Method for recycling waste water in collophanite double-reverse flotation process according to different qualities

A technology of quality separation and reuse, double reverse flotation, applied in flotation, general water supply saving, solid separation, etc., can solve the problems of increasing the cost of mineral processing, the impact of mineral processing indicators, and the difficulty of controlling foam in the double reverse process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

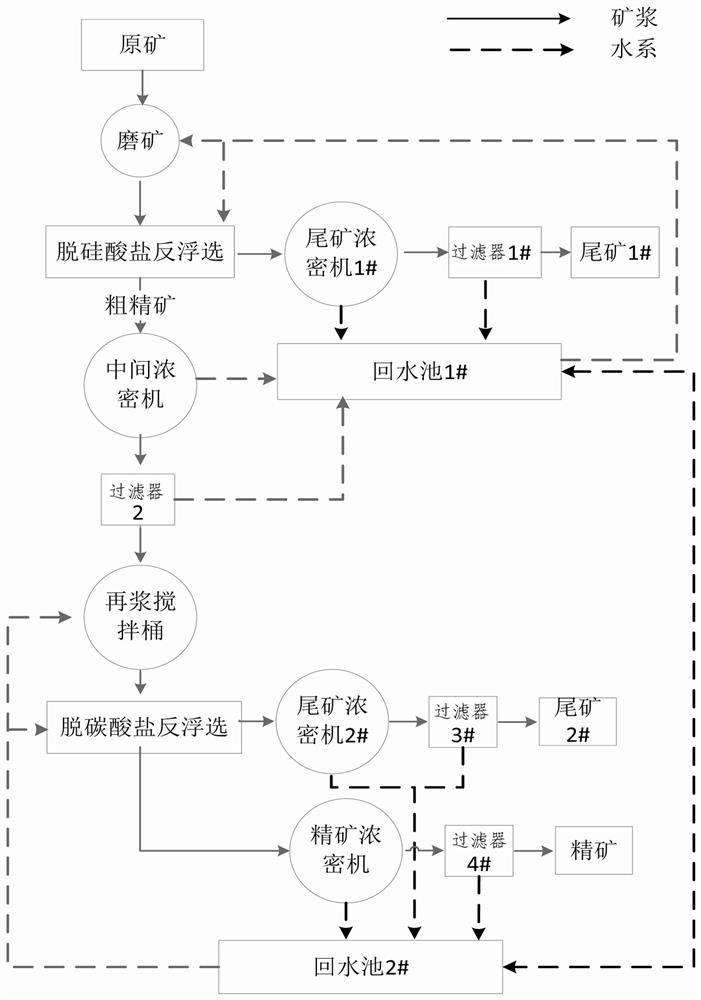

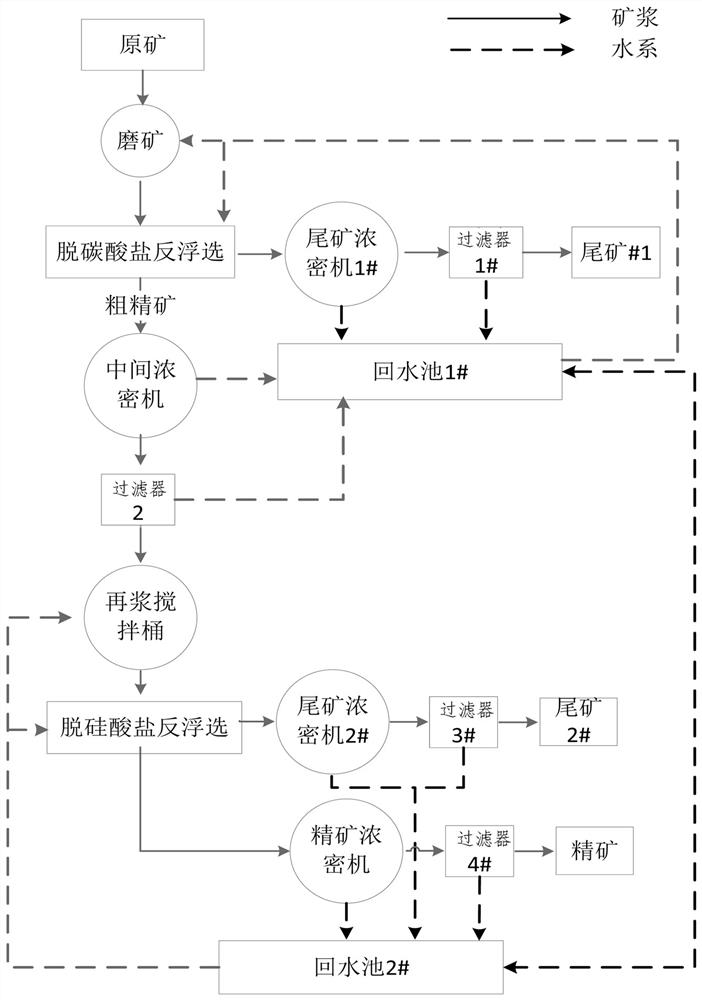

[0028] Embodiment 1: refer to figure 1 , a method for waste water quality separation and reuse in the double reverse flotation process of colphosphane. Mine 1 and coarse concentrate, tailings 1# enter tailings thickener 1# for thickening and then enter filter 1#, overflow and filtrate enter backwater tank 1#, tailings 1# filter cake (water content 12-15%) Carry out follow-up treatment; the coarse concentrate enters the middle thickener and then enters the filter 2#, and the overflow and filtrate enters the return pool 1#, and the filter cake (water content 10-12) is slurried and then reversed to remove carbonate minerals Election to obtain tailings 2# and concentrate; tailings 2# enters tailings thickener 2# for thickening and then enters filter 3#, overflow and filtrate enter backwater pool 2#, tailings 2# filter cake (water content 12- 15%) for follow-up treatment; the concentrate slurry enters the concentrate thickener and then enters the filter 4#, and the overflow and fi...

Embodiment 2

