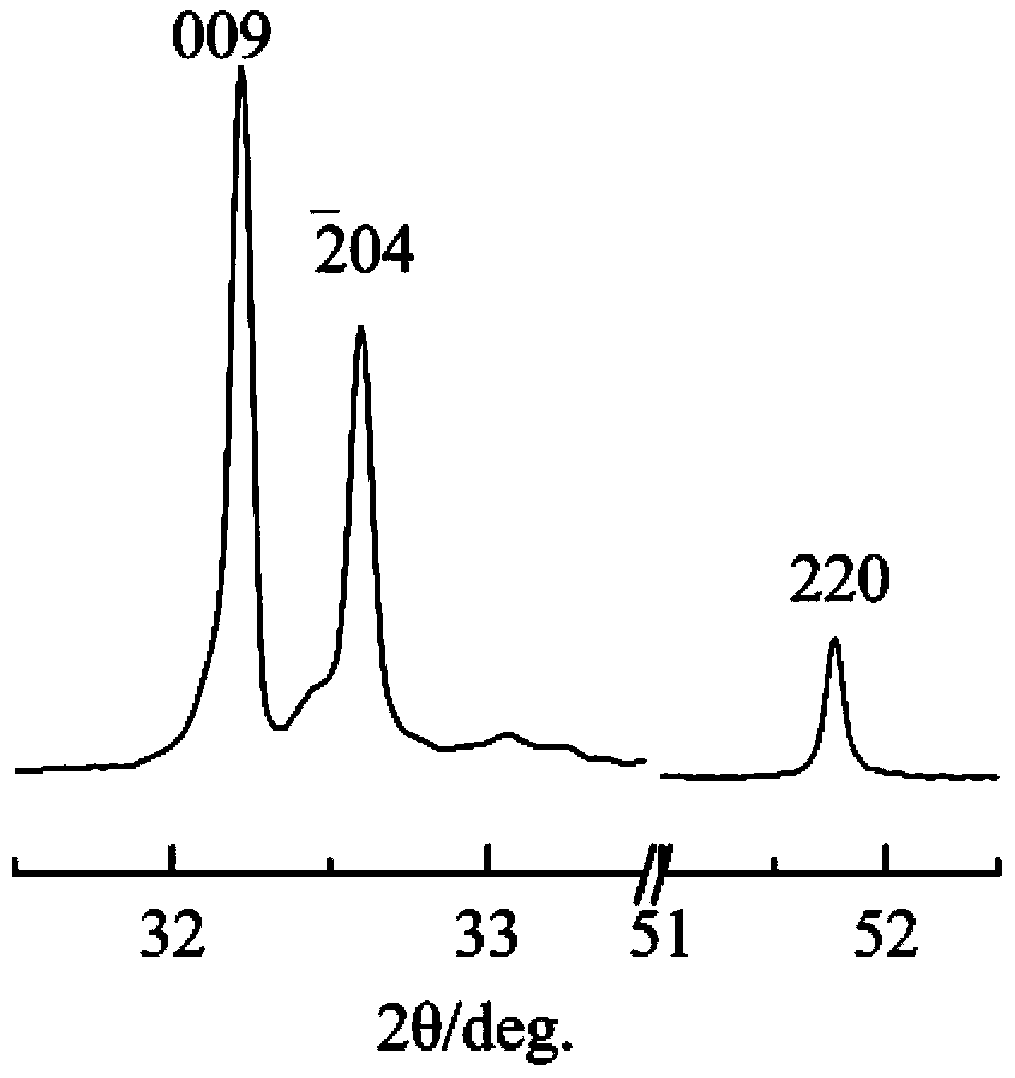

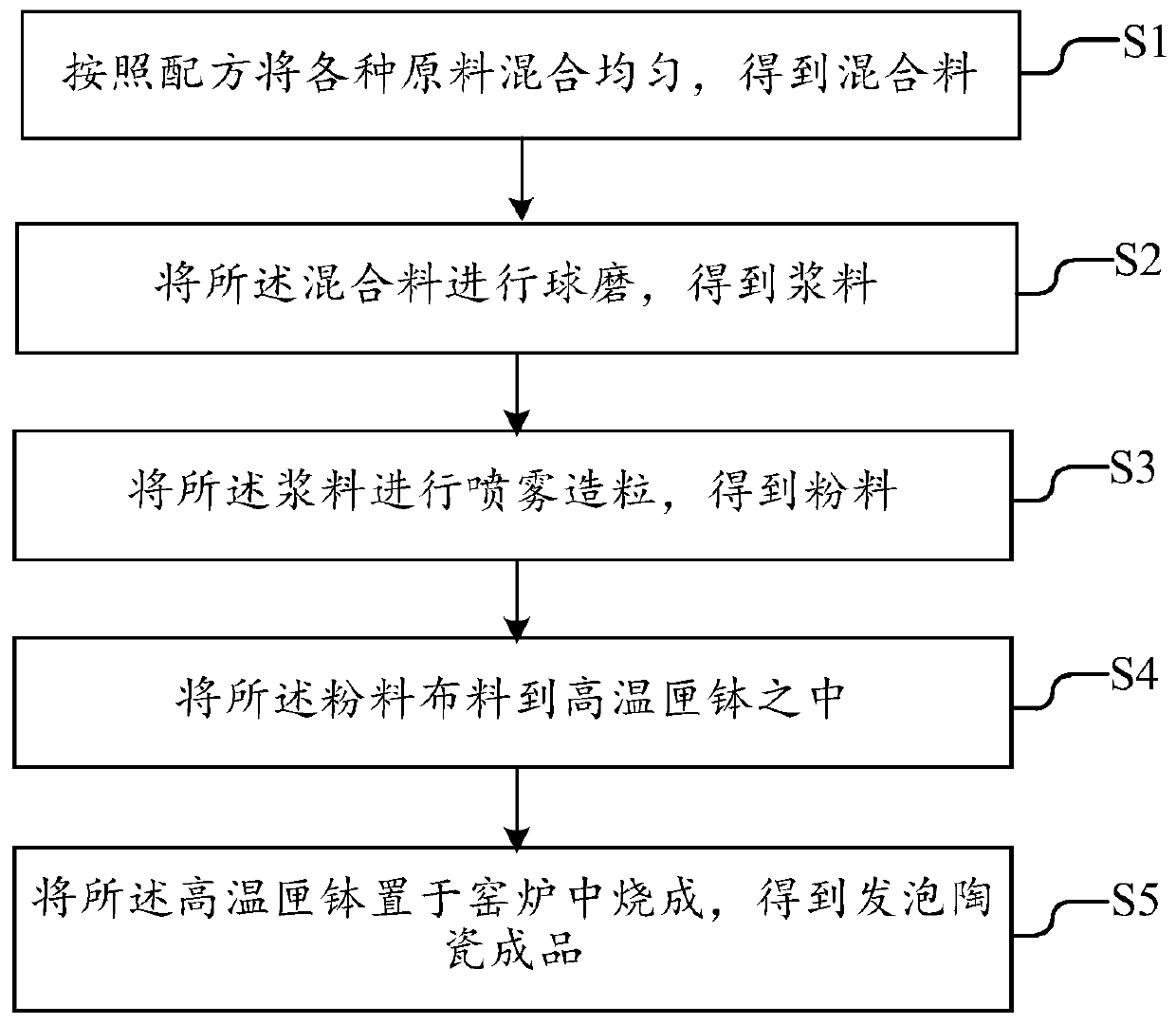

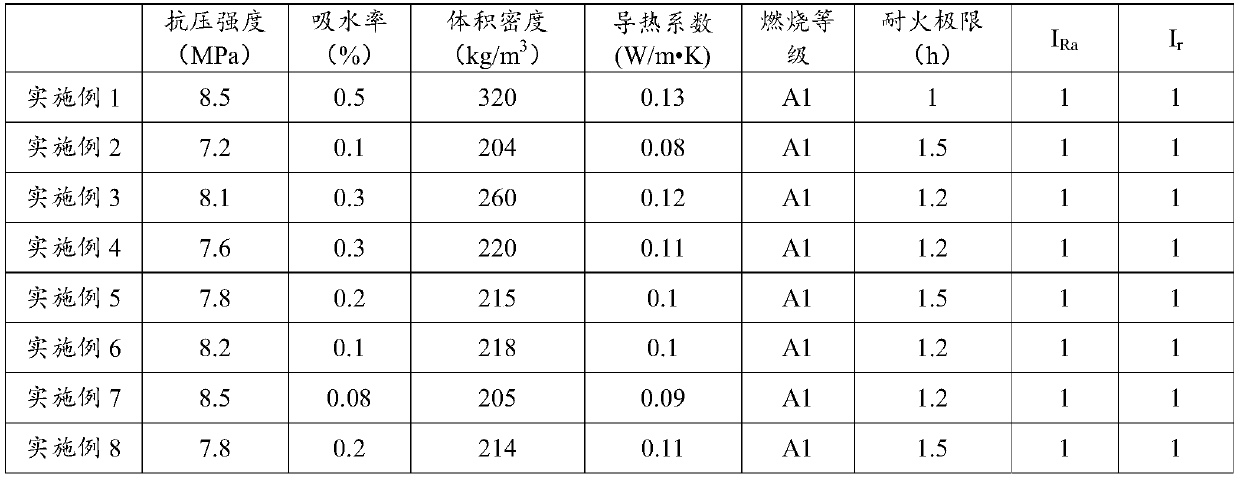

Foaming ceramic and preparation method thereof

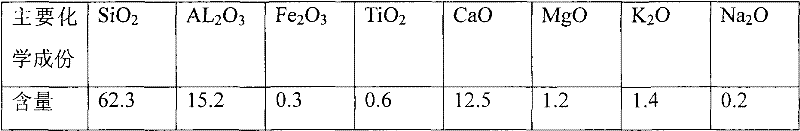

InactiveCN110590329ARealize resourcesHigh value-added utilizationCeramic materials productionCeramicwareFoaming agentResource utilization

