Method for selecting gold from gold ore leaching residue

A leaching slag and gold beneficiation technology, which is applied in chemical instruments and methods, flotation, wet separation, etc., can solve problems affecting the quality of flotation gold concentrate, and achieve low beneficiation cost, easy management and operation, and excellent technological process results simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

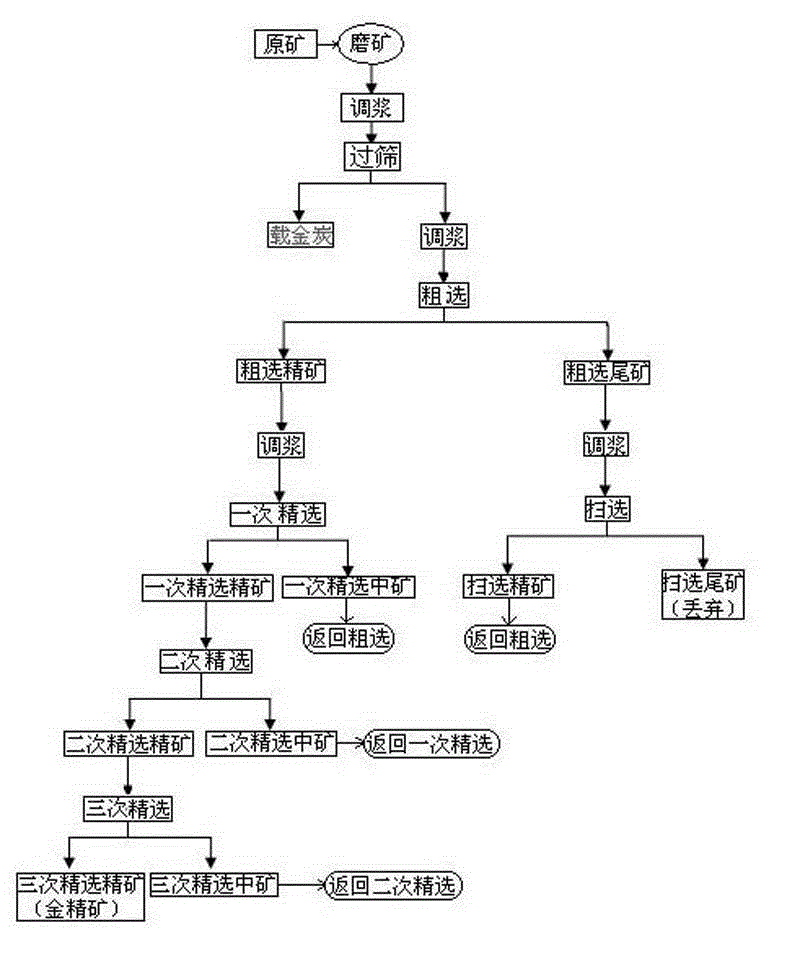

Image

Examples

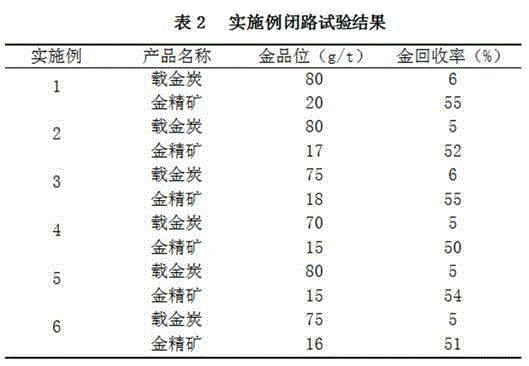

Embodiment 1

[0018] (1) Grinding: Grinding the raw ore slag, grinding the raw ore until the ore particles smaller than 0.074mm account for 75%, adding 1000 g / t of activated carbon during grinding, adding water to adjust the slurry to a concentration of 36%;

[0019] (2) Grid sieve: A 40-mesh grid sieve is used at the ore discharge port of the ball mill to first filter out the gold-loaded carbon with higher gold content on the screen, and then enter the pulp under the screen into the flotation operation;

[0020] (3) Rough separation: add gangue inhibitor, collector, and foaming agent in turn to the slurry, adjust the slurry and stir, and carry out rough separation and flotation operations to obtain rough separation concentrate and rough separation tailings; the addition amount is based on each In terms of tons of raw ore, the inhibitor sodium fluorosilicate is 700 g / t, the collector butyl ammonium black medicine is 10 g / t, and the foaming agent terpineol oil is 10 g / t;

[0021] (4) Sweepin...

Embodiment 2

[0027] (1) Grinding: Grinding the raw ore slag, grinding the raw ore until the ore particles smaller than 0.074mm account for 70%, adding 1200 g / t of activated carbon during grinding, adding water to adjust the slurry to a concentration of 30%;

[0028] (2) Grid sieve: A 40-mesh grid sieve is used at the ore discharge port of the ball mill to first filter out the gold-loaded carbon with higher gold content on the screen, and then enter the pulp under the screen into the flotation operation;

[0029] (3) Rough separation: add gangue inhibitor, collector, and foaming agent in turn to the slurry, adjust the slurry and stir, and carry out rough separation and flotation operations to obtain rough separation concentrate and rough separation tailings; the addition amount is based on each In terms of tons of raw ore, the inhibitor sodium fluorosilicate is 500 g / t, the collector butyl ammonium black medicine is 15 g / t, and the foaming agent terpineol oil is 5 g / t;

[0030] (4) Sweeping...

Embodiment 3

[0036] (1) Grinding: Grinding the raw ore slag, grinding the raw ore until the ore particles smaller than 0.074mm account for 80%, adding 900 g / t of activated carbon during the grinding, adding water to adjust the slurry to a concentration of 40%;

[0037] (2) Grid sieve: A 40-mesh grid sieve is used at the ore discharge port of the ball mill to first filter out the gold-loaded carbon with higher gold content on the screen, and then enter the pulp under the screen into the flotation operation;

[0038] (3) Rough separation: add gangue inhibitor, collector, and foaming agent in turn to the slurry, adjust the slurry and stir, and carry out rough separation and flotation operations to obtain rough separation concentrate and rough separation tailings; the addition amount is based on each In terms of tons of raw ore, the inhibitor sodium fluorosilicate is 900 g / t, the collector butyl ammonium black medicine is 15 g / t, and the foaming agent terpineol oil is 10 g / t;

[0039] (4) Swee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com