A kind of preparation method of high-strength ceramic membrane support

A ceramic membrane support, high-strength technology, used in ceramic products, other household appliances, household appliances, etc., can solve the problems of dust recovery, which is easy to generate secondary dust, increase equipment volume and manufacturing cost, and prevent dust removal equipment from running normally. , to ensure the effect of filtering and dust removal, low equipment maintenance and operating costs, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

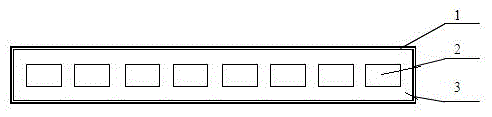

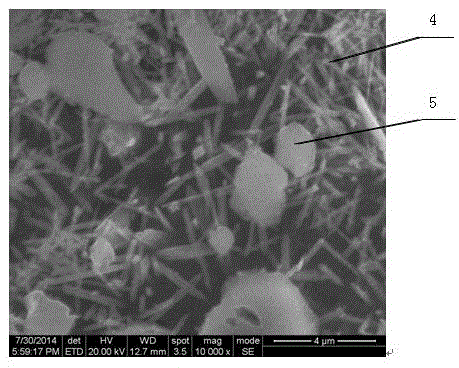

[0028] Example 1 : The preparation method of described a kind of high-strength ceramic membrane support body, specifically:

[0029] (1) The ceramic mud of the support body is composed of 35% calcined bauxite, 35% high plastic clay, 15% china clay and 15% feldspar by weight percentage, and the hard raw materials in the formula are calcined bauxite and feldspar Select the powder that has been crushed to an average particle size below 10 microns, mix the hard raw material powder with other raw materials, and ball mill for 5 hours to obtain a slurry;

[0030] (2) After sieving the slurry and removing iron, add rice bran and 20% rice straw crushed to 150 meshes, accounting for 20% of the mass percentage of the ceramic mud, as pore-forming materials, and then add appropriate amount of water to disperse evenly with a high-speed mixer, press Obtain mud cake after filtering and dehydrating;

[0031] (3) The mud cake is roughed and stale for more than 24 hours, and then vacuum-extru...

Embodiment 2

[0034] Example 2 : The preparation method of described a kind of high-strength ceramic membrane support body, specifically:

[0035] (1) The ceramic mud of the support is composed of 40% calcined bauxite, 30% high plastic clay, 18% china clay and 12% feldspar by weight percentage, and the hard raw materials in the formula are calcined bauxite and feldspar Select the powder that has been crushed to an average particle size below 10 microns, mix the hard raw material powder with other raw materials, and ball mill for 4 hours to obtain a slurry;

[0036] (2) After sieving the slurry and removing iron, add rice bran and 15% straw that are crushed to 250 meshes and account for 15% of the mass percentage of ceramic mud as pore-forming materials, and then add appropriate amount of water to disperse evenly with a high-speed mixer, press Obtain mud cake after filtering and dehydrating;

[0037] (3) The mud cake is roughed and stale for more than 24 hours, and then vacuum-extruded in...

Embodiment 3

[0040] Example 3 : The preparation method of described a kind of high-strength ceramic membrane support body, specifically:

[0041] (1) The ceramic mud of the support body is composed of 45% calcined bauxite, 25% high plastic clay, 20% china clay and 10% feldspar by weight percentage, and the hard raw materials in the formula are calcined bauxite and feldspar Select the powder that has been crushed to an average particle size below 10 microns, mix the hard raw material powder with other raw materials, and ball mill for 5 hours to obtain a slurry;

[0042] (2) After sieving the slurry and removing iron, add rice bran and 15% rice straw crushed to 200 meshes, accounting for 15% of the mass percentage of ceramic mud, as pore-making materials, and then add appropriate amount of water to disperse evenly with a high-speed mixer, press Obtain mud cake after filtering and dehydrating;

[0043] (3) The mud cake is roughed and stale for more than 24 hours, and then vacuum-extruded i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com