The invention discloses a foaming ceramic. The foaming ceramic is mainly prepared from the following raw materials in parts by weight: 90-95 parts of a Luoyuan red tailing, 1-9 parts of clay, 0.1-3 parts of a foaming agent and 0.1-1 part of a stabilizer; wherein the Luoyuan red tailing is mainly prepared from the following components in percentage by weight: 68-73% of SiO2, 12-15% of Al2O3, 1.2-2%of Fe2O3, 0.5-1.5% of CaO, 0.2-0.5% of MgO, 4-5.5% of K2O, 3-5% of Na2O and 0.5-3% of LOI. The invention further discloses a preparation method of the foaming ceramic. According to the foaming ceramic and the preparation method thereof, the Luoyuan red tailing is adopted as a main base material to prepare a foaming ceramic tile, and the resource utilization of the Luoyuan red tailing is effectively realized; and the prepared foaming ceramic tile has high compressive strength, low water absorption rate and low thermal conductivity.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Process for producing coloured polished brick

The invention discloses a method for preparing a colored polishing brick, comprising the existing traditional method for producing a polishing brick; the invention is characterized in that the waste iron tailing material is used for replacing part of glaze and blank material of the original polishing brick and added in the blank material and plus material of the polishing brick; and then the invention is prepared through a common process. The proportion of waste iron tailing material to the glaze and the blank material is more than 20 to 45 percent. By adopting the method for preparing the colored polishing brick by using the waste iron tailings, the method has the advantages of reducing production dependence on mineral material resource with excellent quality, improving utilization rate of the resource, diminishing discharge of solid waste, and greatly reducing the production cost of ceramic products; the used tailing replaces not only the ceramic mineral material, but also pigments, so that pigments only experience one calcining and heating process of ceramic roasting from the mineral to color forming; at the same time, the roasting temperature of the ceramics is decreased and roasting energy consumption of the ceramics is greatly reduced.

Owner:钟旭东

A kind of preparation method of high-strength ceramic membrane support

The invention provides a method for preparing a high-strength ceramic membrane support body. The method is to fully mix ceramic mud with calcined bauxite and high plastic clay as main raw materials and plant pore-forming materials, and then vacuum extrude it into The green body of the ceramic membrane support body is quickly fired in a roller kiln after drying. The strength of the ceramic membrane support is provided by a highly densified multiphase ceramic material with corundum particles and in-situ-generated mullite whiskers as reinforcing phases, while the pore size and porosity are determined by a fibrous or sheet-like structure. The plant pore-forming material that is completely burned out at high temperature is regulated, so it has better pore connectivity characteristics, thereby obtaining a ceramic membrane support with high strength and a highly connected pore structure. The ceramic membrane support also has the characteristics of wide source of raw materials, low preparation cost and the like.

Owner:湖南科一环保科技股份有限公司

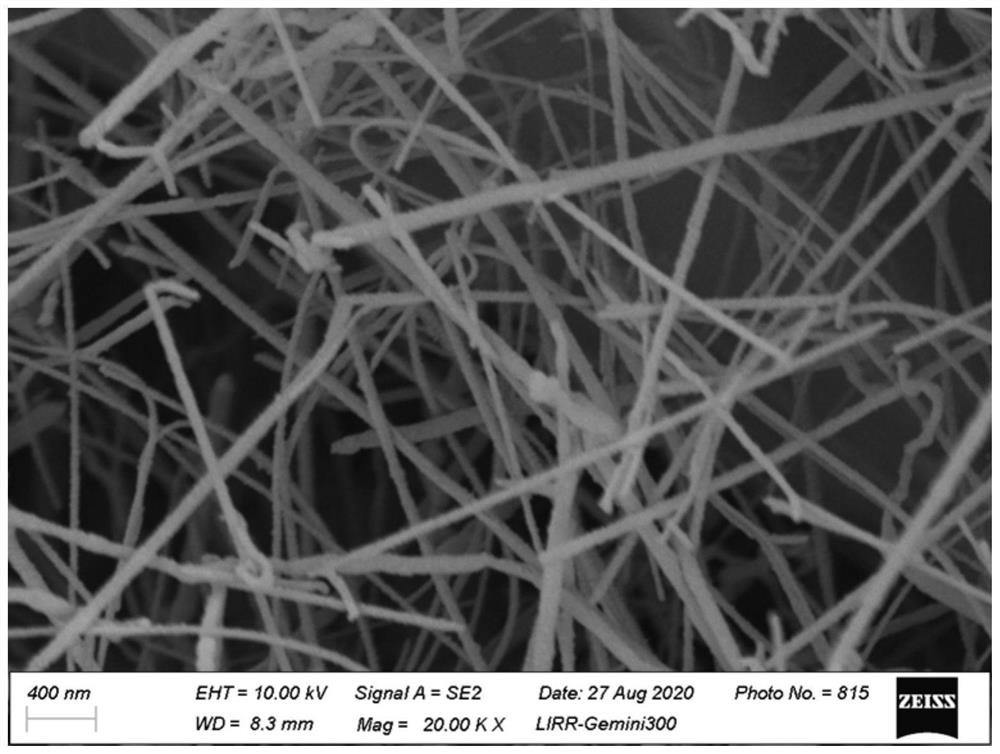

Low temperature high-performance silicon carbide film and preparation method thereof

