Patents

Literature

51results about How to "High resource utilization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

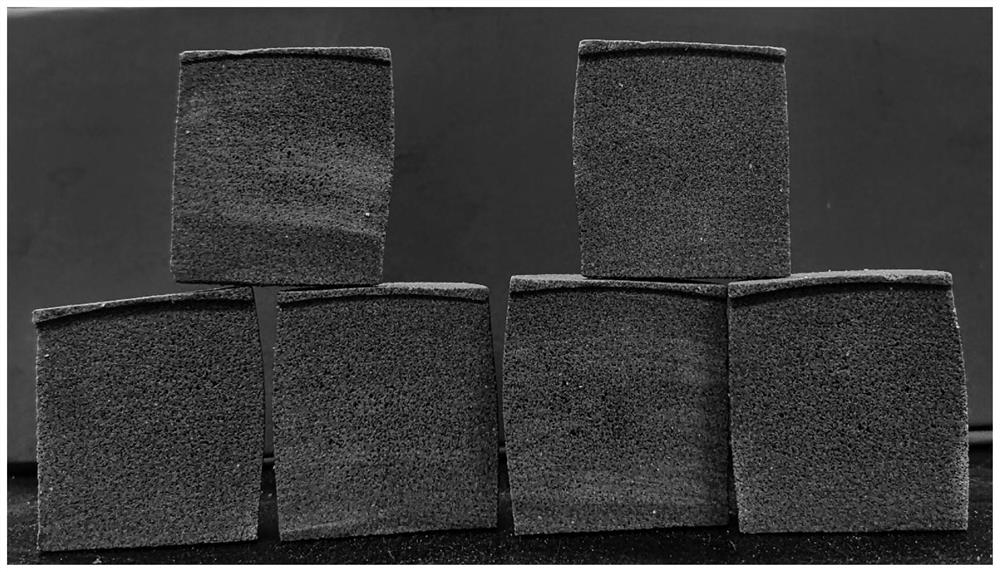

Harmless disposal method of kitchen garbage

InactiveCN102921704AShorten the processing chainPromote engineering applicationSolid waste disposalFurniture waste recoveryOil and greaseEconomic benefits

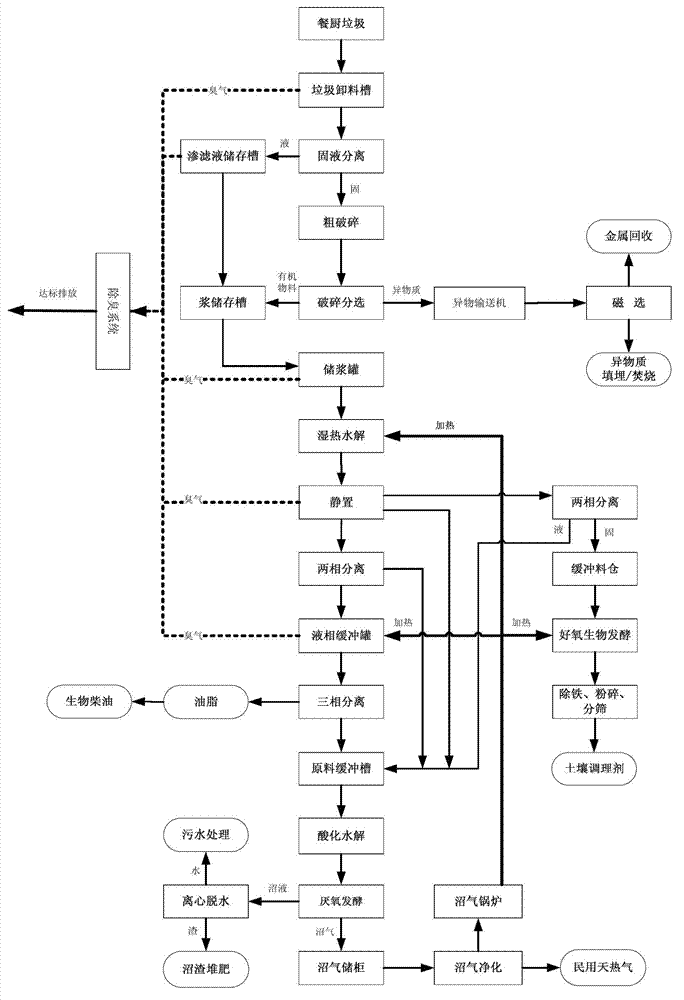

The invention relates to a harmless disposal method of kitchen garbage, which comprises the following steps of: (1) pretreatment: after unloading the kitchen garbage, performing solid-liquid separation, rough crushing, crushing and sorting and performing magnetic separation, and recycling metal substances mixed in the kitchen garbage; (2) hydrothermal hydrolysis: after the pretreatment, adopting the hydrothermal hydrolysis to fully inactivate viruses and bacteria in the kitchen garbage, separating out animal and vegetable fatty oil from the kitchen garbage, and hydrolyzing organic materials at the same time; (3) using the fatty oil obtained in the step (2) as an industrial fatty oil material or further performing deep processing to obtain fatty acid methyl ester or biodiesel; mixing and proportioning the pasty organic materials and then conveying into an anaerobic fermentation system; and conveying large granular organic materials into an aerobic biological fermentation device. The method provided by the invention realizes harmless disposal of the kitchen garbage mainly by the pretreatment and the hydrothermal hydrolysis process, increases the conversion rate of biological energy of the kitchen garbage and increases the economic benefit of kitchen garbage recycling products.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD +2

Method for comprehensively treating construction waste

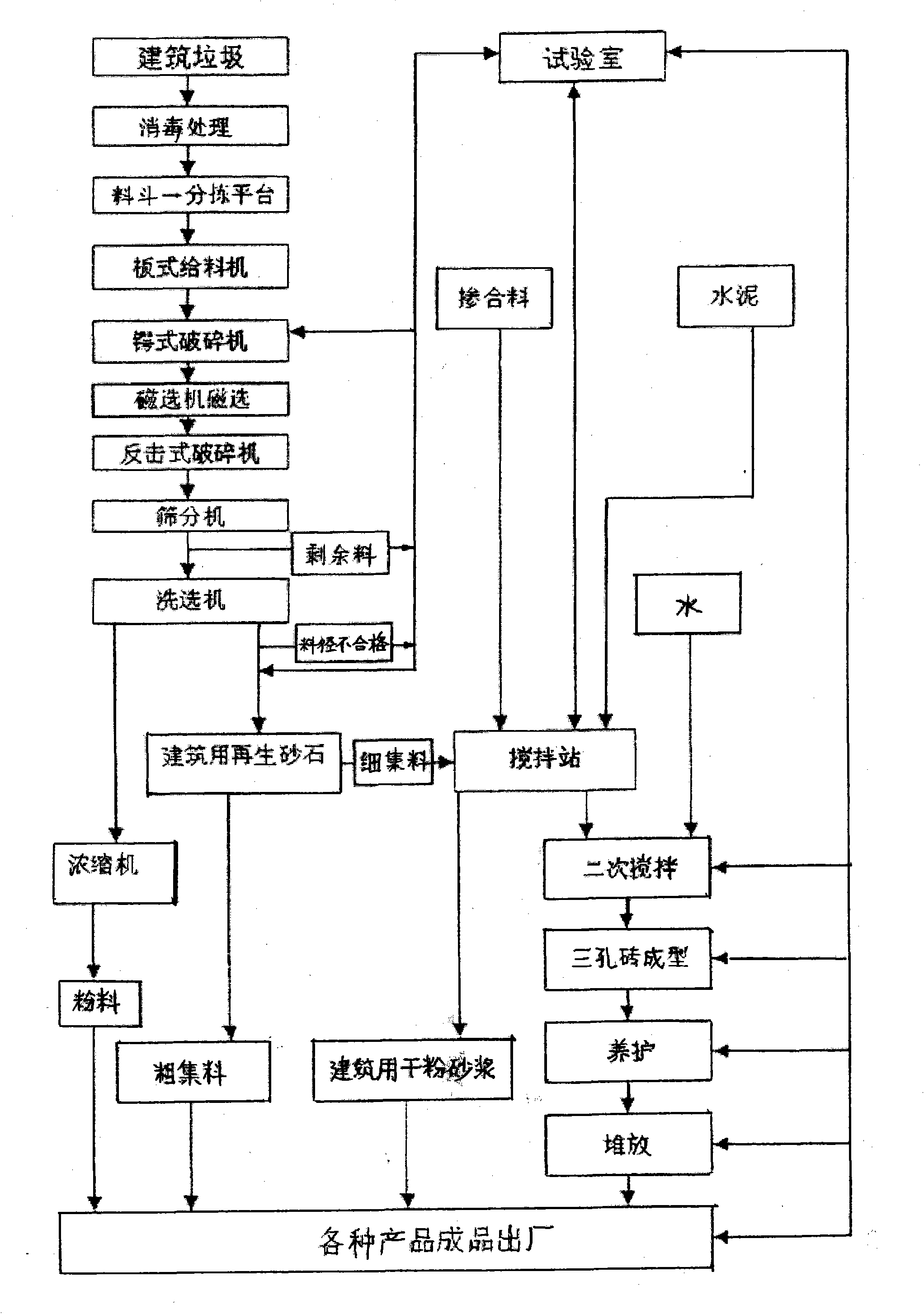

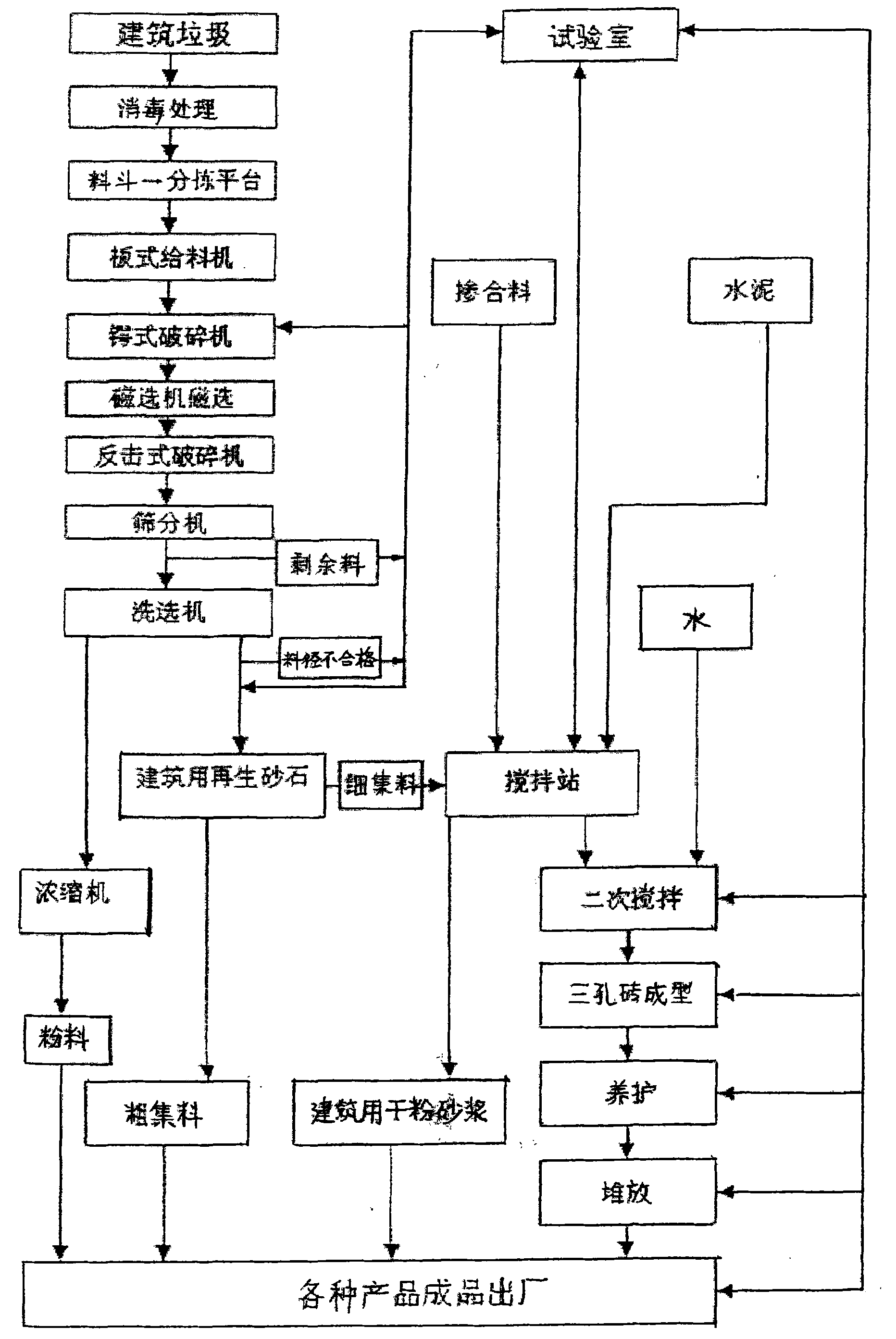

The invention relates to a method for comprehensively treating construction waste, which comprises the following steps of: 1. disinfecting the construction waste to be treated by adopting a chlorine dioxide disinfectant; 2. loading the construction waste obtained from the step 1 to a hopper and conveying to a sorting platform to sort out impurities; 3. feeding the sorted construction waste to an edge-type crusher through a plate feeder to crush initially; 4. feeding the initially crushed construction waste to a hopper of an impact crusher after magnetic separation by a magnetic separator and crushing the construction waste finally by the impact crusher; 5. screening and peeling out sandstone materials from concrete and feeding the sandstone materials after being washed by a washer to a coarse aggregate bin, wherein the aggregate separated from the washed fine powder washed is used as raw materials of dry mortar or ready mixed mortar or three-hole brick of concrete. The invention ensures that the construction waste resources are utilized comprehensively, and the ordering management, the resource management and the harmless treatment of the construction waste are achieved, thereby achieving the purposes of saving land and reducing secondary pollution.

