Magnet device, magnetic separator and application

A technology of magnets and main magnets, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of uneven magnetic field force and magnetic field intensity of permanent magnet magnetic separators, and achieve the effect of improving the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

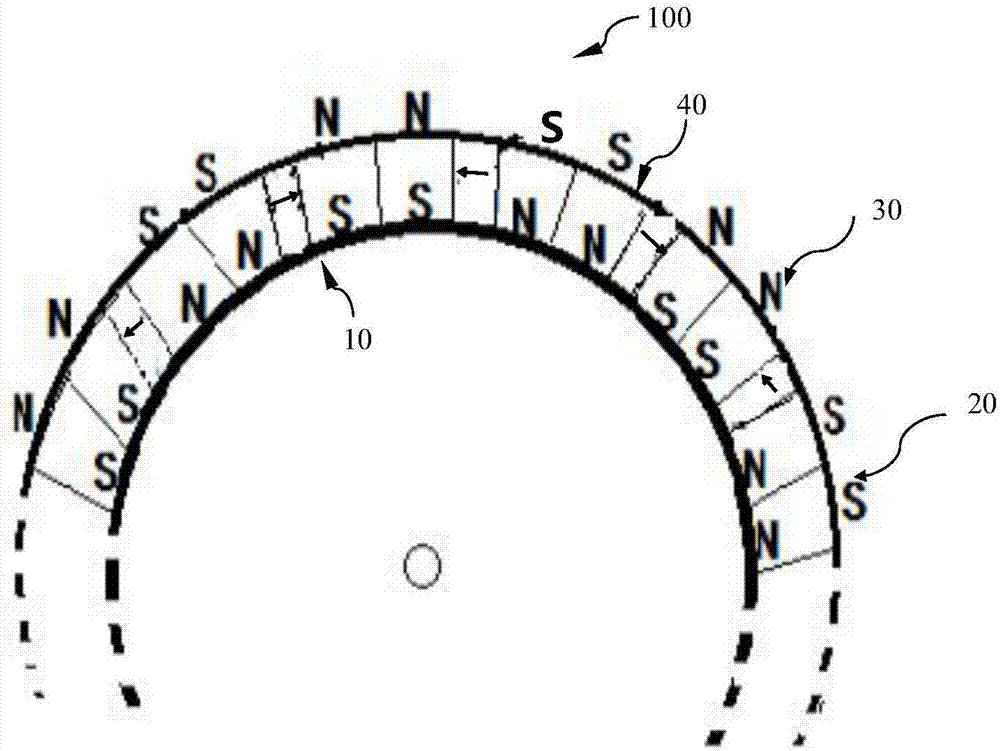

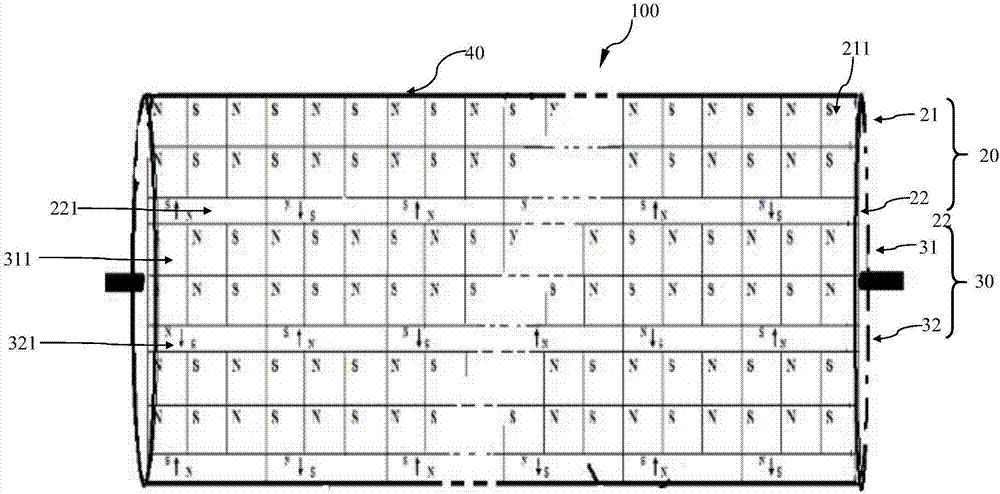

[0026] figure 1 It is a side view of the magnet device in the drum magnetic separator of the present invention.

