Method of recovering lead concentrate from lead oxide ores based on electrochemical size-mixing flotation

A lead oxide and electrochemical technology, applied in flotation, solid separation, etc., can solve the problems of low lead flotation recovery rate, affecting the quality of lead concentrate, and slow flotation speed, etc., achieving outstanding economic and environmental benefits and low cost , the effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

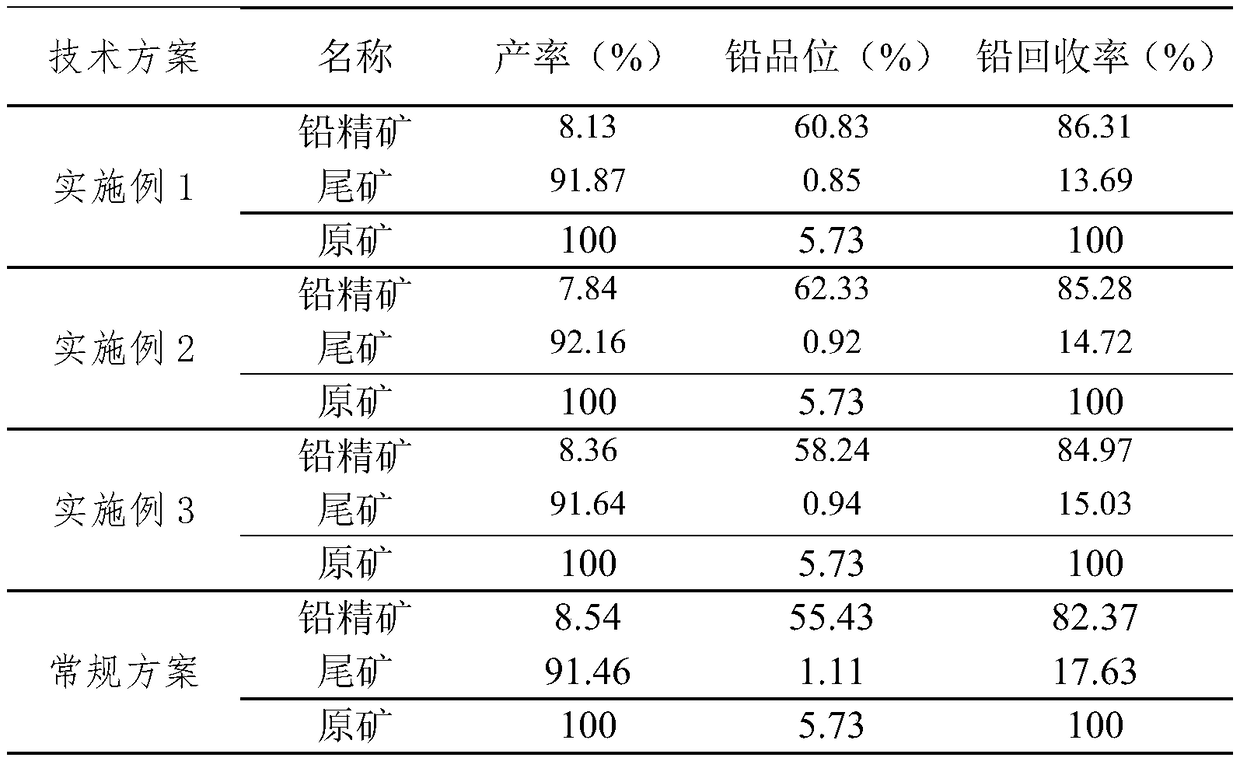

Embodiment 1

[0022] In this embodiment, a certain high-lead refractory oxidized ore is used as the lead oxide raw ore in the flotation experiment. The lead grade of the raw ore is 5.73%, the lead oxidation rate is 92.37%, and the lead in the white lead ore (lead carbonate) accounts for 68.82% of the total lead.

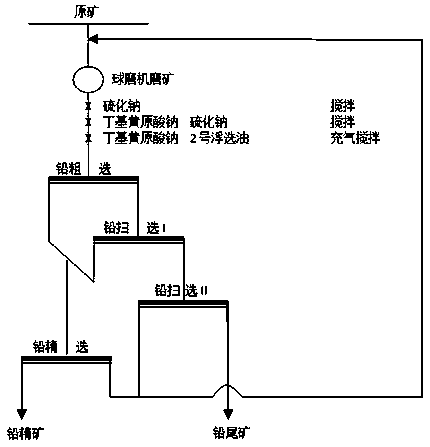

[0023] The method for recovering lead concentrate from lead oxide ore based on electrochemical slurry flotation, specifically comprises the following steps:

[0024] 1) Grinding the lead oxide raw ore in an aqueous medium with a ball mill, and ball milling the raw ore until the mass percentage of particles with a particle size of -0.074mm accounts for 90%, to obtain a pulp;

[0025] 2) Introduce the ore pulp into the mixing tank to stir and adjust the slurry, add sodium sulfide and sodium butyl xanthate in two equal parts, first add sodium sulfide 900g / t and stir for 5min, then add sodium butyl xanthate 30g / t and Sodium sulfide 900g / t, continue to stir for 5min, finally add 30g / t...

Embodiment 2

[0028] In this embodiment, a certain high-lead refractory oxidized ore is used as the lead oxide raw ore in the flotation experiment. The lead grade of the raw ore is 5.73%, the lead oxidation rate is 92.37%, and the lead in the white lead ore (lead carbonate) accounts for 68.82% of the total lead.

[0029] The method for recovering lead concentrate from lead oxide ore based on electrochemical slurry flotation, specifically comprises the following steps:

[0030] 1) Grinding the lead oxide raw ore in an aqueous medium with a ball mill, and ball milling the raw ore until the mass percentage of particles with a particle size of -0.074mm accounts for 85%, to obtain a pulp;

[0031] 2) Introduce the ore pulp into the mixing tank to stir and adjust the pulp, add sodium sulfide and sodium butyl xanthate in two equal parts, first add sodium sulfide 500g / t and stir for 4min, then add sodium butyl xanthate 35g / t and Sodium sulfide 500g / t, continue to stir for 4min, finally add 35g / t o...

Embodiment 3

[0034] In this embodiment, a certain high-lead refractory oxidized ore is used as the lead oxide raw ore in the flotation experiment. The lead grade of the raw ore is 5.73%, the lead oxidation rate is 92.37%, and the lead in the white lead ore (lead carbonate) accounts for 68.82% of the total lead.

[0035] The method for recovering lead concentrate from lead oxide ore based on electrochemical slurry flotation, specifically comprises the following steps:

[0036] 1) Grinding the lead oxide raw ore in an aqueous medium with a ball mill, and ball milling the raw ore until the mass percentage of particles with a particle size of -0.074 mm accounts for 95%, to obtain a pulp;

[0037] 2) Introduce the ore pulp into the mixing tank to stir and adjust the slurry, add sodium sulfide and sodium butyl xanthate in two equal parts, first add sodium sulfide 1000g / t and stir for 8min, then add sodium butyl xanthate 50g / t and Sodium sulfide 1000g / t, continue to stir for 6min, finally add 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com