Portland cement clinker and preparation method thereof

A technology for Portland cement and cement clinker, which is applied in the field of building materials, can solve problems such as environmental pollution, and achieve the effects of high strength, wide sources and increased dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The mineral composition of the designed clinker is C 3 S: 61%, C 2 S: 20%, C 3 A: 7% and C 4 AF: 12%, raw material rate values are KH=0.898, n=2.5, p=1.31, MgO content in clinker is 2%, with CaHPO 4 2H 2 The phosphorus-containing raw material based on O mineral form is a phosphorus source (the following examples are all the same), and the amount of phosphorus introduced in the clinker is 1%P 2 o 5 . As a comparison A does not contain magnesium and phosphorus in the clinker; as a comparison B contains magnesium but does not contain phosphorus in the clinker; as a comparison C does not contain magnesium but contains phosphorus in the clinker. The chemical composition of the obtained cement clinker is shown in Table 1. According to the calculated ratio of raw materials, the raw materials are mixed and mixed evenly. The mixed raw materials are calcined in a high-temperature furnace at 1450°C and then quenched. The cooled clinker is crushed and ground, and the spec...

Embodiment 2

[0046] According to the current chemical composition and mineral composition of my country's benchmark clinker for cement (hereinafter referred to as benchmark clinker), the mineral composition of the designed clinker is C 3 S: 60%, C 2 S: 23%, C 3 A: 7% and C 4 AF: 10%, raw meal rate values are KH=0.887, n=2.95, p=1.44, MgO content in clinker is 2.57%, phosphorus introduction in clinker is 0.6%P 2 o 5 , see Table 3 for the chemical composition of the clinker. According to the calculated ratio of raw materials, the raw materials are mixed and mixed evenly. The mixed raw materials are calcined in a high-temperature furnace at 1450°C and then quenched. The cooled clinker is crushed and ground, and the specific surface area of the clinker fineness is controlled to (340±20)m by using Blaine’s specific surface area measuring instrument. 2 / kg.

[0047] Table 3 Chemical composition of clinker

[0048]

