Carbon organic matter deposited low grade manganese ore flotation technology

A low-grade manganese ore and organic matter technology, applied in flotation, solid separation, etc., can solve the problems of increasing the amount of collector, reducing flotation selectivity, and increasing the cost of beneficiation, so as to avoid mechanical inclusions and transportation difficulties, and is easy to control and stability, the effect of beneficiation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

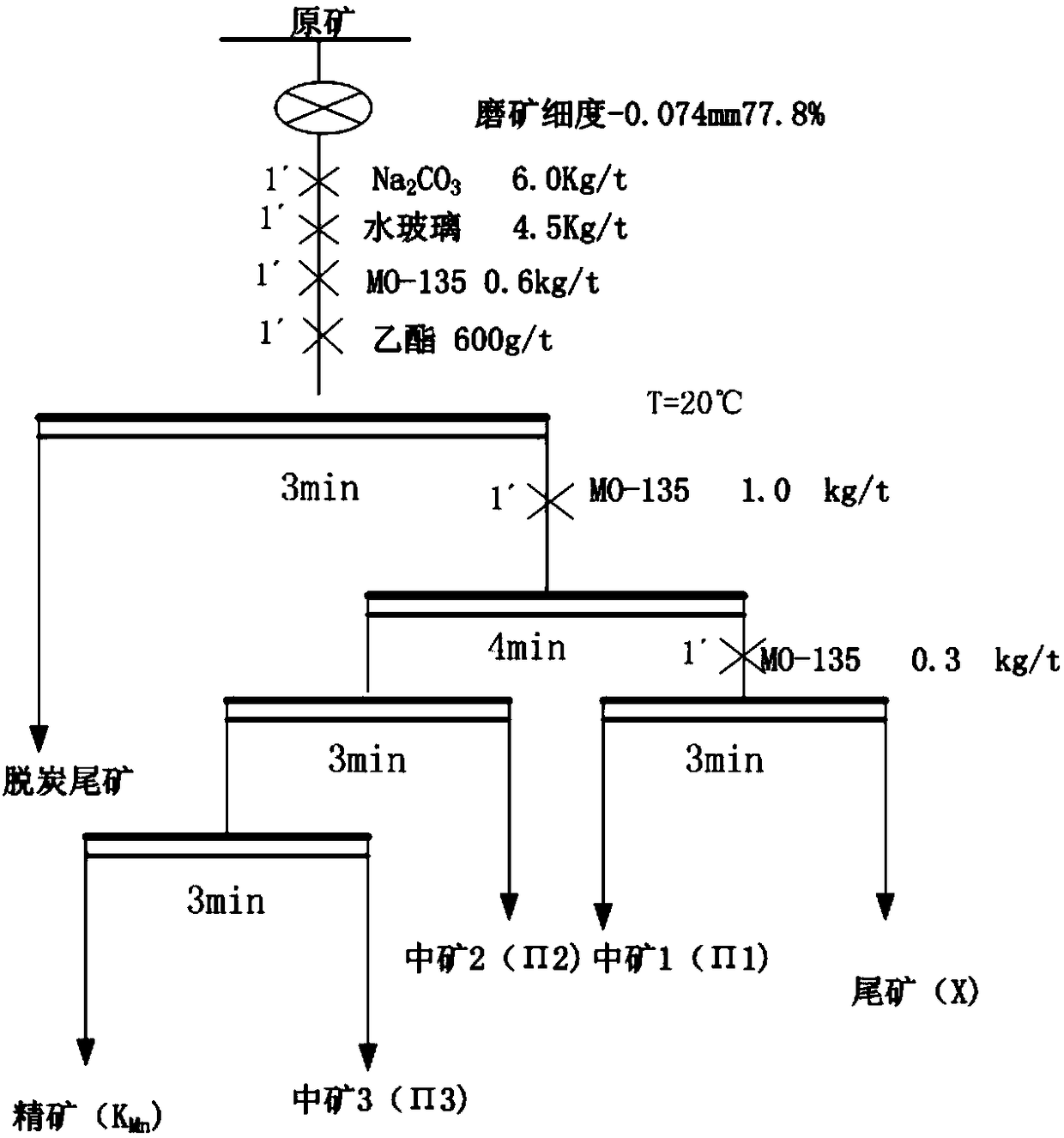

Embodiment 1

[0032] A carbonaceous organic matter deposition type low-grade manganese ore flotation process, the ore raw materials used include: Mn10.01wt%, SiO 2 41.05wt%, TFe 3.84wt%, P 0.34wt%, carbonaceous organic matter 5.0wt%; Concrete flotation process comprises the following steps:

[0033]1) Add water, crush and grind carbonaceous organic matter deposition type low-grade manganese ore (-0.074mm content 77.8%) to obtain a pulp with a mass concentration of 20%, add sodium carbonate to the pulp to adjust the pH value to 10.5, and then add water glass and anion Type fatty acid collector (MO-135) and diethyl phthalate, stirring slurry and using flotation machine for flotation decarbonization roughing, the resulting foam product is carbon-containing, phosphorus tailings (decarbonization tailings ore), the product in the tank enters the positive flotation desiliconization process; the addition of sodium carbonate relative to the original ore is 6.0kg / t, the addition of sodium silicate r...

