Method of producing polishing brick by low-temperature sintering

A low-temperature sintering and polishing brick technology, which is applied in the production field of polished bricks, can solve problems such as powerlessness, achieve the effects of saving processing costs, solving energy shortages, and remarkable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

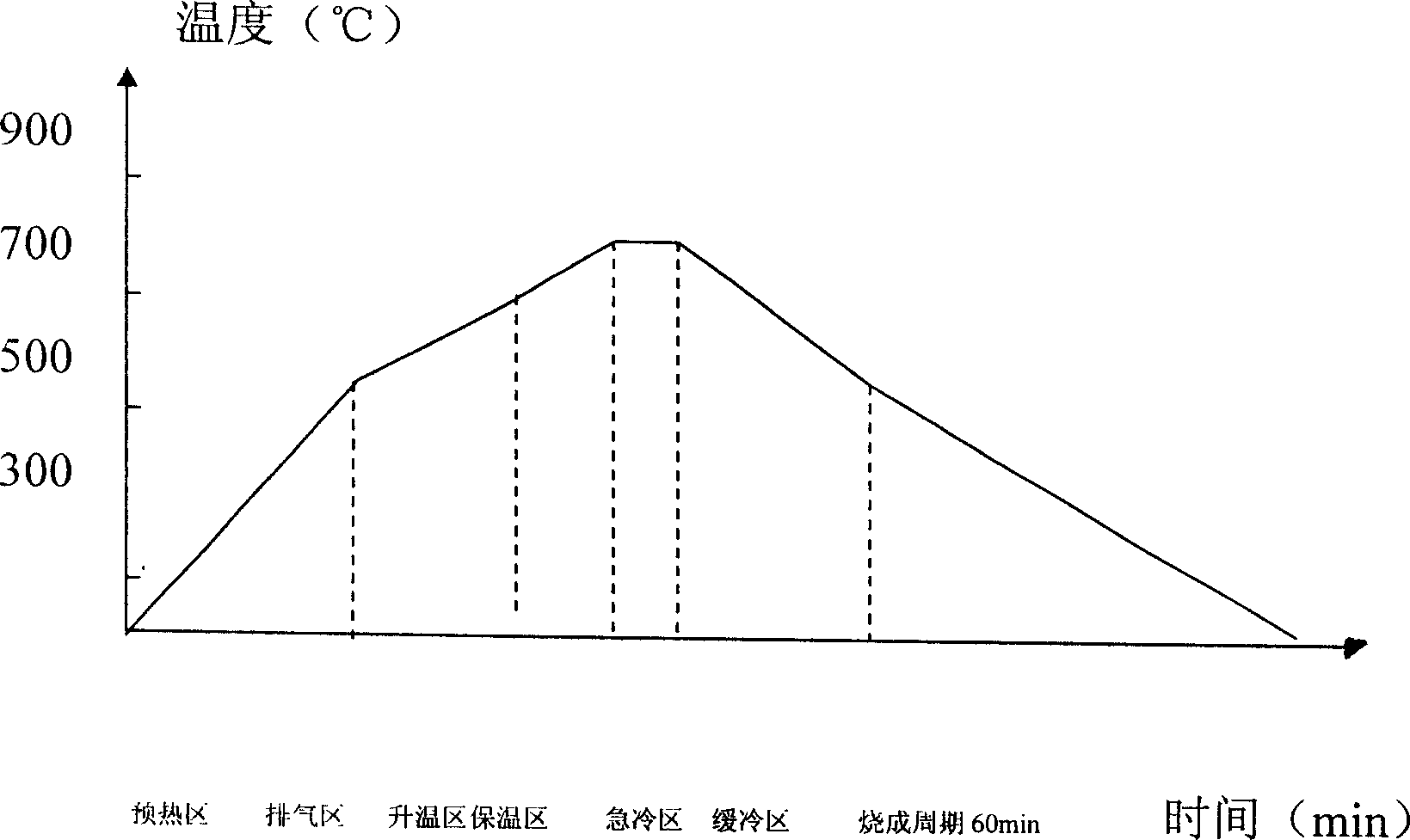

Image

Examples

Embodiment 1

[0022] The production method of "quasi-non" (low temperature) sintered polished tiles includes the following steps:

[0023] 1) Blank formula design:

[0024] According to the existing equipment process layout, combined with the actual situation of raw material distribution in this area, through the comparative test and analysis of different raw materials, it is finally determined that waste glass, boiled bauxite, white mud, bentonite, pigment and sodium tripolyphosphate are the main raw materials . The polished brick adopts the existing production process and equipment. The amount of raw materials used for various blanks is shown in Table 1, and the chemical composition analysis of the blank is shown in Table 2.

[0025] waste glass

cooked bauxite

white clay

sodium tripolyphosphate

colorant

50%

20%

18%

4%

5%

3%

[0026] chemical composition

Al 2 o 3

SiO 2

Fe 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com