InactiveCN109761612AReduce resistanceGood alkali resistanceSemi-permeable membranesCeramicwareRare earthNetwork structure

The invention relates to a low temperature high-performance silicon carbide film and a preparation method thereof. The preparation method comprises the steps that oxidation of silicon carbide powder in high temperature environment is utilized for generating silicon dioxide on the surfaces of particles, silicon dioxide reacts with added nanoscale alumina sol coating the surfaces of the silicon carbide particles to build a mullite network structure, the particle interface strength is enhanced, liquid phase generating temperature is lowered by utilizing existence of nanoscale rare earth oxide molecules, growth of mullite seed crystals is inhibited, so that the aggregate molecular grain size in the film is even, and accordingly the resistance of the film is reduced. The atmosphere does not need to be controlled in the burning process of the silicon carbide film layer, and the oxidation degree of silicon carbide is adjusted through the burning temperature and the adding proportion of alumina sol. The whole preparation technology is simple and controllable, the burning temperature of the film is greatly lowered compared with that of an existing silicon carbide film, burning energy consumption is correspondingly remarkably reduced, and the preparation cost is saved greatly.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Light-weight and high-strength wallboard having decorative surface sintered at one time and production method thereof

InactiveCN109384455AHigh bonding strengthReduce burning energy consumptionCeramic materials productionCeramicwareFiberUltimate tensile strength

The invention discloses a light-weight and high-strength wallboard having a decorative surface sintered at one time, and specifically belongs to the technical field of preparation of an interior partition wall, an exterior wallboard and a heat-insulating decorative panel of a building. A foamable base layer is prepared from the following raw materials in percentage by mass: 35% of iron tailings of200 meshes, 45% of perlite tailings of 200 meshes, 19% of kaolin of 200 meshes and 1% of silicon carbide of 800 meshes; glass phase powder contains the following raw materials in percentage by mass:10% of iron tailings of 200 meshes, 30% of pearl rock tailings of 200 meshes, 10% of kaolin of 200 meshes, 48% of waste glass of 200 meshes and 2% of manganese dioxide of 200 meshes. A blank-foamablebase layer is pressed by using a press; a layer of the glass phase powder is printed on the base layer or the glass phase powder is easily produced on dry powder cloth; ceramic fiber paper is used forcovering; pressing is performed for the second time; the surface of the fiber paper is used to protect the glass layer; one-time sintering is directly performed without a kiln. The method is high inglass layer and foaming layer combination strength.

Owner:辽宁罕王环保科技有限公司

Method for manufacturing polishing brick by utilizing calcium silicate slag

The invention relates to a method for manufacturing a polishing brick by utilizing calcium silicate slag, belonging to the technical field of ceramic manufacture. The polishing brick comprises the following raw materials in percentage by weight: 5%-30% of calcium silicate slag, 10%-30% of pug, 30%-65% of high-temperature sands, 5%-10% of intermediate-temperate sands and 0%-5% of steatites. The calcium silicate slag as raw materials is used in a blank of the polishing brick, thereby the shortage crisis of raw mineral materials is weakened and the discharge of the calcium silicate slag is reduced and then an energy-saving type polishing brick product is produced; the production energy consumption of the polishing brick can be reduced and utilization efficiency of resources is enhanced because the firing temperature of a blank body is reduced through calcium silicate contained in the calcium silicate slag; the invention not only reduces the pollution, but also increases a new member for the polishing bricks; and in addition, the novel polishing brick prepared by using the method has various properties which all accord with or surpass the national standard.