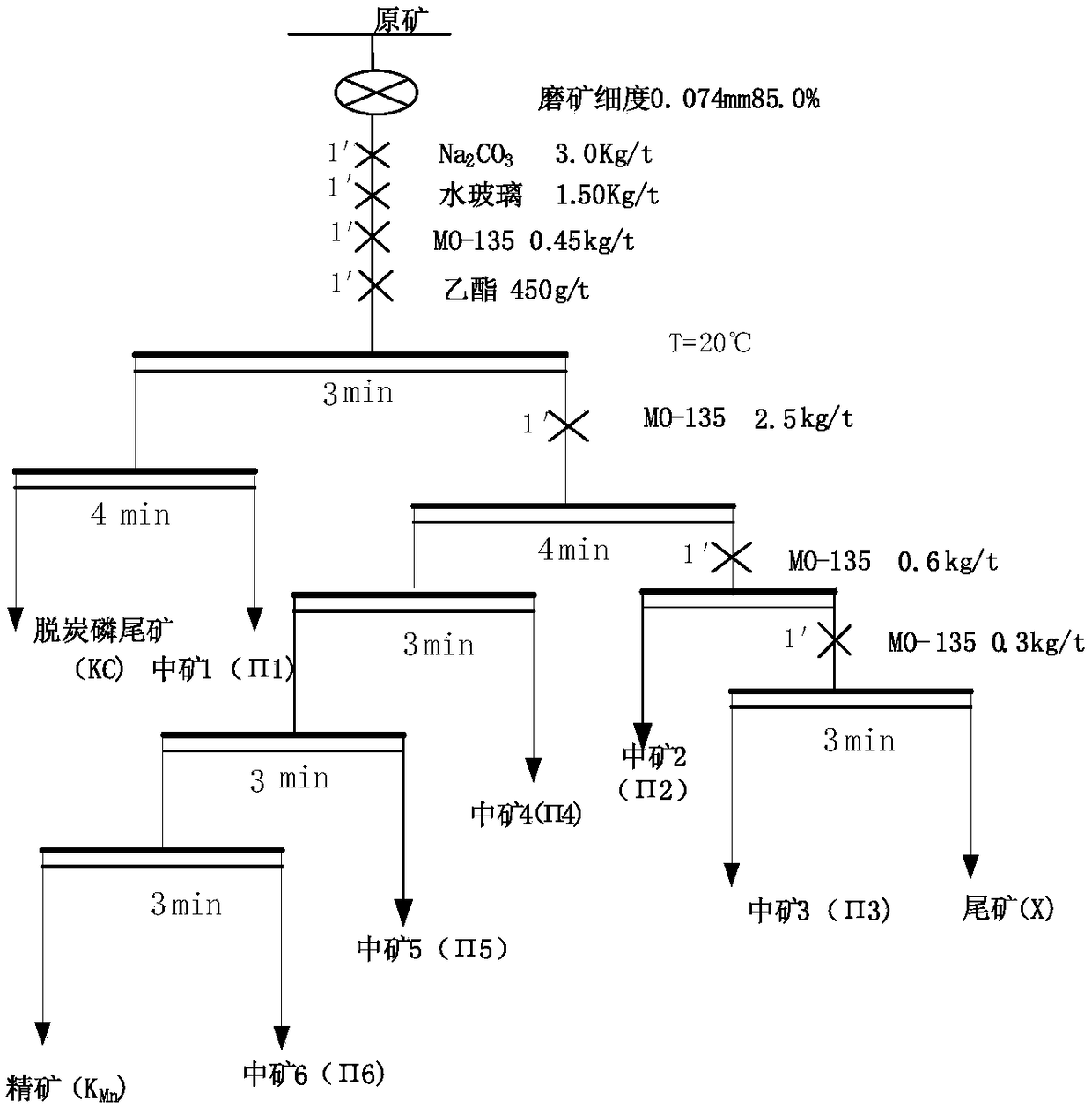

Embodiment 2

[0038] A carbonaceous organic matter deposition type low-grade manganese ore flotation process, the ore raw materials used include: Mn13.55wt%, SiO 2 25.35wt%, TFe 2.30wt%, P 0.14wt%, carbonaceous organic matter 3.5wt%; Concrete flotation process comprises the following steps:

[0039] 1) Add water to crush and grind carbonaceous organic matter deposition type low-grade manganese ore (-0.074mm content 85.0%) to obtain a pulp with a mass concentration of 30%. Add sodium carbonate to the pulp to adjust the pH value to 8.5, then add water glass and anion Type fatty acid collector (MO-135) and diethyl phthalate, stirring slurry and using flotation machine for flotation decarbonization roughing (3min), the resulting foam product is tailings containing carbon and phosphorus, This product is scanned again, the product in the tank obtained by scanning is medium ore, and the medium ore returns to the previous operation, and the foam product obtained by scanning is decarburized phospho...

