Flotation process of ilmenite or bastnaesite

A bastnaesite and ilmenite technology, applied in flotation, solid separation, etc., can solve the problems that restrict the application and promotion of rare earth flotation technology, poor selectivity, and weak collection capacity

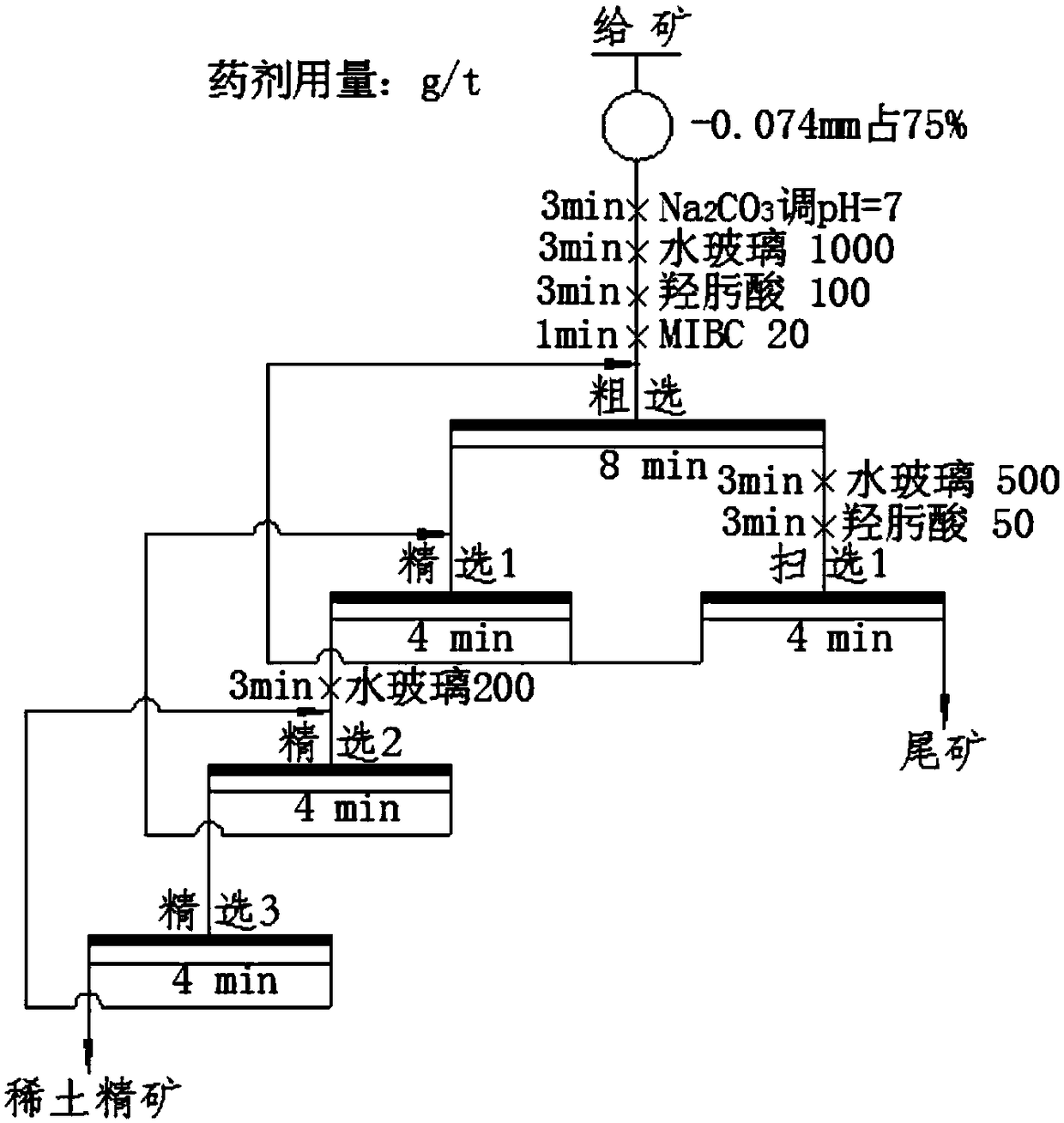

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

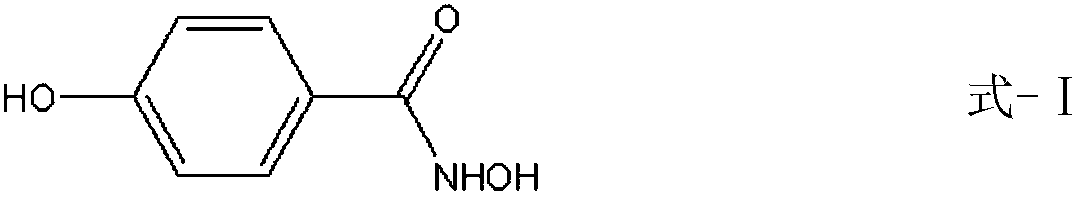

[0019] Embodiment 1: the preparation of paraben hydroxamic acid

[0020] Pour 90mL of distilled water into a 500mL three-necked flask, heat at a constant temperature in an oil bath at 30°C, and condense and reflux at room temperature; first, take 8.34 parts of hydroxylamine hydrochloride and add it to the three-necked flask, then add 8.8 parts of sodium hydroxide in batches, and the reaction time is 30 minutes. Fully free; add methylparaben with the structure shown in formula-II into the free liquid, and then heat the reaction system in a constant temperature oil bath at 60°C for 4h. After the reaction is completed, acidify the obtained reaction solution with sulfuric acid to obtain paraben Gold hydroxamic acid crude product; Gained paraben hydroxamic acid crude product dissolves with dehydrated alcohol under 70 ℃ of conditions, then slowly drips 70 ℃ of distilled water, and constantly stirs, and stop dripping until it appears white insoluble matter, supplement Add a drop of a...

Embodiment 2

[0023] Embodiment 2: Paraben hydroxamic acid and other hydroxamic acids are compared to the flotation performance of bastnaesium single mineral

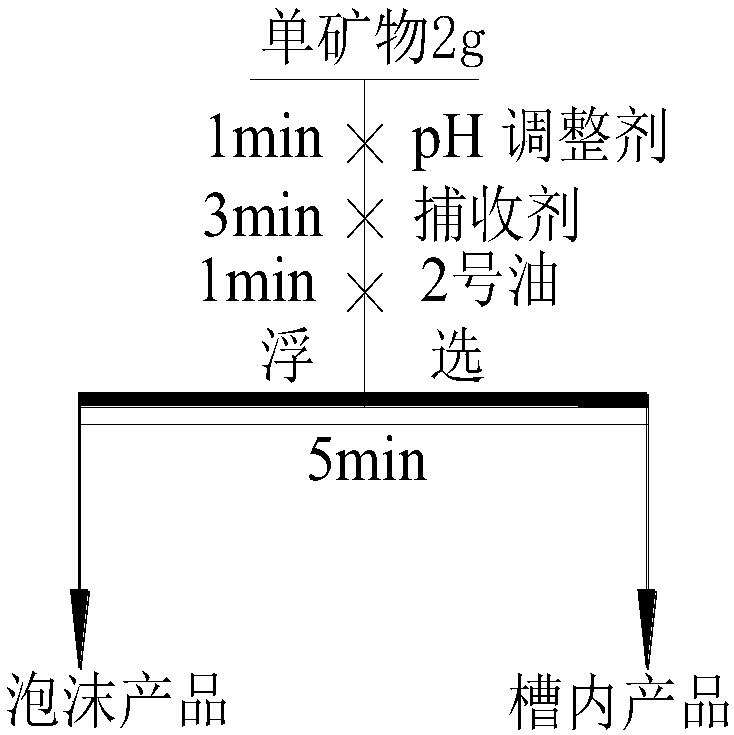