Owner:ORDOS CITY TAOERSI CERAMIC

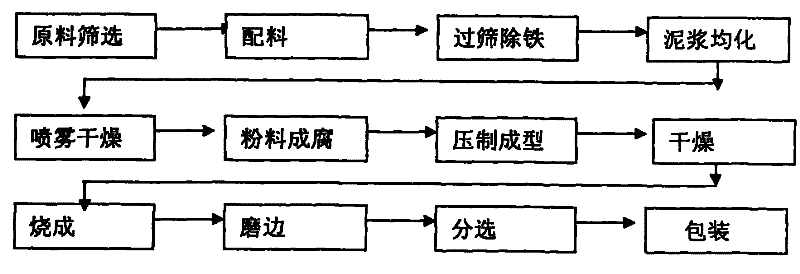

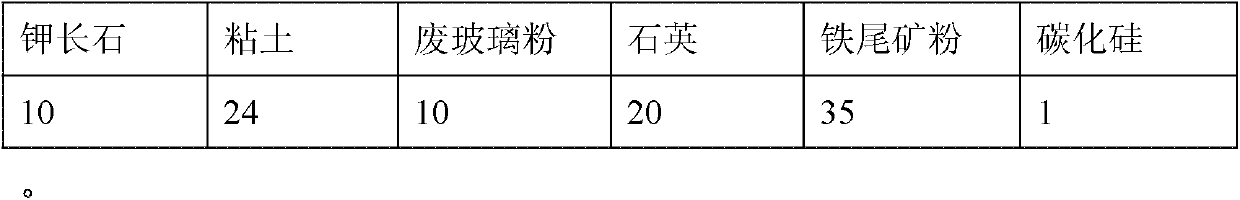

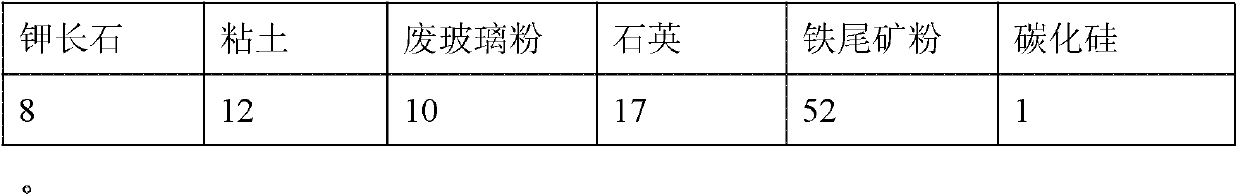

Method for preparing environment-friendly water permeable bricks by using iron tailings

The invention discloses a method for preparing environment-friendly water permeable bricks by using iron tailings, belonging to the field of comprehensive utilization of iron tailing resources and construction ceramic materials. The method is characterized in that through taking iron tailings as basic aggregates and introducing a certain amount of waste broken glass, an environment-friendly water permeable brick with excellent performance is prepared. The method comprises the following process steps of raw material crushing, ball milling, material dispensing, mixing, drying, molding, sintering, cutting and grinding. The dispensed material comprises the following ingredients in percentage by weight: 30-60% of iron tailings powder, 5-15% waste glass powder, 15-30% of clay, 15-24% of quartz, 5-15% of potash feldspar, and 0.25-1.5% of silicon carbide. The prepared water permeable brick is high in compressive strength, good in abrasion resistance and excellent in water permeability, and accords with national related standards of water permeable bricks, therefore, the method creates a new way for the high-technology and high value-added application of iron tailing resources.

Owner:UNIV OF SCI & TECH BEIJING +2

Preparation process for silicate cement clinker

ActiveCN109437617AReduce burning energy consumptionLow costCement productionSilicate CementCement manufacturing

The invention discloses a preparation process for silicate cement clinker, and relates to the technical field of cement manufacturing. According to the invention, limestone moulding sand waste is applied to calcination of clinker to the greatest extent by adopting a limestone moulding sand waste harmful component stripping method, and limestone moulding sand waste partly or completely replace limestone. According to the invention, the limestone moulding sand waste is applied to the calcination of the cement clinker, so that cost of enterprises can be reduced, and waste is changed into things of value, and therefore, great social benefits and economic benefits are achieved for society and the enterprises.

