Method to prepare full-body tiles by iron tailings

A full-body brick and iron tailings technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of consuming high-quality mineral resources, low amount of tailings, consuming a lot of energy, etc. Improve mine safety factor, significant economic and social benefits, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

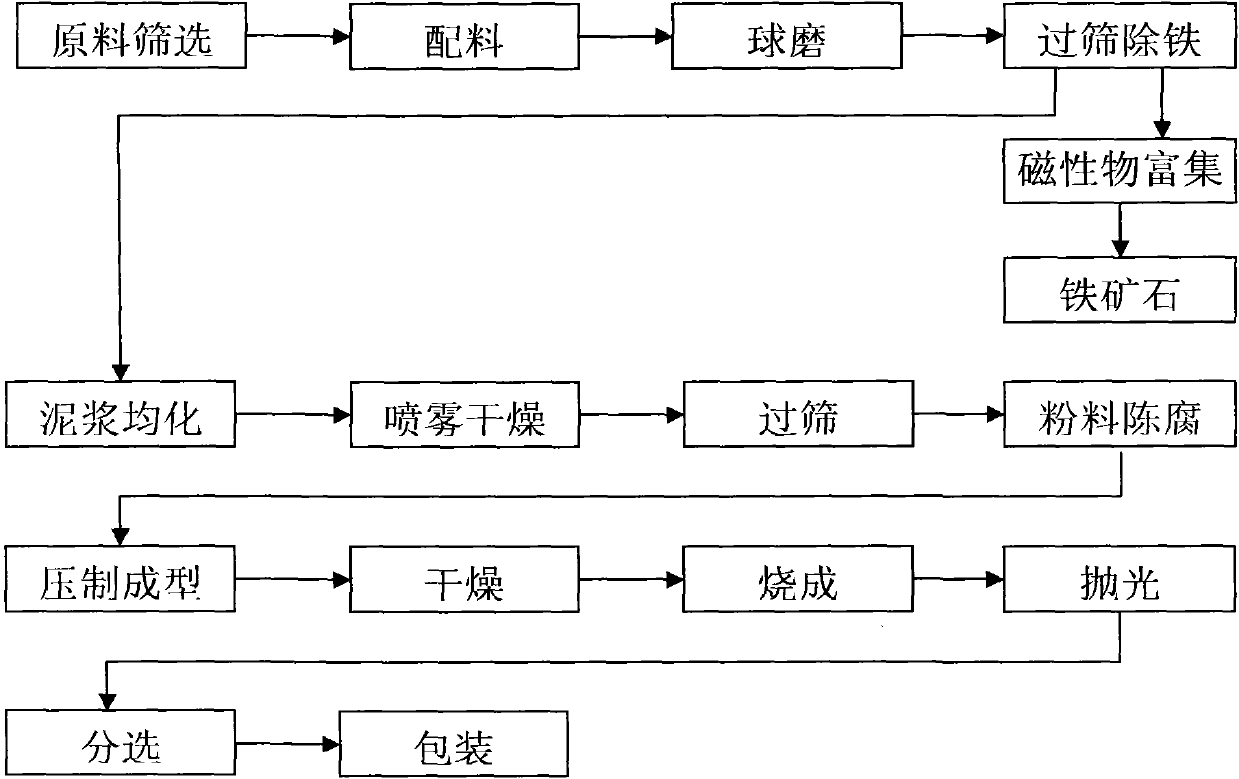

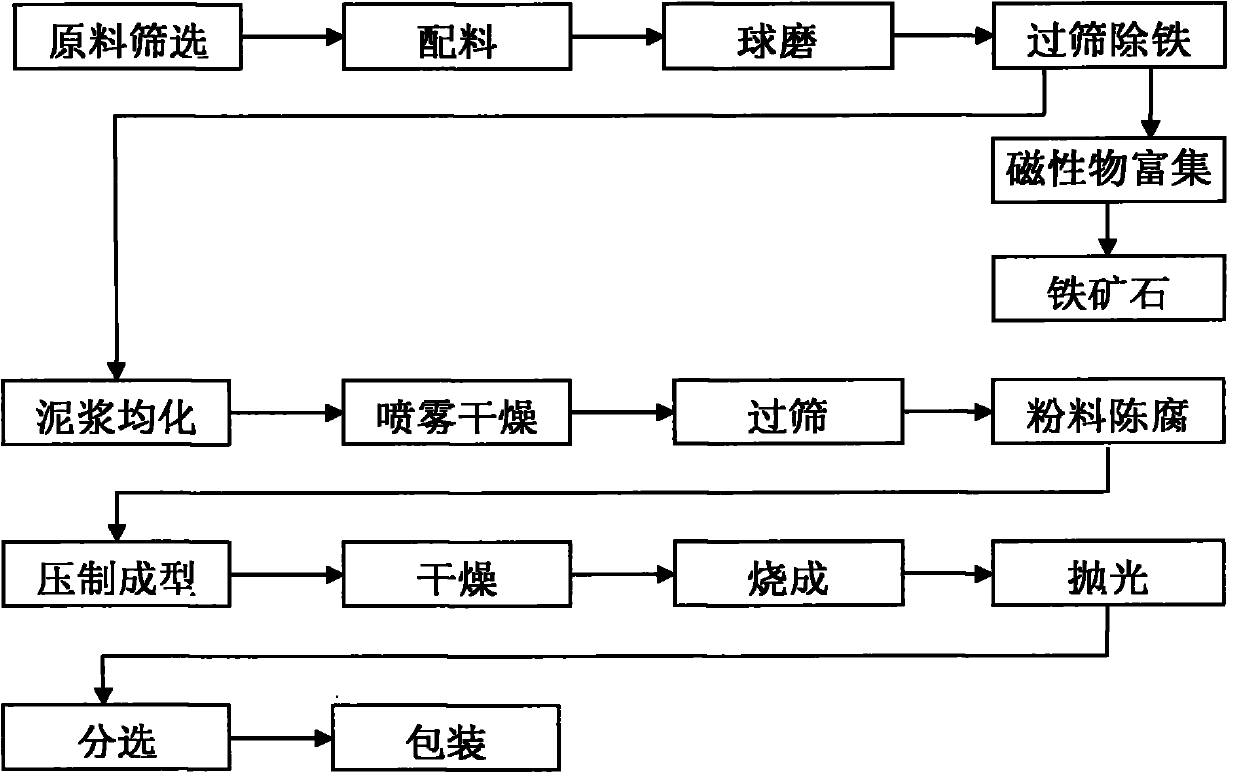

[0028] as per figure 1 As shown in the technological process, the weight ratio of ingredients is 98.4% of iron tailings, MnO 2 1.6%, after a series of processes such as ball milling, sieving to remove iron, magnetic material enrichment, mud homogenization, spray drying, sieving, powder aging, pressing and drying, it can be made at 1180°C for ten minutes The black full-body brick product has been tested and found to have a water absorption rate of 0.30% and a modulus of rupture of 55MPa.

Embodiment 2

[0030] as per figure 1 As shown in the technological process, the weight ratio of ingredients is 98.4% of iron tailings, MnO 2 0.8%, Cr 2 o 3 0.8%, after a series of processes such as ball milling, sieving to remove iron, magnetic material enrichment, mud homogenization, spray drying, sieving, powder aging, pressing and drying, it can be made at 1180°C for ten minutes The black full-body brick product has been tested and found to have a water absorption rate of 0.42% and a modulus of rupture of 58MPa.

Embodiment 3

[0032] as per figure 1 The process flow shown, the weight ratio of ingredients is iron tailings 96.48%, CuO1.22%, Cr 2 o 3 1.73%, NiO0.57%, after a series of processes such as ball milling, sieving to remove iron, magnetic material enrichment, mud homogenization, spray drying, sieving, powder aging, pressing and drying, etc., heat preservation at 1180 ° C for ten years It can be made into a black full-body brick product in minutes. After testing, the product has a water absorption rate of 0.21% and a modulus of rupture of 51MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com