Method for preparing sulphoaluminate cement clinker with fluorgypsum, phosphogypsum and copper tailings

A technology of sulphoaluminate cement and copper tailings, which is applied in the field of building materials, can solve problems such as land occupation and environmental pollution, and achieve the effects of small fineness, increased solid-phase reaction speed, and low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

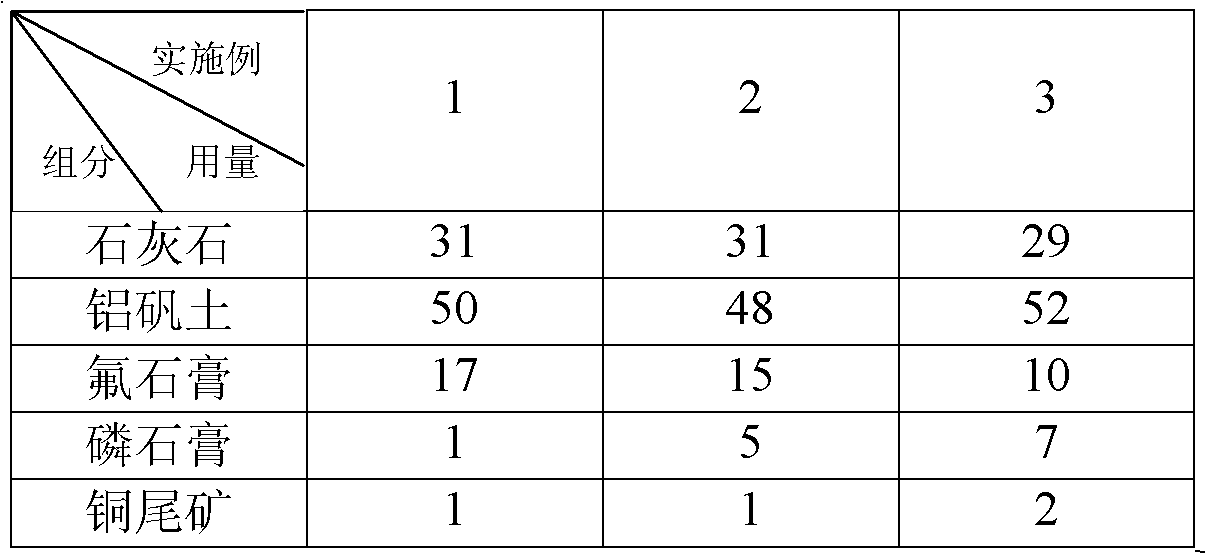

[0019] A method for preparing sulphoaluminate cement clinker by utilizing fluorogypsum, phosphogypsum and copper tailings, the specific steps are: replacing ordinary natural gypsum with industrial solid waste fluorogypsum and phosphogypsum, and adding an appropriate amount of copper tailings, Mix evenly with limestone, bauxite again and grind, under the new dry process cement system, be fired into sulphoaluminate cement clinker by precalcining kiln system at lower temperature (embodiment 1, the firing of 2 and 3 The forming temperatures are about 1260°C, about 1280°C and about 1320°C, respectively), and the mass percentages of each raw material are shown in Table 1.

[0020] The fluorine gypsum used above is a by-product of hydrogen fluoride production with sulfuric acid and fluorspar, its main component is calcium sulfate dihydrate, and its chemical components are calculated by mass percentage: CaO: 33-39%, SO 3 : 40~51%, SiO 2 : 0.62~4.1%, F: 2.7~6.8%, other chemical compon...

Embodiment 1

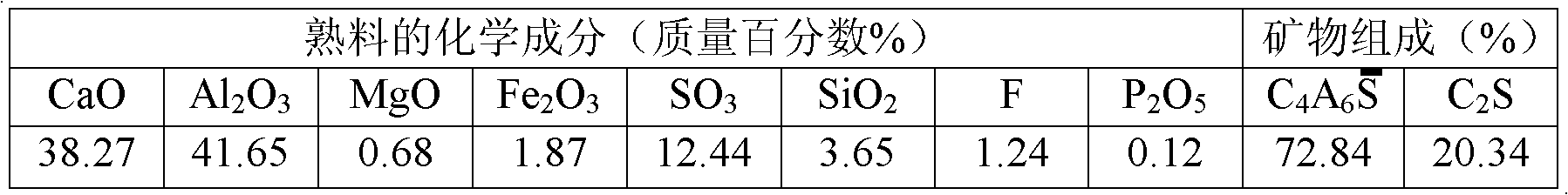

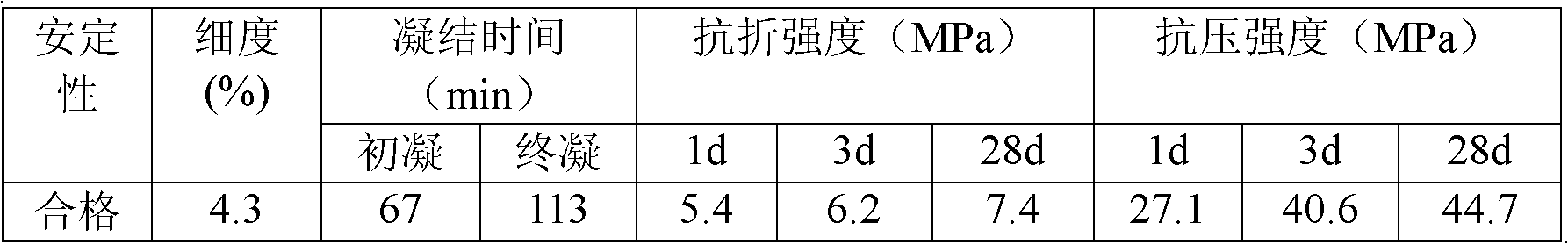

[0021] Embodiment 1: See Table 1 for the mass percentages of each raw material. The prepared sulphoaluminate cement clinker product: its chemical composition and mineral composition are shown in Table 2, and its physical and mechanical properties are shown in Table 3.

Embodiment 2

[0022] Embodiment 2: See Table 1 for the mass percentages of each raw material. The prepared sulphoaluminate cement clinker product: its chemical composition and mineral composition are shown in Table 4, and its physical and mechanical properties are shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com