Owner:YUNNAN CONSTR ENG GRP +2

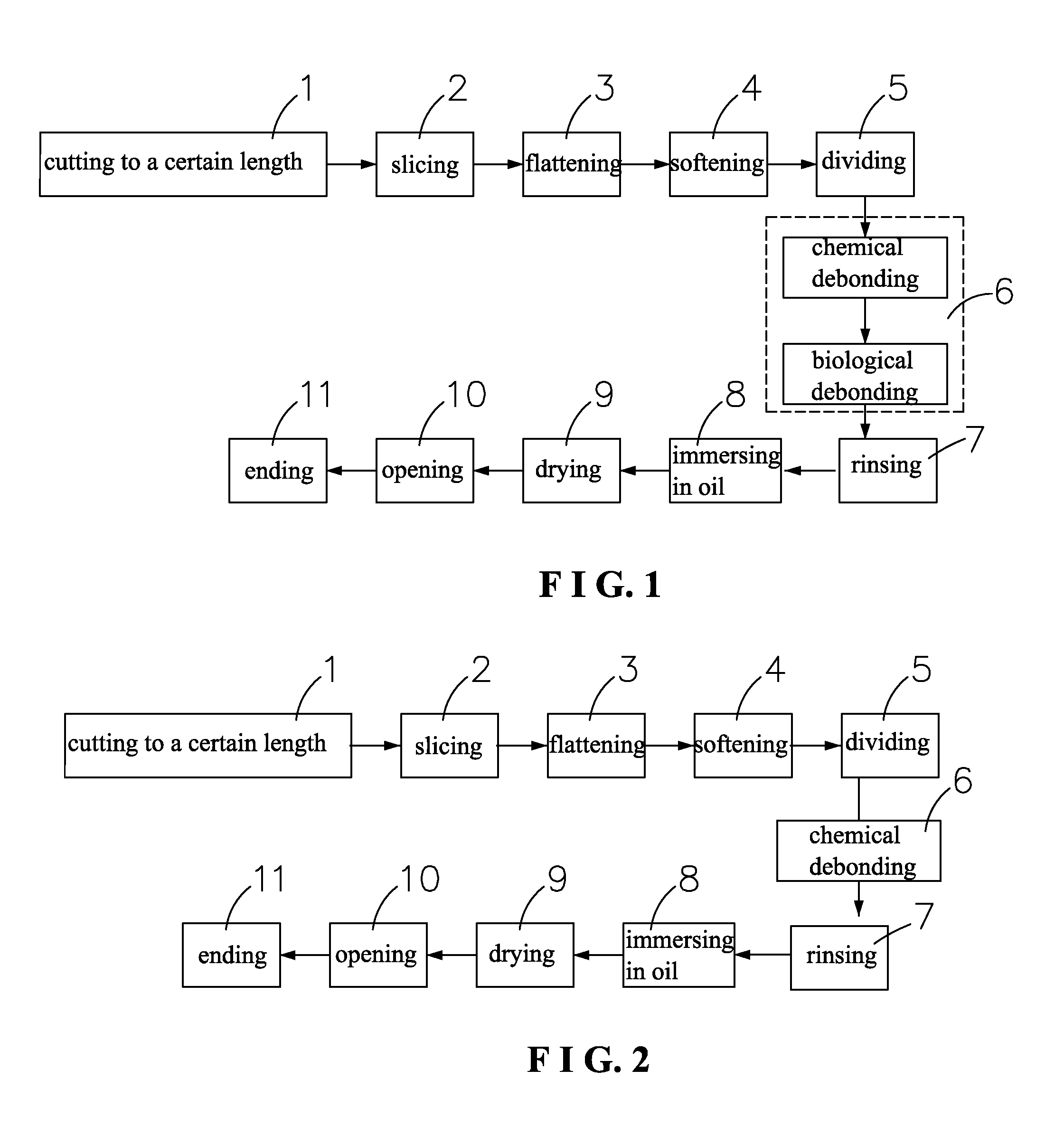

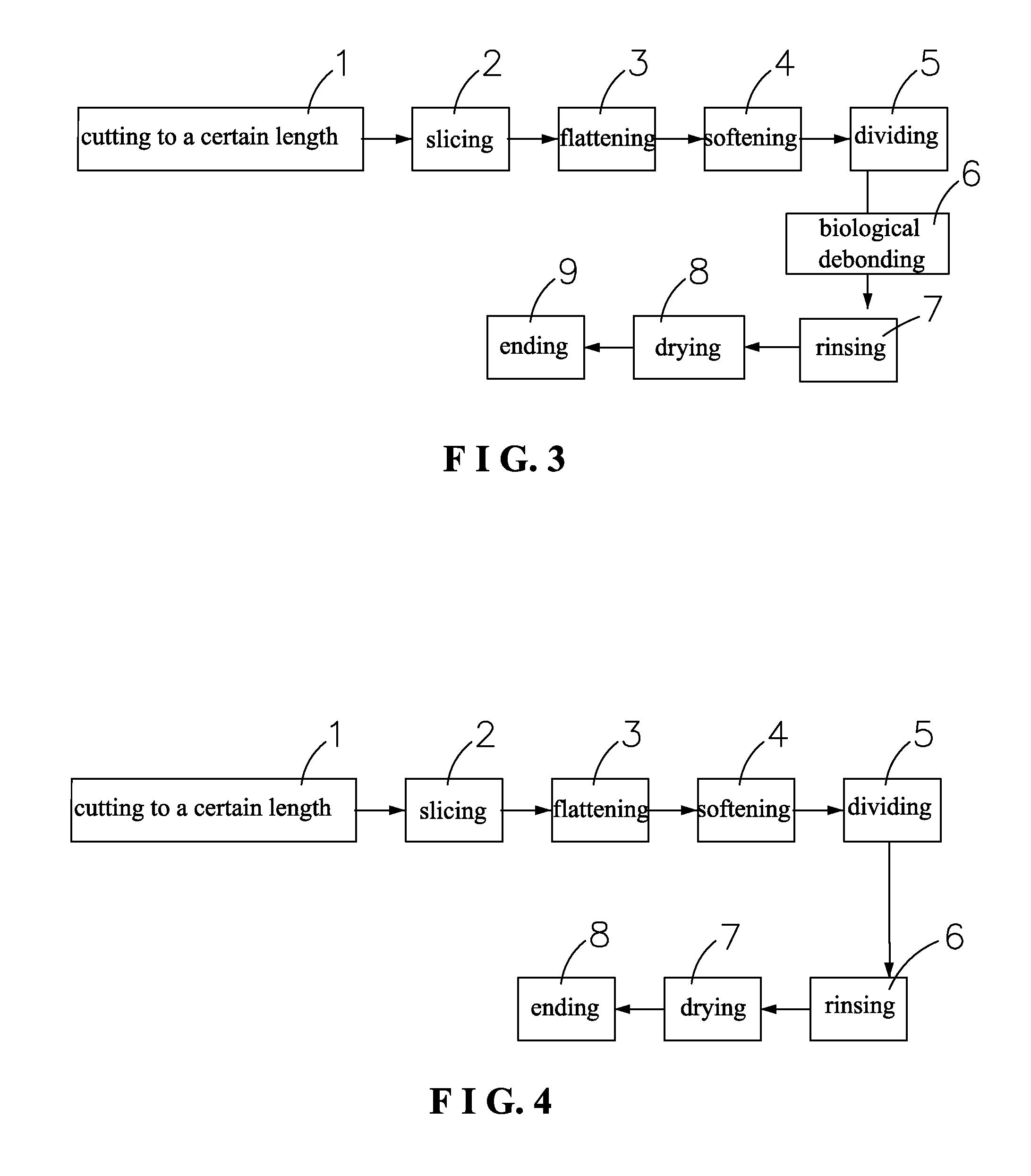

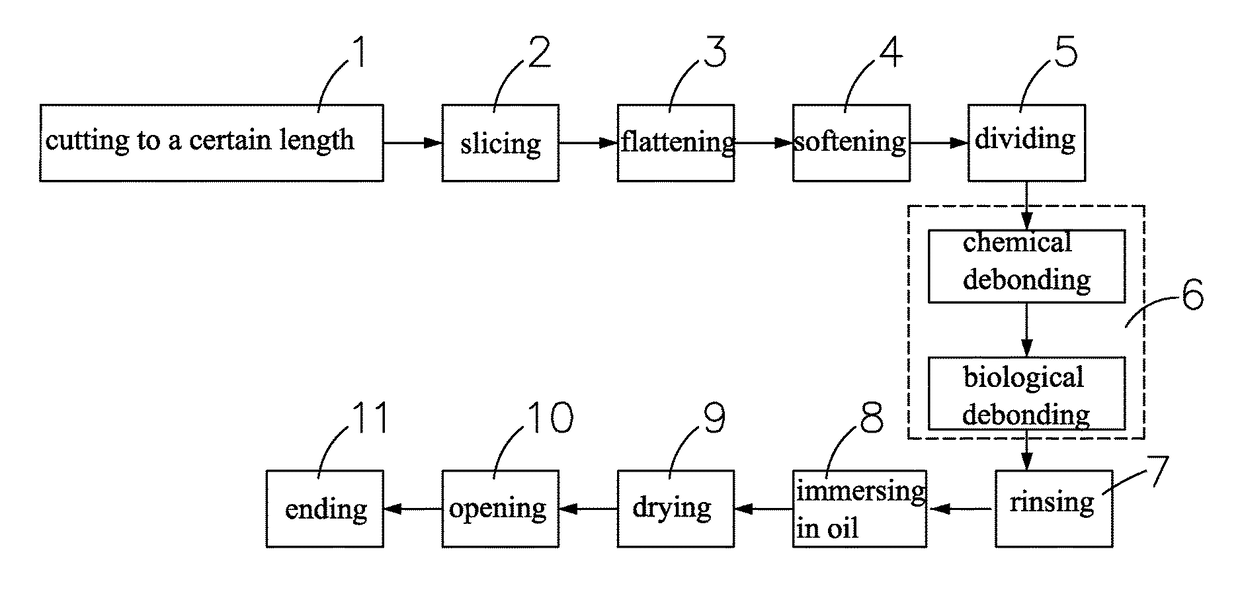

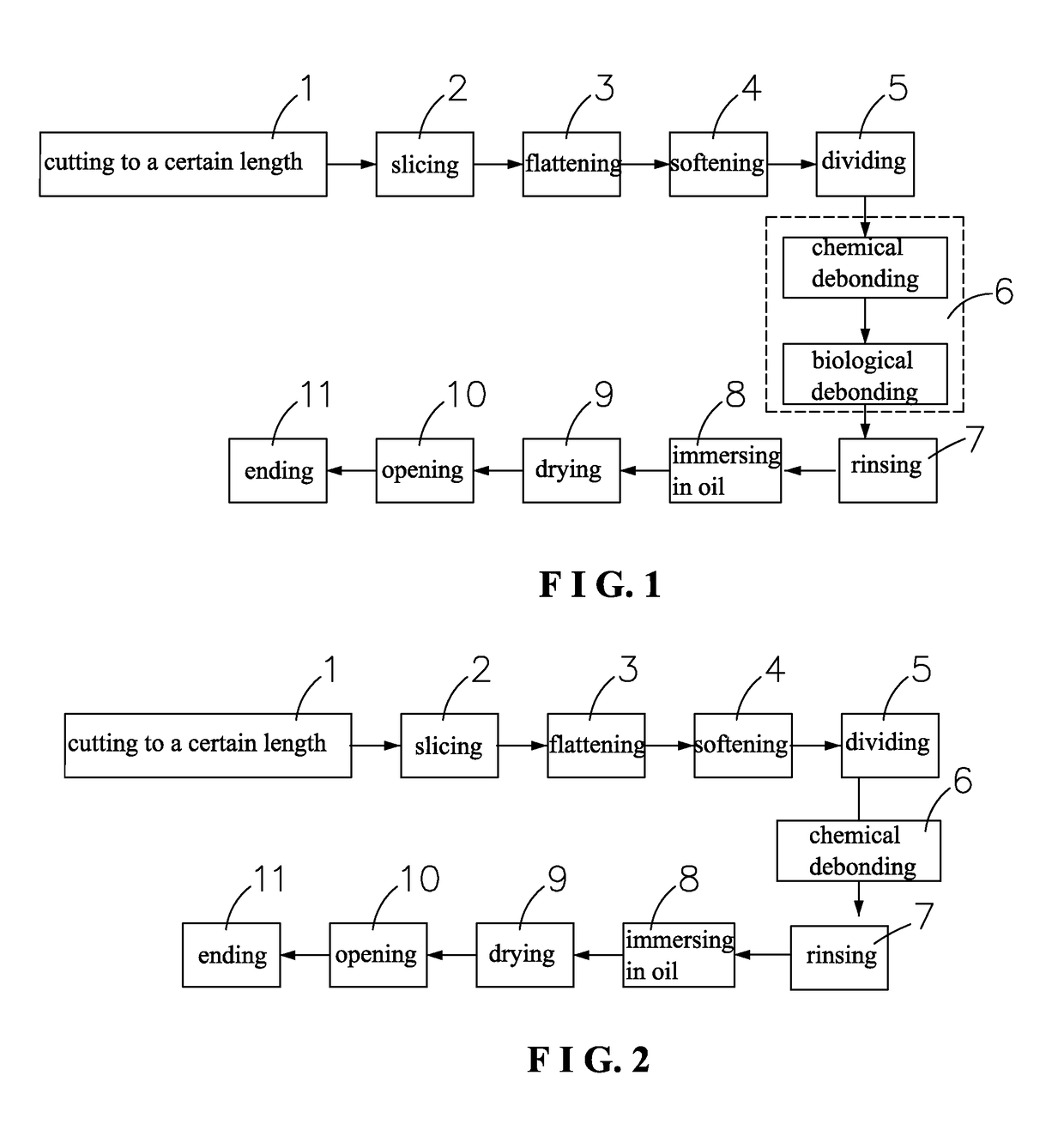

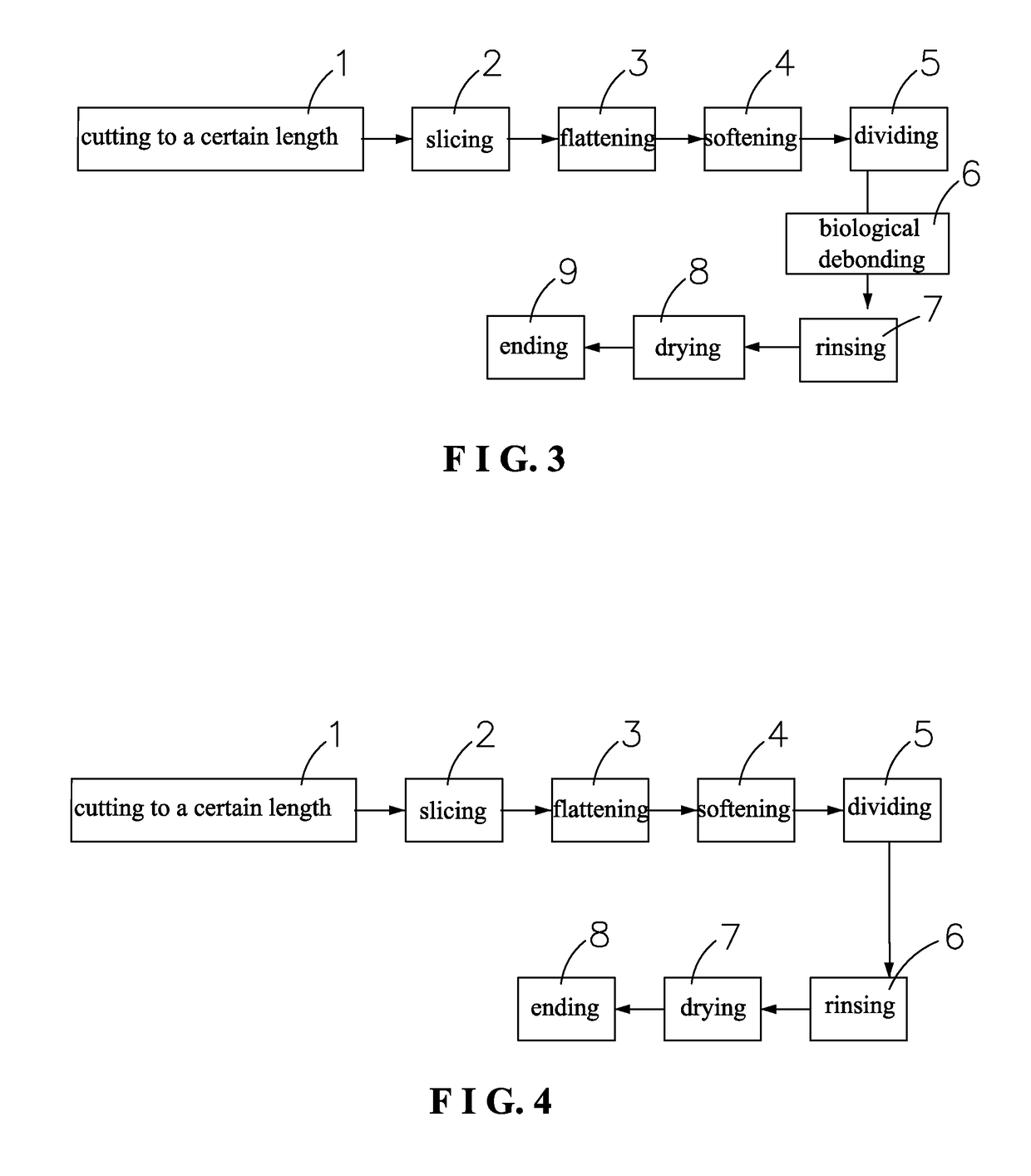

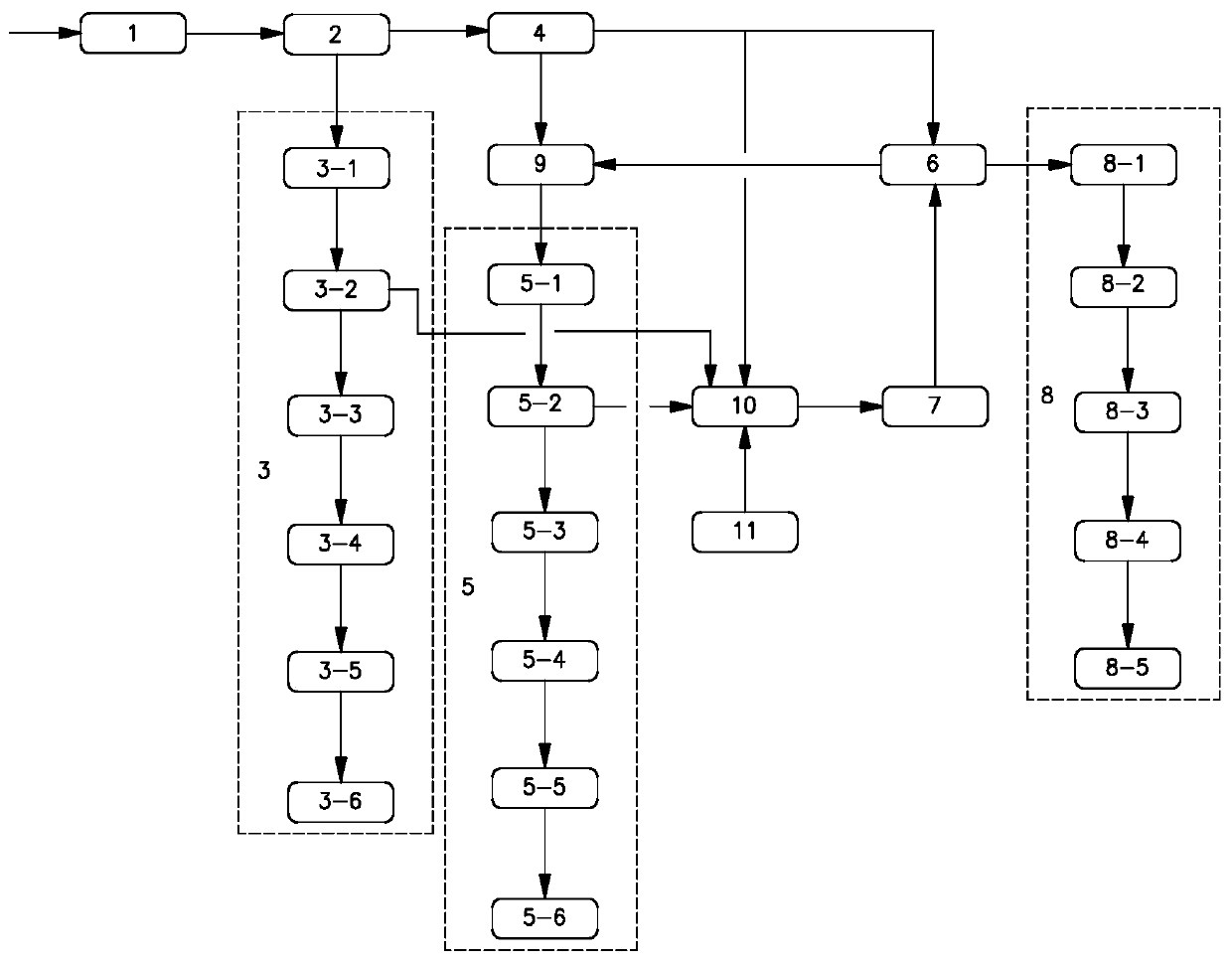

Production technology for natural bamboo fibers

ActiveUS20140000761A1Simple and high-efficient producing methodImprove adaptabilityWood working apparatusPlant material mechanical workingFiberMaterials science

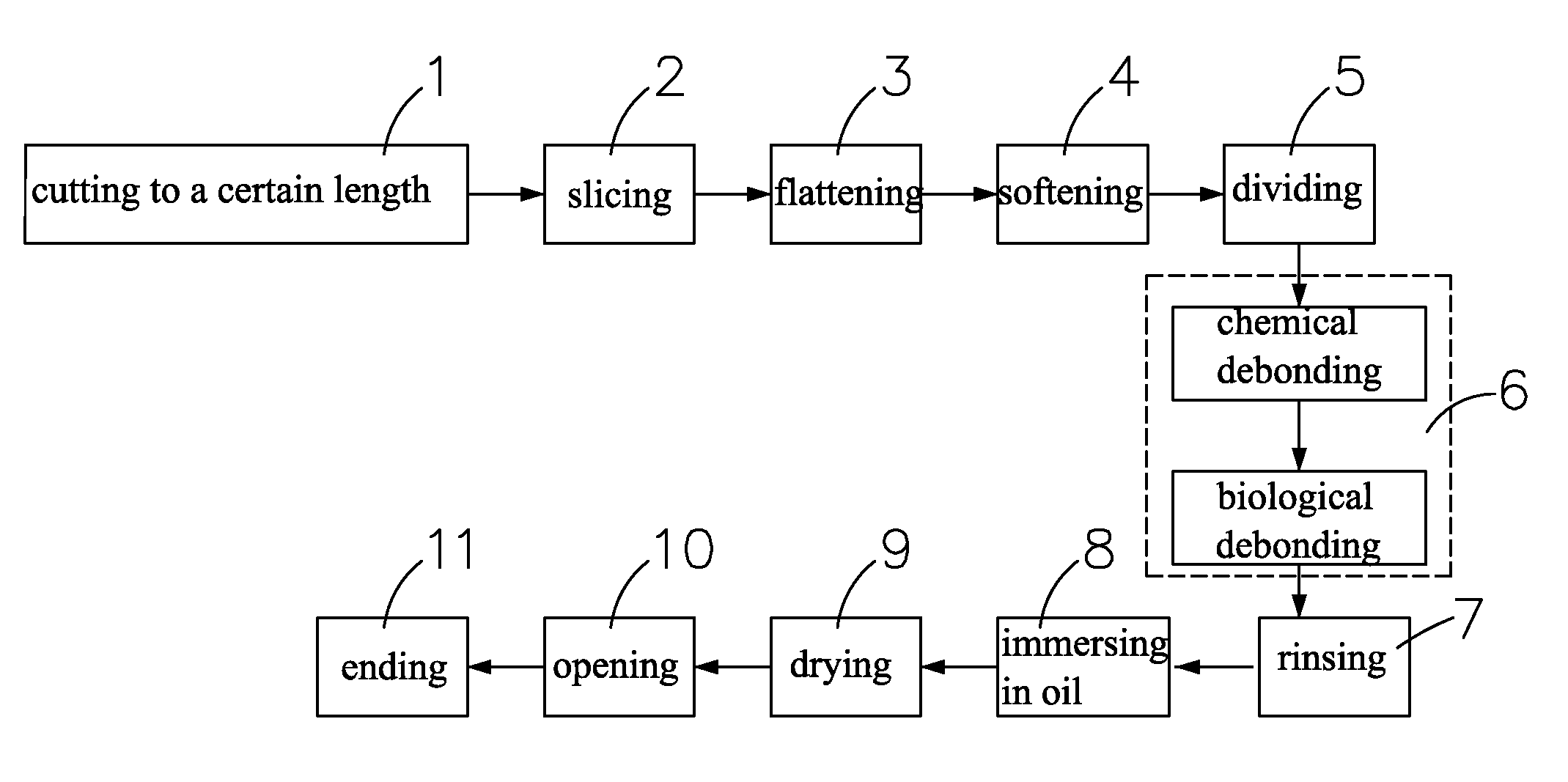

A production technology for natural bamboo fibers is applied in producing woven bamboo fibers, non-woven bamboo fibers, and reinforcing composite bamboo fibers. The woven bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding, rinsing, soaking in oil, drying, and opening. The non-woven bamboo fibers and the reinforcing composite bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding (optional), rinsing, and drying.

Owner:ZHANG YI

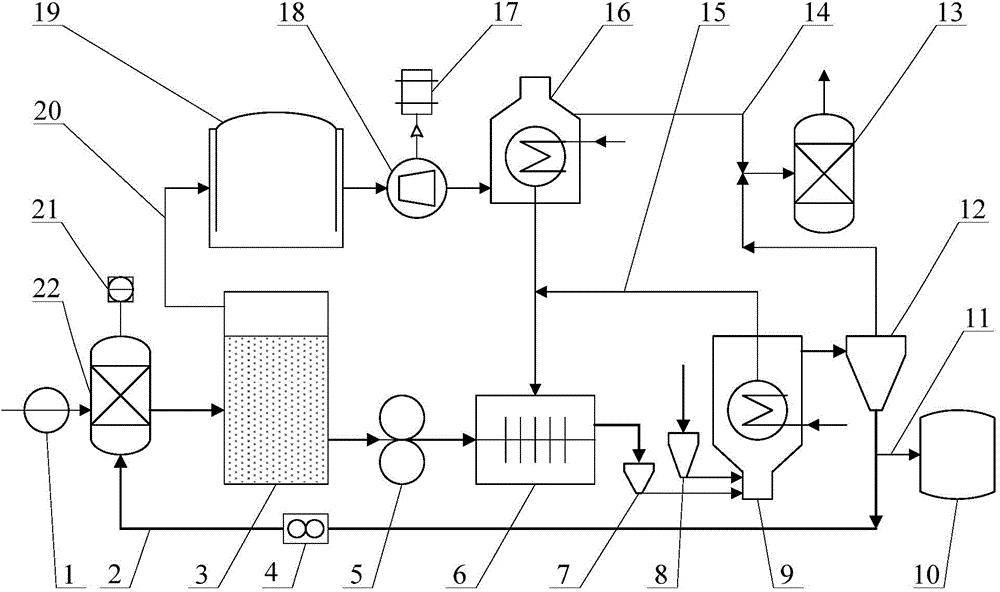

Sludge resource utilization system and method

ActiveCN104154546AReduce moisture contentLow costIncinerator apparatusCombined combustion mitigationSludgeResource utilization

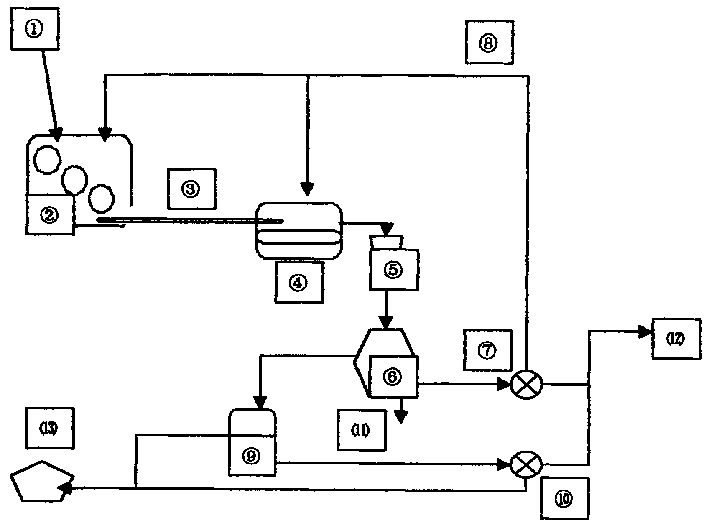

The invention relates to a sludge resource utilization system and method. Surplus calcium oxide is used as agents of a whole sludge treatment process. The system and method have the advantages of being harmless and stable in sludge processing, reduction is achieved, reutilization is achieved, desulfurizing agent consumption is small, and the reutilization rate is high. According to the technical scheme, the system comprises a preprocessor for sludge organic matter decomposing, an outlet of the preprocessor is communicated with an anaerobic fermentation tank, a methane outlet of the anaerobic fermentation tank is connected with a methane tank, a sludge outlet of the anaerobic fermentation tank is connected with a dehydrator and a dryer in sequence, a sludge outlet of the dryer and an inlet of an incinerator are communicated, a smoke outlet of the incinerator is connected with a dust collector, a flying ash outlet of the dust collector is divided into two ways which are connected with a flying ash inlet of the preprocessor and an ash storeroom respectively, an outlet of the methane tank is communicated with an electricity generating fuel machine, a smoke outlet of the fuel machine is connected with a waste heat boiler, and the incinerator and the waste heat boiler provide heat for the dryer through heat supplying pipes.

Owner:凤阳县经济发展投资有限公司

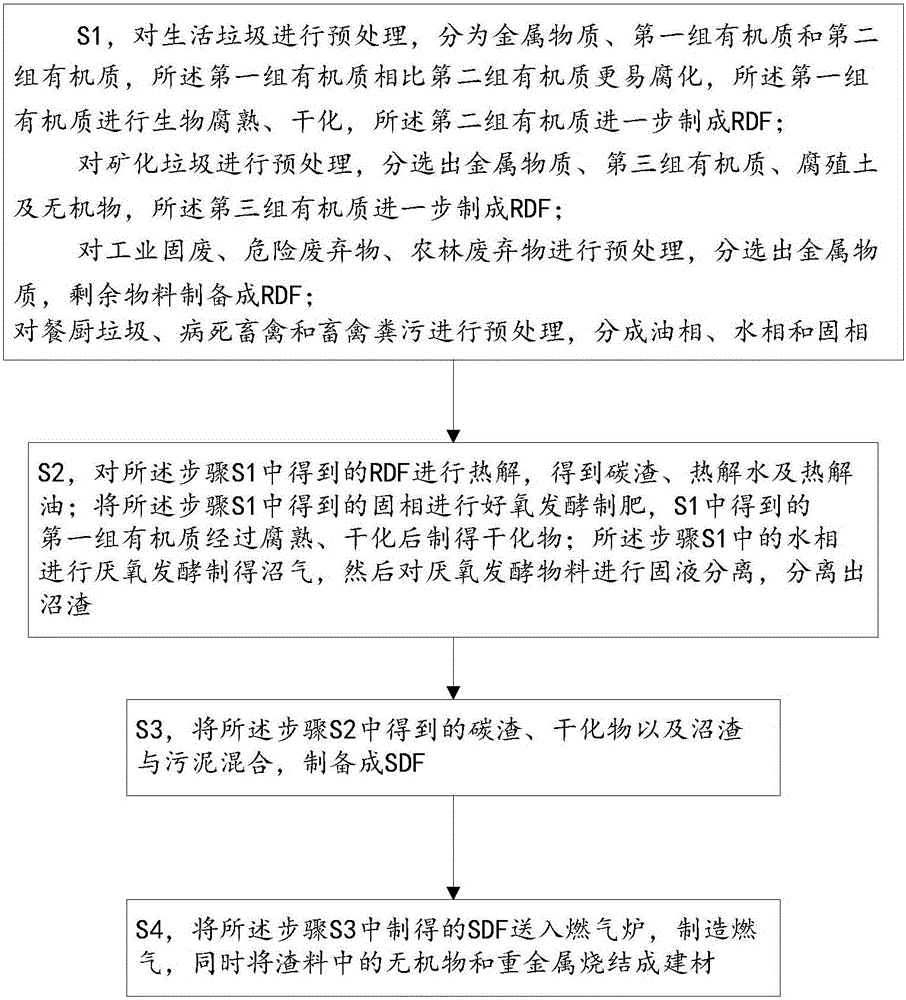

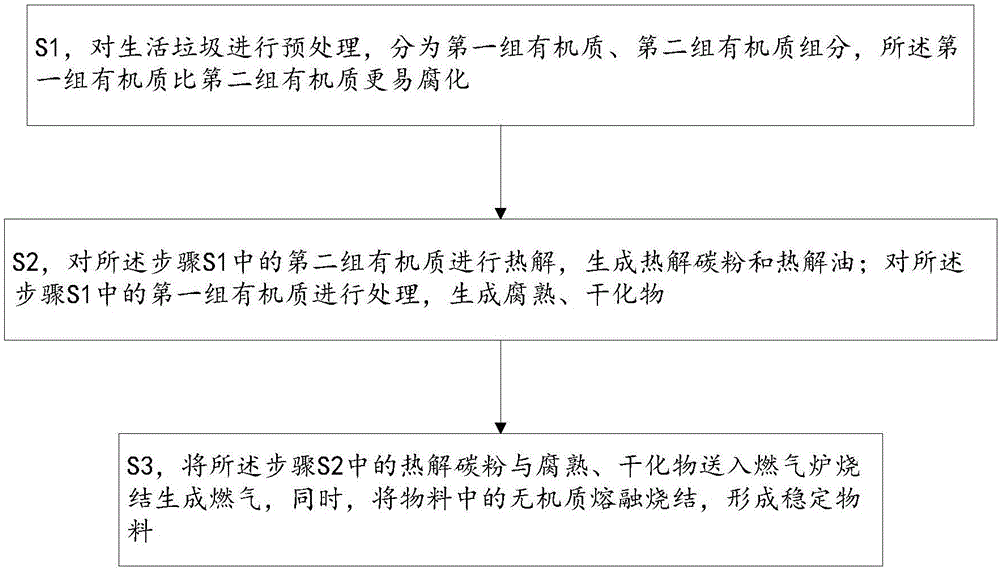

Solid waste disposal method

The invention discloses a solid waste disposal method, and relates to the technical field of disposal of multiple types of solid waste. The solid waste disposal method comprises the following steps that S1, multiple types of solid waste are classified and pretreated; S2, RDF obtained in the step S1 is subjected to pyrolysis to obtain carbon residues and pyrolytic tar, solid-phase materials obtained in the step S1 are subjected to aerobic fermentation, and a water phase obtained in the step S1 is subjected to anaerobic fermentation to obtain methane and biogas residues through separation; S3, the carbon residues, dry compounds and the biogas residues obtained in the step S2 are mixed with sludge, and SDF is prepared; and S4, the SDF obtained in the step S3 is fed into a gas-fired furnace, fuel gas is prepared, and meanwhile inorganic matter and heavy metal in the residues are sintered to form building materials. The solid waste disposal method has the beneficial effects of realizing collaborative and concentrated treatment of multiple types of solid waste, not only realizing treatment of multiple types of solid waste, but also realizing recycling of multiple types of solid waste.

