A kind of bauxite graded flotation desiliconization method

A bauxite and desiliconization technology, applied in flotation, chemical instruments and methods, solid separation, etc., can solve problems such as poor selectivity, influence on coarse-grained flotation effect, large fluctuations in concentrate grade, etc., and achieve reduction Production costs, increased throughput and effects on flotation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

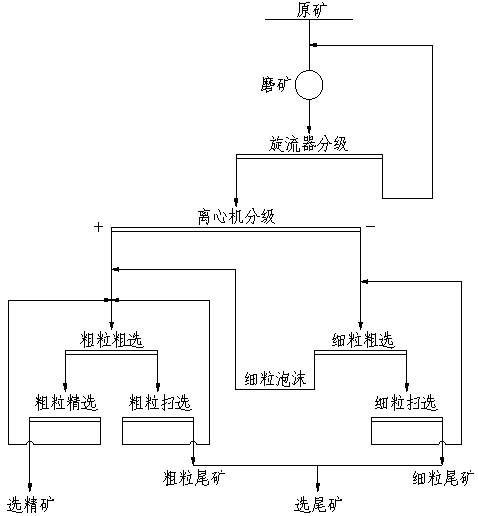

[0020] A bauxite mine in Shanxi, through one-stage grinding, first uses a cyclone for one-stage classification, and the overflow of the cyclone is passed through a high-speed disc classifier for second-stage classification. After classification by the high-speed disc classifier, the fine-grained pulp enters the fine-grained float The coarse-grained ore pulp enters the coarse-grained flotation operation. The specific process conditions are:

[0021] (1) The first stage is classified by FX350 cyclone, and the second stage is classified by KFJG1500 high-speed disc classifier;

[0022] (2) The overflow fineness of the high-speed disc classifier is less than 10μm and the content is 95%;

[0023] (3) After classification, the fine-grained pulp adopts a roughing and a sweeping flotation process;

[0024] (4) After classification, the coarse-grained ore pulp adopts a process flow of one-time roughing, one-time beneficiation, and one-time sweeping;

[0025] (5) The fine-grained ore ...

Embodiment 2

[0030] A bauxite mine in Henan, through one-stage grinding, first uses a cyclone for one-stage classification, and the overflow of the cyclone is passed through a high-speed disc classifier for second-stage classification. After classification by the high-speed disc classifier, the fine-grained pulp enters the fine-grained float The coarse-grained ore pulp enters the coarse-grained flotation operation. The specific process conditions are:

[0031] (1) The first stage is classified by FX250 cyclone, and the second stage is classified by KFJG1000 high-speed disc classifier;

[0032] (2) The overflow fineness of the high-speed disc classifier is less than 1 μm and the content is 95%;

[0033] (3) After classification, the fine-grained pulp adopts a roughing and a sweeping flotation process;

[0034] (4) After classification, the coarse-grained ore pulp adopts a process flow of one-time roughing, one-time beneficiation, and one-time sweeping;

[0035] (5) The fine-grained ore p...

Embodiment 3

[0040] A bauxite mine in Guizhou, through one-stage grinding, first uses a cyclone for one-stage classification, and the overflow of the cyclone is passed through a high-speed disc classifier for second-stage classification. After classification by the high-speed disc classifier, the fine-grained pulp enters the fine-grained float The coarse-grained ore pulp enters the coarse-grained flotation operation. The specific process conditions are:

[0041] (1) The first stage is classified by FX550 cyclone, and the second stage is classified by KFJG2000 high-speed disc classifier;

[0042] (2) The overflow fineness of the high-speed disc classifier is less than 5μm and the content is 95%;

[0043] (3) After classification, the fine-grained pulp adopts a roughing and a sweeping flotation process;

[0044] (4) After classification, the coarse-grained ore pulp adopts a process flow of one-time roughing, one-time beneficiation, and one-time sweeping;

[0045] (5) The fine-grained ore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com