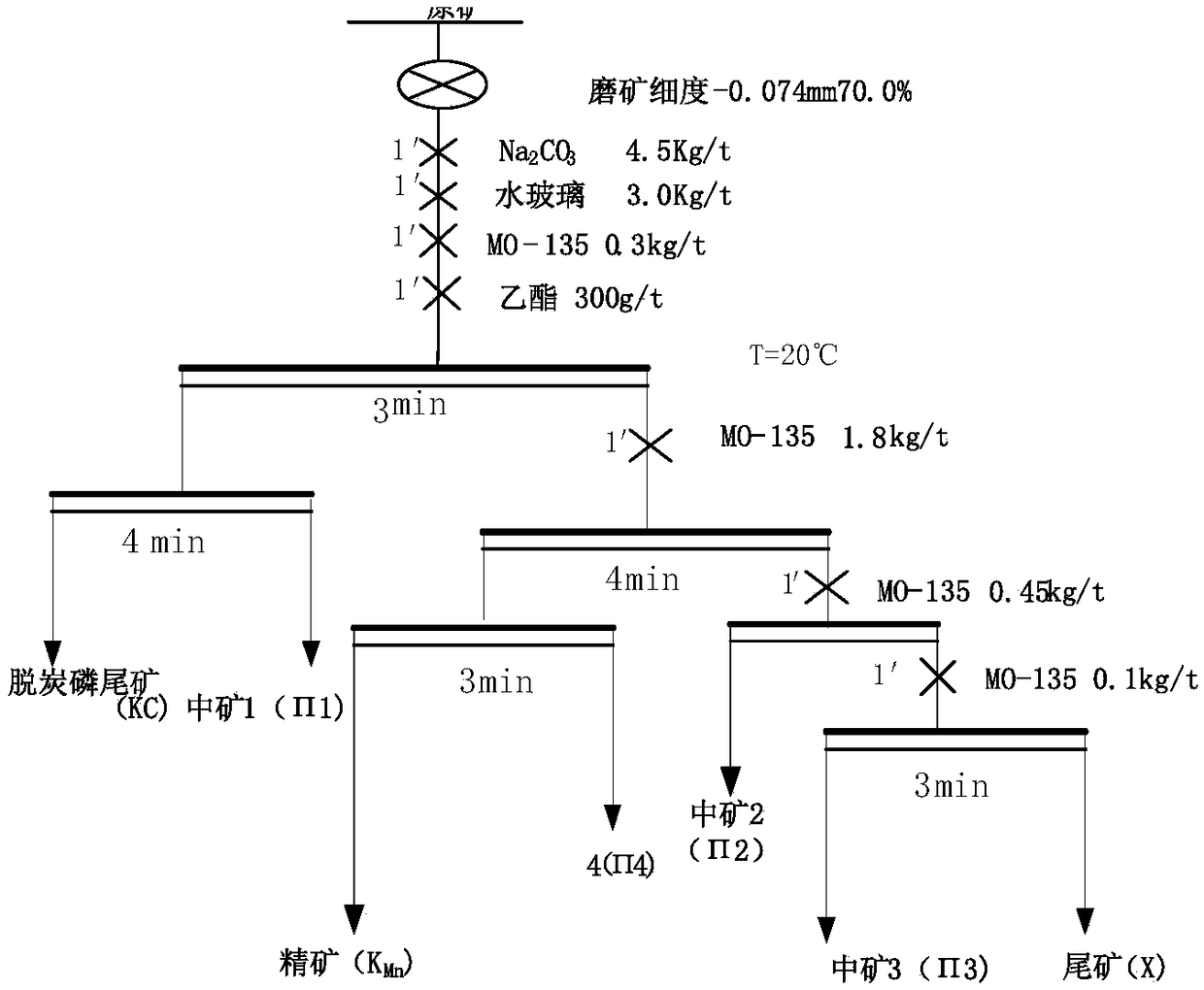

Embodiment 3

[0044] A carbonaceous organic matter deposition type low-grade manganese ore flotation process, the ore raw materials used include: Mn12.35wt%, SiO 2 33.12wt%, TFe 2.81wt%, P 0.25wt%, carbonaceous organic matter 0.5wt%; Concrete flotation process comprises the following steps:

[0045] 1) Add water to crush and grind carbonaceous organic matter deposition type low-grade manganese ore (-0.074mm content 70.0%) to obtain a pulp with a mass concentration of 40%. Add sodium carbonate to the pulp to adjust the pH to 9.5, then add water glass and anion Type fatty acid collector (MO-135) and diethyl phthalate, stirring slurry and using flotation machine for flotation decarbonization roughing, the resulting foam product is tailings containing carbon and phosphorus, this product Sweeping again, the product in the tank obtained by sweeping is middle ore, and the middle ore returns to the previous operation, and the foam product obtained by sweeping is decarburized phosphorus tailings; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com