Preparation method for cement clinker

A cement clinker and raw material technology, applied in cement production, etc., can solve the problems that affect the economic benefits of extracting alumina from fly ash, cannot be used, and the secondary pollution of the environment, so as to realize resource utilization, facilitate implementation and promotion, The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The main component obtained after the extraction of alumina by fly ash soda lime sintering method is the residue of silicon calcium, and the above residue is processed through the dealkalization process to obtain the aluminum extraction residue of fly ash. The steps of the dealkalization process are as follows : (1), adding water to the aluminum extraction residue and stirring to obtain the aluminum extraction residue slurry; (2), under the condition of stirring, slowly adding calcium carbide slag to the aluminum extraction residue slurry to carry out dealkalization reaction; (3), mixing The aluminum extraction residue slurry after the dealkalization reaction is filtered and washed. The alkali content of the fly ash aluminum extraction residue obtained after the above process is below 0.6%, and its main chemical components are CaO and SiO 2 , the main phase of fly ash aluminum extraction residue is C 2 S, accounts for 72%-78% of the total weight of the al...

Embodiment 2

[0037] Embodiment 2: Different from Embodiment 1, the raw materials used in this embodiment include 75 parts by weight of fly ash aluminum extraction residue, 20 parts by weight of limestone, and 2 parts of iron ore are mixed and homogenized, and the homogenized raw materials Take a small amount for particle size test, pass through a 100-mesh sieve, and 7.3% remains after sieving, which meets the particle size requirements of raw materials. The homogenized raw materials are sent to a rotary kiln for high-temperature calcination at a temperature of 1300°C, and cement clinker is obtained after cooling.

[0038] The aluminum extraction residue from fly ash includes components in the following weight ratios: CaO: 53.10, SiO 2 : 21.40, Al 2 o 3 : 4.12, Fe 2 o 3 : 1.83, MgO: 2.16, Na 2 O+0.66K 2 O: 0.48, water <30, loss on ignition: 8.21.

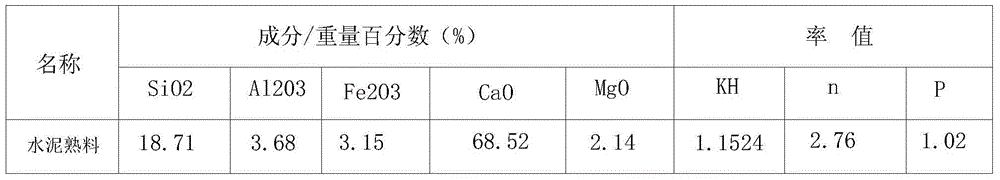

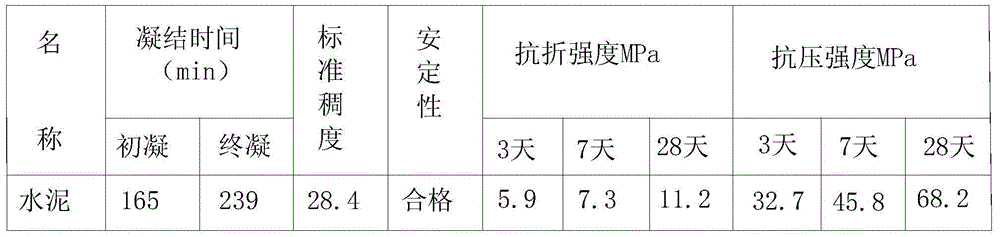

[0039] The chemical composition and rate of the cement clinker prepared in this example are shown in Table 3, and the physical and mechan...

Embodiment 3

[0044] Embodiment 3: Different from the above two embodiments, the raw materials used in this embodiment include 80 parts by weight of fly ash aluminum extraction residue, 17 parts by weight of limestone, and 1.3 parts of iron ore mixed and homogenized. Take a small amount of the raw material for particle size test, pass through a 110-mesh sieve, and the remaining 7.1% of the sieve meets the particle size requirements of the raw material. The homogenized raw materials are sent to a rotary kiln for high-temperature calcination at a temperature of 1300°C, and cement clinker is obtained after cooling.

[0045] The aluminum extraction residue from fly ash includes components in the following weight ratios: CaO: 54.70, SiO 2 : 23.60, Al 2 o 3 : 3.87, Fe 2 o 3 : 2.12, MgO: 2.54, Na 2 O+0.66K 2 O: 0.57, water <30, loss on ignition: 8.32.

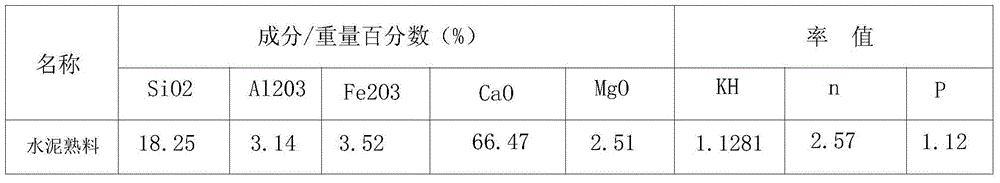

[0046] The chemical composition and ratio of the cement clinker prepared in this example are shown in Table 5, and the physical and mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com