A semi-solid die-casting method for impeller of turbocharger

A technology of turbocharger and impeller, which is applied in the field of turbocharger impeller manufacturing and semi-solid die-casting, can solve the problems of inability to meet the requirements of harsh conditions, restrictions on wide application, and high preparation cost, and improves the utilization of materials. efficiency, reduce process flow, and reduce the effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

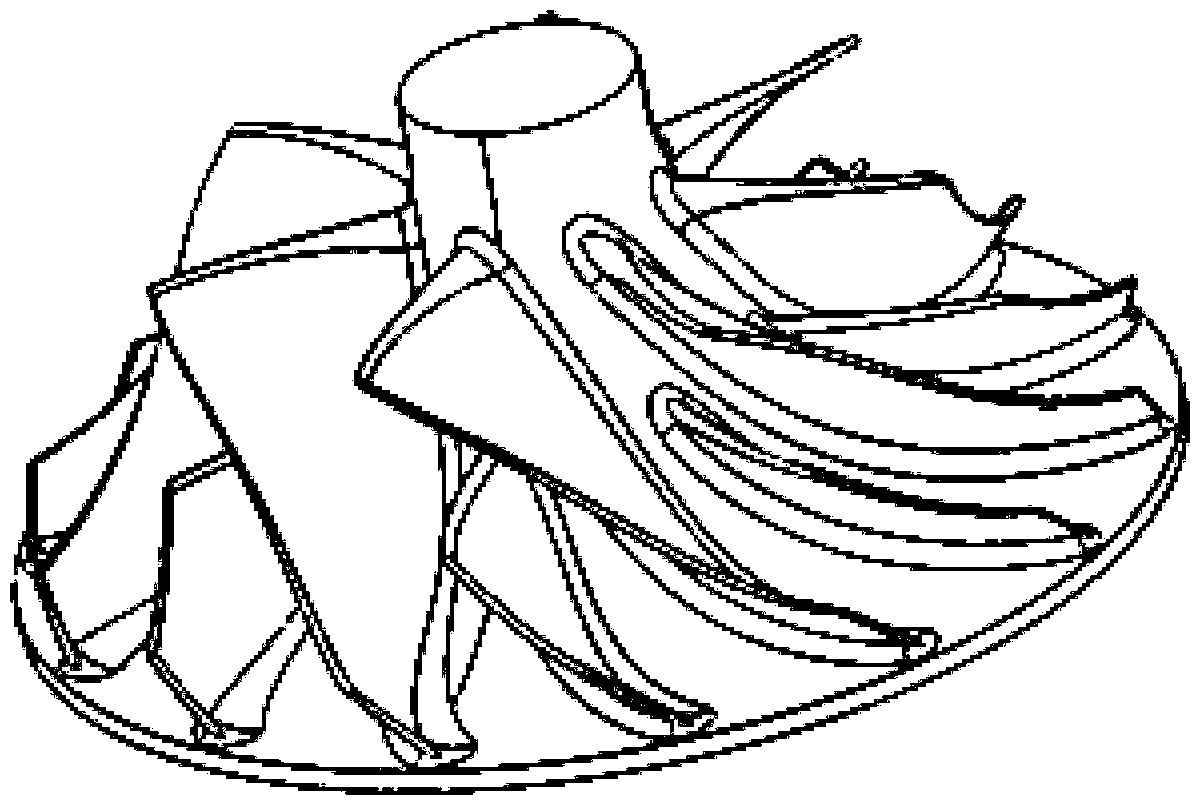

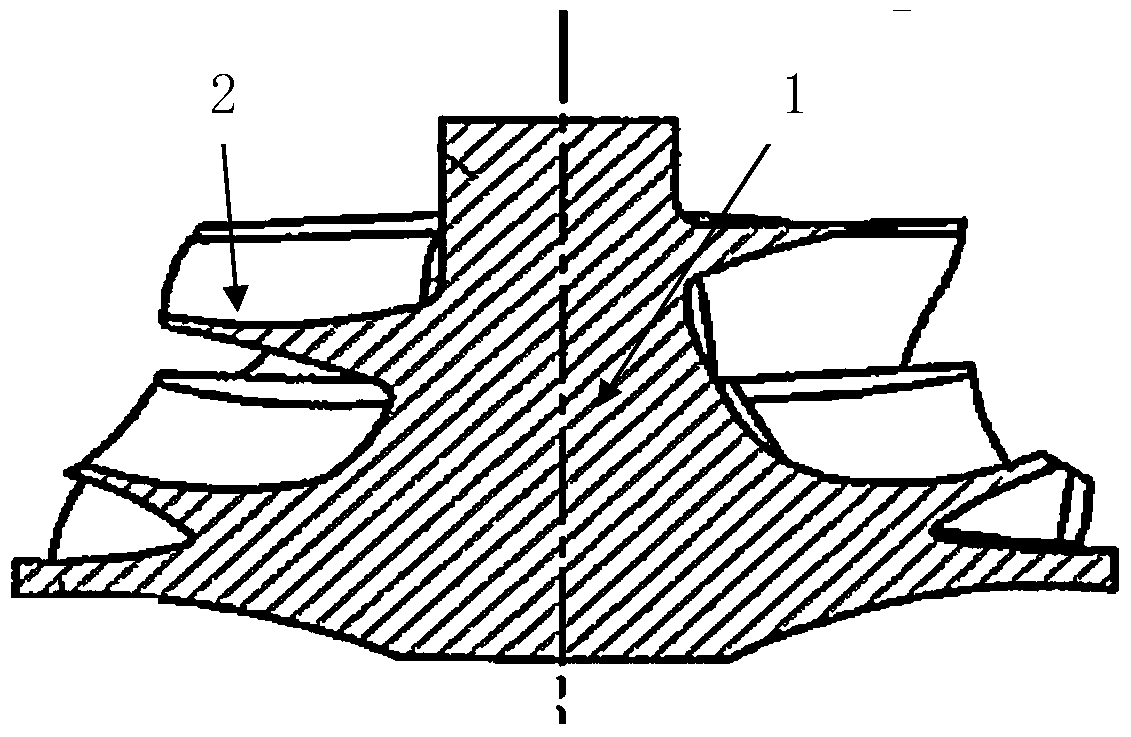

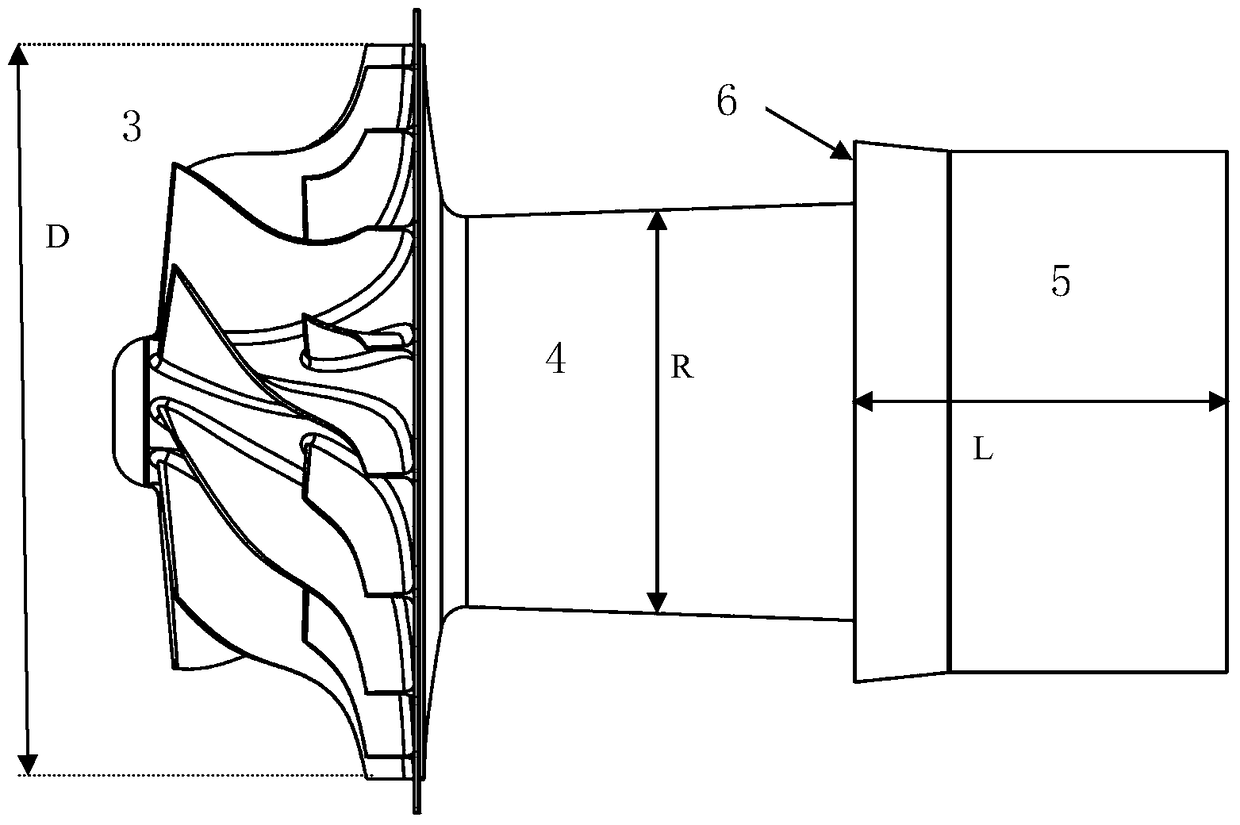

[0024] The pressure impeller product with an outer diameter of 20 mm is prepared by the present invention, and the number of blades of the product is 8, and the blades have the same size and are evenly distributed along the outer diameter. A356 alloy (liquidus 615°C, solidus 555°C) was used to prepare semi-solid billets. When the temperature of the alloy melt reaches 660°C, the melt is transferred to a specific cylindrical container, and the melt is naturally cooled in the container while stirring the container. When the temperature of the melt drops to the semi-solid temperature range