Inhibitor for sorting molybdenum bismuth ore, and application thereof

A molybdenum-bismuth ore and inhibitor technology, applied in flotation, solid separation, etc., to achieve the effects of improving the utilization rate of mineral resources, improving efficiency, and simplifying the chemical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

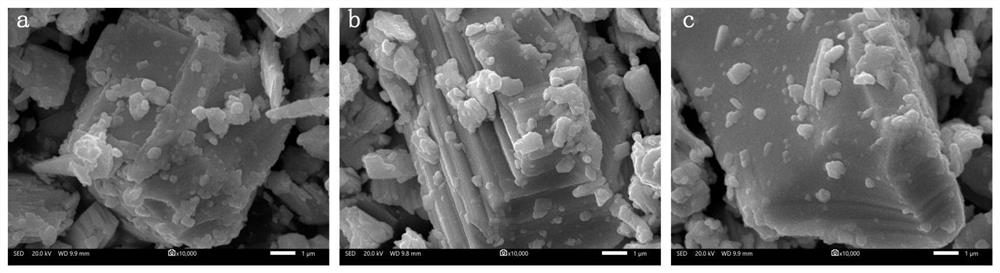

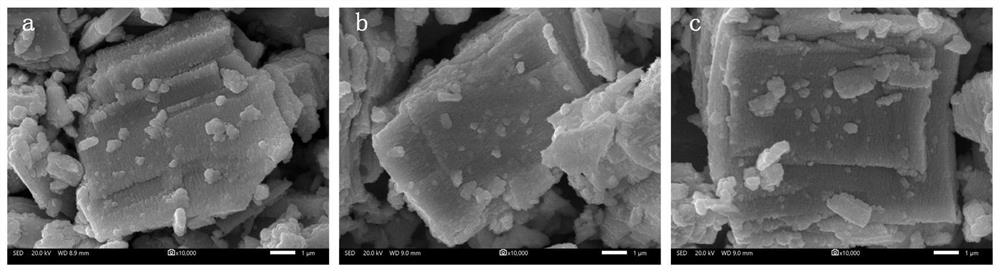

[0046] 1. Mineral raw materials

[0047] A molybdenum-bismuth mixed coarse concentrate in Hunan contains 4-5% molybdenum and 9-10% bismuth. The molybdenum is mainly molybdenite, and the bismuth is mainly bismuthite. Grinding to -0.074mm accounts for 80%;

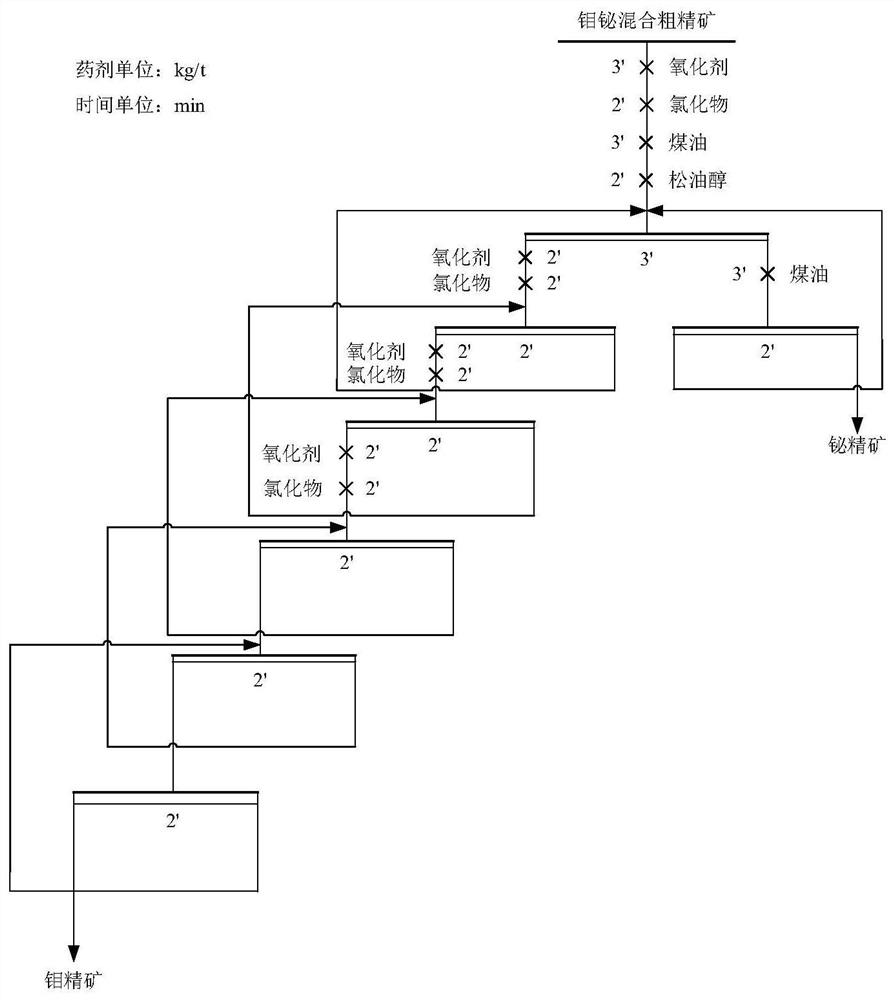

[0048] 2. The operation steps and technical conditions are as follows:

[0049] ① Rough selection operation: Weigh a certain amount of molybdenum-bismuth mixed concentrate, add water to adjust the pulp concentration to 25-30%, pour the pulp into a suitable flotation tank, and add 21% concentration of the present invention to the flotation tank in turn 500g / t of oxygen, 3000g / t of calcium hypochlorite, 1000g / t of kerosene as a collector, 25g / t of pine alcohol oil as a foaming agent, stirring for 3 to 5 minutes for each agent, and then roughing separation of molybdenum and bismuth. Obtain molybdenum coarse concentrate and tailings; before roughing, add calcium hypochlorite and stir for 5 minutes, add collector kerosene and c...

Embodiment 2

[0058] Other conditions are consistent with Example 1, except that: in step ①, the maximum dosage of the inhibitor of the present invention is 10000g / t, and the results are shown in Table 1.

Embodiment 3

[0060] Other conditions are all consistent with embodiment 1, difference is: in step 1. in, add the inhibitor minimum dosage of the present invention, promptly oxygen 0g / t, calcium hypochlorite 300g / t, its result is as shown in table 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com