Owner:HUNAN VARY TECH

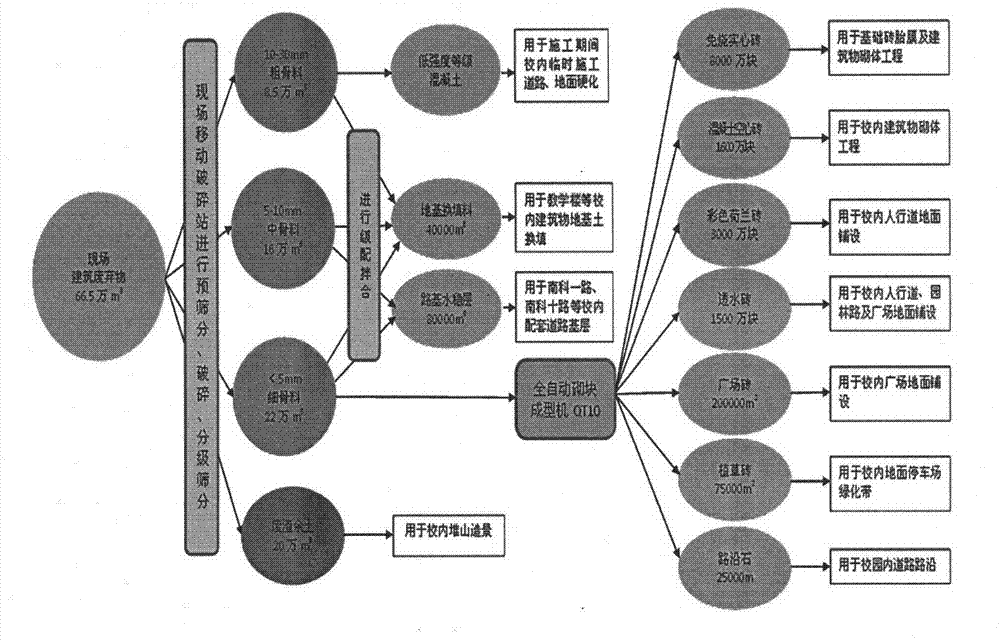

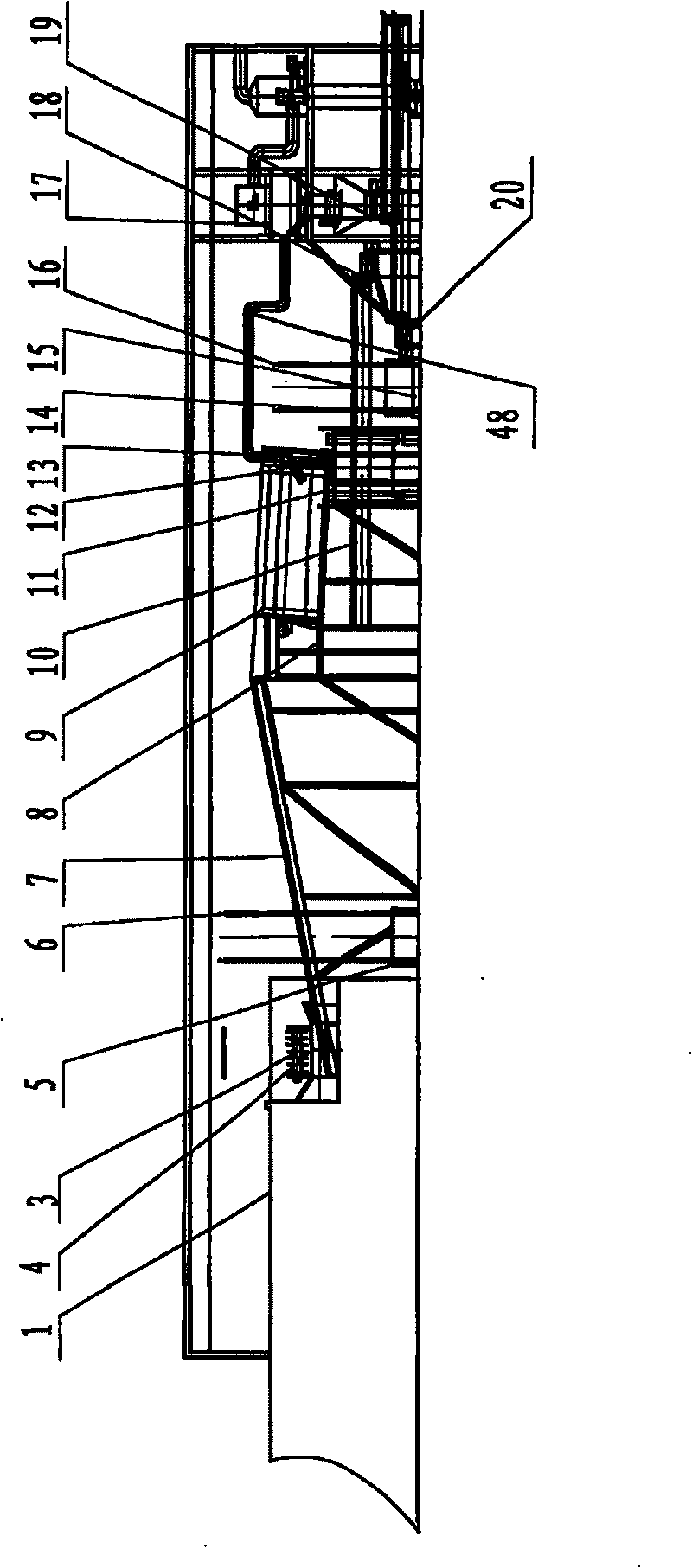

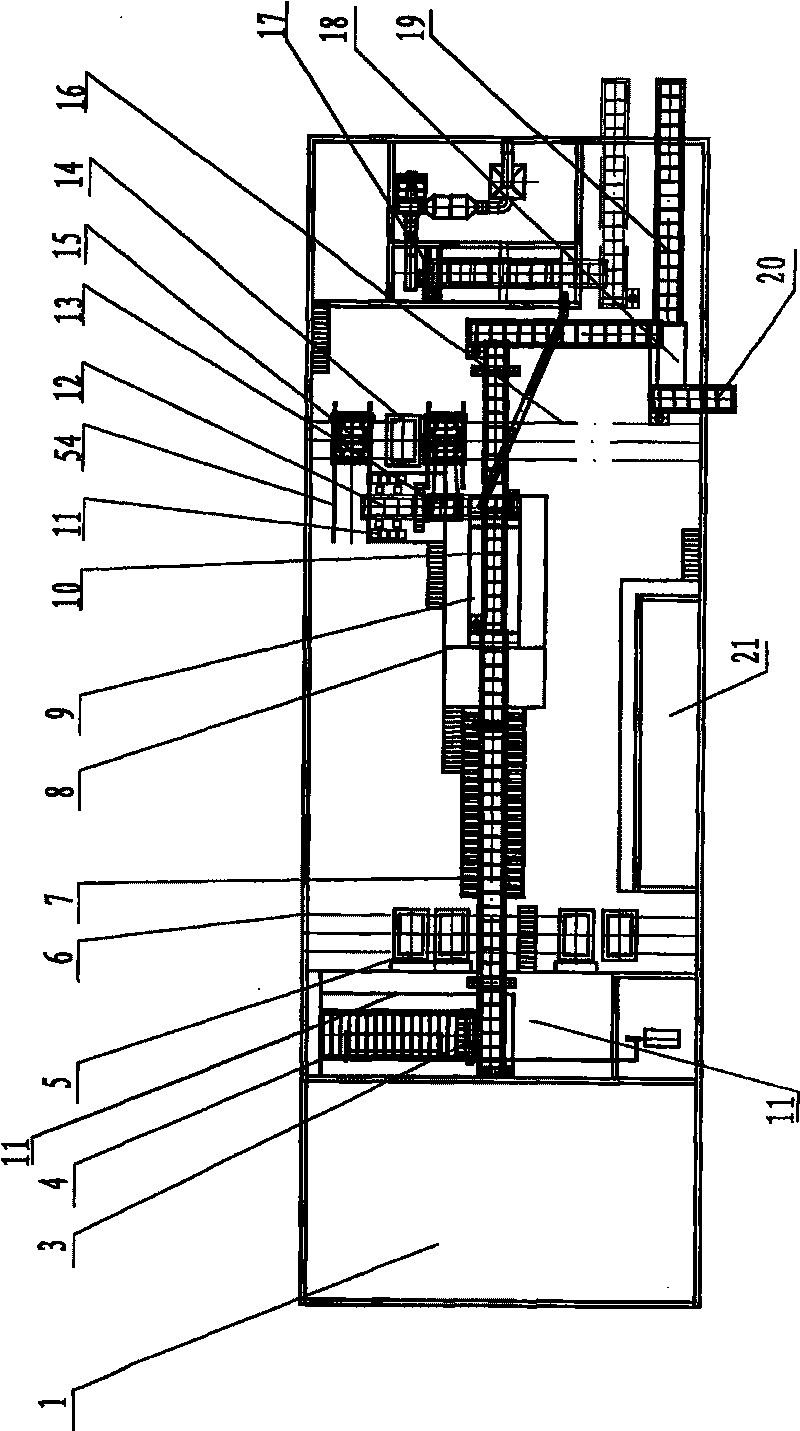

Mobile production system capable of demolishing buildings selectively on site and recycling construction waste

ActiveCN102873072ASmall sizeFlexibleConstruction waste recoverySolid waste disposalBuilding materialZero emission

The invention provides a mobile production system capable of demolishing buildings selectively on site and recycling construction waste. The mobile production system is characterized in that on a building demolition site, after a building is selectively demolished, construction waste is processed into raw materials which can be made into environment-friendly construction material like recycled aggregate by using mobile site screening and crushing equipment, and then the material is manufactured into environment-friendly construction material by mobile site production equipment, like recycled aggregate environment-friendly bricks, recycled aggregate concrete, recycled aggregate dry powder mortar and recycled aggregate filling, so that the process of transporting construction waste out of the construction site is avoided, and zero emission of construction waste is realized.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

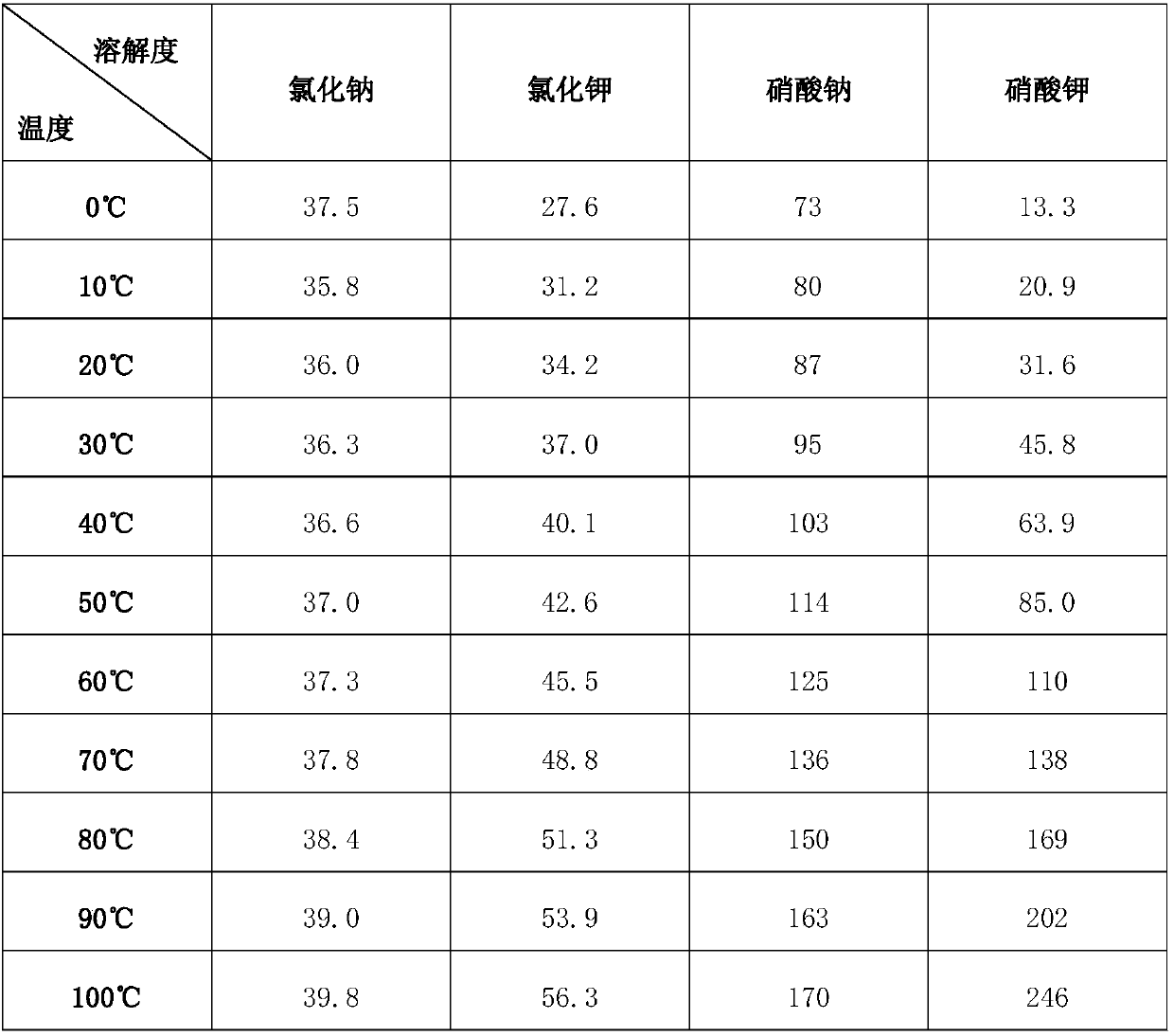

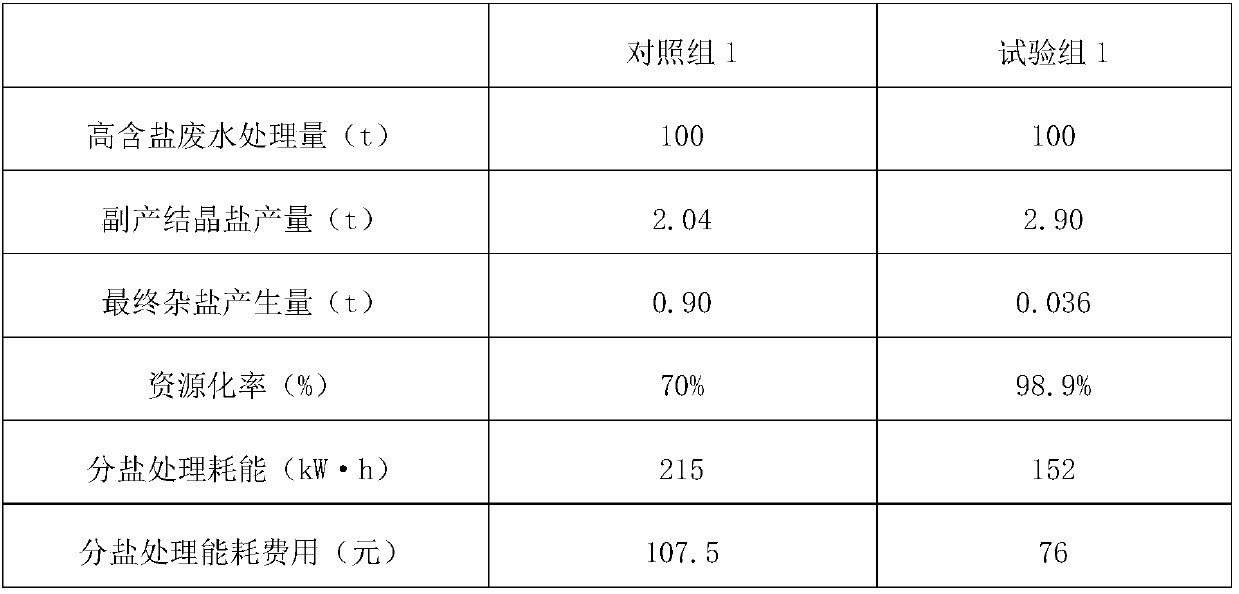

Miscellaneous salt resource utilization method and miscellaneous salt resource utilization system

PendingCN110877943AAvoid huge running costsReduce productionWater contaminantsWater/sewage treatment by ion-exchangeEnvironmental engineeringOrganic matter

The invention discloses a miscellaneous salt resource utilization method and a miscellaneous salt resource utilization system. The method comprises the following steps: S1, removing organic matters; S2, dissolving; S3, carrying out salt separation treatment. The system comprises an organic matter removal unit, a dissolving pool, a pretreatment system and a salt separation treatment system. With the method and the system of the invention, miscellaneous salt generated by industrial treatment or piled miscellaneous salt can be effectively treated, so that the problems that conventional miscellaneous salt cannot be eliminated and is excessively stacked and accumulated are solved, miscellaneous salt having high harm and incapable of being effectively treated can be subjected to resource utilization after being treated, the recycling rate of miscellaneous salt treatment can reach 70-96%, the purposes of harmlessness, reduction and recycling treatment of miscellaneous salt is truly achieved,and the environmental problem caused by direct landfill of the miscellaneous salt is relieved; and the huge operation cost caused by direct incineration of the miscellaneous salt can be avoided, the waste of energy and resources due to secondary solid waste landfill treatment after traditional incineration treatment is avoided, the byproduct crystalline salt obtained through treatment can be soldoutside, and the overall cost of miscellaneous salt treatment is reduced by 89-100%.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

