Ore benefication process for low-grade fine particle grade embedded distribution refractory iron ore

A fine-grained, low-grade technology, applied in the direction of selective deposition, solid separation, chemical instruments and methods, etc., can solve the problems of inapplicability in large-scale mines, easy fluctuation of desliming effect, difficult control, etc., and achieve great flexibility Excellent performance and adaptability, remarkable desliming effect, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

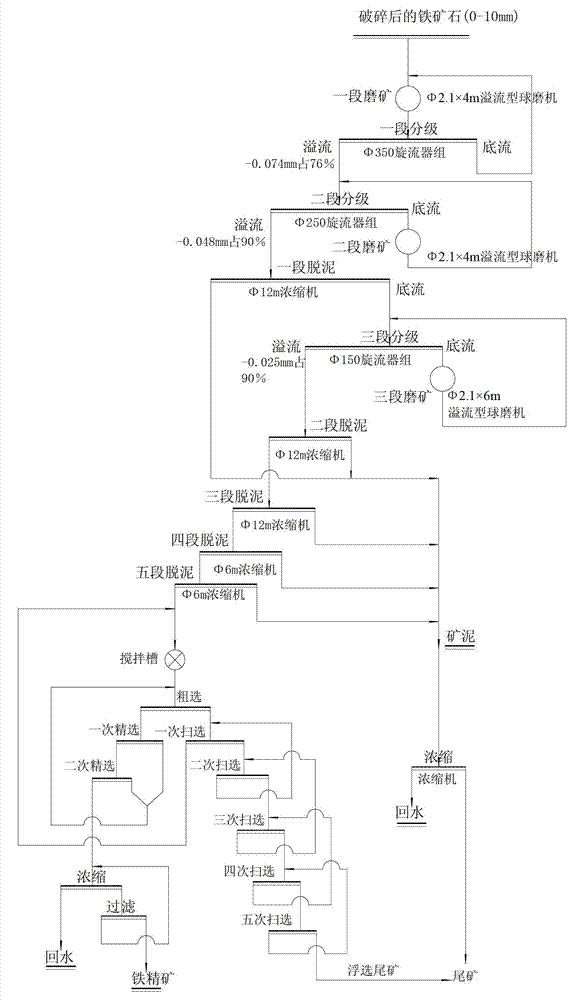

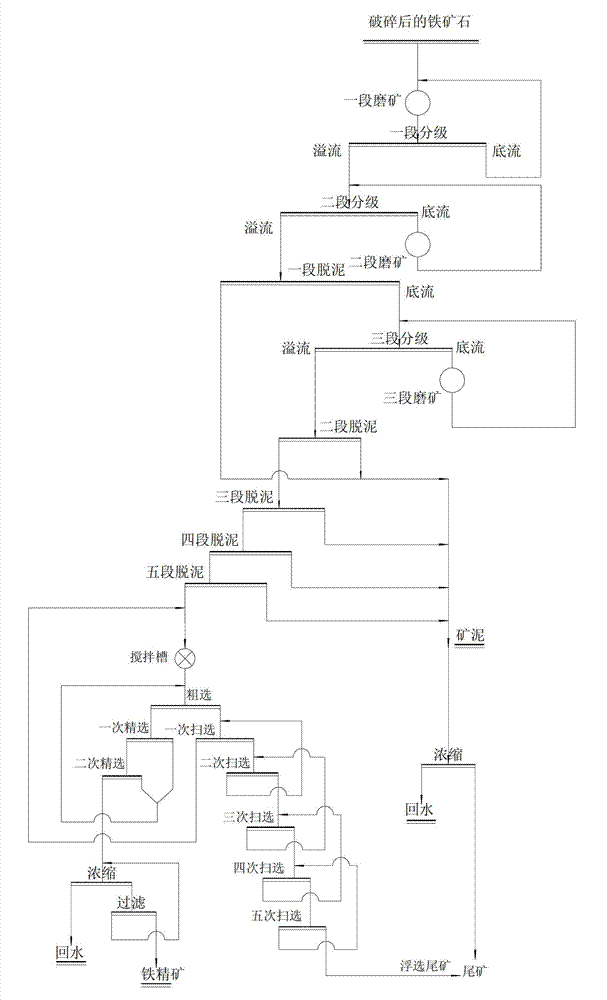

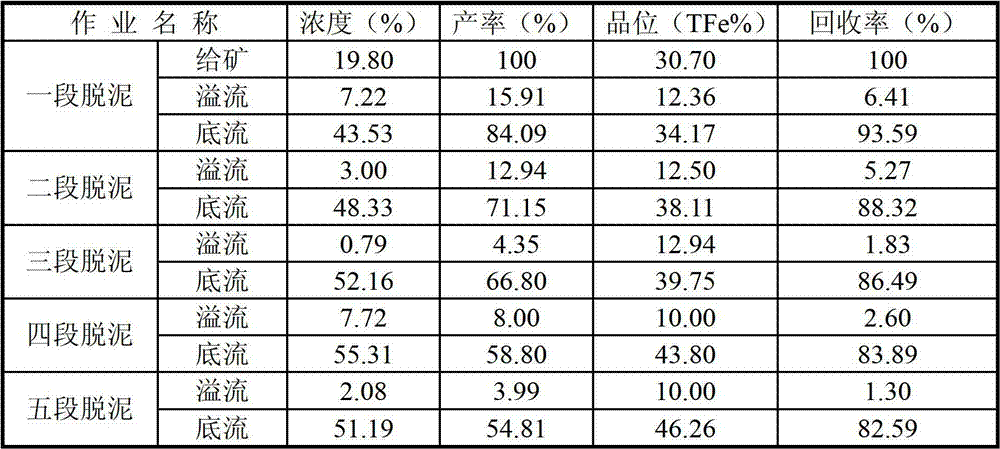

[0041] a kind of like figure 1 The beneficiation process of the low-grade fine-grained grade embedding refractory iron ore shown in the present invention comprises the following steps:

[0042] (1) A fine-grained iron ore whose particle size after crushing is controlled below 10 mm (assuming a production scale of 300,000 t / a, the iron ore is mainly composed of magnetite, hematite and a small amount of false hematite, and Mainly magnetite, the raw ore grade is about 28%, and the particle size of the useful minerals is mostly 2μm~30μm) for one-stage grinding, using a closed-circuit grinding consisting of a φ350mm cyclone group and a Φ2.1×4m overflow ball mill The system conducts one stage of grinding, the discharge after one stage of grinding is classified for one stage, the underflow after one stage of classification returns to enter one stage of grinding again, and the overflow after one stage of classification enters the next step (discharge fineness control of one stage of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com