Application of an inhibitor hpma in positive flotation demagnesia of phosphate rock

A technology of inhibitor and phosphate rock, which is applied in flotation, solid separation, etc., can solve the problems of increasing the difficulty of phosphorus chemical products, the difficulty of flotation and separation of apatite and dolomite, and the reduction of the grade of phosphorus concentrate, so as to achieve the convenience of industrial Production application, low cost, and the effect of increasing floating difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of application of inhibitor HPMA in the positive flotation demagnesization of phosphate rock, comprises the following steps:

[0048] Step 1: Blending

[0049] Put the artificially mixed phosphate rock sample in the flotation equipment-hanging tank flotation machine, add deionized water and inhibitor HPMA solution with a mass concentration of 2g / L, and stir for 3min at the impeller speed of 1800r / min until mixed Uniformly, obtain phosphate rock flotation pulp; Wherein, deionized water and phosphate rock mass ratio are 6:1, and inhibitor HPMA accounts for the mass concentration of phosphate rock flotation pulp to be 40mg / L;

[0050] Step 2: Magnesium removal by positive flotation

[0051] At room temperature (21-25°C), add 1.2% NaOH aqueous solution to the phosphate rock flotation pulp, adjust the pH of the phosphate rock flotation pulp to 11.5, and stir for 2 minutes to obtain a pH value of 11.5 phosphate rock flotation slurry;

[0052] To the phosphate rock f...

Embodiment 2

[0057] A kind of application of inhibitor HPMA in the positive flotation demagnesization of phosphate rock, comprises the following steps:

[0058] Step 1: Blending

[0059] Put the artificially mixed phosphate rock sample in the flotation equipment-hanging tank flotation machine, add deionized water and inhibitor HPMA solution with a mass concentration of 3g / L, and stir for 3min at the impeller speed of 2100r / min until mixed Uniformly, obtain phosphate rock flotation pulp; Wherein, the mass ratio of deionized water and phosphate rock is 6:1, and the mass concentration of inhibitor HPMA accounting for phosphate rock flotation pulp is 60mg / L;

[0060] Step 2: Magnesium removal by positive flotation

[0061] At room temperature (21-25°C), add 0.4% NaOH aqueous solution to the phosphate rock flotation pulp, adjust the pH of the phosphate rock flotation pulp to 8.5, and stir for 2 minutes to obtain a pH value of 8.5 phosphate rock flotation slurry;

[0062] To the phosphate roc...

Embodiment 3

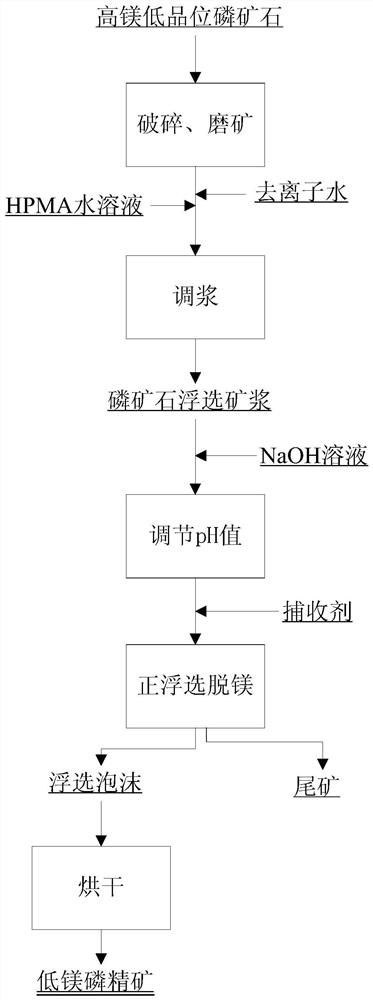

[0065] The application of a kind of inhibitor HPMA in the positive flotation magnesification of phosphate rock, the process flow diagram of its application is shown in figure 1 , including the following steps:

[0066] Step 1: Grinding

[0067] Crushing and grinding high-magnesium and low-grade phosphate rock to obtain phosphate rock powder; wherein, in the phosphate rock powder, the mass of the phosphate rock powder with a particle size of ≤74 μm accounts for 75% of the total mass of the phosphate rock powder;

[0068] Step 2: Blending

[0069] Put the above-mentioned phosphate rock powder in the flotation equipment—single-cell flotation machine, add deionized water and inhibitor HPMA solution with a mass concentration of 4g / L, stir at the impeller speed of 1900r / min for 3min until mixed evenly, and obtain Phosphate rock flotation pulp; wherein, the mass ratio of deionized water and phosphate rock is 4:1, and the mass concentration of inhibitor HPMA in the phosphate rock fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com