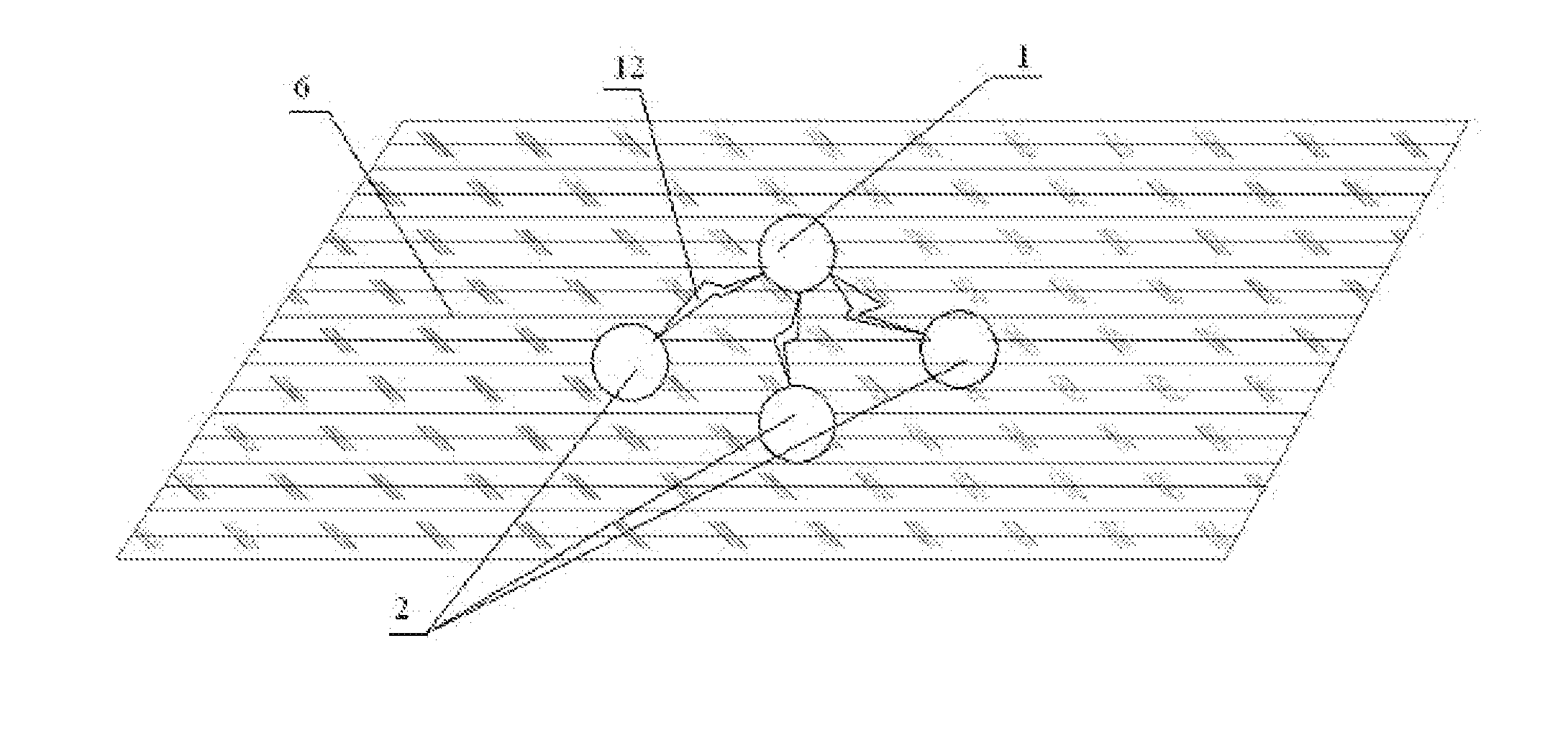

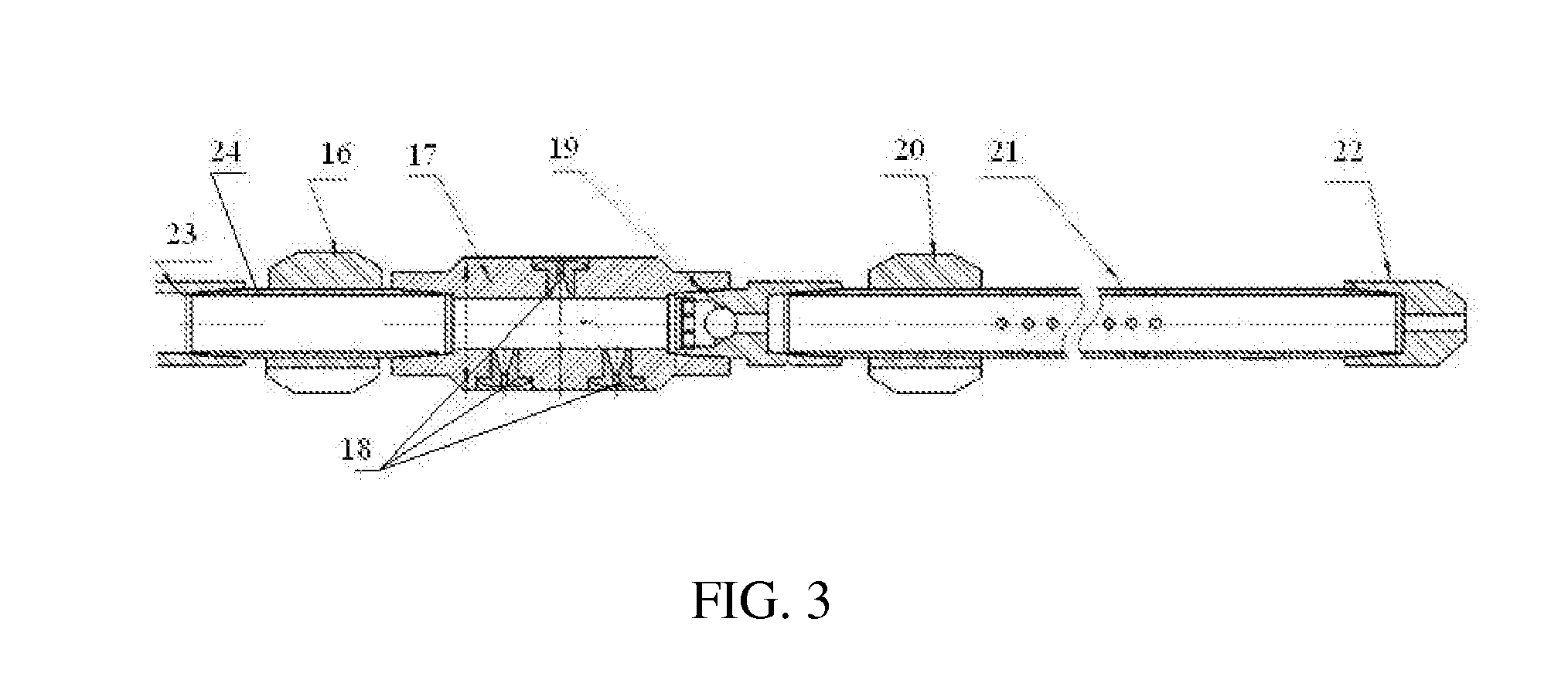

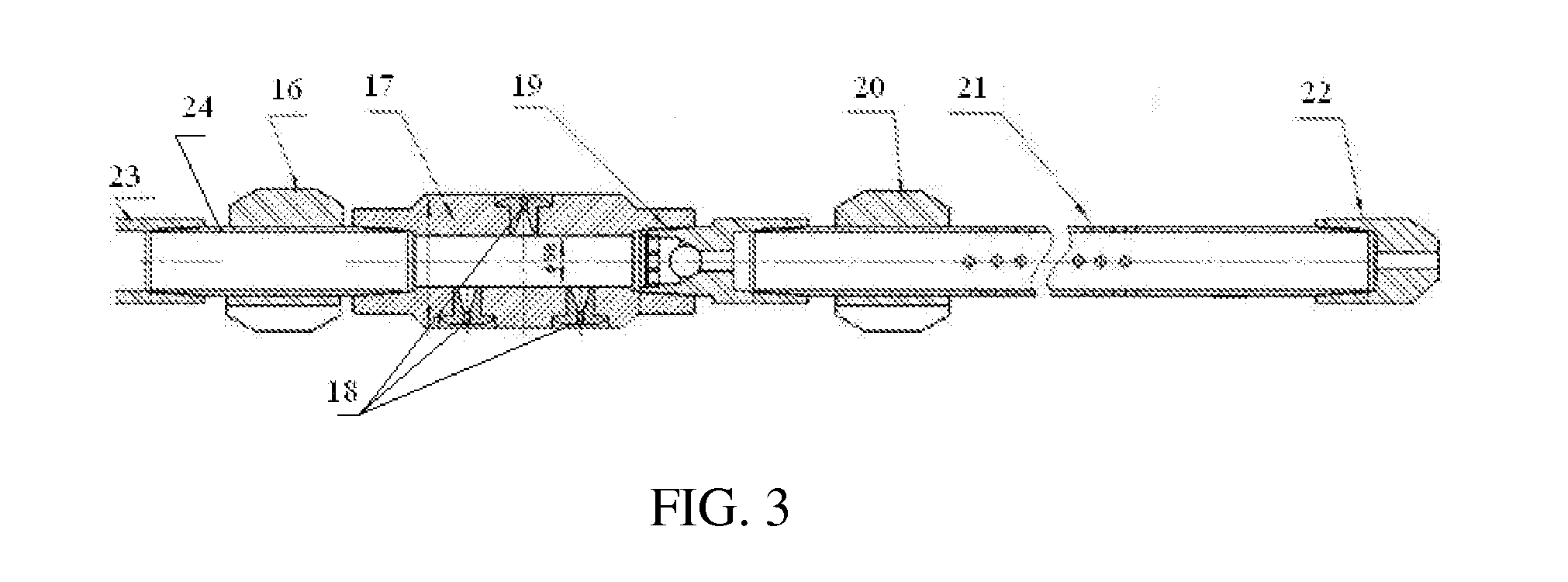

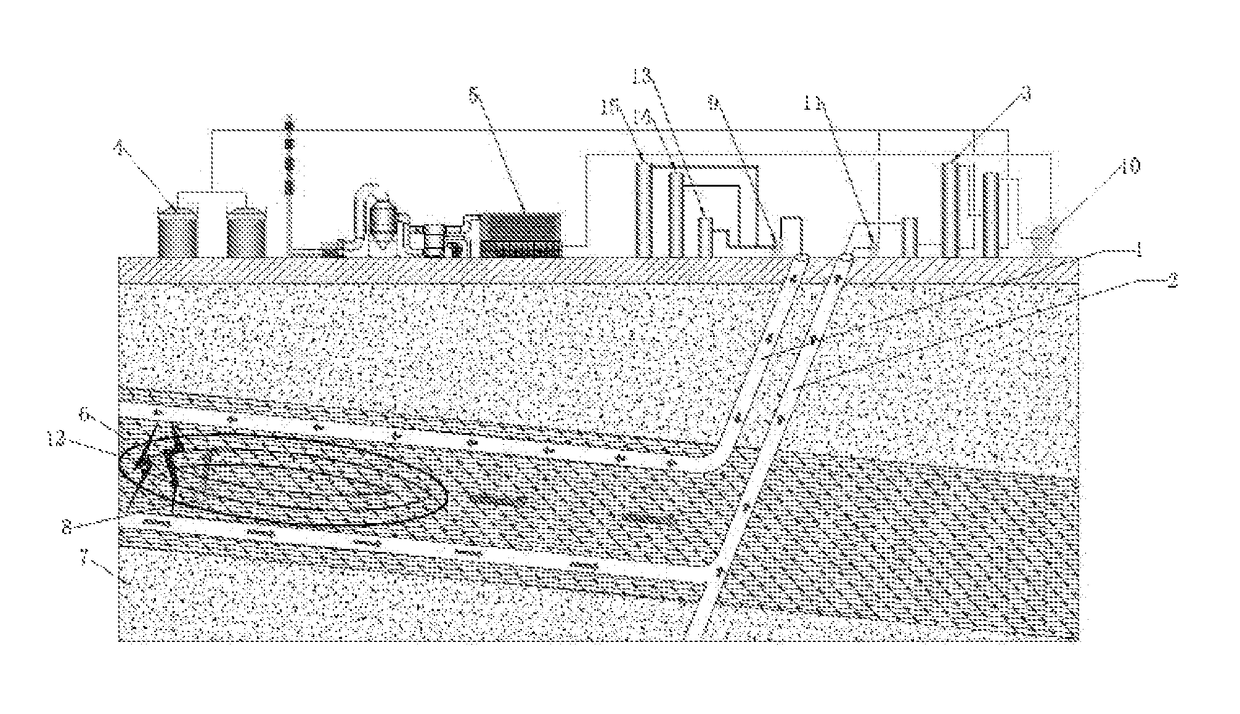

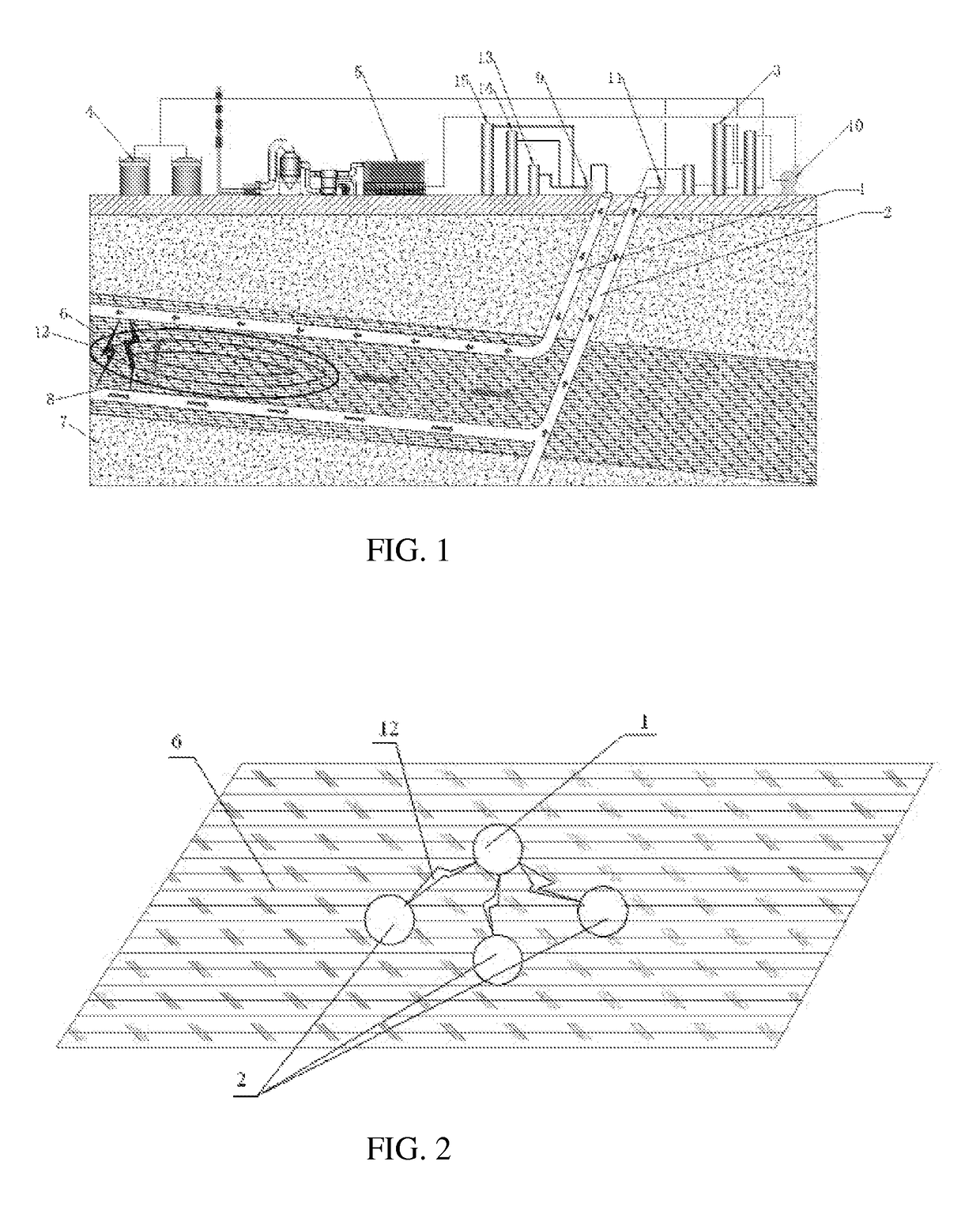

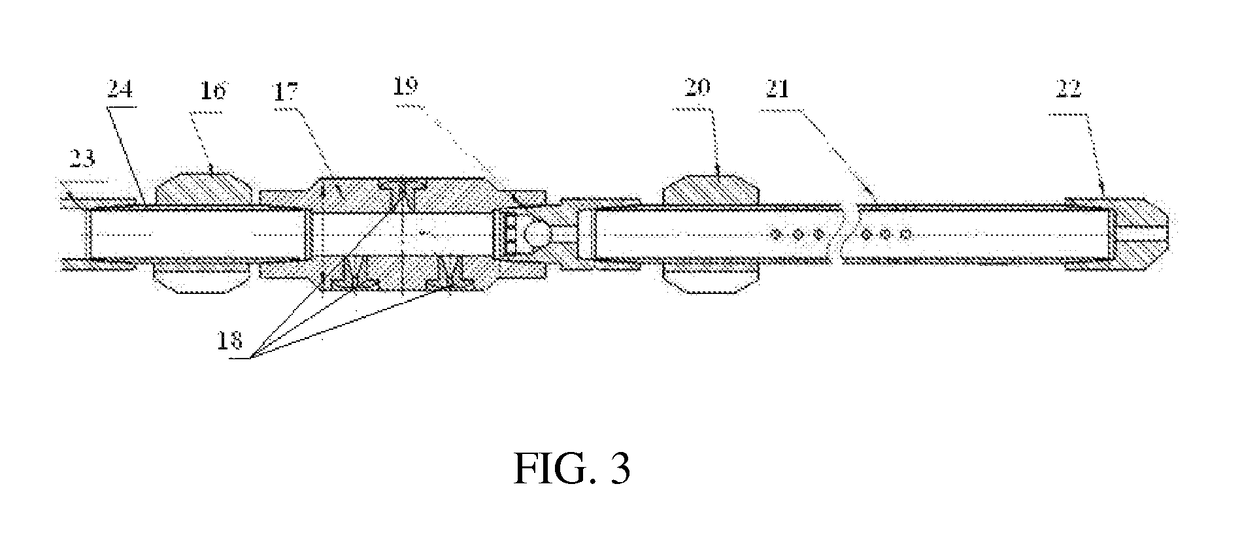

Method and process for extracting shale oil and gas by fracturing and chemical retorting in oil shale in-situ horizontal well

ActiveUS20160076350A1Avoid environmental pollutionSmall investmentArtificial islandsFluid removalOil shale gasHigh pressure

A method and a process for extracting shale oil and gas by fracturing and chemical retorting in oil shale in-situ horizontal well. An inclined well is drilled from the ground to the upper part of an underground oil shale stratum, and a horizontal well is drilled in parallel to the oil shale stratum in the upper part of the oil shale stratum. Behind the horizontal well and the inclined well in the upper part, an inclined well leading to the lower part of the oil shale stratum is drilled, and a horizontal well is drilled in parallel to the lower part of the oil shale stratum. Highly pressurized media (air, water, and quartz sand) are injected into the horizontal well in the upper part of the oil shale stratum, cracks of 1 to 3 mm are fractured in the oil shale stratum with the horizontal well in the upper part of the oil shale stratum serving as the center and are filled with a gap support, and, an oil and gas channel connecting the horizontal well in the lower part is established. A heating apparatus is added into the horizontal well in the upper part of the oil shale stratum, the oil shale stratum is heated to 550 DEG C., the oil shale is initially retorted, shale oil and gas are extracted, and the shale oil and gas are led out of the ground from the horizontal well in the lower part via the oil and gas passages, and then are introduced to an oxidant for oxidization reaction with asphaltenes and fixed carbon contained in the oil shale when retorted, where the heat generated is used as a heat source for subsequent retorting, thus implementing underground in situ shale oil extraction. The shale oil that is led out of the ground is separated via a ground-level gas-liquid separation apparatus, and the separated shale oil is transferred to a product oil tank for storage and sale, while a combustible gas is transferred to a combustible gas power generation apparatus for use in power generation. This solves the problem that existing ground-level retorting has in terms of large recovery costs, difficult treatment of tailings, a variety of environmental issues, and large land-use footprint. In addition, there disclose a process implementing the method and a nozzle used in the method.

Owner:JILIN ZHONGCHENG AUTOMOTIVE SERVICE CHAIN +1

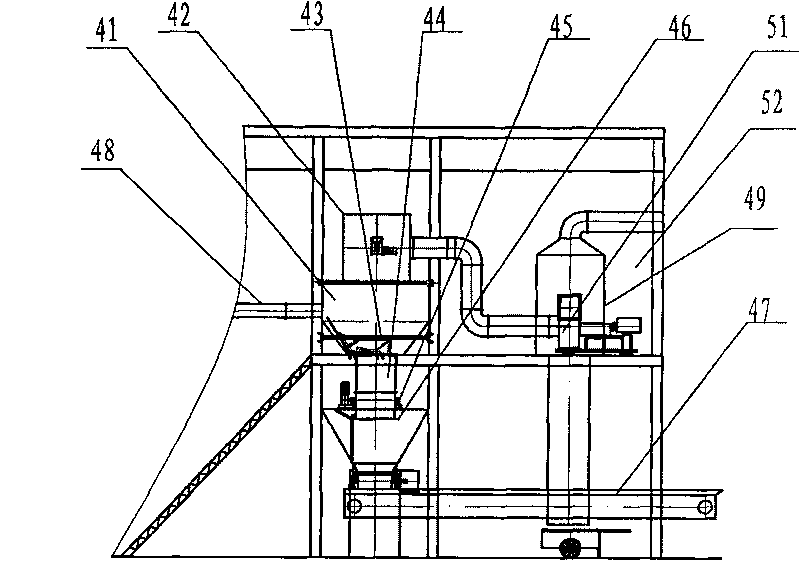

Plastic winnowing device

InactiveCN101032719AHigh separation purityHigh resource utilization rateGas current separationPlastic recyclingEngineeringSediment

The plastic winnowing apparatus includes a sediment chamber, a blower fan outside the sediment chamber, and a silencing and damping device. Inside the sediment chamber, there are a unloading device connected via aspirating pipeline to the blower fan and the silencing and damping device in the upper part, an upper sealing unit, a bin, a material guide device, a lower sealing unit, a material aspirating pipeline below the upper sealing unit and a material guiding chute connected to the lower part of the lower sealing unit. The apparatus has both plastic conveying and plastic separating functions. It may be also used in separating grains, coal and garbage.