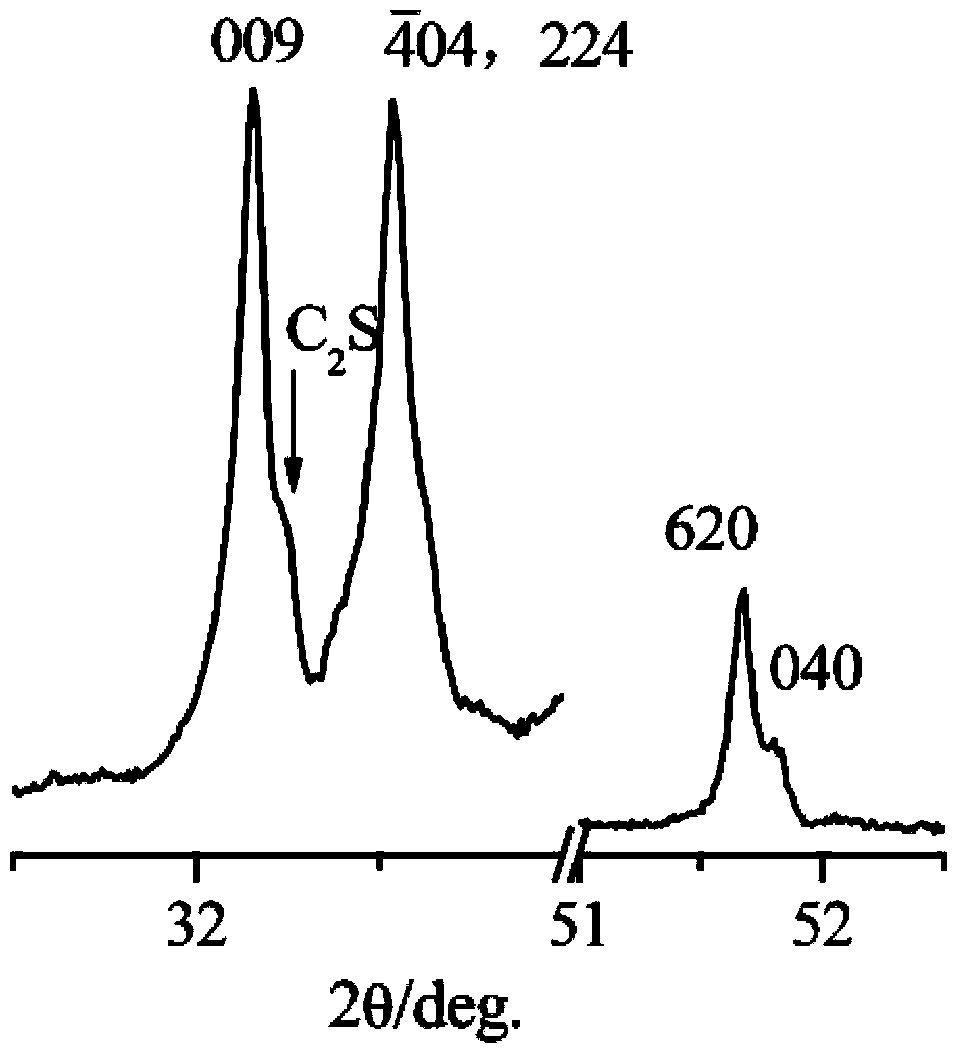

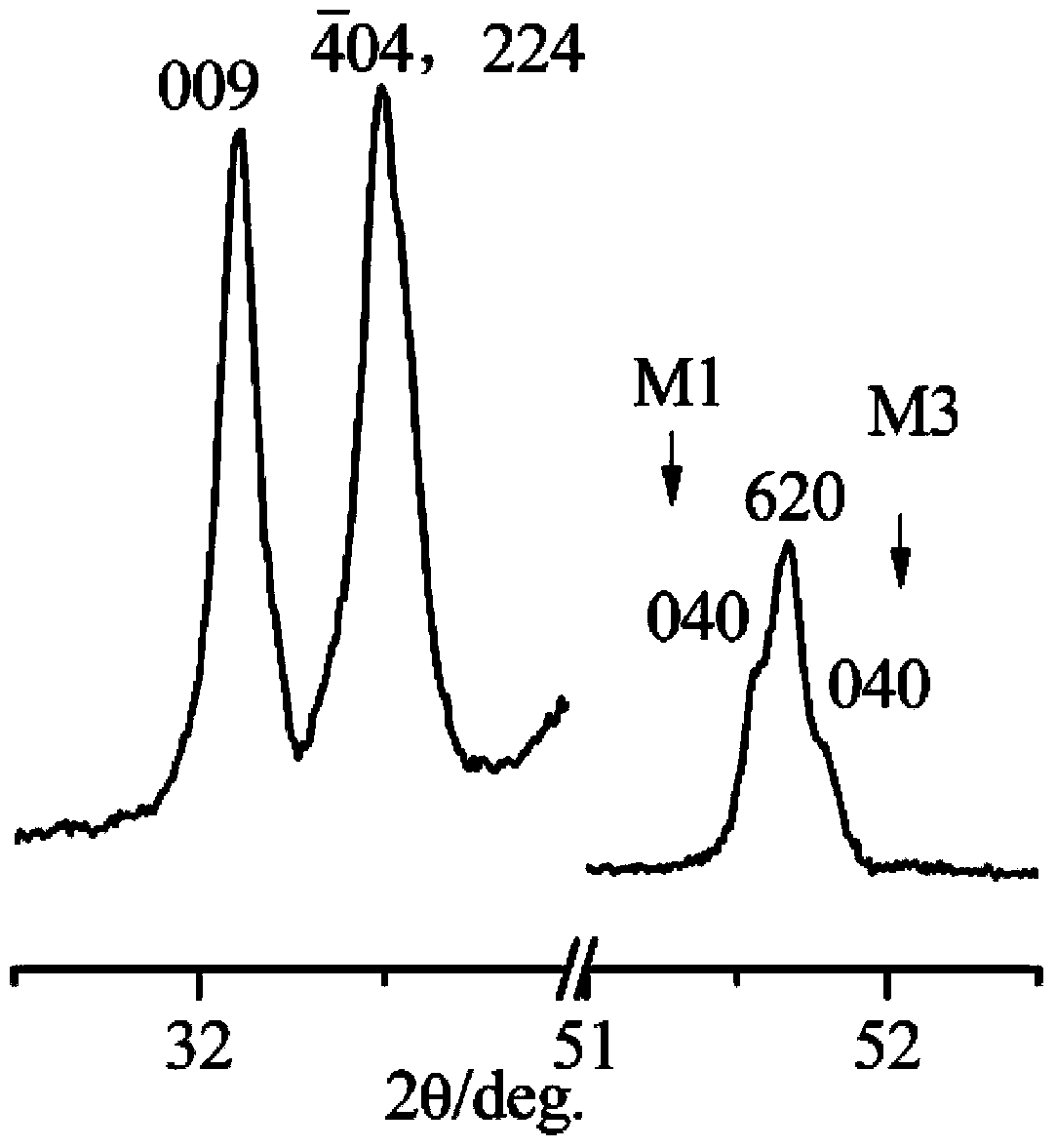

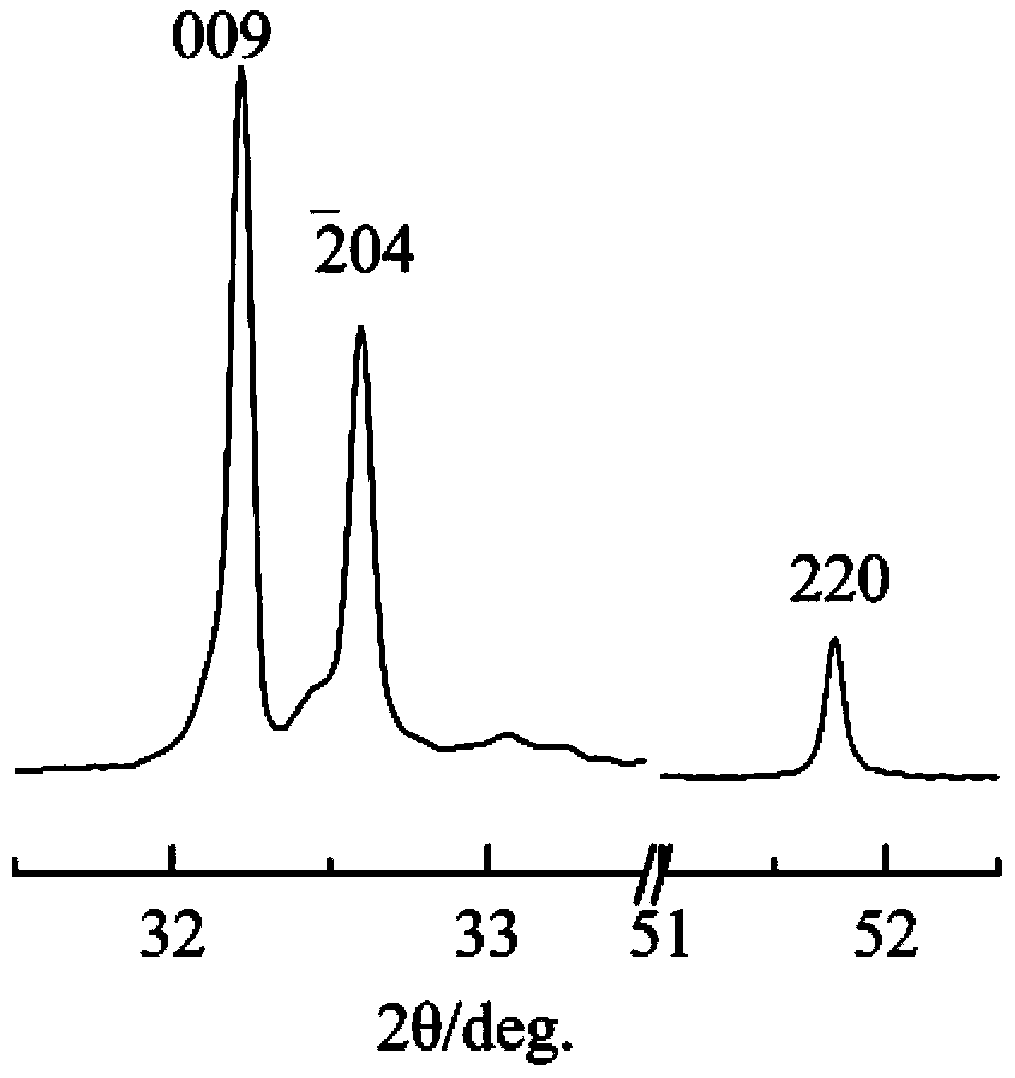

[0049] figure 2 The diffraction peaks in the ranges of 32°~33° a...

Embodiment 3

[0054] According to the current chemical composition and mineral composition of my country's benchmark cement special clinker, the design clinker mineral composition is C 3 S: 60%, C 2 S: 23%, C 3 A: 7% and C 4 AF: 10%, raw meal rate values are KH=0.887, n=2.95, p=1.44, MgO content in clinker is 2.56%, phosphorus introduction in clinker is 1%P 2 o 5 The ingredients and clinker chemical composition are shown in Table 5. According to the calculated ratio of raw materials, the raw materials are mixed and mixed evenly. The raw materials are calcined in a high-temperature furnace at 1450°C and then quenched. The cooled clinker is crushed and ground, and the specific surface area of the clinker fineness is controlled to (340±20)m by using Blaine’s specific surface area measuring instrument. 2 / kg.

[0055] Table 5 Chemical composition of clinker

[0056]

[0057] According to GB / T17671-1999, the compressive strength test was carried out on the clinker samples. The wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com