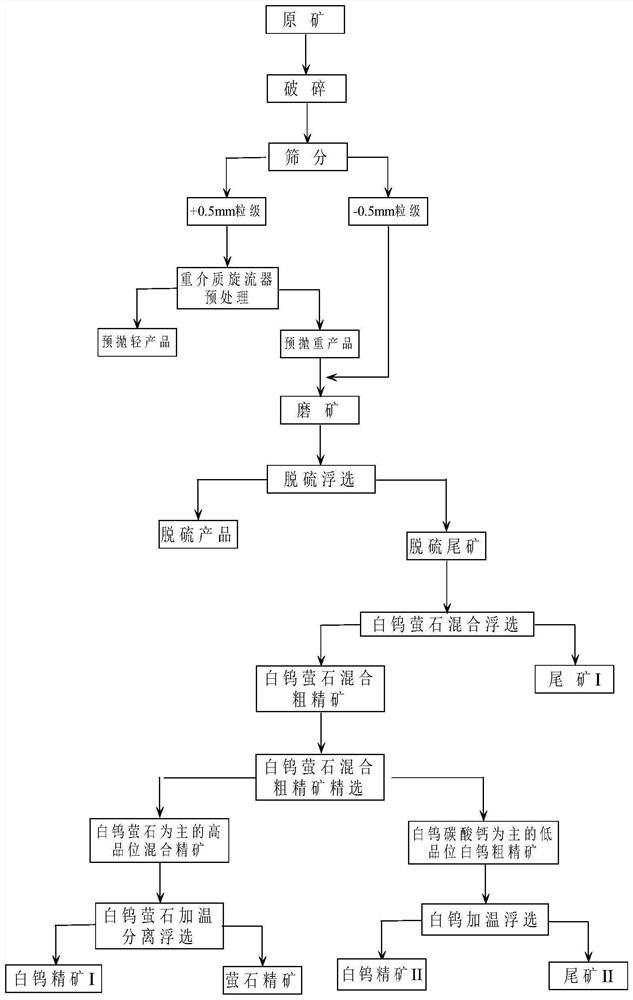

Beneficiation method for high-calcium-carbonate low-grade scheelite

A beneficiation method and low-grade technology, applied in flotation, solid separation, grain processing, etc., can solve problems such as complex process flow, fine scheelite particle size, and high fluorite yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The average grade of raw ore is: CaCO 3 Grade 37.86%, WO 3 Grade 0.32%, CaF 2 Grade 9.19%, the main metal minerals are scheelite, a small amount of pyrite, non-metallic minerals are mainly calcite, fluorite, a small amount of feldspar, quartz and other silicate gangue minerals, the raw ore belongs to high calcium carbonate low-grade white Tungsten.

[0051] The specific steps of the mineral processing method of the present embodiment are as follows:

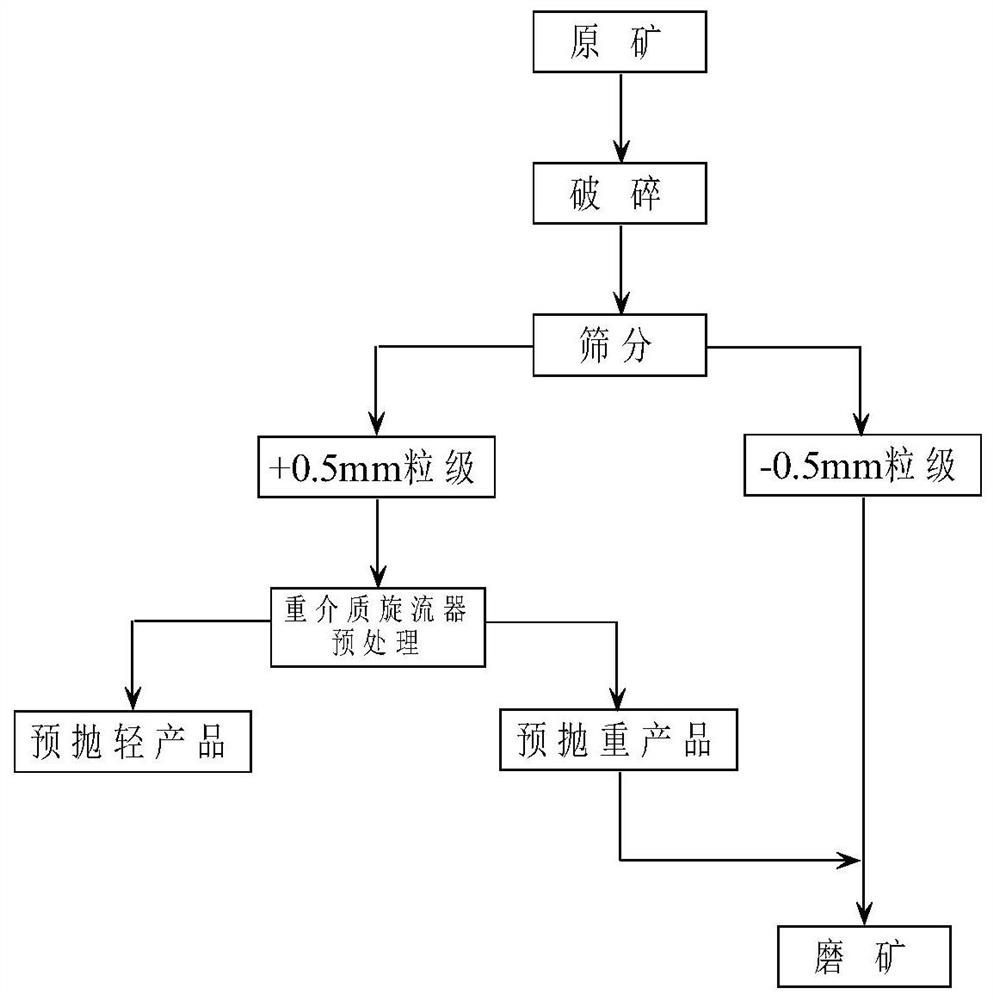

[0052] a) Dense medium cyclone pretreatment: crush the raw ore to -15mm, then sieve into -15+0.5mm particle size and -0.5mm particle size; pour -15+0.5mm particle size into Pretreatment in the medium cyclone to obtain pre-throwing light products and pre-throwing heavy products; then the pre-throwing heavy products and -0.5mm particle size are combined into the mill for subsequent selection, such figure 2 shown.

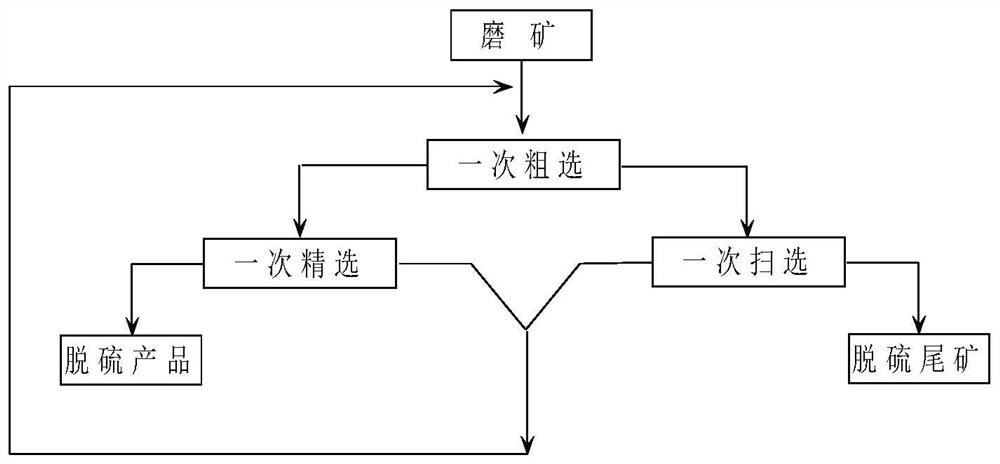

[0053] b) Removal of sulfide minerals: After grinding, add 50g / t copper sulfate, 50g / t butyl xanthate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com