of 570-580°C, The semi-solid billet is pressed into the cup of the die casting machine. In the mold design, the diameter of the sprue is 20mm, the diameter of the cake is 30mm, and the thickness of the cake is 50mm. The injection rod presses the semi-solid blank in the material cup into the mold cavity through the sprue cavity, directly fills the mold, and prepares the impeller sample.

Embodiment 2

[0026] The pressure impeller product with an outer diameter of 500 mm is prepared by the present invention, and the number of product blades is 30, and the interval between large and small blades is evenly distributed along the outer diameter. A356 alloy (liquidus 615°C, solidus 555°C) was used to prepare semi-solid slurry. When the temperature of the alloy melt reaches 680°C, the melt is transferred to a specific cylindrical container, and the melt is naturally cooled in the container while stirring the container. When the melt temperature drops to the semi-solid temperature range of 590-600°C, Pour the semi-solid slurry into the die casting machine cup. In the mold design, the diameter of the sprue is 100mm, the diameter of the cake is 120mm, and the thickness of the cake is 50mm. The injection rod presses the semi-solid blank in the material cup into the mold cavity through the sprue cavity, directly fills the mold, and prepares the impeller sample.

Embodiment 3

[0028] The pressure impeller product with an outer diameter of 150 mm is prepared by the present invention, and the number of product blades is 16, and the intervals between large and small blades are evenly distributed along the outer diameter. A356 alloy (liquidus 615°C, solidus 555°C) was used to prepare semi-solid slurry. When the temperature of the alloy melt reaches 680°C, the melt is transferred to a specific cylindrical container, and the melt is naturally cooled in the container while stirring the container. When the melt temperature drops to the semi-solid temperature range of 590-600°C, Pour the semi-solid slurry into the die casting machine cup. In the mold design, the diameter of the sprue is 75mm, the diameter of the cake is 100mm, and the thickness of the cake is 100mm. The injection rod presses the semi-solid blank in the material cup into the mold cavity through the sprue cavity, directly fills the mold, and prepares the impeller sample.

[0029] The tensile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com