[0027] figure 2 It is a front view of the magnet device in the drum magnetic separator of the present invention.

[0028] This embodiment takes the drum type magnetic separator as an example, as figure 1 , 2 As shown, the drum magnetic separator includes a cylindrical magnet device 100 , a supporting shaft supporting the cylindrical magnet device 100 and a corresponding driving device (not shown in the figure). The ore slurry flows through the magnet device 100 , contacts and rolls on the outer surface of the magnet device 10 driven by the drive device, and completes magnetic separation to obtain concentrate.

[0029] Such as figure 1 As shown, the magnet device 100 includes a cylindrical magnetic permeable layer 10 , a magnet layer composed of a plurality of first magnet parts 20 and a plurality of second magnet parts 30 , and a protective layer 40 .

[003...

Embodiment 2

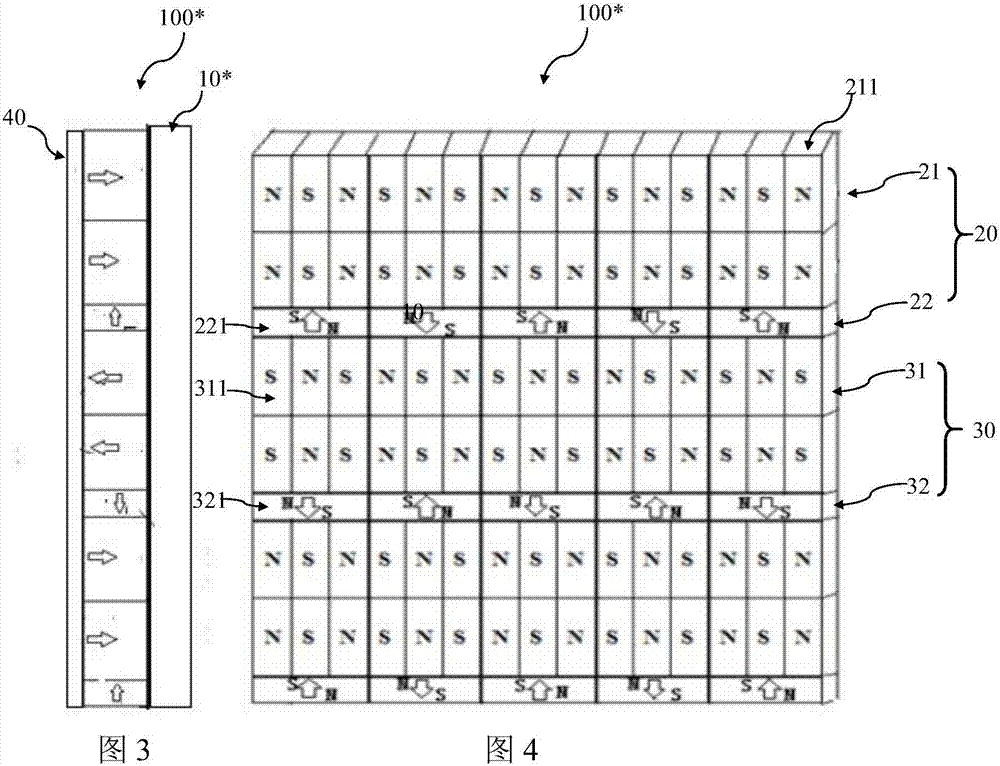

[0063] image 3 It is a side view of the magnet device in the plate magnetic separator of the present invention.

[0064] Figure 4 It is a front view of the magnet device in the plate magnetic separator of the present invention, with the protective layer removed.

[0065] The above embodiment provides a drum-type magnetic separator, and this modified example provides a plate-type magnetic separator 100*, and the magnetically conductive layer of the corresponding magnet device is a rectangular magnetically conductive plate 10*. In this embodiment, the same structures as those in Embodiment 1 are given the same numbers, the first direction is the longitudinal direction of the magnetically conductive plate, and the second direction is the transverse direction of the magnetically conductive plate.

[0066] This plate type magnetic separator can not only be used for magnetic separation, but also suitable for removing iron or other strong magnetic impurities from non-magnetic min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com