Process for producing coloured polished brick

A polished brick and colored technology, which is applied in the field of ceramic manufacturing, can solve the problems of resource waste and environmental pollution, and achieve the effects of reducing emissions, reducing energy consumption, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

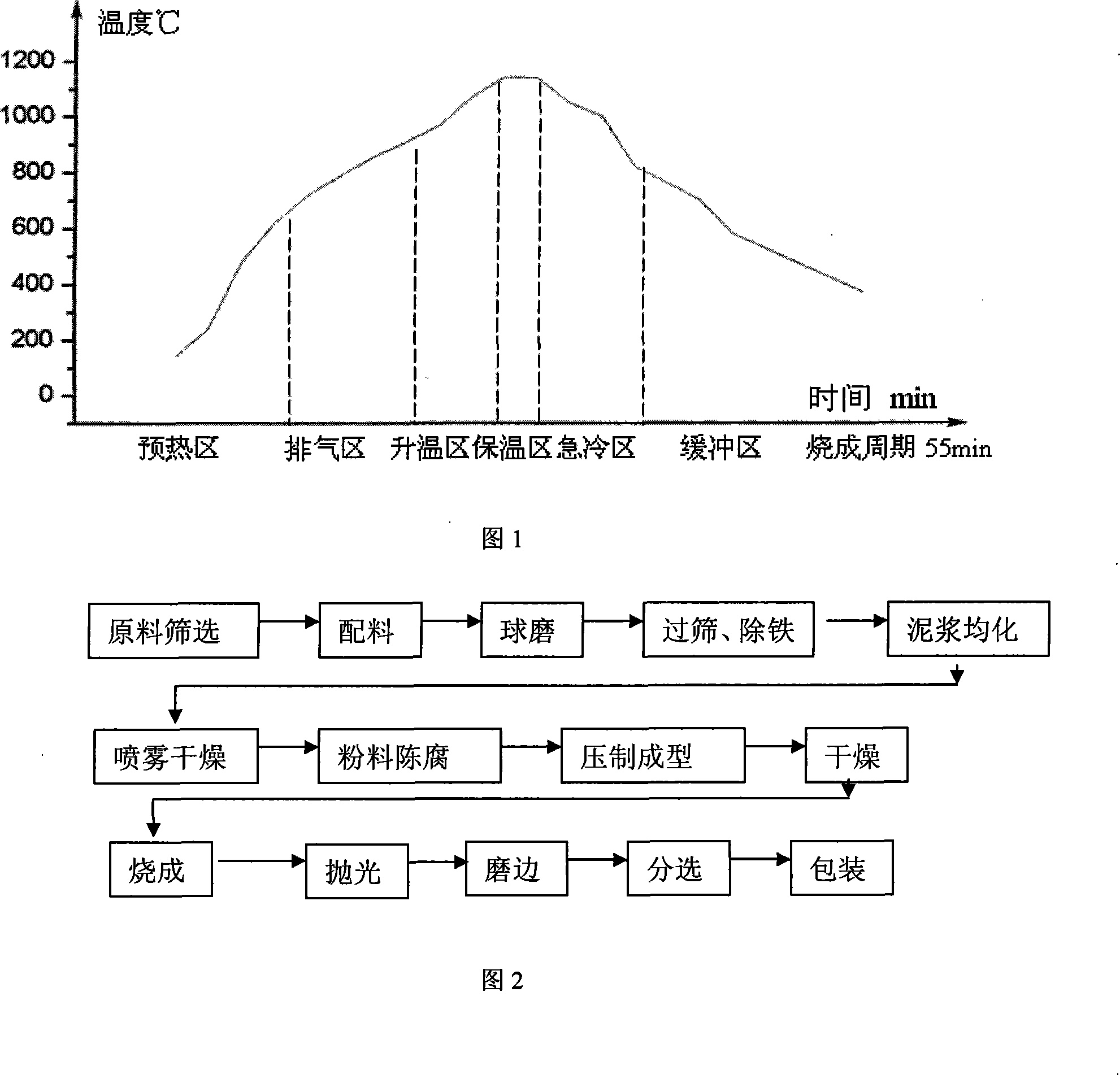

[0017] The preparation method of the colored polished brick of the present embodiment of the present invention is first to carry out mixing cloth with the existing glaze material and blank of 70% polished brick according to the weight ratio of waste iron tailings raw material 30%, and then according to the existing conventional polished brick The production method is firing and surface treatment.

[0018] The invention adopts the waste iron tailings raw material and uses it in the blank of the polished brick, which weakens the shortage crisis of ceramic mineral raw materials and reduces the discharge of iron tailings. At the same time, the metal components in the tailings are used to analyze different valence Combined with the color development mechanism of different metal elements, a composite color development formula is formed to replace the body colorant-pigment in the traditional process, which not only saves precious non-ferrous metal resources, but also supports the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com