[0024] The feed particle size of bastnaesium single mineral is 0.074mm~0.038mm. First, add 2g of pure minerals and 35mL of distilled water to the flotation cell, stir and adjust the slurry for 1min; then use hydrochloric acid or NaOH to adjust the pH of the slurry to the value set in Table 5 and Table 6, and stir for 2min; then, add the collector hydroxime in sequence Acid, action time 3min, foaming agent MIBC15mg / L, action time 1min, and finally inflated and scraped for 5min; after the flotation test, the foam product was filtered, dried, weighed, and the recovery rate was calculated. The detailed test process and pharmaceutical system are as follows: figure 1 As shown, the test results are shown in Table 1 and Table 2.

Embodiment 3

[0025] Embodiment 3: Paraben hydroxamic acid and other hydroxamic acids are compared to the flotation performance of ilmenite single mineral

[0026] The particle size of ilmenite feed is 0.074mm~0.038mm. First, add 2g of pure minerals and 35mL of distilled water to the flotation cell, stir and adjust the slurry for 1min; then use hydrochloric acid or NaOH to adjust the pH of the slurry to the value set in Table 7 and Table 8, and stir for 2min; then, add the collector hydroxime in sequence Acid, action time 3min, foaming agent MIBC15mg / L, action time 1min, and finally inflated and scraped for 5min; after the flotation test, the foam product was filtered, dried, weighed, and the recovery rate was calculated. The detailed test process and pharmaceutical system are as follows: figure 1 As shown, the test results are shown in Table 3 and Table 4.

[0027] Table 1 hydroxamic acid to the flotation performance test research result (%) of bastnaesite single mineral

[0028]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com