Preparation process for silicate cement clinker

A portland cement and preparation technology, which is applied in the field of cement manufacturing, can solve the problems of increased waste sand, increased cost of castings, waste of resources, etc., achieve huge social and economic benefits, solve the problem of reuse, and save firing The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

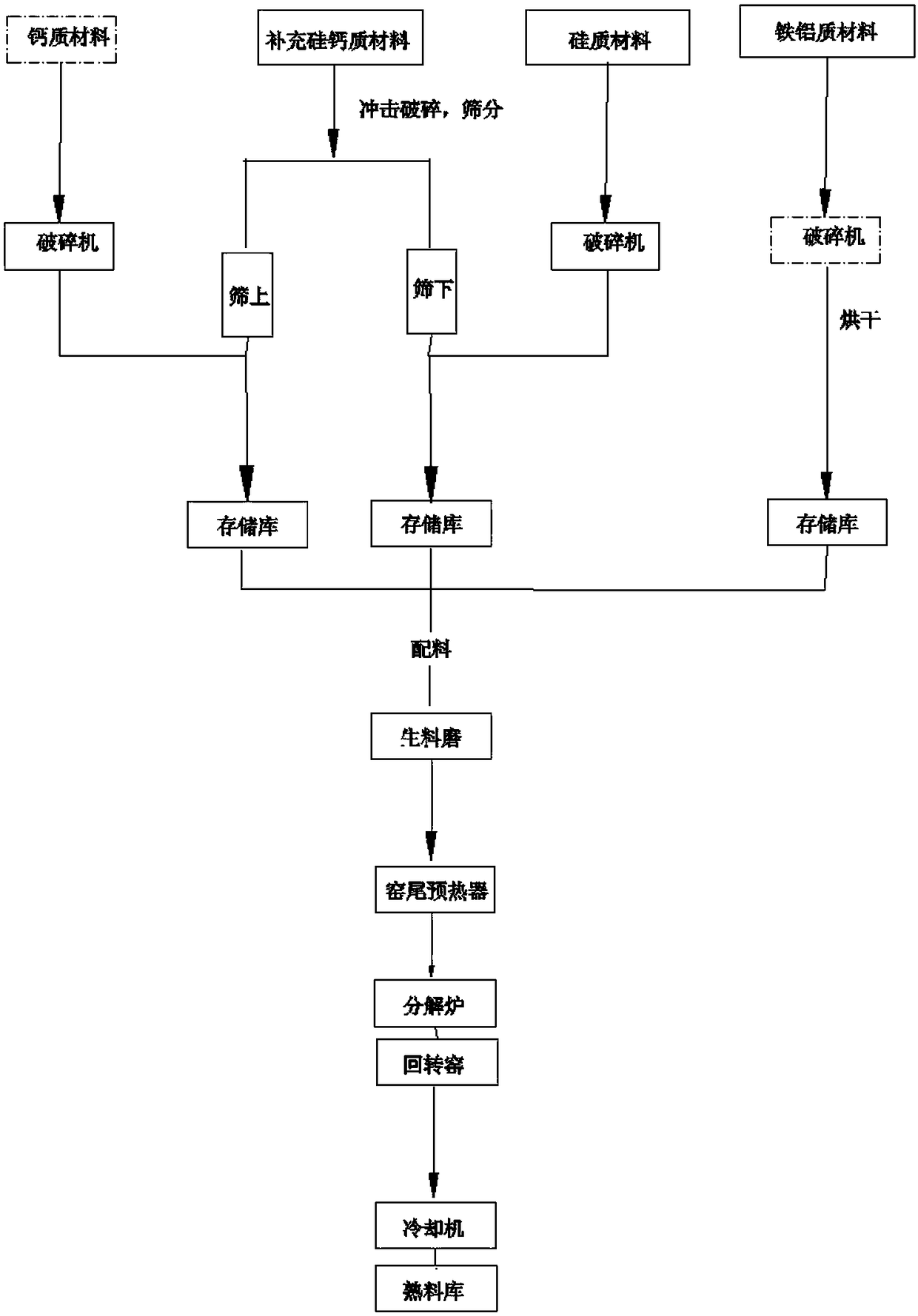

[0031] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0032] A preparation process for Portland cement clinker, comprising the following steps:

[0033] A. Material pretreatment step, use impact crusher to carry out primary crushing of limestone molding sand waste, and the crushed particles are less than 25mm; use ball mill to grind the limestone molding sand waste after primary crushing, and increase sorting after grinding Sieve, control the aperture of the sorting sieve to be 20 mesh, separate the limestone molding sand waste after grinding into the upper part of the sieve and the lower part of the sieve for subsequent use;

[0034] B. Raw material crushing step: silicon materials, calcium materials, iron materials and iron-aluminum materials are crushed by jaw crusher for primary crushing, and impact crushing is used for secondary crushing, and the particle size of the incoming abrasive is controlled ...

Embodiment 2

[0041] Further as a preferred embodiment, a preparation process of Portland cement clinker comprises the following steps:

[0042] Calcium material: limestone; Supplementary siliceous-calcium material: limestone molding sand waste, supplementary siliceous-calcium material is water glass limestone sand waste, water glass clay limestone sand waste, clay dry limestone sand waste; siliceous material contains : Quartz sand; iron-aluminum materials: sulfuric acid slag and aluminum ore waste rock.

[0043] A. Material pretreatment step, use impact crusher to carry out primary crushing of limestone molding sand waste, the gap between the grate bars in the feeding groove of the impact crusher is 500mm, and the raw materials are transported to the impact crusher through the belt conveyor, and the particles are broken The particle size is less than 25mm; use a ball mill to pre-grind limestone molding sand waste, add a sorting screen after grinding, control the aperture of the sorting scr...

Embodiment 3

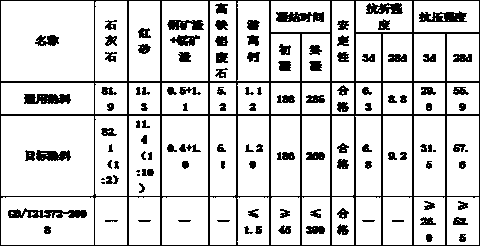

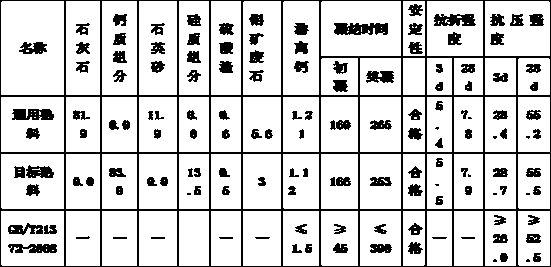

[0050] Further as a preferred embodiment, prepare according to the process of above-mentioned embodiment 1 and embodiment 2, take limestone molding sand waste and carry out preliminary screening, the part on the sieve: the part under the sieve=9:1, the chemical composition of the component on the sieve is oxidized Calcium = 53.61%, magnesium oxide = 0.50%, alkali content = 0.11%, sulfur trioxide = 0.1%, silicon dioxide = 2.95%, so it is directly used as a substitute for limestone, under the sieve: quartz sand = 1:10 for mixing , and then carry out raw material batching according to the ratio. As shown in Table 3 below:

[0051]

[0052] table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com