Owner:北京厨房设备有限公司

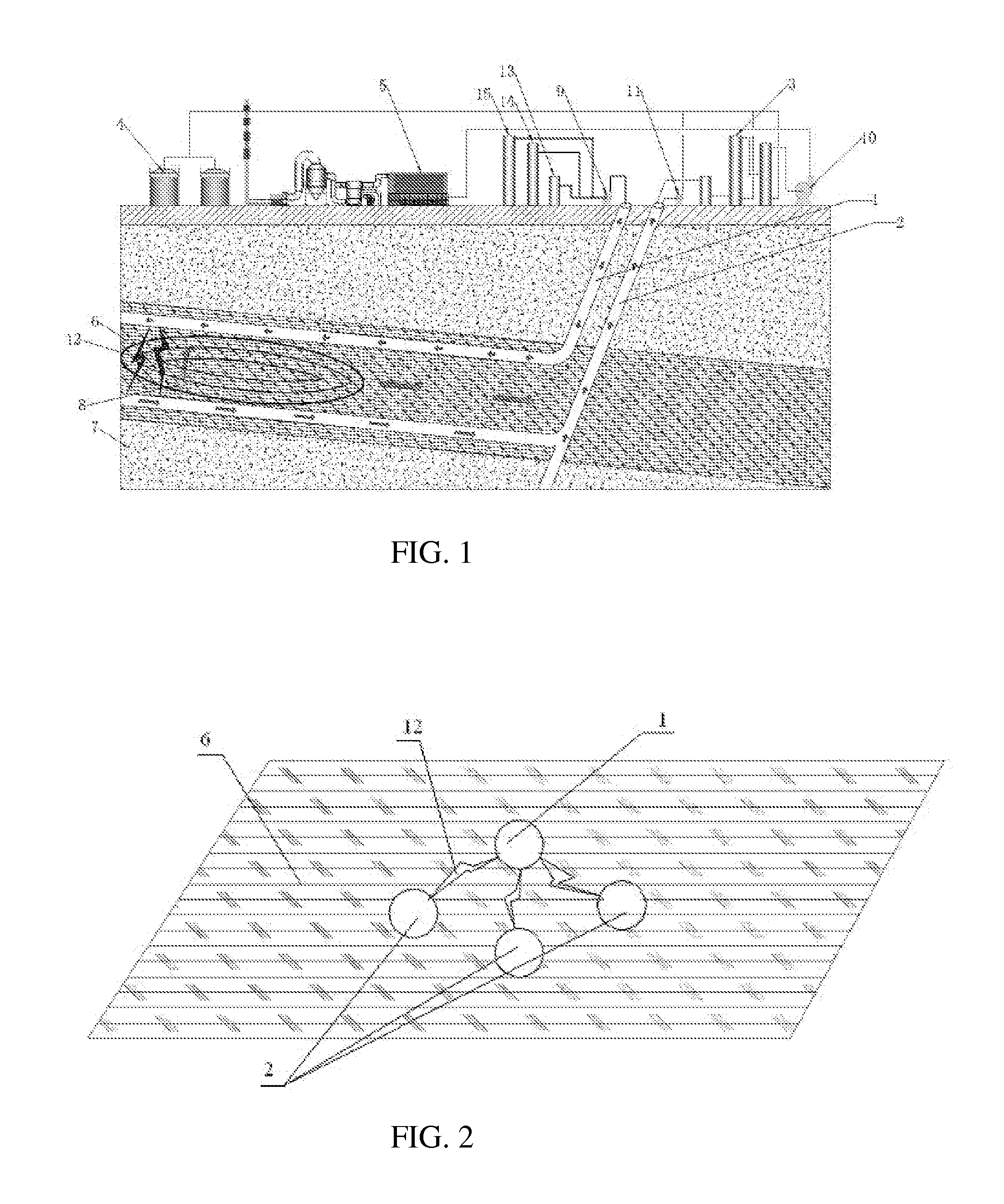

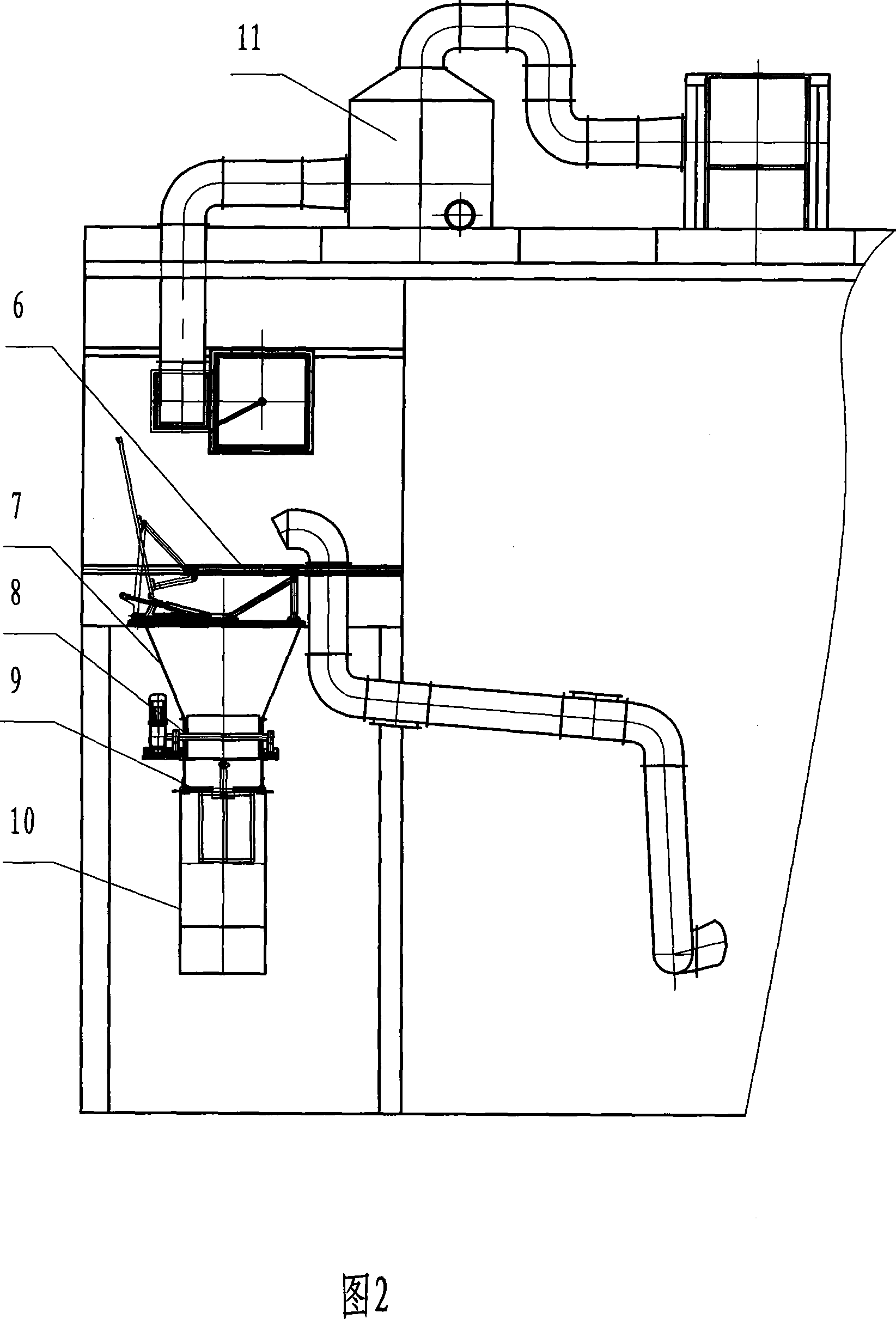

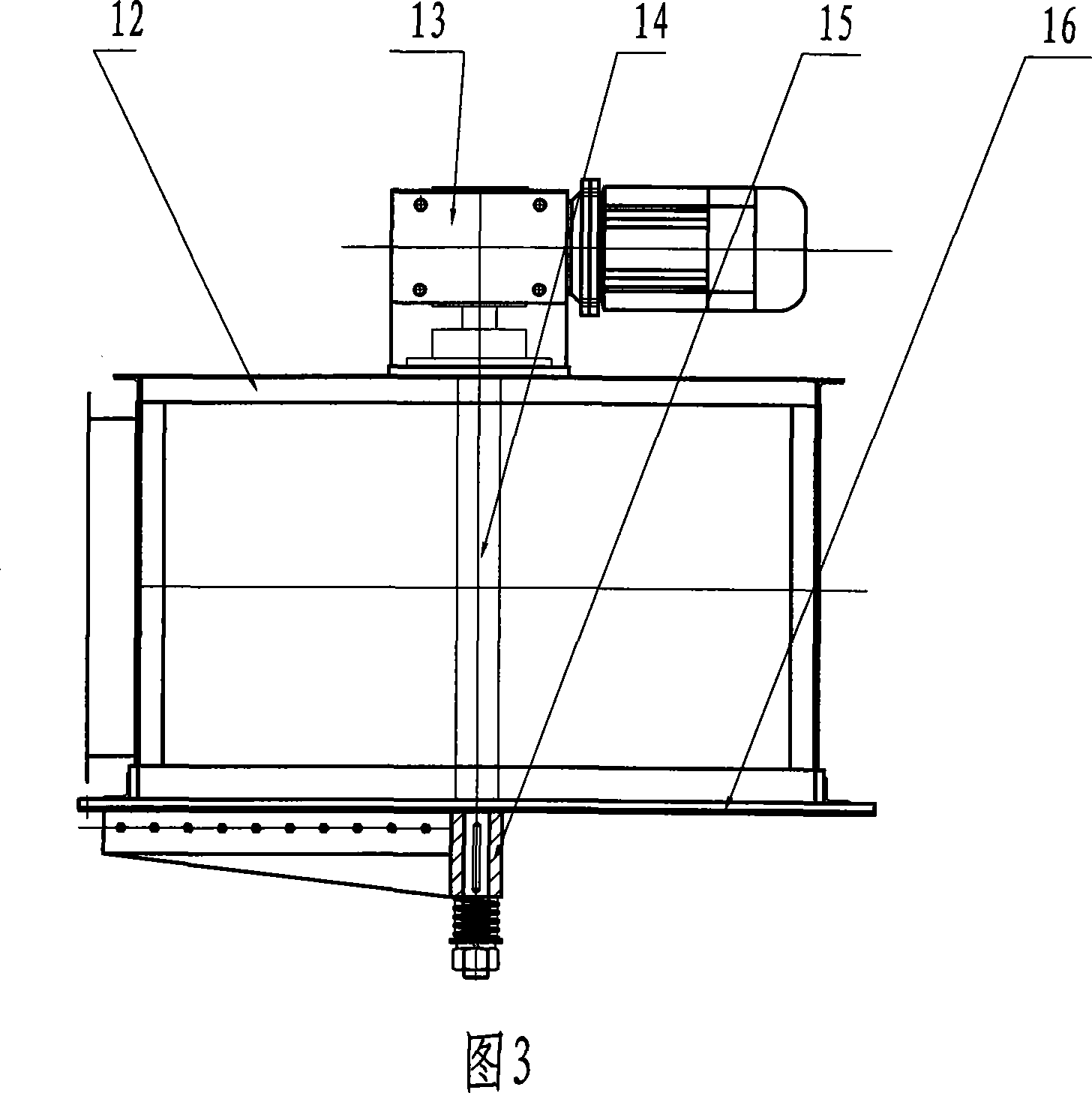

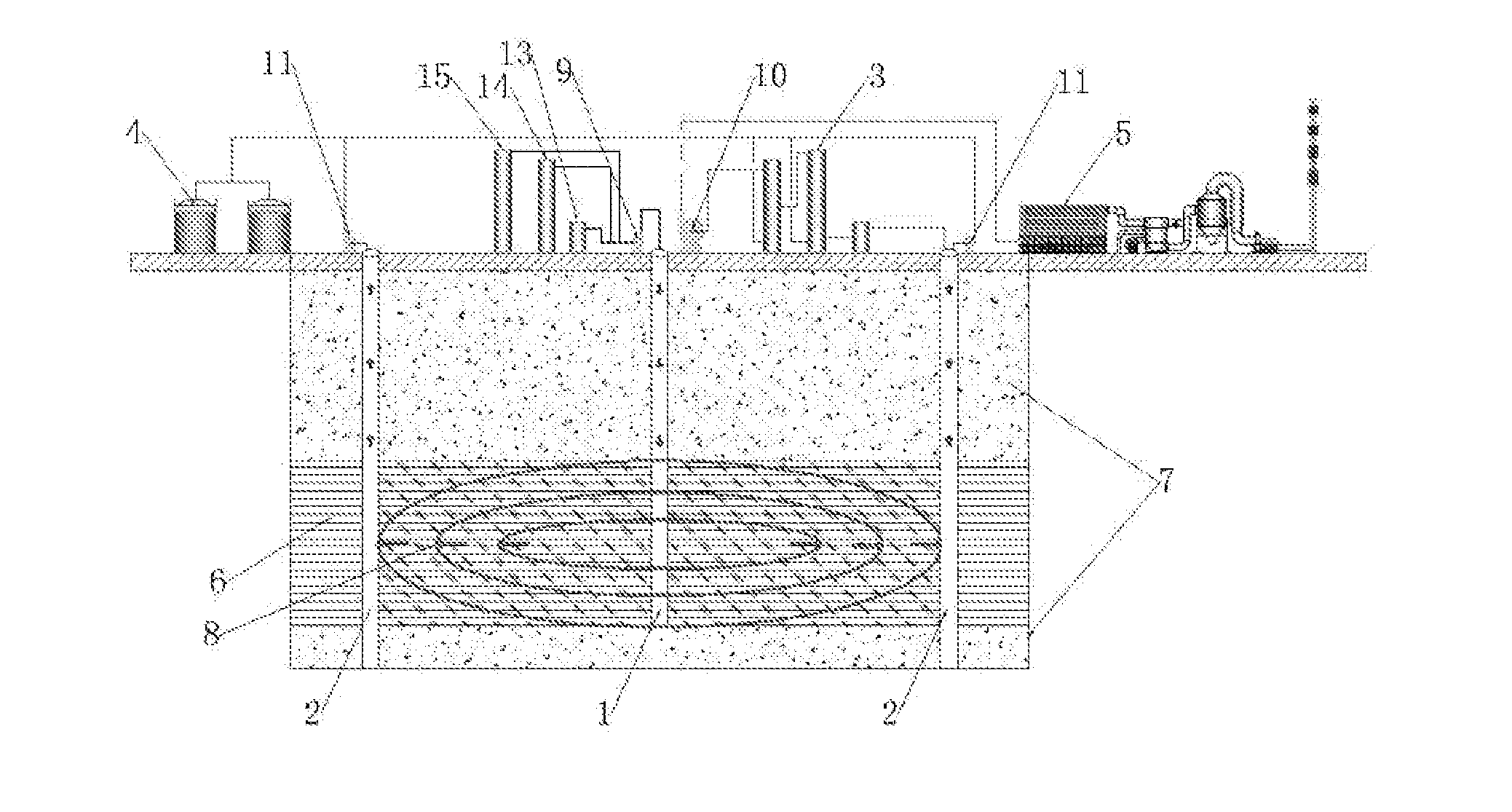

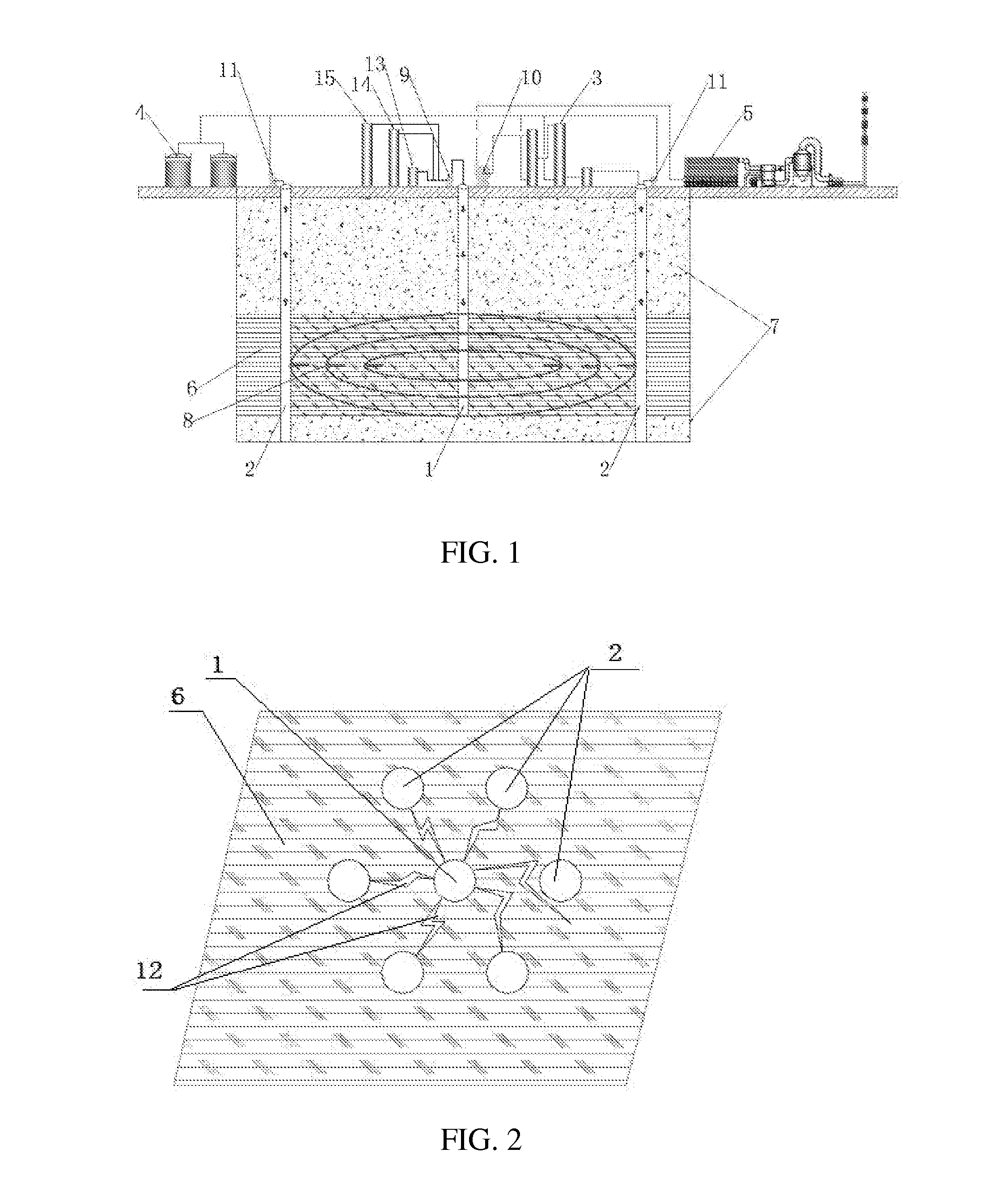

Method and process for extracting shale oil and gas by fracturing and chemical retorting in oil shale in-situ vertical well

InactiveUS20160069170A1High strengthSmall investmentInsulationFluid removalOil and natural gasHigh pressure

The present invention provides a method and a process for extracting shale oil and gas by fracturing and chemical retorting oil shale in in-situ vertical well. A vertical well (1) is drilled towards an underground oil shale stratum (6) and a highly pressurized medium is injected into the oil shale stratum. Cracks of 1 to 3 mm are fractured out in the oil shale stratum with the well serving as a center and are filed with gap fillers, so that oil gas passages (8) are established. Then, a heating apparatus is added into the oil shale stratum to heat the oil shale stratum to 550° C., the oil shale is initially retorted, the shale oil and gas are extracted, and the shale oil and gas are led out of the ground via the oil and gas channel. After that, an oxidizer is introduced for oxidization reaction with a sphaltenes and fixed carbon contained in the oil shale after being retorted, where the heat generated is used as a heat source for subsequent retorting, thus achieving underground in-situ shale oil extraction. This solves the problem that existing ground-level retorting has in terms of large recovery costs, difficult treatment of tailings, a variety of environmental issues, and large land-use footprint.

Owner:JILIN ZHONGCHENG AUTOMOTIVE SERVICE CHAIN +1

Household garbage treating method

InactiveCN106734082APreprocessing deepeningImplement classificationTransportation and packagingSolid waste disposalSoil organic matterOrganic matter

The invention discloses a household garbage treating method and relates to the technical field of solid waste disposition. The household garbage treating method comprises the following steps that S1, household garbage is pretreated and divided into a first group of organic matters, a second group of organic matters and metal components, and the first group of organic matters is easier to decay than the second group of organic matters; S2, the second group of organic matters in the step S1 is subjected to thermal decomposition to generate thermolysis carbon powder and thermolysis oil, and the first group of organic matters in the step S1 is treated to generate decomposed materials and dried materials; and S3, the thermolysis carbon powder, the decomposed materials and the dried materials in the step S2 are sent into a gas furnace to be sintered to generate fuel gas, and meanwhile, inorganic matters in the materials is melted and sintered to form stable materials. The household garbage treating method has the beneficial effects that the household garbage can be decomposed into the fuel gas and the stable materials, so that the resource rate of the household garbage is improved. Compared with the prior art, landfilling and burning are not needed, a large amount of land does not need to be occupied, and burning pollution does not caused.

Owner:HUNAN VARY TECH

Production technology for natural bamboo fibers

ActiveUS9630337B2Simple and high-efficient producing methodImprove adaptabilityPlant material mechanical workingVegetable materialFiberMaterials science

A production technology for natural bamboo fibers is applied in producing woven bamboo fibers, non-woven bamboo fibers, and reinforcing composite bamboo fibers. The woven bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding, rinsing, soaking in oil, drying, and opening. The non-woven bamboo fibers and the reinforcing composite bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding (optional), rinsing, and drying.