Owner:EMEISHAN QIANGHUA SPECIAL CEMENT

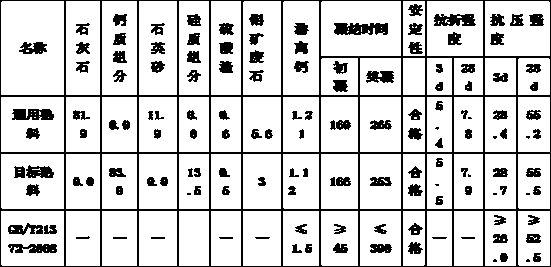

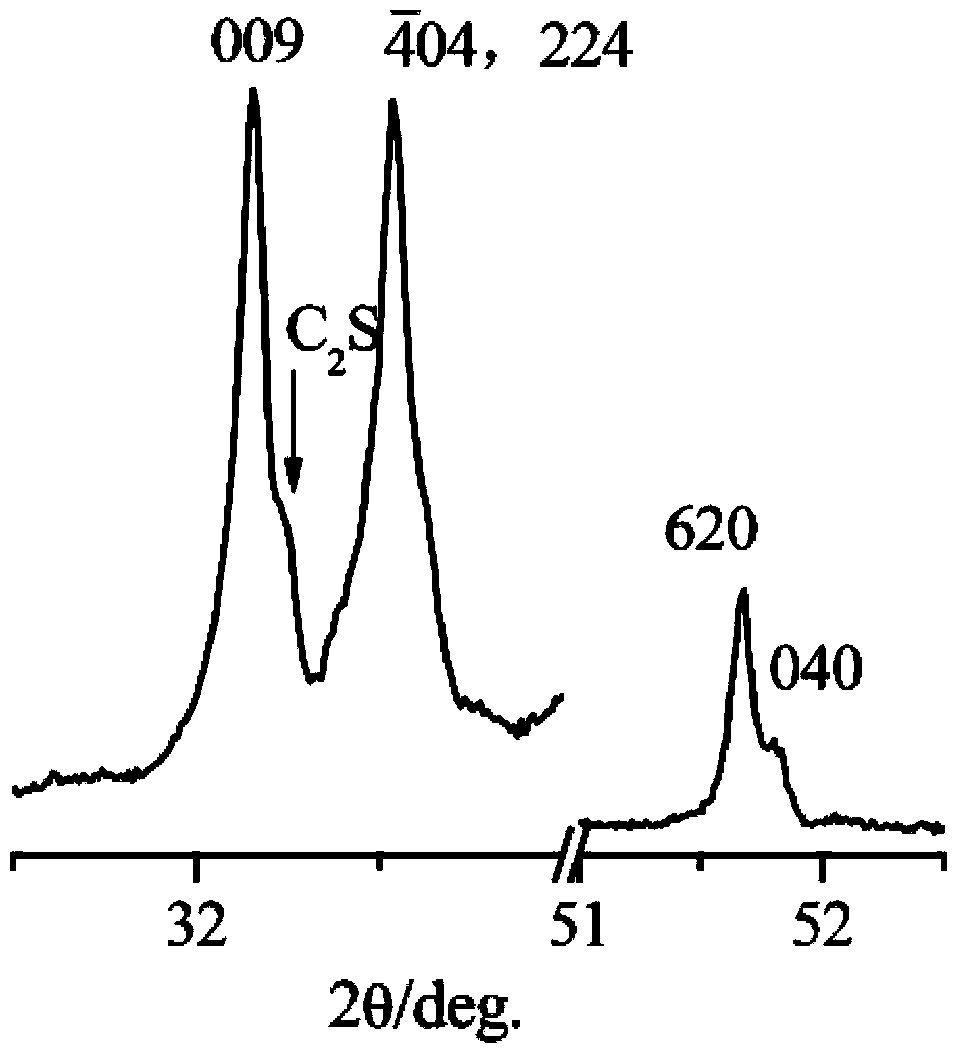

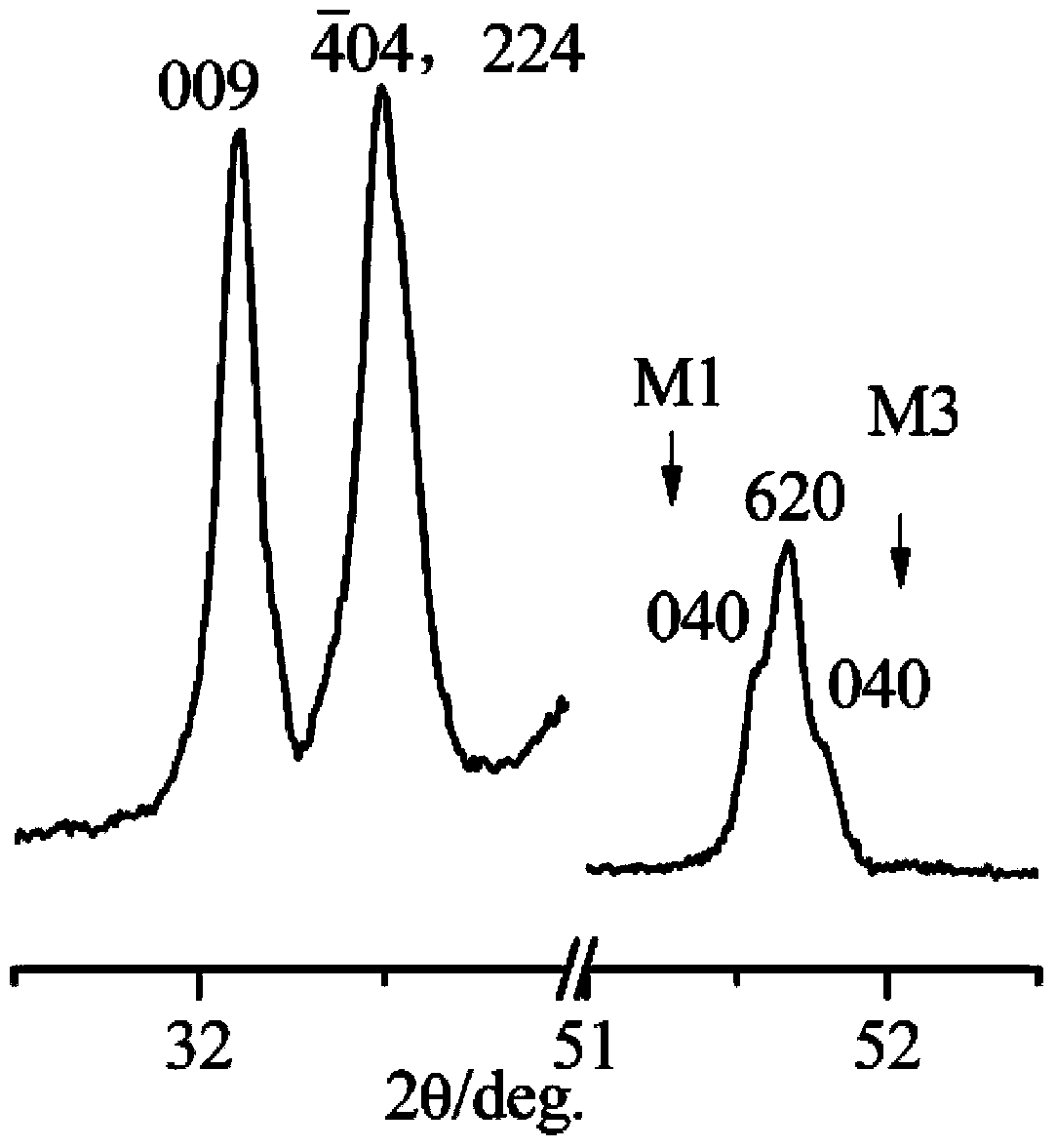

Beta-SiC combined SiC refractory material with low binding phase content as well as preparation method and product thereof

ActiveCN114853489ALow content of binding phaseHigh puritySolid waste managementNanowireMaterials science

The invention discloses a beta-SiC combined SiC refractory material with low binding phase content as well as a preparation method and a product thereof, and belongs to the technical field of refractory materials. The beta-SiC combined SiC refractory material with the low binding phase content comprises a binding phase and a principal crystalline phase, the binding phase is beta-SiC, and the mass percentage of the binding phase is 3%-7%; the main crystal phase is alpha-SiC, and the mass percentage of the main crystal phase is 92%-95%; and the beta-SiC binding phase covers the surface of the main crystal phase in a nanowire form. The liquid-state high-viscosity organic matter adopted by the invention is a carbon source and a binder, and the formability of the pug and the ignition loss in the sintering process can be ensured by adjusting the addition amount and the residual carbon rate of the liquid-state high-viscosity organic matter, so that the density of a finished product is ensured. The beta-SiC combined SiC refractory material disclosed by the invention is low in binding phase content, the purity of silicon carbide can reach 96% or above, the preparation method is simple, the sintering process is carried out in a low-temperature, micro-pressure and oxygen-free atmosphere, the environment pollution is avoided, and the sintering energy consumption is low.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

