Flotation separation process of copper sulfide lead ore

A copper sulfide and lead ore technology, applied in flotation, solid separation and other directions, can solve the problems of complicated operation, ecological environment pollution, and difficult application of heating method, achieve good beneficiation indicators, low cost of chemicals, and reduced sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment is a kind of ore flotation separation process of copper-lead sulfide ore. Taking a copper-lead polymetallic sulfide ore in Shaanxi as an ore sample, the raw ore contains 0.19% Cu grade, the primary copper sulfide occupation rate is 58.97%, and the secondary copper sulfide occupation rate is 58.97%. The rate is 30.24%, and the Pb grade is 0.42%. The specific steps are as follows:

[0019] (1) Prepare combined inhibitors: mix ferric sulfate and magnesium chloride at a mass ratio of 3:1 to obtain combined inhibitors; prepare combined collectors: mix ethylthiocarbamate, O-isooctyl-N-ethoxy Carbonylthiocarbamate and 4-terpene alcohol are mixed according to the mass ratio of 4:1:1 to obtain a combined collector;

[0020] (2) Grinding the copper-lead sulfide ore until the mass percentage of the particle fineness is less than 0.074mm is 95%;

[0021] (3) adding water to the grinding product of step (2) to adjust the mass percentage concentration of the pulp to ...

Embodiment 2

[0025] This embodiment is a kind of flotation separation process of copper-lead sulfide ore. Taking a copper-lead polymetallic sulfide ore in Yunnan as an ore sample, the raw ore contains 0.23% Cu grade, the primary copper sulfide share is 55.97%, and the secondary copper sulfide share is 32.24%, Pb grade 0.58%, the specific steps are as follows:

[0026] (1) Prepare combined inhibitors: mix ferric sulfate and magnesium chloride at a mass ratio of 3:2 to obtain combined inhibitors; prepare combined collectors: mix ethylthiocarbamate, O-isooctyl-N-ethoxy Carbonylthiocarbamate and 4-terpene alcohol are mixed according to the mass ratio of 8:2.5:3 to obtain a combined collector;

[0027] (2) Grinding the copper-lead sulfide ore until the mass percentage of the particle fineness is less than 0.074mm is 85%;

[0028] (3) adding water to the grinding product in step (2) to adjust the mass percentage concentration of the pulp to 30%;

[0029] (4) The product obtained in step (3) is...

Embodiment 3

[0032] This embodiment is a kind of flotation separation process of copper-lead sulfide ore. A copper-lead polymetallic sulfide ore in Shaanxi is used as an ore sample. 18.24%, Pb grade 1.34%, the specific steps are as follows:

[0033] (1) Prepare combined inhibitors: mix ferric sulfate and magnesium chloride at a mass ratio of 6:5 to obtain combined inhibitors; prepare combined collectors: mix ethylthiocarbamate, O-isooctyl-N-ethoxy Carbonylthiocarbamate and 4-terpene alcohol are mixed according to the mass ratio of 6:2:3 to obtain a combined collector;

[0034] (2) Grinding the copper-lead sulfide ore until the mass percentage of the particle fineness is less than 0.074mm is 70%;

[0035] (3) adding water to the grinding product of step (2) to adjust the mass percentage concentration of the pulp to 35%;

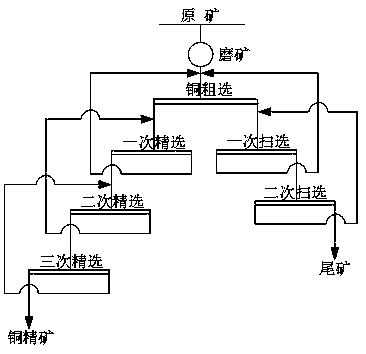

[0036] (4) The product of step (3) is subjected to flotation through the sorting closed-circuit process of "one rough, three fine and two sweeps, and the medium ore is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com