Owner:ZHANG YI

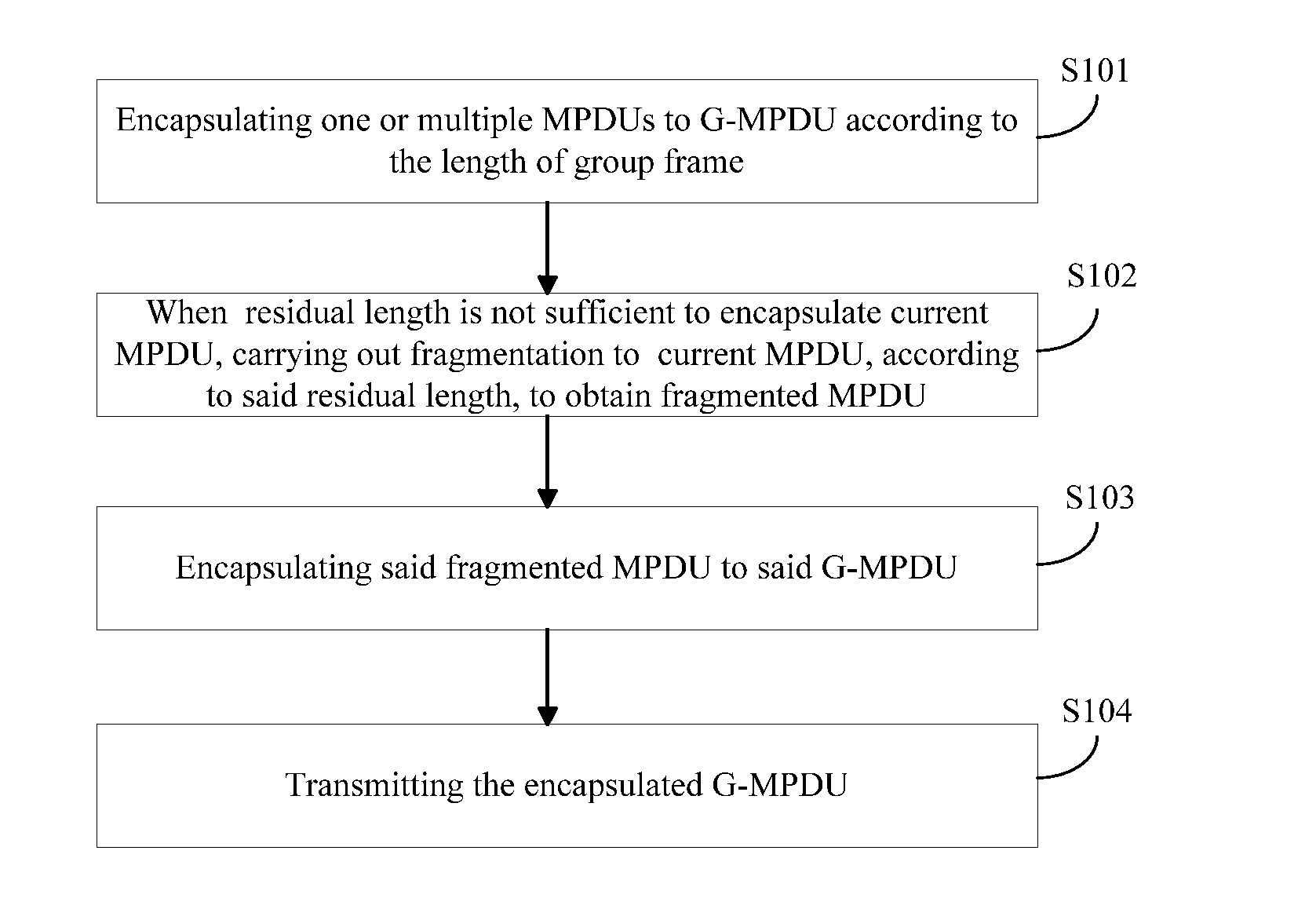

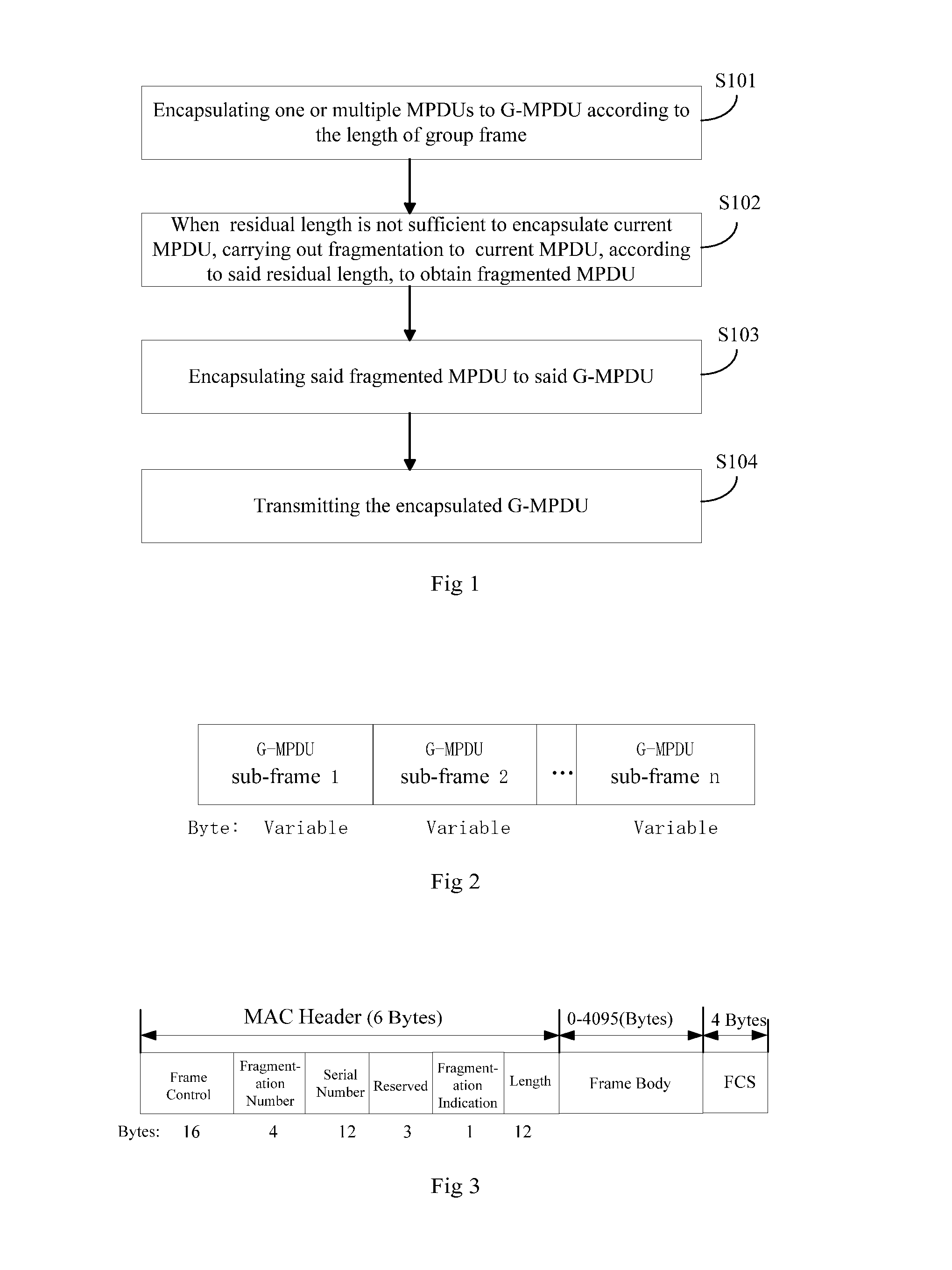

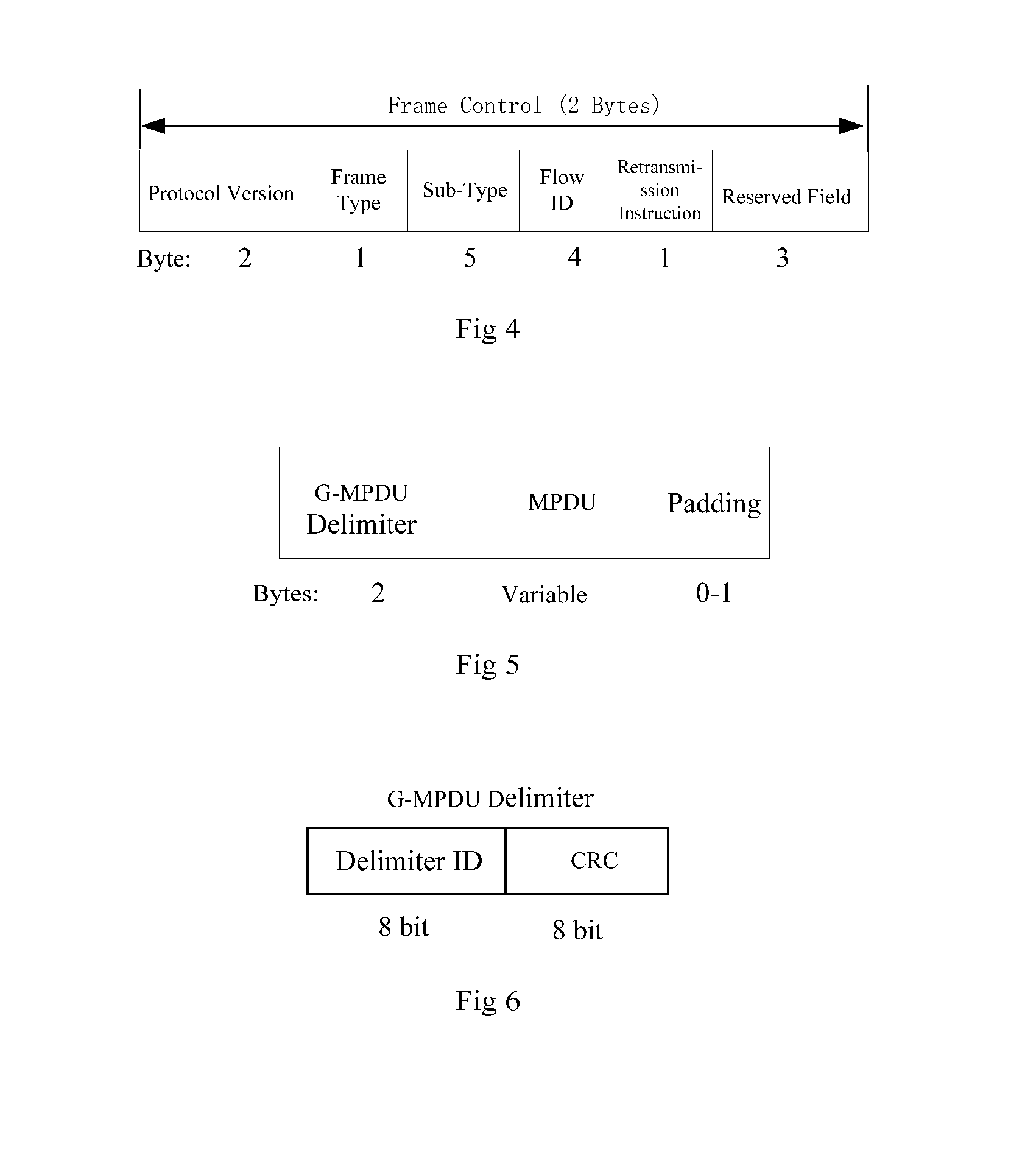

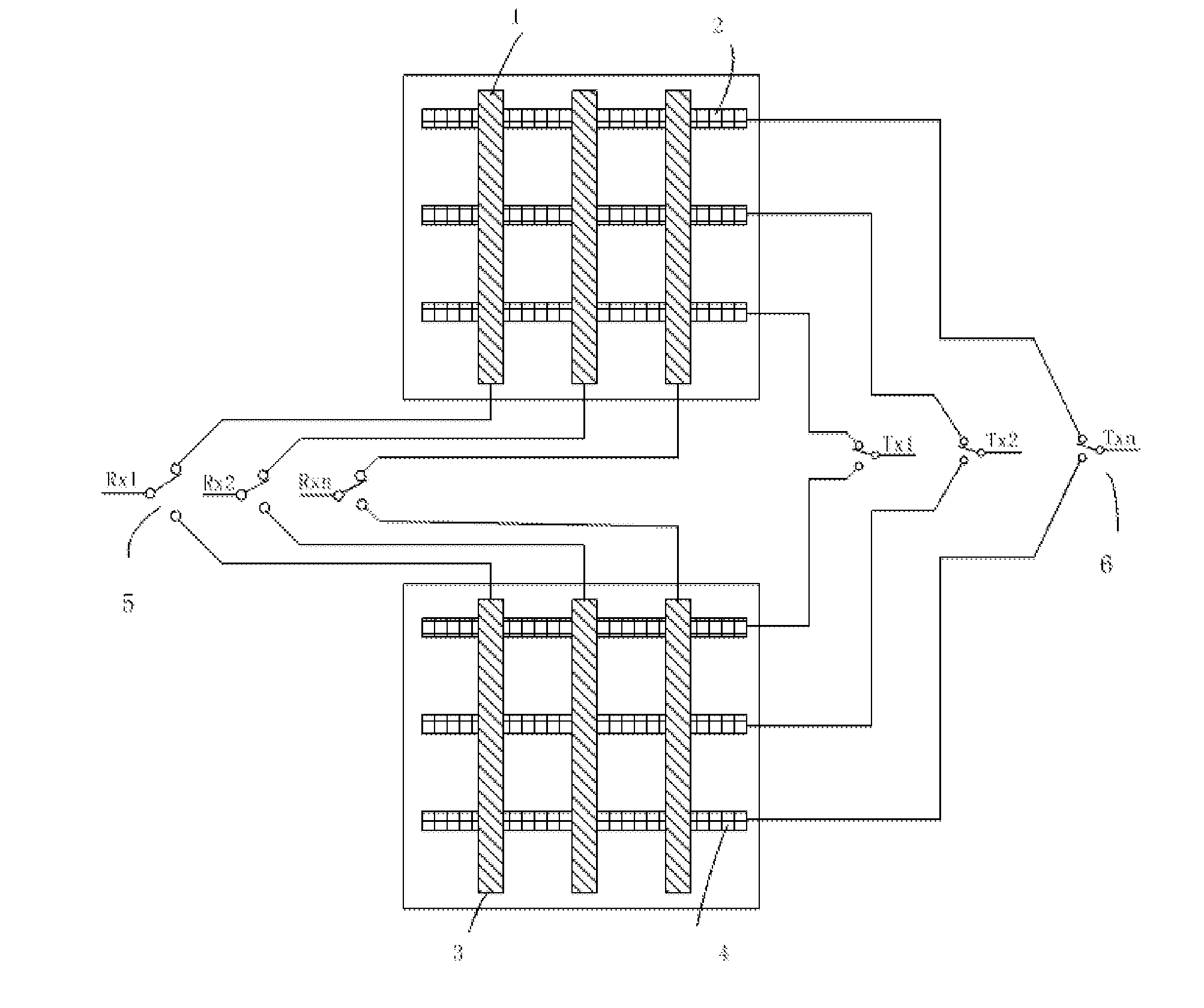

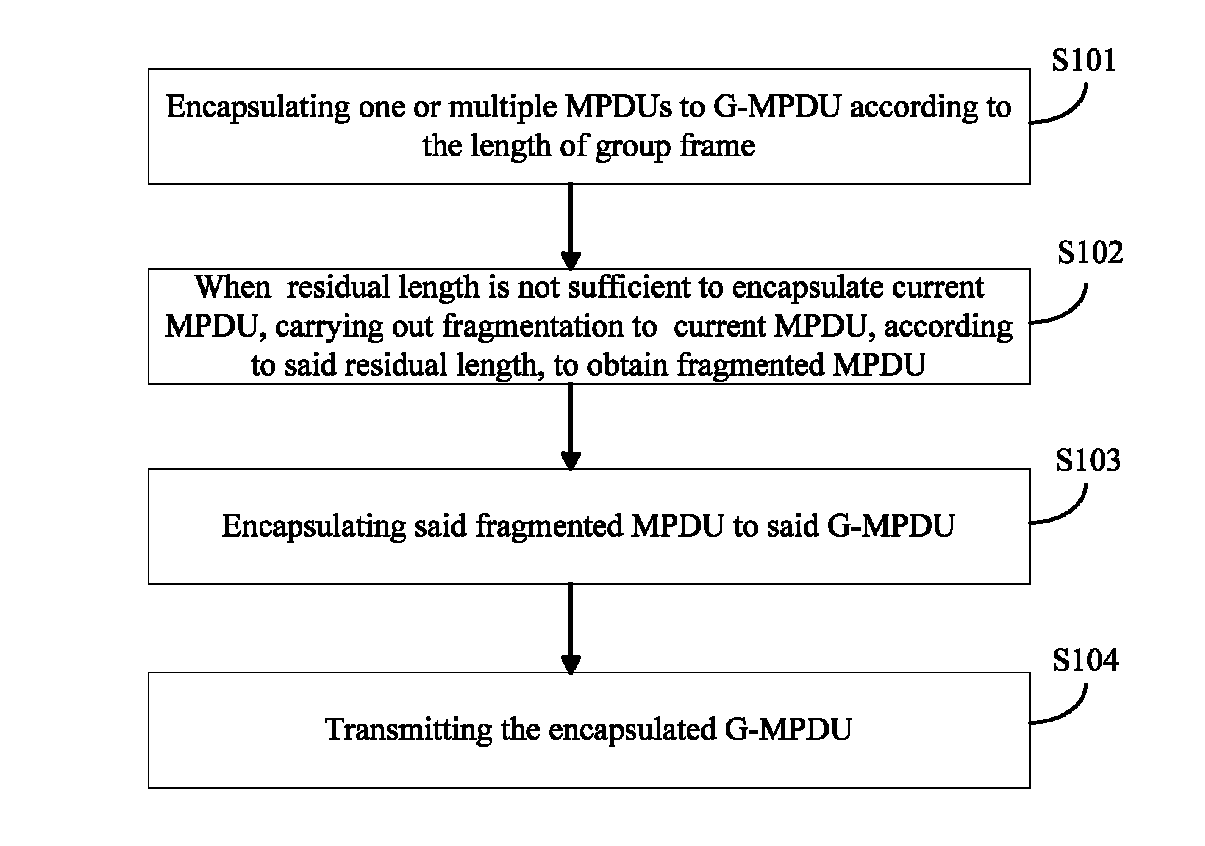

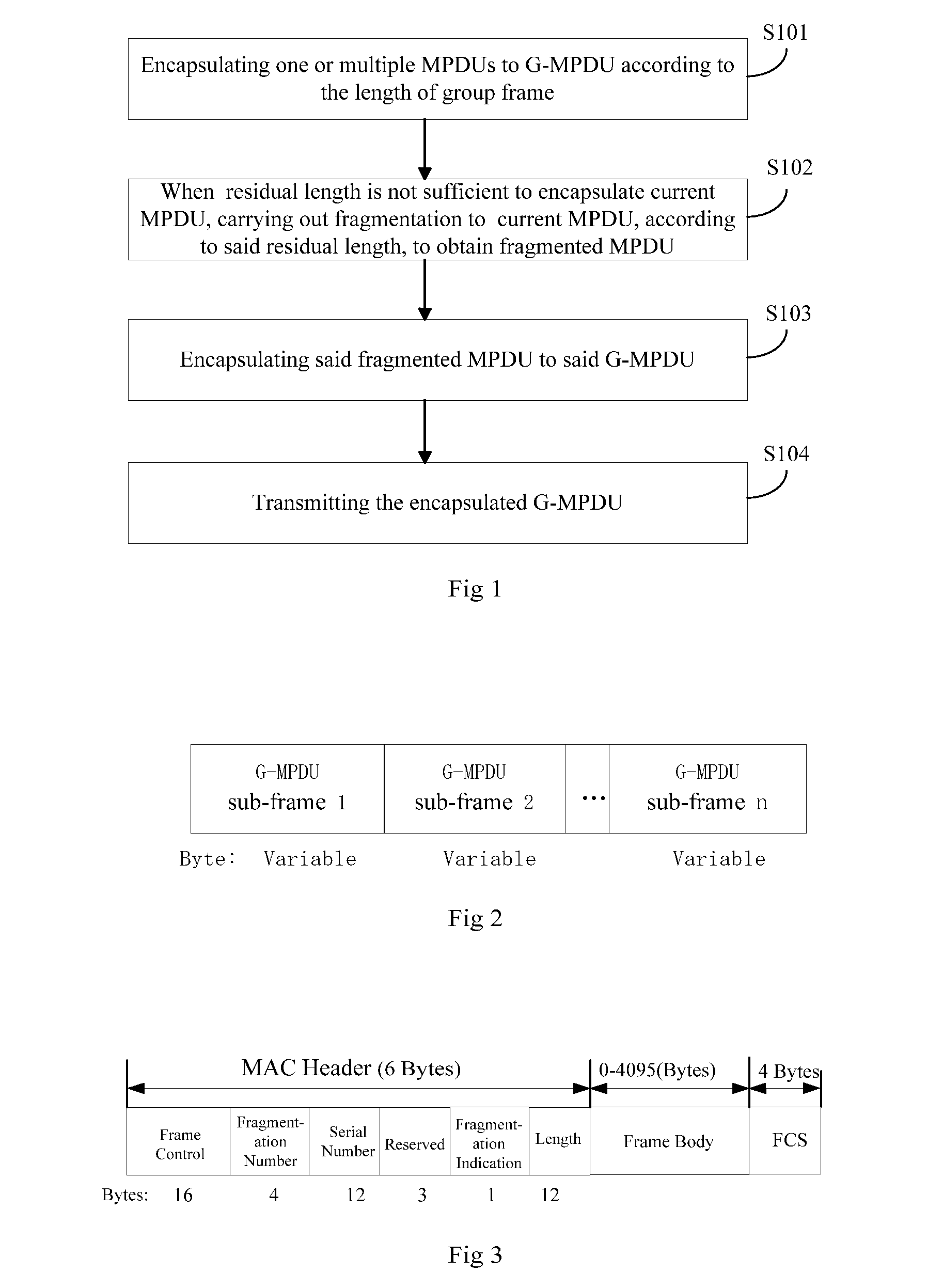

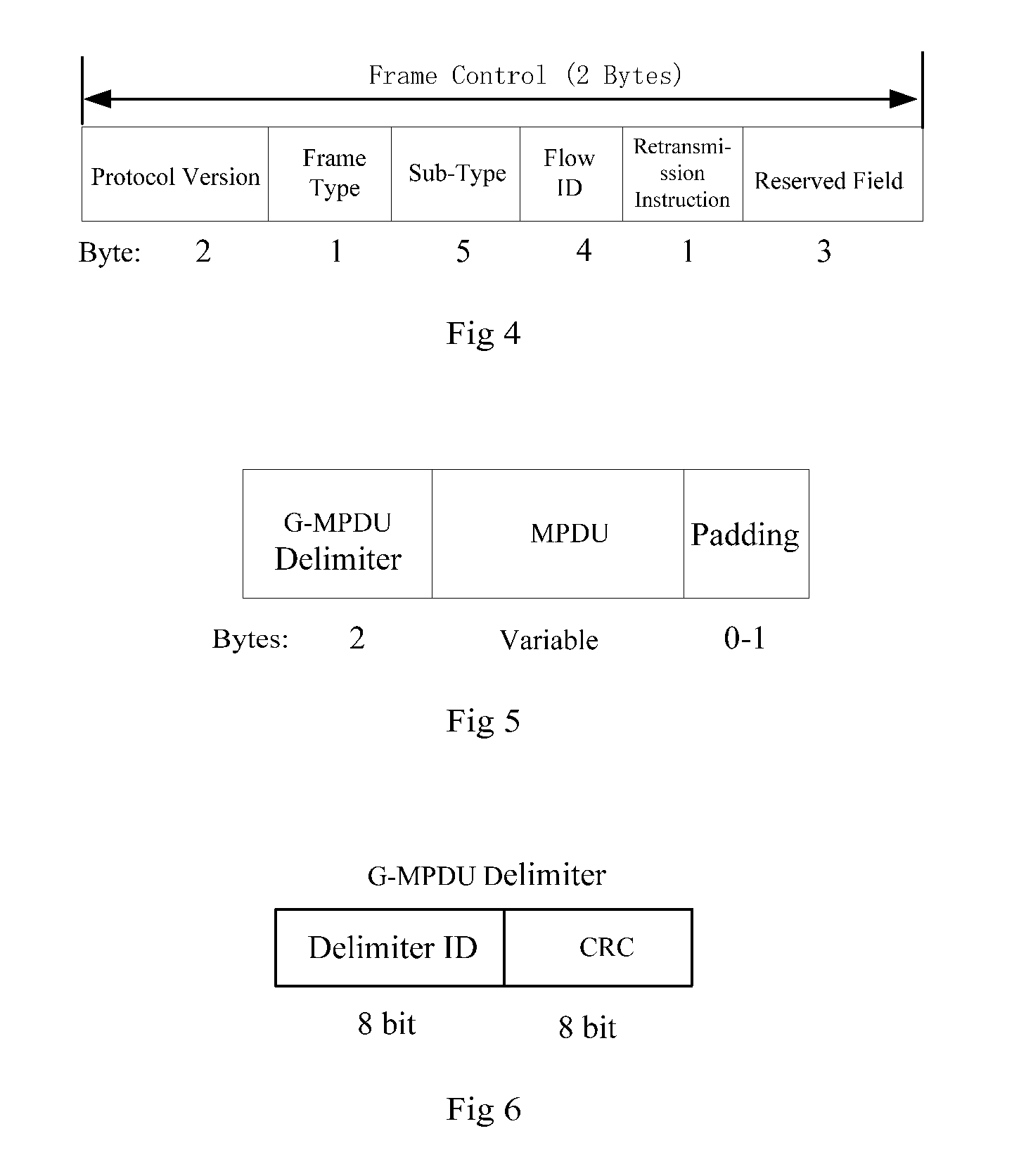

Method and apparatus for transmitting and receiving data

ActiveUS20150010019A1Improve data transfer rateSolve low resource utilizationTime-division multiplexTransmissionResource utilizationMedia access control

A method and apparatus for transmitting and receiving data are disclosed. The method for transmitting data, comprising encapsulating one or multiple media access control protocol data units (MPDU) as a group media access control protocol data unit (G-MPDU) based on a length of the group media access control protocol data unit G-MPDU; fragmenting a current MPDU according to a residual length to obtain a fragmented MPDU when the residual length is insufficient to encapsulate the current MPDU; encapsulating the fragmented MPDU to the G-MPDU; and transmitting the encapsulated G-MPDU. The method ensures a high data transmission rate and does not wasting excess time to execute the fragmentation processing. The method also ensures a high resource utilization rate, utilizing fully the remaining length of the data unit.