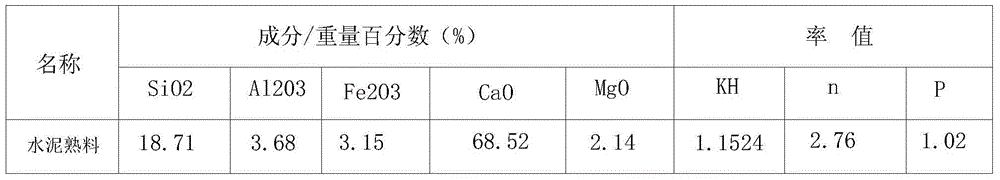

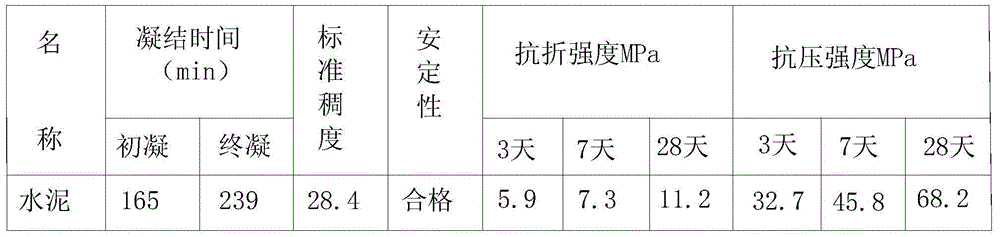

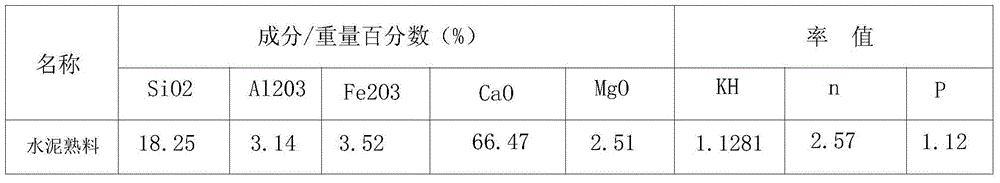

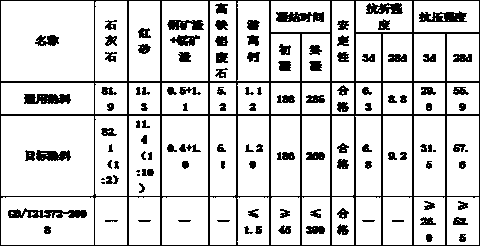

Portland cement clinker and preparation method thereof

The invention discloses a Portland cement clinker which contains trace magnesium and trace phosphorus, and R type Alite accounting for 52wt%-65wt%. The invention also discloses a preparation method of the Portland cement clinker; the preparation method comprises the following steps: step 1, selecting raw material components according to the composition of the desired cement clinker and determining the weight proportion of each raw material component, wherein the raw material components include at least one magnesium raw material and at least one phosphorus raw material; step 2, thoroughly mixing the raw material components, and then performing high-temperature calcination on the mixture, and then quickly cooling to a room temperature, thereby obtaining the cement clinker; in the cement clinker, the weight percentage of the phosphorus content in terms of the oxide P2O5 is 0.5%-1.2%, while the weight percentage of the magnesium in terms of the oxide MgO is 1%-5%. The Portland cement clinker prepared by the preparation method contains R type tricalcium silicate, and the compressive strength of the clinker can be greatly improved in contrast with the clinker prepared by use of other methods.

Owner:CHINA BUILDING MATERIALS ACAD

Method for producing belite-gypsum material from roasted sludge and waste gypsum of furnace in fluid bed

The invention discloses a method for producing a belite-gypsum material from roasted sludge and waste gypsum of a furnace in fluid bed. The method comprises the following steps: (1) transforming high water-content sludge ridge grain seeds into modified sludge residues; (2) carrying out raw material compounding and homogenizing on the modified sludge residues obtained in the step (1) with waste gypsum, waste rock ballasts and a corrective material; (3) drying the raw material mixture obtained in the step (2) by virtue of hot exhaust air of the furnace in fluid bed, and carrying out flue gas desulfuration and sulfur fixation; (4) mixing the raw material mixture dried in the step (3) with a proper amount of fire coal, adding to the furnace in fluid bed and roasting into a clinker; and (5) grinding the clinker obtained in the step (4) to obtain powder, namely the belite-gypsum material, or taking the clinker obtained in the step (4) as the belite-gypsum material. The method is simple in process, low in control requirements, and low in grinding energy consumption and firing energy consumption; bulk waste residues such as sludge and industrial waste gypsum can be largely and widely dissolved; and the prepared belite-gypsum material is wide in application.

Owner:长沙紫宸科技开发有限公司

Foam ceramic and preparation method thereof

InactiveCN110590328ARealize resourcesHigh value-added utilizationCeramic materials productionCeramicwareFoaming agentResource utilization

The invention discloses a foam ceramic. The foam ceramic is mainly prepared from the following raw materials in parts by weight: 90-95 parts of Bainbrook brown tailings, 1-9 parts of clay, 0.1-3 partsof a foaming agent and 0.1-1 part of a stabilizer. The Bainbrook brown tailings is mainly prepared from the following components in percentage by weight: 68-73% of SiO2, 12-15% of Al2O3, 1.2-2% of Fe2O3, 0.5-1.5% of CaO, 0.2-0.5% of MgO, 4-5.5% of K2O, 3-5% of Na2O and 0.5-3% of LOI. The invention further discloses a preparation method of the foam ceramic. According to the foam ceramic and the preparation method of the foam ceramic, the Bainbrook brown tailings is used as a main base material to prepare foam ceramic tiles, and the resource utilization of the Bainbrook brown tailings is effectively realized; and the prepared foam ceramic tiles have high compressive strength, low water absorption and low heat conductivity coefficient.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Silicon carbide high-temperature ceramic filter pipe and preparation method thereof

ActiveCN101920142BHigh strengthHigh bonding strengthDispersed particle filtrationFiltration separationCold airThermal insulation

The invention relates to a silicon carbide high-temperature ceramic filter pipe and a preparation method thereof, the silicon carbide high-temperature ceramic filter pipe is used for filtering and dedusting of high-temperature gas, the length of the silicon carbide high-temperature ceramic filter pipe is 1500-3000mm, the average pore diameter is 40-120 mu m, the porosity is 30-60%, the compressive strength is 50-80MPa, and the silicon carbide high-temperature ceramic filter pipe further has the thermal shock resistance of 1000 DEG C-20 DEG C, no cracking when being impacted by cold air for 10times, large product size, uniform density, high strength, good thermal stability and good air permeability. The preparation method sequentially comprises the steps of preparing materials, molding and firing, and is characterized in that the molding adopts the isostatic pressing molding, the molding pressure is controlled to be 40-150 Mpa, the firing temperature is controlled to be 1250-1450 DEG C, the thermal insulation time is 2-3h, and the preparation method is scientific, reasonable, simple and easy to operate, and can ensure the product performances.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com