A kind of beneficiation method of spodumene ore

A beneficiation method, spodumene technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of resource loss, low grade lithium concentrate, etc., to overcome the large gap, the flotation process is stable, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

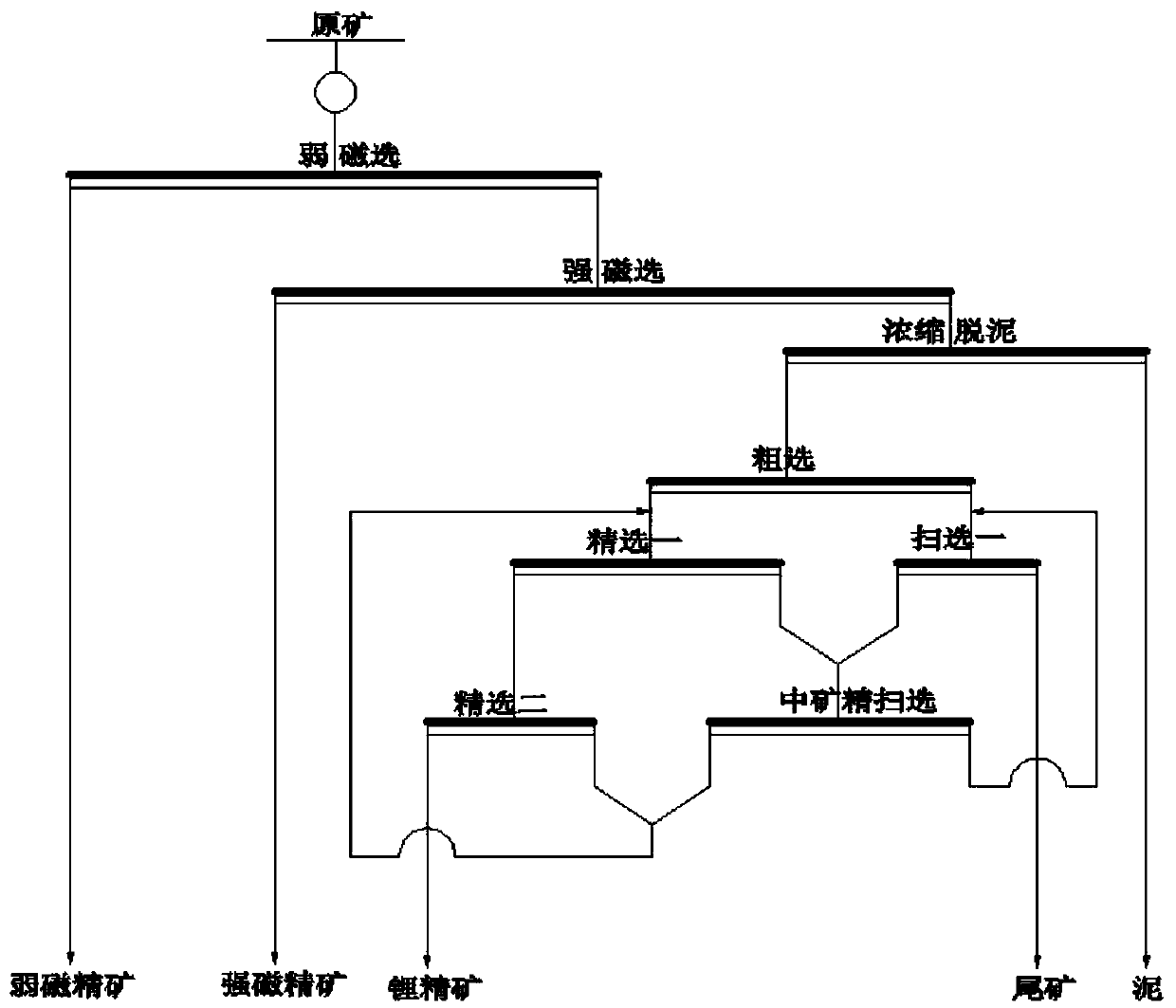

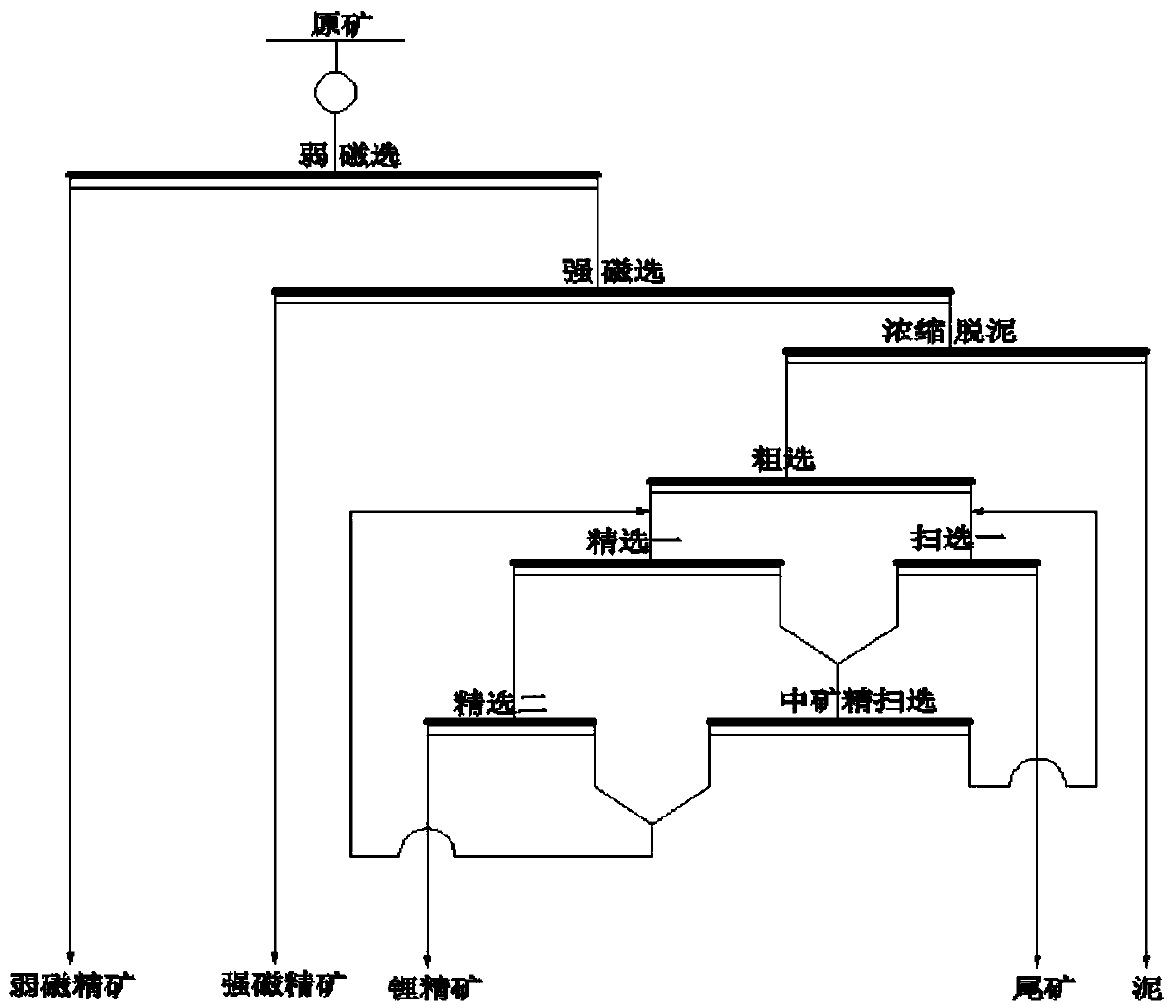

Method used

Image

Examples

Embodiment 1

[0026] The test ore sample is a foreign spodumene ore, containing Li 2 O1.53%, the main mineral composition is spodumene, potassium albite, quartz, diopside, and ordinary pyroxene, followed by a small amount of muscovite, biotite, and trace amounts of tantalum niobium iron (manganese) ore.

[0027] First, the spodumene ore is crushed and ground to -0.076mm, accounting for 75%; then the ore pulp after grinding is subjected to weak magnetic separation and strong magnetic separation in turn. The strength is 796.18kA / m; then the strong magnetic tailings are concentrated and deslimed, and the deslimed amount is 3.79%; finally, the deslimed strong magnetic tailings are subjected to lithium mineral flotation, and the flotation process is a roughing, Two times of sweeping, two times of fine selection, rough selection modifier Na 2 CO 3 The dosage is 1150g / t, the dosage of NaOH is 900g / t, and the dosage of CaCl 2 The dosage is 130g / t, the dosage of collector MA is 900g / t; the dosage...

Embodiment 2

[0030] The test ore sample is a spodumene ore in China, containing Li 2 O1.50%, the main mineral composition is spodumene, potassium albite, quartz, followed by a small amount of mica.