Owner:GUANGDONG NUFRONT COMP SYST CHIP

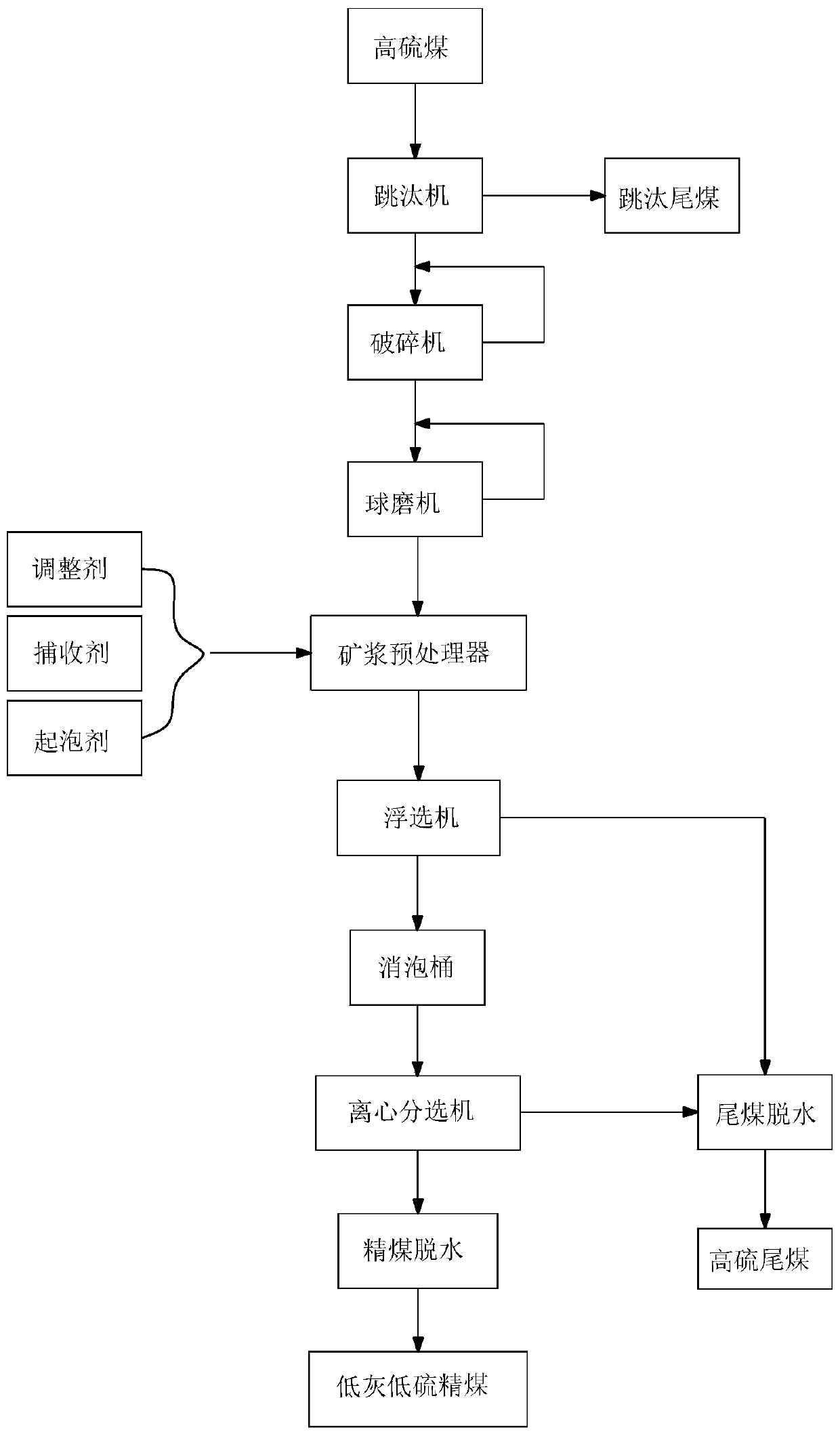

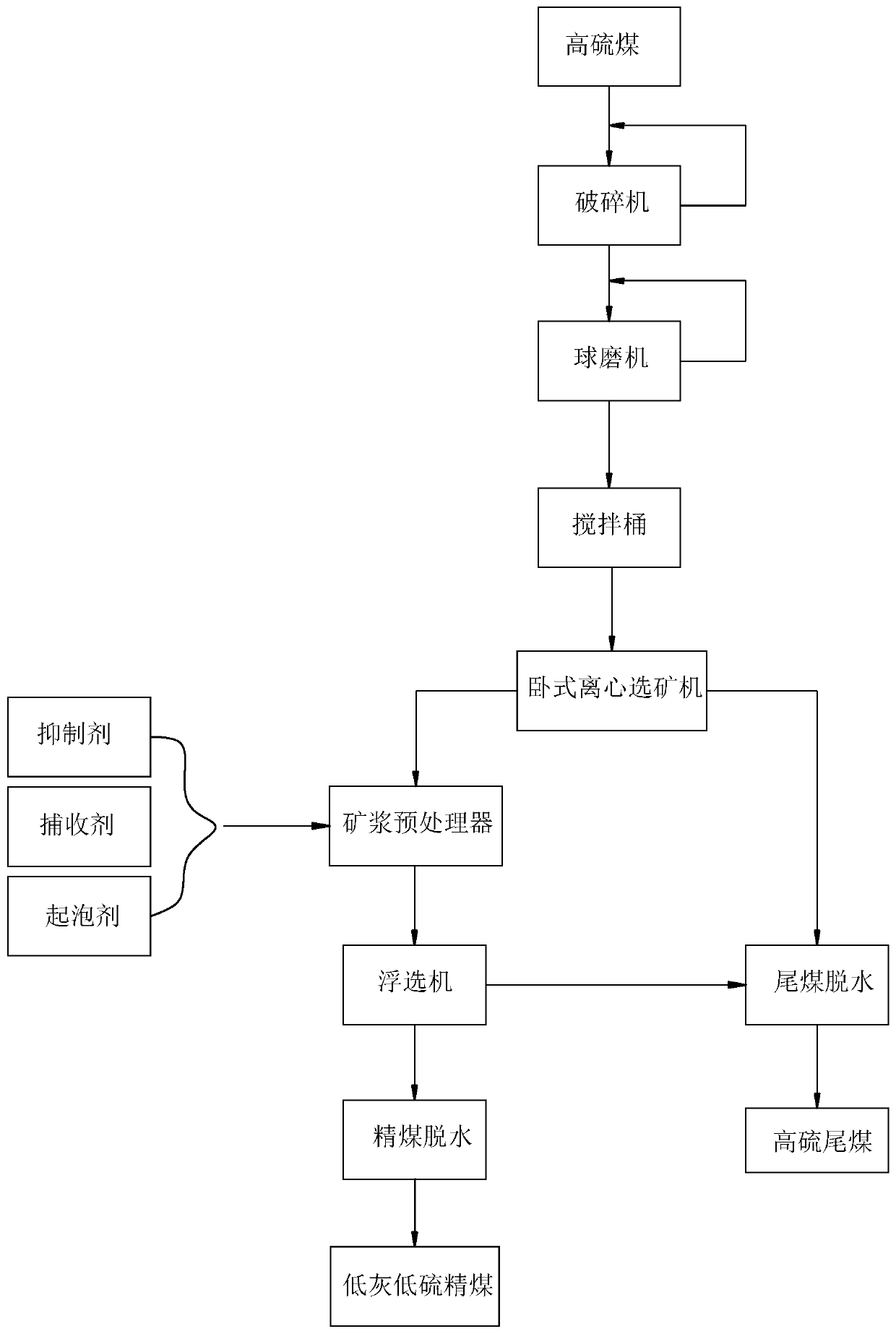

Separation technology reducing sulfur content and ash content in coal

The invention discloses a separation technology reducing the sulfur content and the ash content in coal. The separation technology includes the following steps that firstly, the high-sulfur coal is fed into a jigger to be subjected to jigging separation, and jigging cleaned coal is obtained; secondly, the jigging cleaned coal is fed into a breaking machine to be broken, and a broken product is obtained; thirdly, the fine broken product is fed into a ball grinding machine to be subjected to ball grinding, and a ball grinding product is obtained; fourthly, the fine ball grinding product is led into a pulp preprocessor, a chemical agent and water are added, stirring is conducted, and then fine ball grinding product pulp is obtained; fifthly, the fine ball grinding product pulp is led into a floating machine to be subjected to floatation, and floatation cleaned coal and floatation tailings are obtained; sixthly, the floatation cleaned coal is fed into a defoaming barrel to be stirred, anddefoaming cleaned coal is obtained; seventhly, the defoaming cleaned coal is fed into a centrifugal separation machine to be subjected to centrifugal separation, and water-containing low-ash low-sulfur cleaned coal and centrifugal tailings are obtained; and eighthly, the water-containing low-ash low-sulfur cleaned coal and the tailings are subjected to dehydration treatment respectively. By meansof the separation technology, the sulfur content and the ash content in the high-sulfur coal can be reduced, the sulfur and ash removing efficiency is high, and the technological process is simple.

Owner:XIAN UNIV OF SCI & TECH

Resin purifying treatment method for chlorinated tail gas leaching wastewater

ActiveCN108191105ALower pHReduce manufacturing costWater treatment parameter controlWater/sewage treatment by ion-exchangeMetal impuritiesIon-exchange resin

The invention belongs to the technical field of treatment of industrial wastewater and particularly relates to a resin purifying treatment method for chlorinated tail gas leaching wastewater. For solving the technical problem, the invention provides the resin purifying treatment method for the chlorinated tail gas leaching wastewater, the resin purifying treatment method comprises the following steps: a, adding hydrochloric acid into the wastewater, regulating and controlling the pH value of a system to 1-2, stirring and removing free chlorine; b, using an anion exchange resin to adsorb and remove acid and alkaline metals and acid metal impurities in the wastewater treated in the step a; c, adding liquid caustic soda into the wastewater treated in the step b, regulating and controlling thepH of the system to 9-11; and d, using a cation exchange resin to adsorb and remove the rest of metal impurities in the wastewater treated in the step c. The wastewater treated through the method contains a large quantity of NaCl, the content of other impurities is quite low, the wastewater can be directly recycled by the chlor-alkali industry, so that the environmental protection pressure, caused by the wastewater, on the relevant manufacturers producing TiCl4 is reduced or eliminated, and the production cost of the chlor-alkali industry is also lowered.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

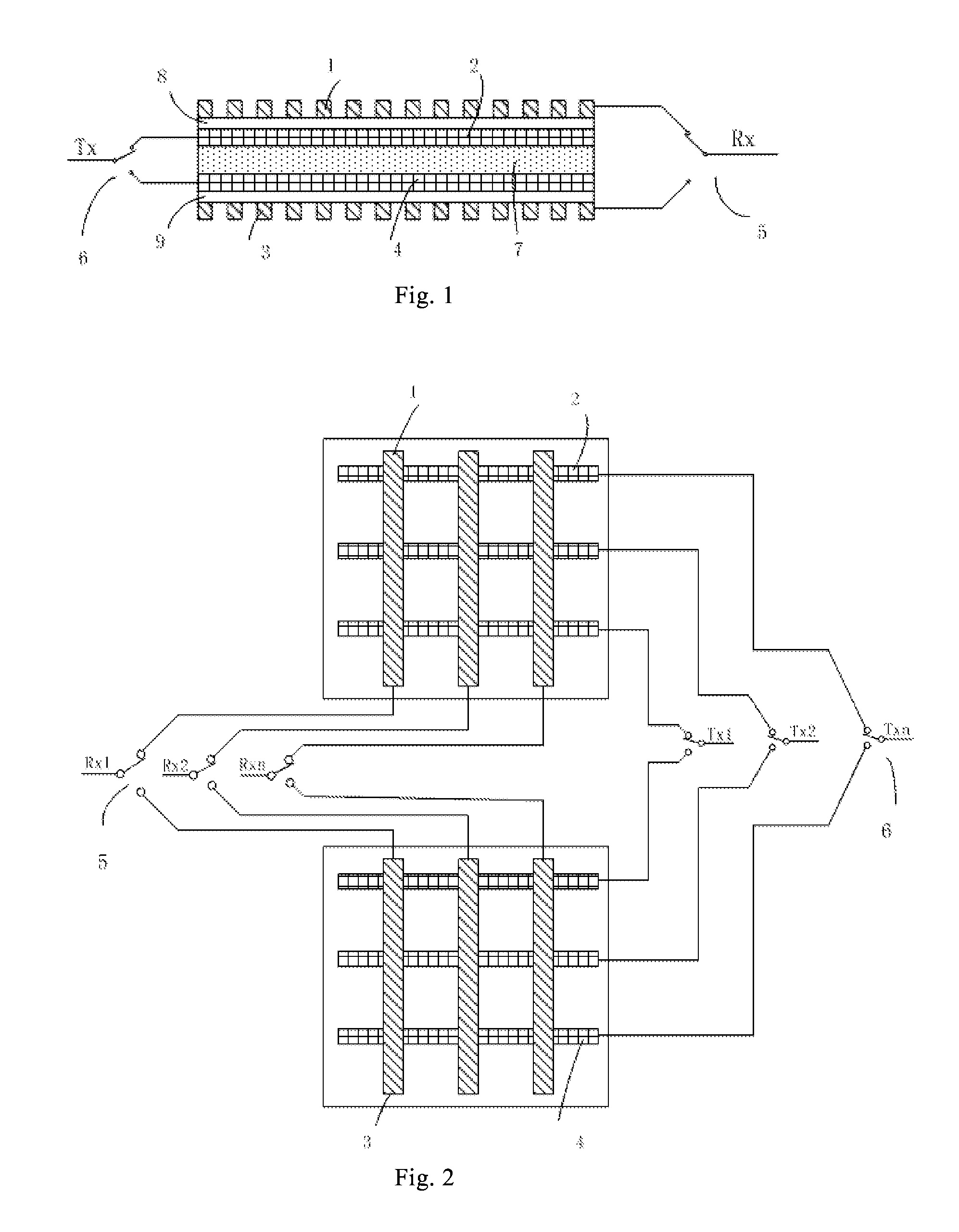

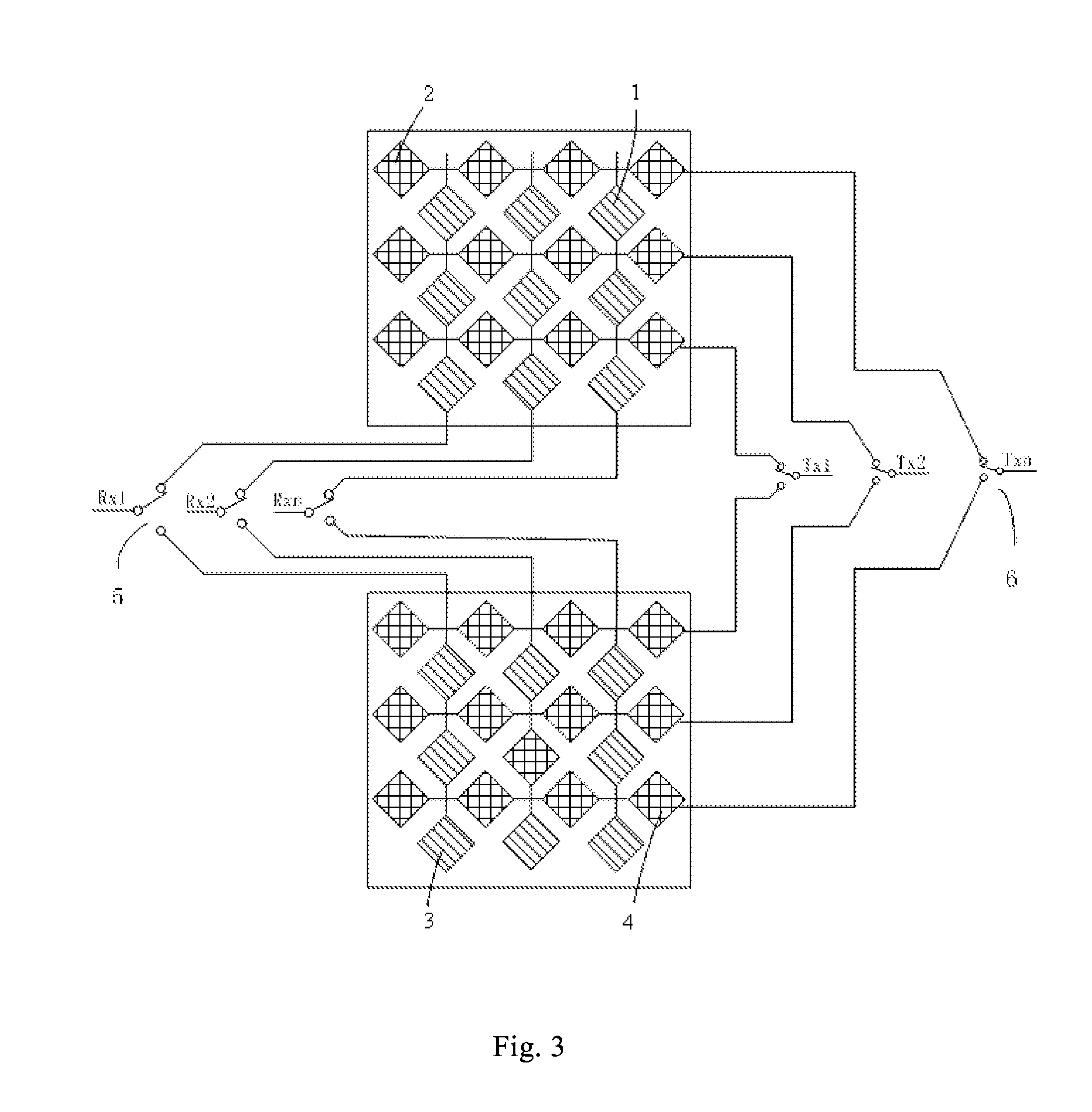

Double-Sided Touch Control Substrate, Double-Sided Touch Control Device and Double-Sided Touch Control Display Device

InactiveUS20160299619A1Solve low resource utilizationLow costInput/output processes for data processingDisplay deviceTime-sharing

The present invention provides a double-sided touch control substrate, a double-sided touch control device and a double-sided touch control display device. The double-sided touch control substrate comprises a base having a first side and a second side opposite to each other, a first touch control mechanism is provided on the first side, and a second touch control mechanism is provided on the second side. Both the first touch control mechanism and the second touch control mechanism are connected to a touch control driving unit through a switching mechanism, and the switching mechanism enables the first touch control mechanism and the second touch control mechanism to share the touch control driving unit in a time-sharing manner. With the double-sided touch control substrate, a streamlined touch-control device that is not limited to single-sided touch control is implemented by using fewer resources.

Owner:BOE TECH GRP CO LTD

High-salt wastewater treatment system and process for improving sodium chloride recycling rate

PendingCN111153537AAvoid destructionHigh purityTreatment involving filtrationMultistage water/sewage treatmentSludgeFiltration

The invention discloses a high-salt wastewater treatment system for improving the sodium chloride recycling rate. The system comprises an adjusting tank, a first-stage nanofiltration membrane device,a sodium sulfate evaporative crystallization unit, an RO membrane device, an RO concentrated water tank, a sodium chloride evaporative crystallization unit, a second-stage nanofiltration membrane device, a mother liquor mixing tank, a dosing tank, a filtering device and an impure salt evaporative crystallization unit. The water resource is saved, the environment is protected, salt in the high-saltwastewater is recycled, and the economic benefit of an enterprise is improved. The invention further discloses a high-salt wastewater treatment process for improving the sodium chloride recycling rate. The high-salt wastewater treatment process comprises the following steps: 1, first-stage nanofiltration salt separation; 2, reverse osmosis filtration; 3, sodium trisulfate crystallization and sodium chloride crystallization; 4, mixing and dosing; 5, filtering to remove silicon; 6, second-stage nanofiltration salt separation; 7, crystallization of impure salts. The recycling rate of sodium chloride is increased, and the problems of high sludge yield, high medicament addition amount and low medicament cost caused by traditional methods are avoided.

Owner:内蒙古晶泰环境科技有限责任公司

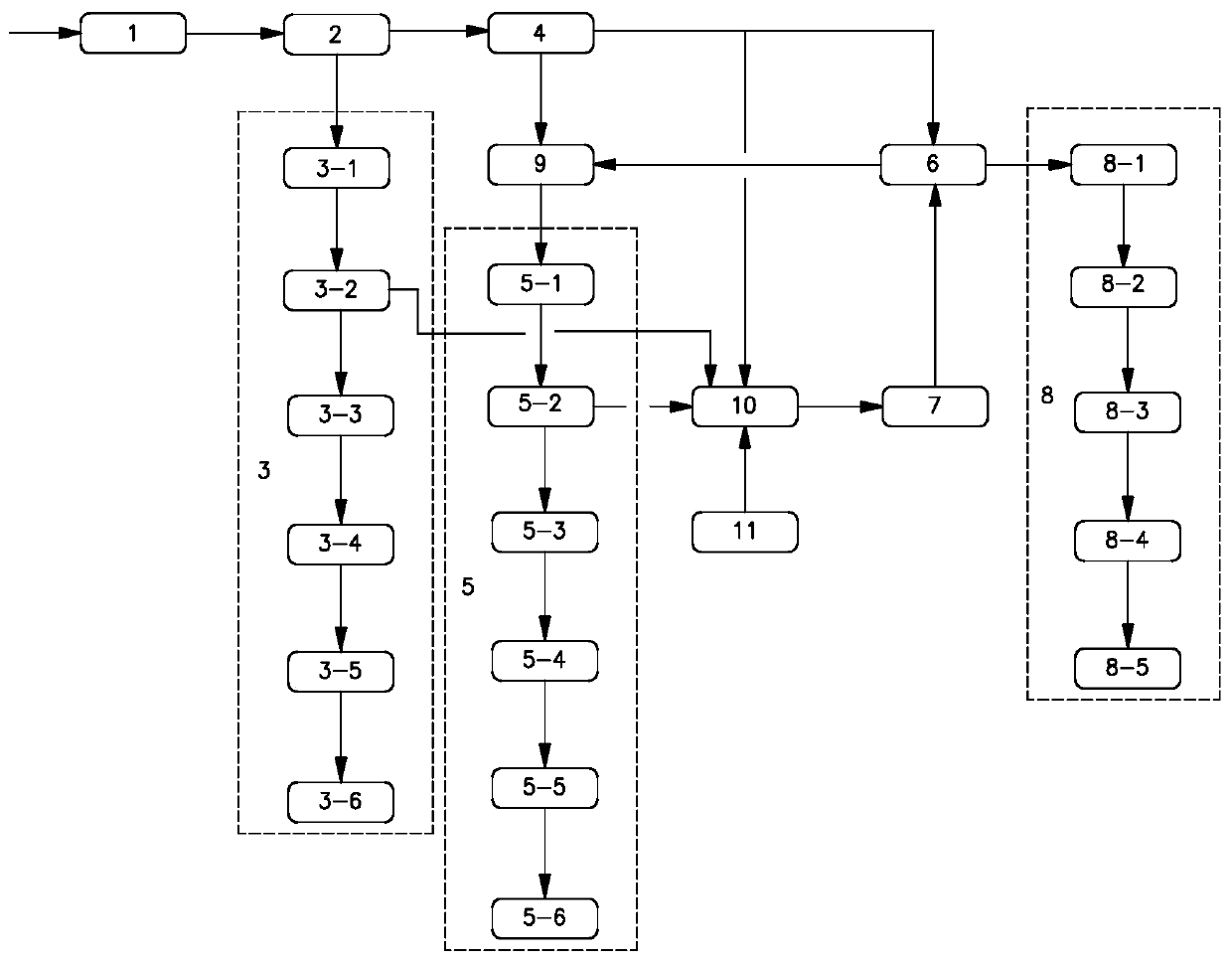

Foaming ceramic based on phosphate tailings and coal gangue and preparation method thereof

PendingCN114409431APromote generationLow viscosityCeramic materials productionCeramicwareHeat conservationCoal gangue

The invention relates to foamed ceramic based on phosphate tailings and coal gangue and a preparation method of the foamed ceramic. According to the technical scheme, 60-80 wt% of phosphate tailings and 20-40 wt% of coal gangue serve as raw materials and are mixed and stirred, 3-5 wt% of a binding agent and 5-9 wt% of water are added, stirring, mechanical pressing and drying are conducted, and a green body is prepared; and heating the green body to 600-650 DEG C at a rate of 5-10 DEG C / min, then heating to 900-950 DEG C at a rate of 3-4 DEG C / min, then heating to 1150-1200 DEG C at a rate of 1-2 DEG C / min, carrying out heat preservation for 30-90 minutes, and carrying out furnace cooling to room temperature, thereby obtaining the foamed ceramic based on the phosphate tailings and the coal gangue. The method is high in recycling rate, low in cost and simple in process, and the prepared product is low in volume density, high in compressive strength, small in heat conductivity coefficient and high in acid resistance.

