System and method for evaluating floatability of particles

A particle and buoyancy technology, which is applied in the field of particle flotation, can solve problems such as inaccurate judgment, and achieve the effect of simplifying the test operation process, shortening test time, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

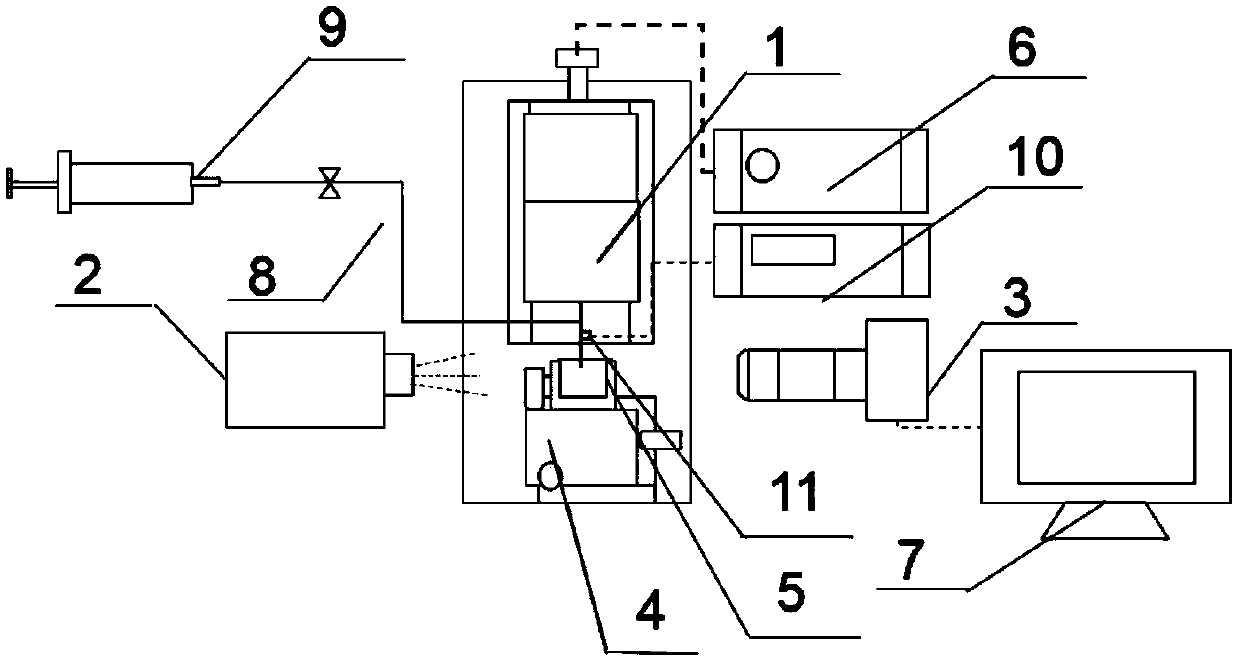

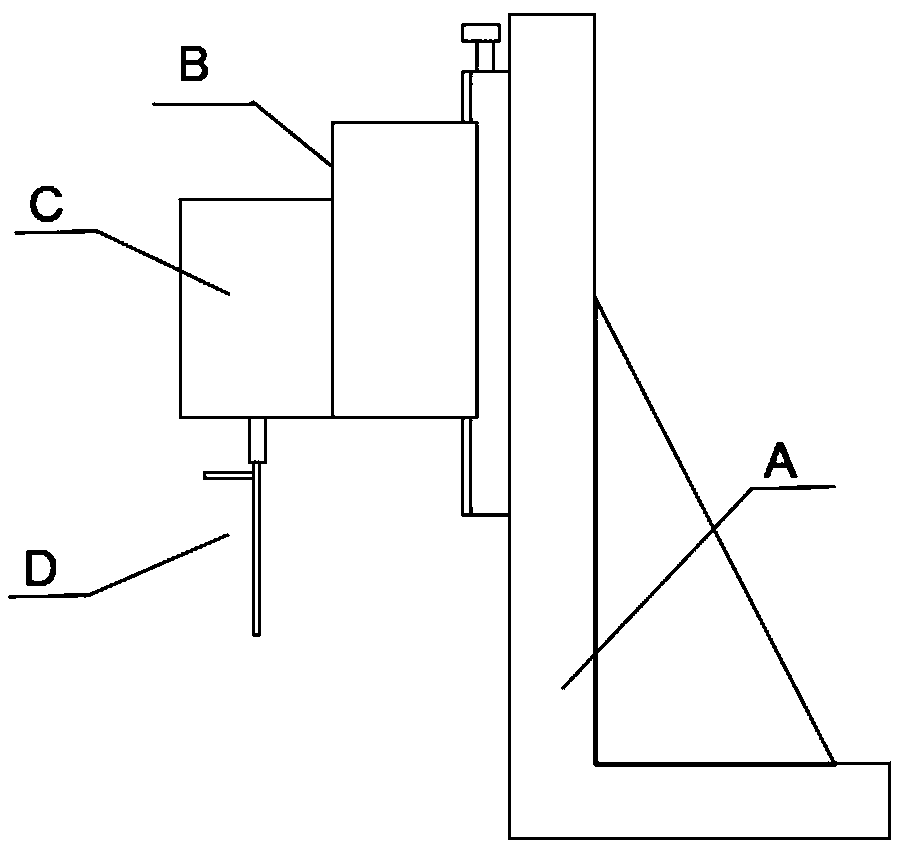

[0064] Such as figure 1 As shown, the liquid phase (flotation agent) is contained in the sample tank 5, first the particles to be measured are put into the bottom of the sample tank 5 and the particle bed is kept flat, and the sample tank 5 with the particles to be measured is placed on the three-axis On the sample stage 4, turn on and adjust the light source 2 and the high-speed camera 3, and manually adjust the relative distance between the particle and the lower end of the T-shaped capillary D through the three-axis sample stage 4, so that a clear image of the capillary and the particle bed can be obtained on the computer 7 . Through the hose 8 with a stop valve, the gas injector 9 generates air bubbles of appropriate size and closes the stop valve. The distance between the lower end of the bubble and the particle bed is fine-tuned by moving the drive unit 1 to the upper stage B, and the controller 6 is turned on. Control the movement of motion platform C (movement distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com