Method for recovering tin metal from low-grade tin old tailings

A tin metal, low-grade technology, applied in the field of tin metal recovery from low-grade tin tailings, can solve problems such as difficult to achieve effective recovery and utilization of tin metal, achieve good promotion and application prospects, improve tin recovery rate indicators, reduce investment The effect of beneficiation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

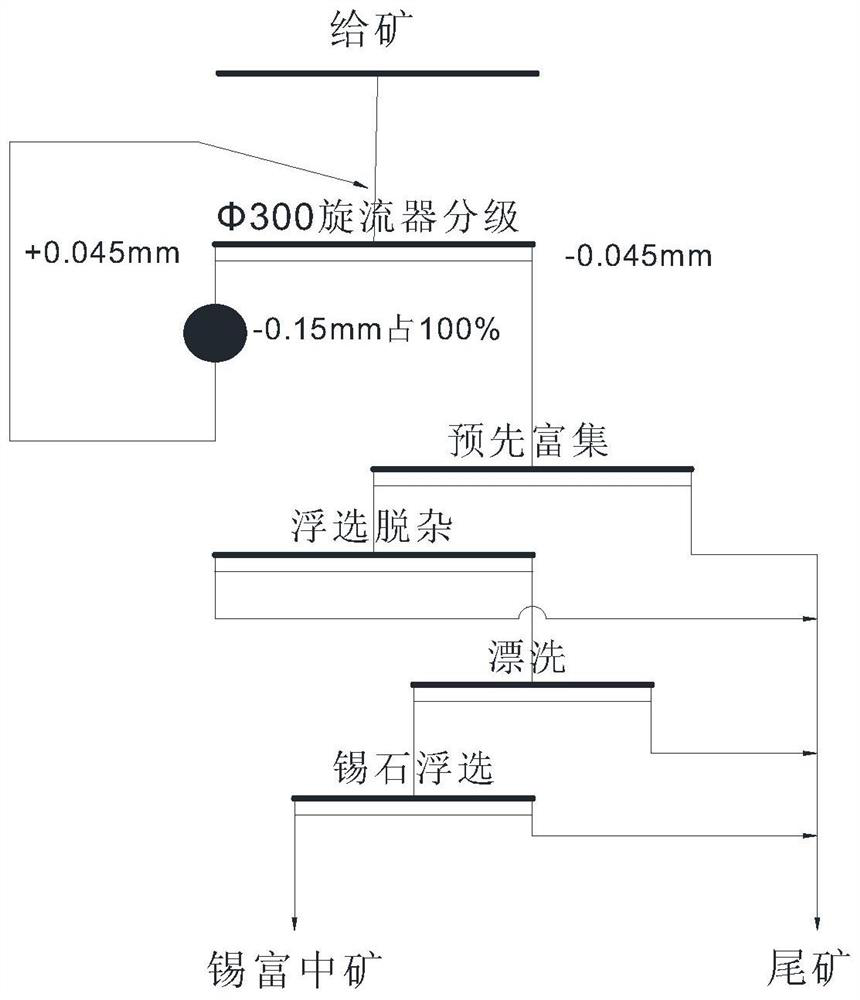

Embodiment 1

[0038] Tin old tail mine sample contained: SN0.177%, FE12.22%, PB0.902%, Zn0.412%, Cu0.12%, MnO1.23%, SiO 2 12.12%, CaO15.08%, Al 2 O 3 11.33%. The sample was analyzed, and the yield of -0.074 mm yield was 73.35%, of which the yield of -0.010 mm yield was 37.23%, the tin containing range was 0.113%, and the tin metal rate was 23.71%. The sample is graded, grinding, and the pre-enrichment enters the flotation dehydrated product containing 10.524%, the minerals are pulped, and sodium hydroxide is 1600 g / t, water glass 5000g / t, and the stone map 300g / T after T after T, a coarse selection, a selection of calcium-containing impurities, the impurity contains 33.7%, including 0.075% of the tin, and a tin metal rate of 2.05%. Duedrawal of the slurry of the slurry of the slurry, stirred, precipitate, concentrates 3% micro-mud, adjusted the tin slurry concentration, and adjusted the mine concentration of 35% to the tin stone flotation. Tinite flotation coarse selection is added to the...

Embodiment 2

[0040] Tin old tail mine sample is in Example 1. The sample is graded, grinding, and the pre-enrichment enters the lyophilized flotation work product containing 0.546%, adding sodium hydroxide 1800 g / t, water glass 4000 g / t, and the stone mam soap 250g / t is detached. The chosen, the ore gas is pulp, once a coarse selection, a selection of calcium impurities, 34.14% of the impurity containing calcium, including 0.087% of the tin, and 1.86% tin recovery rate. Duedrawal of the slurry of the slurry of the slurry, stirred, precipitate, concentrate, and adjust the concentration of the slurry to 33%, and enter the tin flotation. The tin stone flotation coarse selection is added to the oxalic acid 1000 g / t, the capture agent TL-11400G / T, the auxiliary collector P86 120G / T; Capture I, the selection II adds a capture agent TL-1 400 g / t, Accessories P86 40G / T; Preferred I Additive: Capture TL-1 150 g / t. In the end, it was 5.81% of the wealth of 中 中 otters and the total proc...

Embodiment 3

[0042] Tin old tail mine sample is in Example 1. The sample is graded, grinding, and the pre-enrichment enters the lyophilized flotation work product containing 0.533%, adding sodium hydroxide 1700 g / t, water glass 5000g / t, and then deductive floating Select, minerals are pulp, once a coarse selection, once after a selection, the calcium impurities are removed, and the impurity contains 36.03%, including the tin containing 0.071%, and the tin metal rate is 2.11%. Duedrawal of the slurry of the slurry, the slurry is added 3 times the water, stirring, precipitate, concentrates 3% micro-mud, adjusting the mine concentration to 35%, and enter tin stone flotation. The tin stone flotation coarse selection is added to the oxalic acid 800 g / t, the collector TL-11600G / T, the auxiliary catching agent P86 150G / T; scans I, the selection II, the selection III (three cleaning) is added to add arrested Receiving TL-1500G / T, auxiliary catching agent P86 40g / t; selected I added a cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com