Owner:WUHAN UNIV OF SCI & TECH

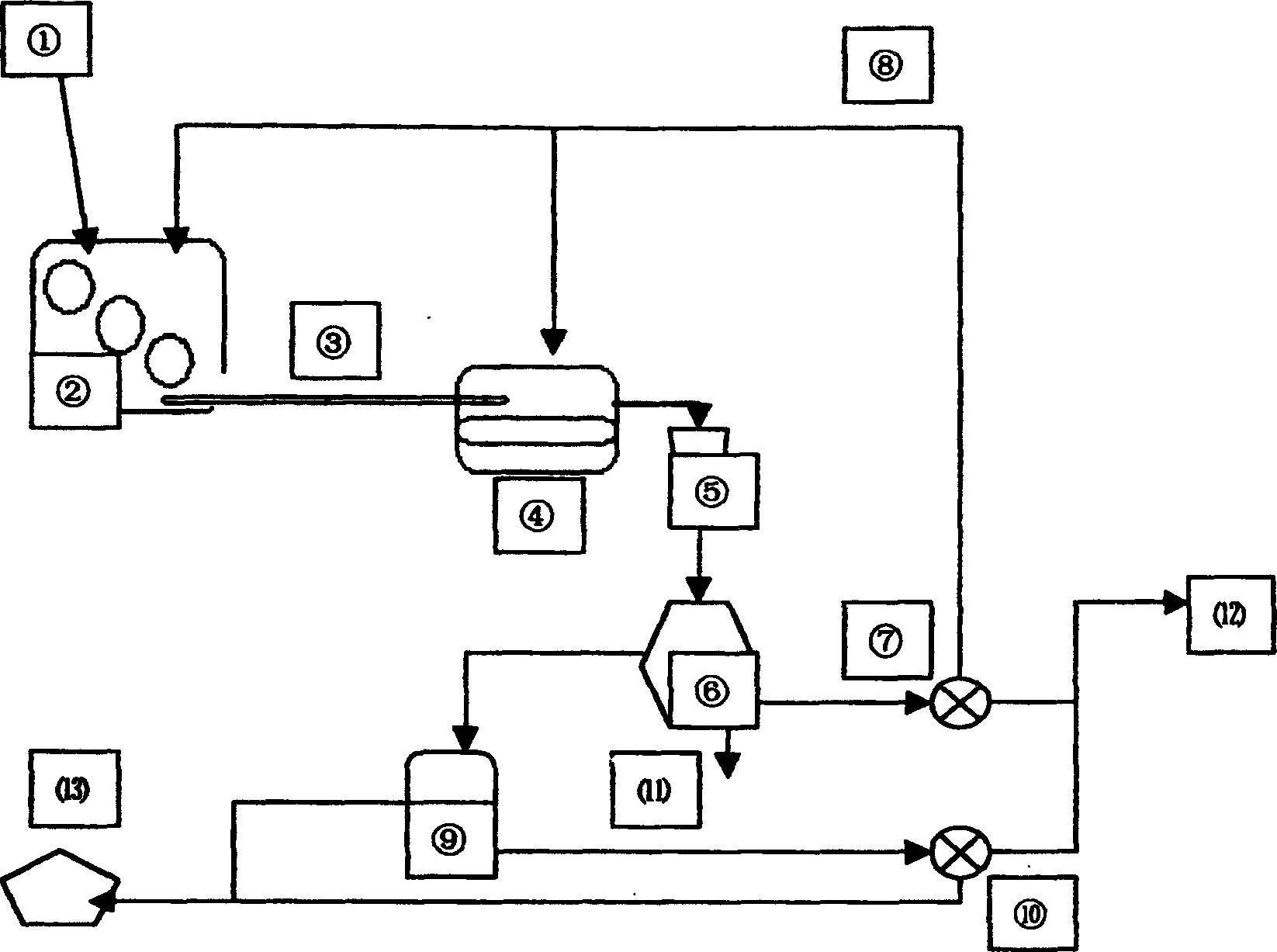

Harmless treatment methods of kitchen waste

InactiveCN102921704BHigh resource utilization rateHigh degree of harmlessnessSolid waste disposalFurniture waste recoveryEconomic benefitsEngineering

The invention relates to a harmless disposal method of kitchen garbage, which comprises the following steps of: (1) pretreatment: after unloading the kitchen garbage, performing solid-liquid separation, rough crushing, crushing and sorting and performing magnetic separation, and recycling metal substances mixed in the kitchen garbage; (2) hydrothermal hydrolysis: after the pretreatment, adopting the hydrothermal hydrolysis to fully inactivate viruses and bacteria in the kitchen garbage, separating out animal and vegetable fatty oil from the kitchen garbage, and hydrolyzing organic materials at the same time; (3) using the fatty oil obtained in the step (2) as an industrial fatty oil material or further performing deep processing to obtain fatty acid methyl ester or biodiesel; mixing and proportioning the pasty organic materials and then conveying into an anaerobic fermentation system; and conveying large granular organic materials into an aerobic biological fermentation device. The method provided by the invention realizes harmless disposal of the kitchen garbage mainly by the pretreatment and the hydrothermal hydrolysis process, increases the conversion rate of biological energy of the kitchen garbage and increases the economic benefit of kitchen garbage recycling products.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD +2

System for processing categorized consumer waste

InactiveCN101347789BHigh separation purityImprove sorting efficiencySievingScreeningLitterHandling system

Owner:北京厨房设备有限公司

Solid waste material vertical solidifying and gasifying technique secondary power generation comprehensive utilization method

InactiveCN1199739CHigh resource utilization rateNo secondary pollutionSolid waste disposalIncinerator apparatusSlagWaste material

A comprehensive utilization method for secondary power generation by solid waste solidification and gasification process, comprising the following steps: 1) solid waste solidification: turning domestic waste into dense and hard solid waste rods; (2) waste gasification: solid waste rods Add anti-fire gasifier dry distillation to generate combustible gas; (3) Gasification power generation: supply the generated combustible gas to the internal combustion generator for power generation; (4) Secondary power generation: collect the waste heat of the internal combustion generator, and send it to the low-pressure boiler to generate steam, The generated steam is used to drive the low-pressure steam generator to generate electricity to achieve secondary power generation; (5) slag utilization; (6) waste heat utilization, using the waste heat of the low-pressure steam generator to break open the plastic bags of garbage and dry the garbage moisture. The present invention has the advantages of high recycling rate of domestic waste, no secondary pollution, less project investment, etc., solves the problem of waste leakage pollution, the odor problem caused by the centralized stacking of waste, and the problem of mass production of dioxin, and creates a new A precedent for secondary power generation from domestic waste.

Owner:张连发

High-performance ceramsite based on phosphate tailings and preparation method of high-performance ceramsite

ActiveCN114394850ASimple preparation processShorten the production cycleCeramic materials productionCeramicwarePolyvinyl alcoholPhosphate

The invention relates to high-performance ceramsite based on phosphate tailings and a preparation method of the high-performance ceramsite. According to the technical scheme, 80-95 wt% of high-silicon phosphate tailings and 5-20 wt% of high-magnesium calcium phosphate tailings are used as raw materials, 3-5 wt% of dextrin is added, and the raw materials are mixed to be uniform; putting the mixture into a granulator, spraying a 3% polyvinyl alcohol aqueous solution which accounts for 2-5wt% of the mixture under a rotating condition, granulating, and drying; heating to 950-1080 DEG C in a medium-temperature furnace at the speed of 2-3 DEG C / min, preserving heat for 2-4 hours, and cooling along with the furnace; and putting the mixture into a modified solution with the concentration of 0.5-3 mol / L, oscillating for 1-1.5 hours in a constant-temperature oscillator, standing and drying to obtain the high-performance ceramsite based on the phosphate tailings. The method has the characteristics of high resource rate of the phosphate tailings, simple process, low production cost and short production period, and the prepared high-performance ceramsite based on the phosphate tailings is high in strength, high in apparent porosity, small in volume density, low in hydrochloric acid solubility and high in removal rate of heavy metal ions Ag < 2 + >, Ni < 2 + > and Cu < 2 + >.

Owner:WUHAN UNIV OF SCI & TECH

CaO-MgO-SiO2-H2O cementing material for mine filling and preparation method of CaO-MgO-SiO2-H2O cementing material

ActiveCN114455866AHigh resource utilization rateSimple processSolid waste managementCement productionNon-ferrous metalPre treatment

The invention relates to a CaO-MgO-SiO2-H2O cementing material for mine filling and a preparation method of the CaO-MgO-SiO2-H2O cementing material. According to the technical scheme, the preparation method comprises the following steps: mixing 60-80wt% of pretreated iron tailing micro-powder and 20-40wt% of pretreated phosphate tailing micro-powder to obtain a first mixture; adding silica powder accounting for 5-10 wt% of the first mixture, sodium hydroxide accounting for 1-5 wt% of the first mixture and water accounting for 100-200 wt% of the first mixture into the first mixture, and mixing to obtain a second mixture; adjusting the pH value of the second mixture to 11-13, and magnetically stirring to obtain slurry; carrying out solid-liquid separation on the slurry, freezing and drying the separated solid, carrying out heat preservation for 1-3 hours under the condition of 800-1000 DEG C, and carrying out furnace cooling and grinding, so as to obtain the CaO-MgO-SiO2-H2O cementing material for mine filling. The method has the characteristics of high recycling rate, low production cost and simple process, the strength of the prepared product conforms to the specification of Code for Design of Mining of Non-ferrous Metal (GB 50771-2012), and the filling slurry is low in bleeding rate and high in additional value.

Owner:WUHAN UNIV OF SCI & TECH

Comprehensive utilization technology for reducing sulfur content of high-sulfur coal ash

The invention discloses a comprehensive utilization technology for reducing sulfur content of high-sulfur coal ash. The technology comprises the following steps: 1, crushing high-sulfur coal to obtaina crushed product; 2, ball-milling the fine crushed product to obtain a ball-milled product; 3, mixing the fine ball milled product to obtain a mixed pulp product; 4, feeding the size mixing productinto a horizontal centrifugal concentrator for separation to obtain centrifugal clean coal and centrifugal tail coal; 5, feeding the centrifugal clean coal into an ore pulp preprocessor, adding an additive, and stirring to obtain centrifugal clean coal ore pulp; 6, introducing the centrifugal clean coal ore pulp into a flotation machine for flotation to obtain water-containing low-ash low-sulfur clean coal and flotation tail coal; and 7, correspondingly dehydrating the water-containing low-ash low-sulfur clean coal, the centrifugal tailings and the flotation tailings. According to the technology, the dissociation degree of sulfur in the coal is refined by crushing and grinding, and the dissociated coal sample is subjected to centrifugal separation and flotation combined separation, so thatthe sulfur content and ash content in the high-sulfur coal are reduced, the feasibility is provided for the utilization of the high-sulfur coal, and the environmental pollution of the high-sulfur coal in the utilization process is reduced.

Owner:XIAN UNIV OF SCI & TECH

Method and process for extracting shale oil and gas by fracturing and chemical retorting in oil shale in-situ horizontal well

ActiveUS9784086B2High strengthImprove abilitiesFluid removalDirectional drillingOil shale gasHigh pressure

Owner:JILIN ZHONGCHENG AUTOMOTIVE SERVICE CHAIN +1

Purifying treatment method for chloridized tail gas leaching wastewater

InactiveCN108002586AEliminate environmental pressureReduce manufacturing costWater contaminantsTreatment involving filtrationIndustrial wastewater treatmentExhaust gas

The invention belongs to the technical field of industrial wastewater treatment, and specifically relates to a purifying treatment method for chloridized tail gas leaching wastewater. The technical problem to be solved of the invention is to provide the purifying treatment method for chloridized tail gas leaching wastewater and the method comprises the following steps: a, adding hydrochloric acidinto the wastewater to regulate the pH (Potential of Hydrogen) value of a control system to be 1 to 2, stirring and removing free chlorine; b, adding alkali liquor to regulate the pH value of the control system to be 3 to 4, and filtrating to remove the solid; c, then adding alkali liquor again to regulate the pH value of the control system to be 9 to 11, and filtrating to remove the solid, wherein the obtained filter liquor is a purified solution. The wastewater subjected to purification through the treatment method provided by the invention is extremely low in impurity content, except for alarge amount of NaCl, and can be recycled directly by the chlor-alkali industry, not only can the environmental protection pressure, which is brought by the wastewater, on related TiCl4 manufacturersbe reduced or even eliminated, but also the manufacturing cost of the chlor-alkali industry is reduced.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

Method and apparatus for transmitting and receiving data

A method and apparatus for transmitting and receiving data are disclosed. The method for transmitting data, comprising encapsulating one or multiple media access control protocol data units (MPDU) as a group media access control protocol data unit (G-MPDU) based on a length of the group media access control protocol data unit G-MPDU; fragmenting a current MPDU according to a residual length to obtain a fragmented MPDU when the residual length is insufficient to encapsulate the current MPDU; encapsulating the fragmented MPDU to the G-MPDU; and transmitting the encapsulated G-MPDU. The method ensures a high data transmission rate and does not wasting excess time to execute the fragmentation processing. The method also ensures a high resource utilization rate, utilizing fully the remaining length of the data unit.

Owner:GUANGDONG NUFRONT COMP SYST CHIP

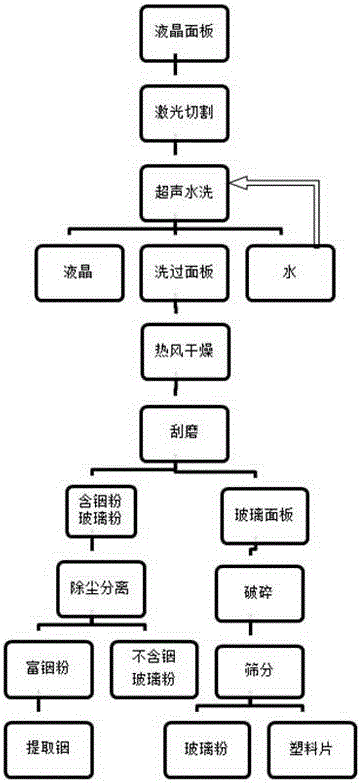

Liquid crystal display panel recycling process

ActiveCN106166562AEfficient separation and recoverySuitable for large-scale industrial applicationsSolid waste disposalLiquid-crystal displaySurface layer

The invention discloses a liquid crystal display panel recycling process which includes the steps: placing a liquid crystal display panel on a conveying belt; cutting the liquid crystal display panel into a proper size by a laser cutting machine; separating glass on two sides of the liquid crystal display panel from the middle after cutting to clean and enrich liquid crystals between the glass on the two sides; drying a liquid crystal display by hot air; sucking the glass of the liquid crystal display panel from the upper portion by a vacuum sucker; scraping an ITO (indium tin oxide) surface layer of the lower portion on an assembly line by a grinder to obtain ITO and powder of parts of the glass; collecting indium-rich powder and the glass powder without the ITO obtained by separation through a dust removal system; crushing the glass of the liquid crystal display panel without the ITO layer into powder, and crushing plastics in the liquid crystal display panel into flakes; finally, separating the glass powder from the flaky plastics by screening. The liquid crystal display panel recycling process has the advantages of high efficiency, no pollution, high resource recovery rate, simplicity in operation and the like, and is suitable for large-scale industrial application of environmental protection and resource recovery enterprises.

Owner:南京万舟发机电科技有限公司

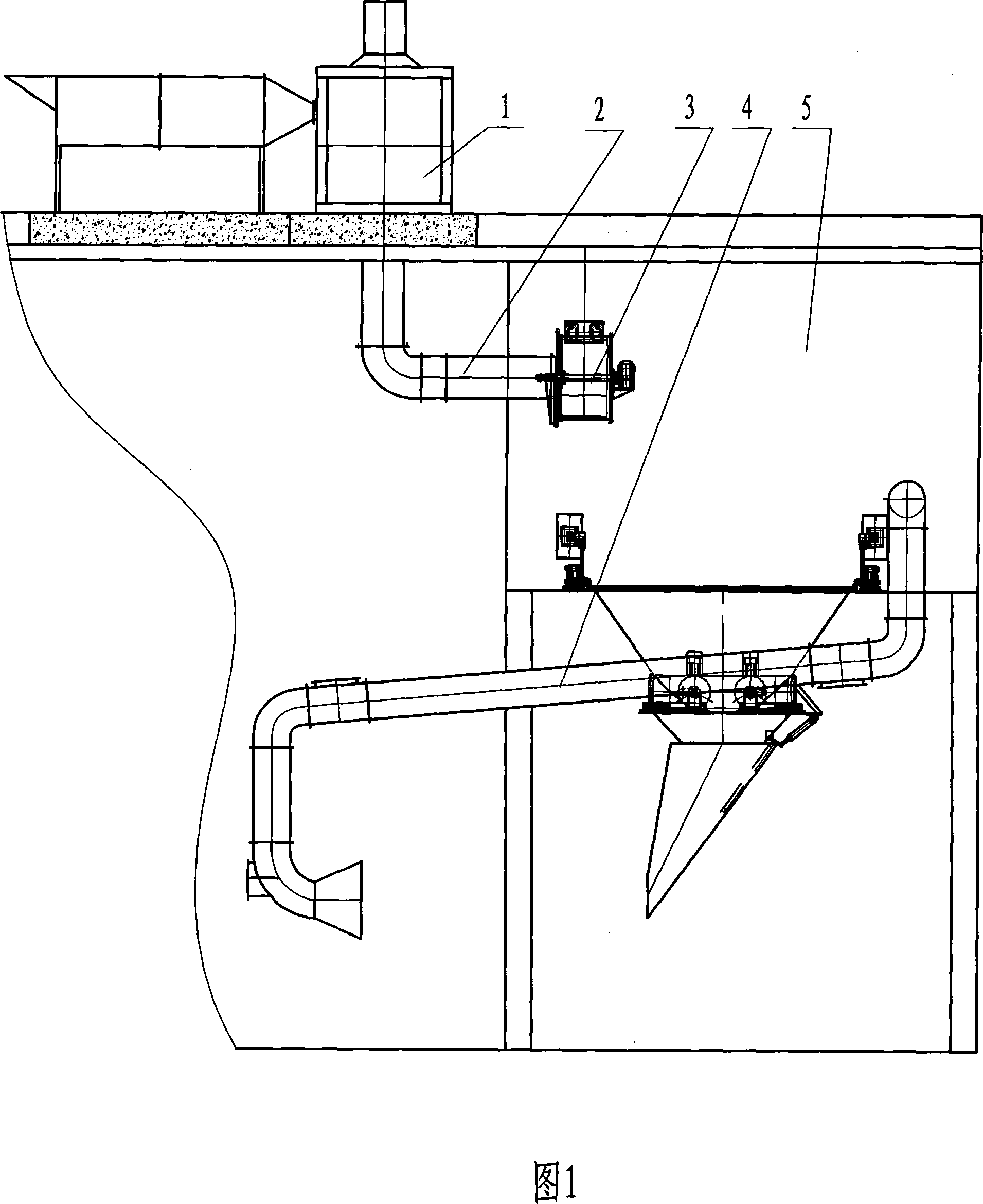

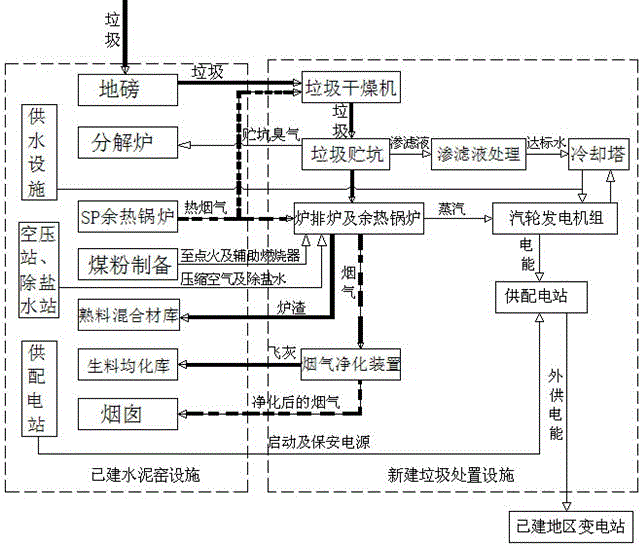

A method for co-processing waste power generation in cement plants

InactiveCN104006390BQuality is not affectedLow investment costEnergy industryIncreasing energy efficiencySlagSilo

The invention discloses a method for generating power through cooperative garbage disposal of a cement plant. The method includes the following steps that garbage is placed into a garbage storage pit, garbage leachate is qualified and reused after being processed by means of a biofilm process, stink in the storage pit is led into a raw material decomposing furnace and decomposed in a harmless way at high temperature, and the garbage is conveyed into a grate furnace for combustion; after heat of flue gas generated by combustion is absorbed in a waste heat boiler through a cooling wall, an evaporator, an overheater and the like, generated steam is input into a turbine generator, the flue gas after heat exchange is input into a flue gas purifying device, the flue gas is exhausted from a chimney, furnace slag is input into a clinker admixture bin, and fly ash generated by flue gas purification is input into a raw material homogenization silo. The method solves the problems that in the prior art, quality of cement finished products is influenced, the garbage can not be disposed during the overhaul process of cement production equipment, dioxin in the flue gas exceeds standards, the stink in the storage pit is not treated, and public and auxiliary facilities of the cement plant do not fully cooperate.

Owner:重庆问源环保工程有限公司

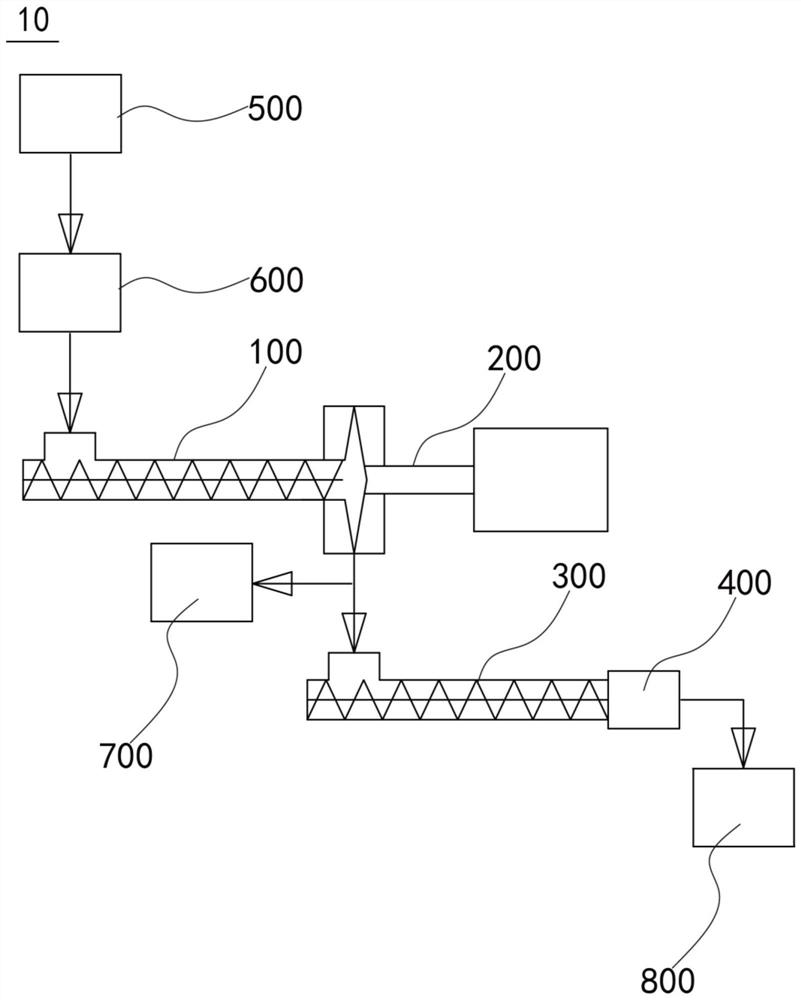

Equipment and preparation method for preparing environment-friendly plastic alloy new material from garbage and sludge in full-dose mode

InactiveCN112676310AAchieve recyclingReduce processing costsSolid waste disposalSludgeMolding machine

The invention discloses equipment and a preparation method for preparing an environment-friendly plastic alloy new material from garbage and sludge in a full-dose mode. The equipment for preparing the environment-friendly plastic alloy new material from the garbage and sludge in a full-dose mode comprises a first screw heating machine, a grinding and mixing machine, a second screw heating machine and a forming mechanism, wherein the first screw heating machine, the grinding and mixing machine, the second screw heating machine and the forming mechanism are connected in sequence. According to the equipment for preparing the environment-friendly plastic alloy new material from the garbage and the sludge in a full-dose mode, full-dose resource recycling of the garbage and the sludge can be achieved, zero incineration and zero landfill are achieved, the construction number of garbage incineration power plants and sludge treatment plants can be greatly decreased, therefore, land occupation and carbon emission are greatly reduced, in addition, waste recycling can be achieved, garbage and sludge treatment cost is reduced, and contribution is made to development of circular economy.

Owner:金茂(深圳)生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com