Method for producing color blank glaze archaizing brick by using iron mine tailing

A technology of antique bricks and iron tailings, applied in the field of ceramic manufacturing, can solve the problems of resource waste and environmental pollution, and achieve the effects of reducing emissions, reducing energy consumption and pollution, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

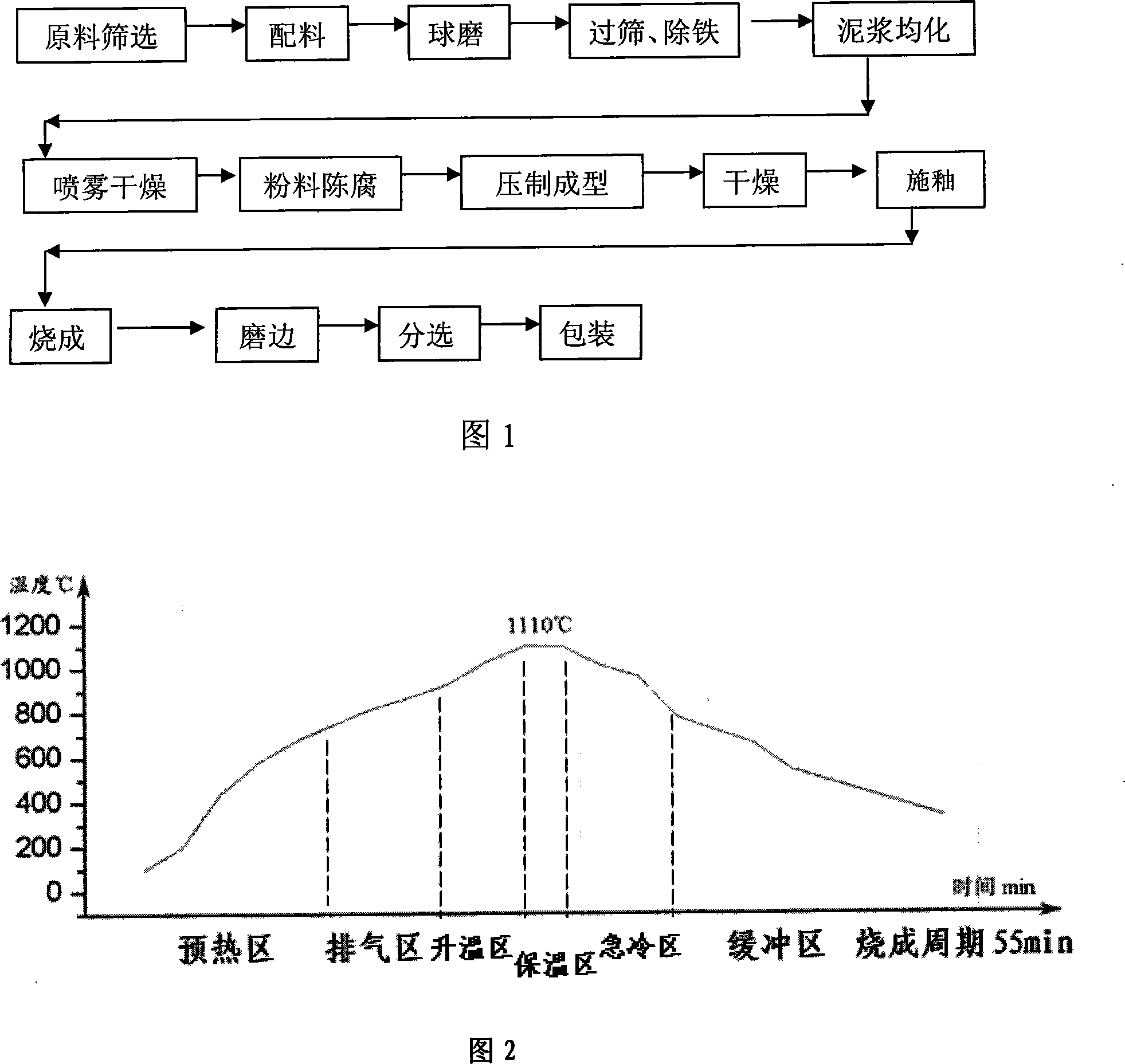

[0018] The preparation method of the colored blank glazed archaize brick of the present invention is first to carry out mixing cloth with the existing glaze material and blank of 70% archaize brick according to the weight ratio of waste iron tailings raw material 30%, and then according to the existing conventional glaze antique The production method of bricks is firing and surface treatment. The technological process is as shown in Figure 1 below, through raw material screening, batching, ball milling, sieving, iron removal, slurry homogenization, spray drying, powder aging, pressing, drying, glazing, firing, edging, sorting, and packaging Prepared by conventional techniques.

[0019] The present invention adopts waste iron tailings raw materials and uses them in the raw materials of antique bricks, which weakens the shortage crisis of ceramic mineral raw materials, reduces the discharge of iron tailings, and utilizes the metal components in tailings to analyze different vale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com