Method for manufacturing glazed brick by utilizing silico-calcium slag

A technology of silicon-calcium slag and glazed tiles, which is applied in the field of manufacturing glazed tiles, can solve problems such as difficult control of product quality, restrictions on ceramic production, and restricted development, and achieve the effects of improving utilization efficiency, reducing shortage crises, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Put 30% calcium-calcium slag, 20% Dongsheng clay and 50% Zhujita clay into the ball mill after processing each raw material by weight percentage, and the particle size after ball milling is less than 200 mesh.

[0036] (2) The ball-milled mixture is placed in a ceramic green body abrasive tool for dry pressing molding, and the molding pressure is 10 MPa.

[0037] (3) After the molded body is dried, spray water and apply glaze. The heating rate of the low-temperature and medium-temperature sections is the same as the traditional method, and the high-temperature roasting temperature is controlled to be 1100°C.

[0038] (4) After keeping the temperature for 90 minutes at the calcination temperature, enter the cooling zone.

Embodiment 2

[0040] (1) Put 40% calcium-silicon slag, 10% Dongsheng clay and 50% Zhujita clay into the ball mill after processing each raw material by weight percentage, and the particle size after ball milling is less than 200 mesh.

[0041] (2) The ball-milled mixture is placed in a ceramic green body abrasive tool for dry pressing molding, and the molding pressure is 10 MPa.

[0042] (3) After the molded body is dried, spray water and apply glaze. The heating rate of the low-temperature and medium-temperature sections is the same as the traditional method, and the high-temperature roasting temperature is controlled to be 1100°C.

[0043] (4) After keeping the temperature for 90 minutes at the calcination temperature, enter the cooling zone.

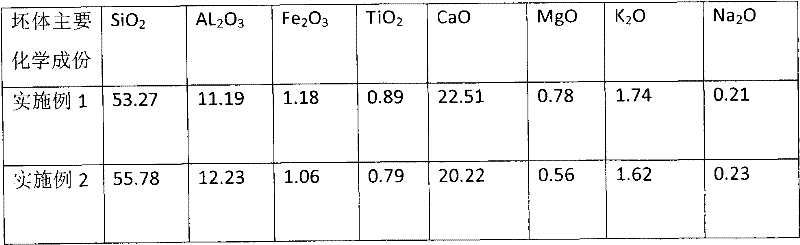

[0044] Table 1. Main chemical composition of green body

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com