[0031] First, the spodumene ore is crushed and ground to -0.076mm, accounting for 70%; then the ore pulp after grinding is subjected to weak magnetic separation and strong magnetic separation in turn. The strength is 796.18kA / m; then the strong magnetic tailings are concentrated and deslimed, and the deslimed amount is 3.90%; finally, the deslimed strong magnetic tailings are subjected to lithium mineral flotation, and the flotation process is a roughing, Two times of sweeping, two times of fine selection, rough selection modifier Na 2 CO 3 Dosage 1000g / t, NaOH dosage 800g / t, CaCl 2 The dosage is 150g / t, the dosage of collector MA is 1000g / t; the dosage of Sweep-NaOH is 300g / t, the dosage of collector MA is 400g / t, and the dosage of Sweeping Collector MA is 100g / t. Flotation to obtain lith...

Embodiment 3

[0034] The test ore sample is a domestic spodumene ore, and a domestic spodumene ore contains Li 2 O1.30%, the main mineral composition is spodumene, potassium albite, quartz, followed by a small amount of mica.

[0035] First, the spodumene ore is crushed and ground to -0.076mm, accounting for 80%; then the ore pulp after grinding is subjected to weak magnetic separation and strong magnetic separation in turn. The strength is 796.18kA / m; then the strong magnetic tailings are concentrated without desliming; finally, the deslimed strong magnetic tailings are subjected to lithium mineral flotation. The flotation process is one roughing, two sweeping, two Sub-selection, coarse selection regulator Na 2 CO 3 Dosage 1200g / t, NaOH dosage 1000g / t, CaCl 2 The dosage is 100g / t, the dosage of collector MA is 800g / t; the dosage of Sweep-NaOH is 400g / t, the dosage of collector MA is 500g / t, and the dosage of Sweeping Collector MA is 50g / t. Flotation to obtain lithium concentrate and ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com