Magnetic-flotation combined beneficiation process of spodumene

A spodumene and process technology, which is applied in the field of spodumene magnetic-flotation ore separation, can solve the problems of unsatisfactory recovery rate and other problems, and achieve the effects of strong anti-fine mud interference, excellent beneficiation index, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The test ore sample is a foreign spodumene ore, containing Li 2 O1.53%, the main mineral composition is spodumene, potassium albite, quartz, diopside, and ordinary pyroxene, followed by a small amount of muscovite, biotite, and trace amounts of tantalum niobium iron (manganese) ore.

[0026] The collector adopts the compound of MA, hydroxylamine compound and oleic acid, and the ratio of MA, hydroxylamine compound and oleic acid is 7:1.5:1.5.

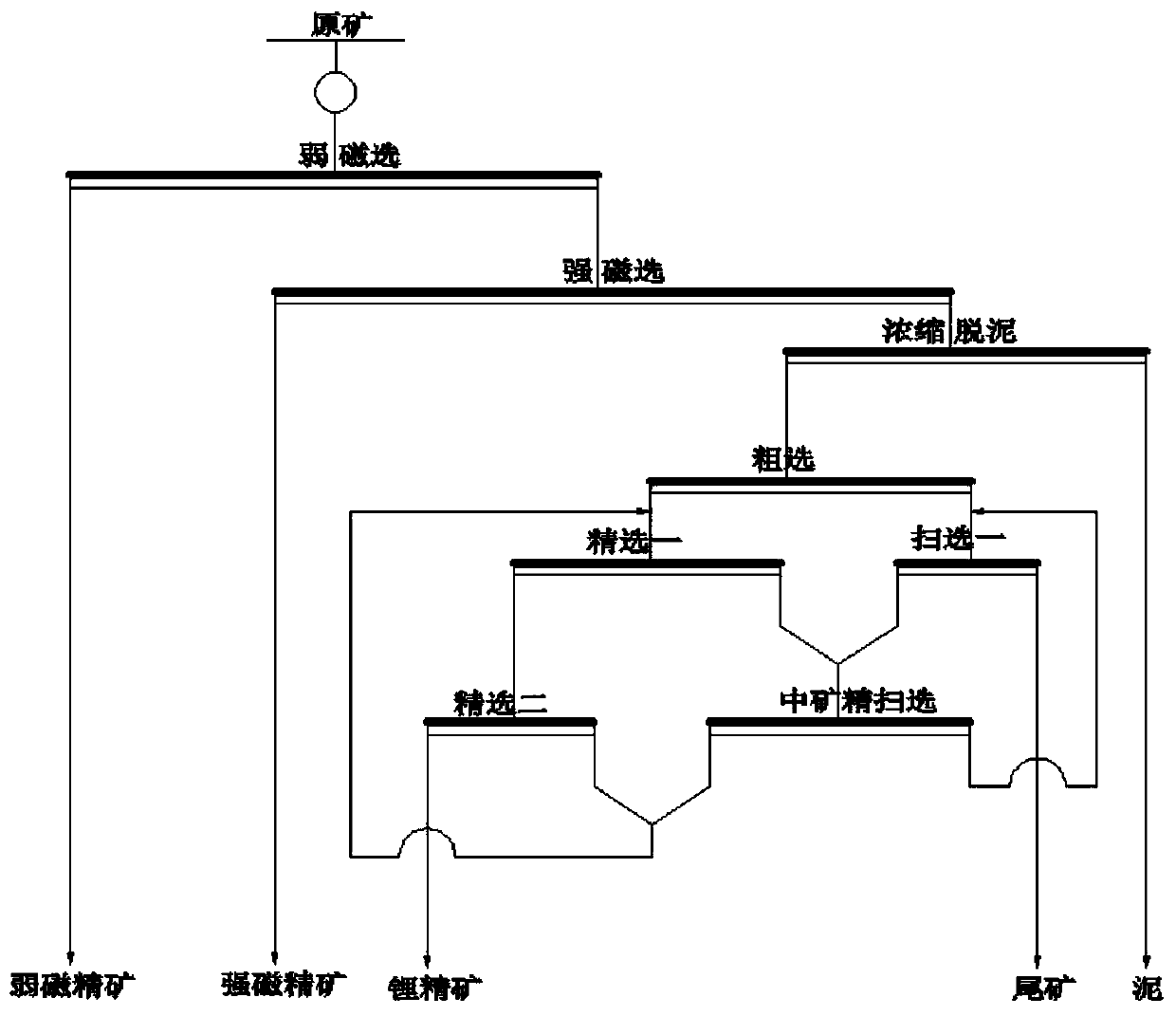

[0027] First, the spodumene ore is crushed and ground to -0.076mm, accounting for 75%; then the ore pulp after grinding is subjected to weak magnetic separation and strong magnetic separation in turn. The strength is 796.18kA / m; then the strong magnetic tailings are concentrated and deslimed, and the deslimed amount is 3.79%; finally, the deslimed strong magnetic tailings are subjected to lithium mineral flotation, and the flotation process is a roughing, Two times of sweeping, two times of fine selection, rough selection modifie...

Embodiment 2

[0030] The collector adopts the compound of MA, hydroxylamine compound and oleic acid, and the ratio of MA, hydroxylamine compound and oleic acid is 6.5:2.3:1.2.

[0031] The test ore sample is a spodumene ore in China, containing Li 2 O1.50%, the main mineral composition is spodumene, potassium albite, quartz, followed by a small amount of mica.

[0032] First, the spodumene ore is crushed and ground to -0.076mm, accounting for 70%; then the ore pulp after grinding is subjected to weak magnetic separation and strong magnetic separation in turn. The strength is 796.18kA / m; then the strong magnetic tailings are concentrated and deslimed, and the deslimed amount is 3.90%; finally, the deslimed strong magnetic tailings are subjected to lithium mineral flotation, and the flotation process is a roughing, Two times of sweeping, two times of fine selection, rough selection modifier Na 2 CO 3 Dosage 1000g / t, NaOH dosage 800g / t, CaCl 2The dosage is 150g / t, the dosage of collector i...

Embodiment 3

[0035] The collector adopts the compound of MA, hydroxylamine compound and oleic acid, and the ratio of MA, hydroxylamine compound and oleic acid is 6.7:1.8:1.5.

[0036] The test ore sample is a domestic spodumene ore, and a domestic spodumene ore contains Li 2 O1.30%, the main mineral composition is spodumene, potassium albite, quartz, followed by a small amount of mica.

[0037] First, the spodumene ore is crushed and ground to -0.076mm, accounting for 80%; then the ore pulp after grinding is subjected to weak magnetic separation and strong magnetic separation in turn. The strength is 796.18kA / m; then the strong magnetic tailings are concentrated without desliming; finally, the deslimed strong magnetic tailings are subjected to lithium mineral flotation. The flotation process is one roughing, two sweeping, two Sub-selection, coarse selection regulator Na 2 CO 3 Dosage 1200g / t, NaOH dosage 1000g / t, CaCl 2 The dosage is 100g / t, the dosage of collector is 800g / t; the dosag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com