[0031] Embodiment 2: refer to figure 1 , a method for waste water quality separation and reuse in the double reverse flotation process of colphosphane. Mine 1 and coarse concentrate, tailings 1 enter tailings thickener 1 for thickening into filter 1, overflow and filtrate enter backwater tank 1, tailings 1 filter cake (water content 12-15%) for subsequent treatment; coarse and fine The ore enters the middle thickener and then enters the filter 2, and the overflow and filtrate enter the return pool 1. After the filter cake (water content 10-12%) is slurried, reverse flotation to remove carbonate minerals is carried out to obtain tailings 2 and refined Mine; tailings 2 enter tailings thickener 2 for thickening and then enter filter 3, overflow and filtrate enter backwater tank 2, tailings 2 filter cake (water content 12-15%) for subsequent treatment; concentrate slurry enters concentrate thickening After the machine is thickened, it enters the filter 4, the overflow and filtrat...

Embodiment 3

[0034] Embodiment 3: refer to figure 1 , a method for waste water quality separation and reuse in the double reverse flotation process of colphosphane. Mine 1 and coarse concentrate, tailings 1 enter tailings thickener 1 for thickening into filter 1, overflow and filtrate enter backwater tank 1, tailings 1 filter cake (water content 12-15%) for subsequent treatment; coarse and fine The ore enters the middle thickener and then enters the filter 2, and the overflow and filtrate enter the return pool 1. After the filter cake (water content 10-12%) is slurried, reverse flotation to remove carbonate minerals is carried out to obtain tailings 2 and refined Mine; tailings 2 enter tailings thickener 2 for thickening and then enter filter 3, overflow and filtrate enter backwater tank 2, tailings 2 filter cake (water content 12-15%) for subsequent treatment; concentrate slurry enters concentrate thickening After the machine is thickened, it enters the filter 4, the overflow and filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com