Method for manufacturing polishing brick by utilizing calcium silicate slag

A technology of polishing bricks and calcium silicate, which is applied in the field of ceramic manufacturing, can solve problems such as difficult control of product quality, restrictions on ceramic production, and restricted development, so as to reduce firing energy consumption, weaken crisis of shortage, reduce energy consumption and pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

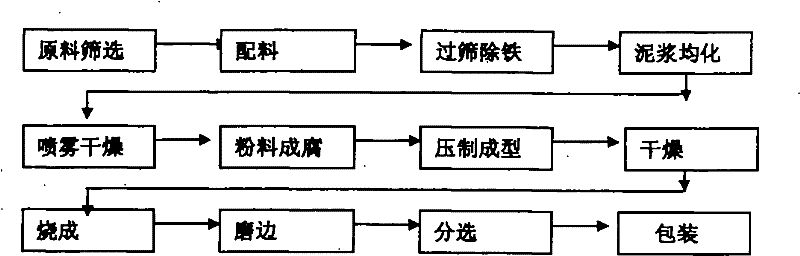

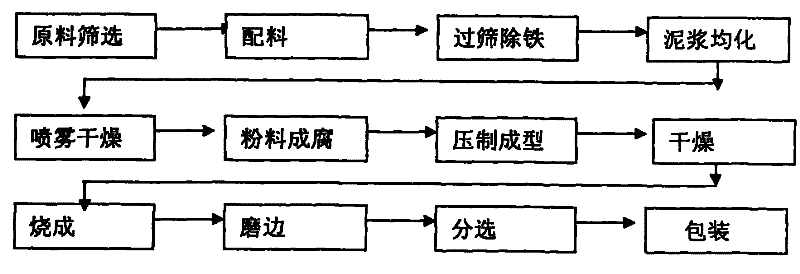

Method used

Image

Examples

Embodiment Construction

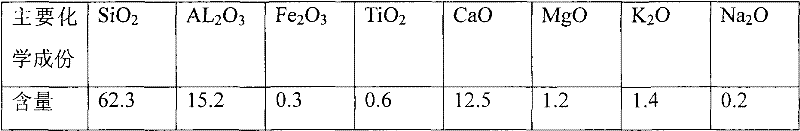

[0028] Table 1 is the formula composition of the green body of the present invention; Table 2 is the chemical composition of the green body of the present invention.

[0029] The present invention at first mixes 30% by weight of calcium silicate slag raw material and 70% other blanks, mixing material: water=1: 1, makes green body mud slurry, then burns by existing conventional production method, burns The forming temperature is 1150° C. to 1200° C., and it only needs to be polished.

[0030] The composition of calcium silicate slag mainly includes: SiO 2 : 37~40%; CaO: 38~41%; AL 2 o 3 : 0.5~0.9%; Fe 2 o 3 2 O2 O<0.5%; discretionary amount<4.0%.

[0031] The mud composition mainly includes: SiO 2 : 55~65%; AL 2 o 3 ≥21%; Fe 2 o 3 +TiO 2 2 O+Na 2 O<1.5%; discretionary reduction<11%.

[0032] The whiteness of the mud is ≥55°, the shrinkage is less than 5%, and the plasticity: the flexural strength is required to be greater than 42 N.

[0033] The composition of hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com