Sedimentation device for sewage treatment

A settling device and sewage treatment technology, which is applied in the direction of the feeding/discharging device of the settling tank, settling tank, etc., can solve the problems of large kinetic energy of suspended particles, long standing time, and high production cost, so as to reduce production cost and increase production cost. Large attachment area, effect of reducing tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

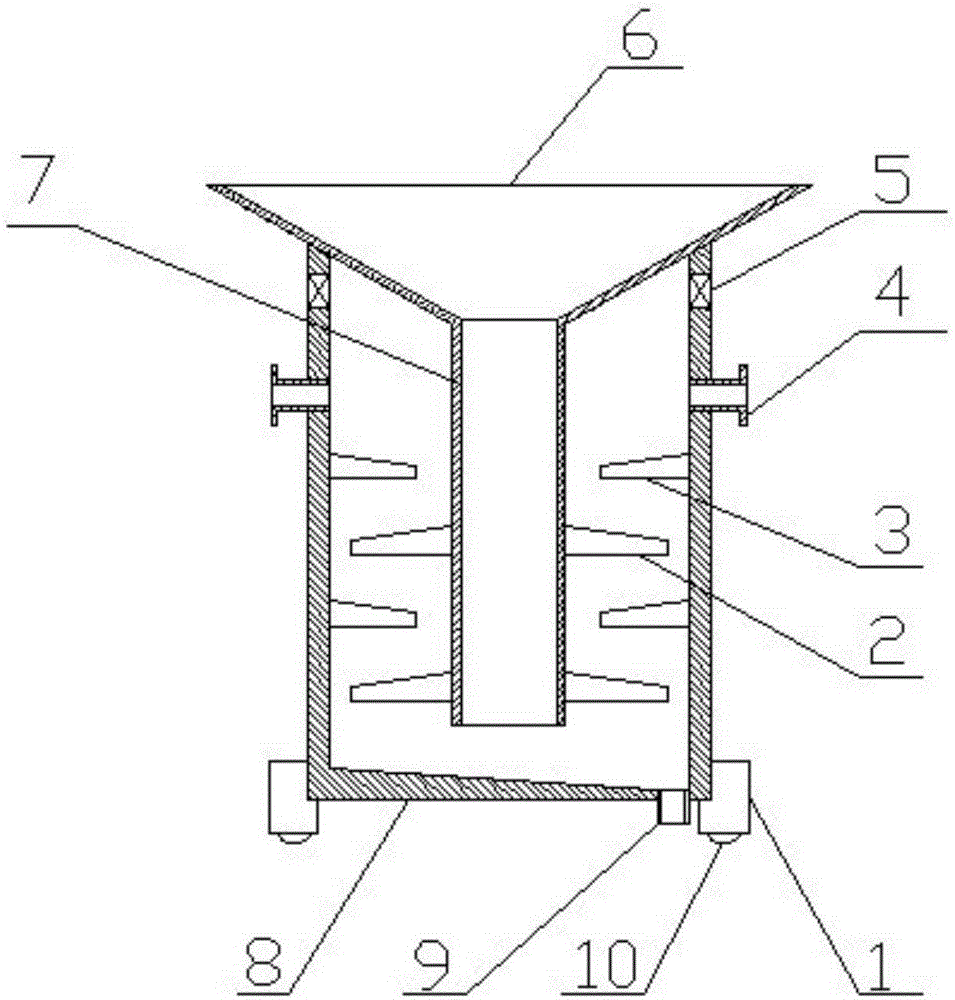

[0015] Such as figure 1 The shown settling device for sewage treatment includes a support base 1, a settling chamber 8, a feed pipe 7, a feed hopper 6 and a discharge pipe 4, and the settling chamber 8 is installed on the support base 1, so The settling chamber 8 is a cylindrical cavity structure with the bottom inclined towards the sewage outlet. The inner wall of the settling chamber 8 is obliquely equipped with a deflector A3, and a deflector B2 is arranged between the deflectors A3. The deflector B2 is obliquely installed on the feed pipe 7, and the feed pipe 7 is installed on the feed hopper 6, and the feed hopper 6 is installed on the upper edge of the settling chamber 8, and the discharge pipe 4 Installed below the upper edge of the settling chamber 8 , the settling chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com