Comprehensive utilization technology for reducing sulfur content of high-sulfur coal ash

A technology of sulfur coal ash and process, which is applied in the field of comprehensive utilization technology for reducing the sulfur content of high-sulfur coal ash, can solve the problems that it is difficult to meet the sulfur content requirements of coking coal blending and restrict the effective utilization of coking coal, and achieve strong innovation and low cost , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

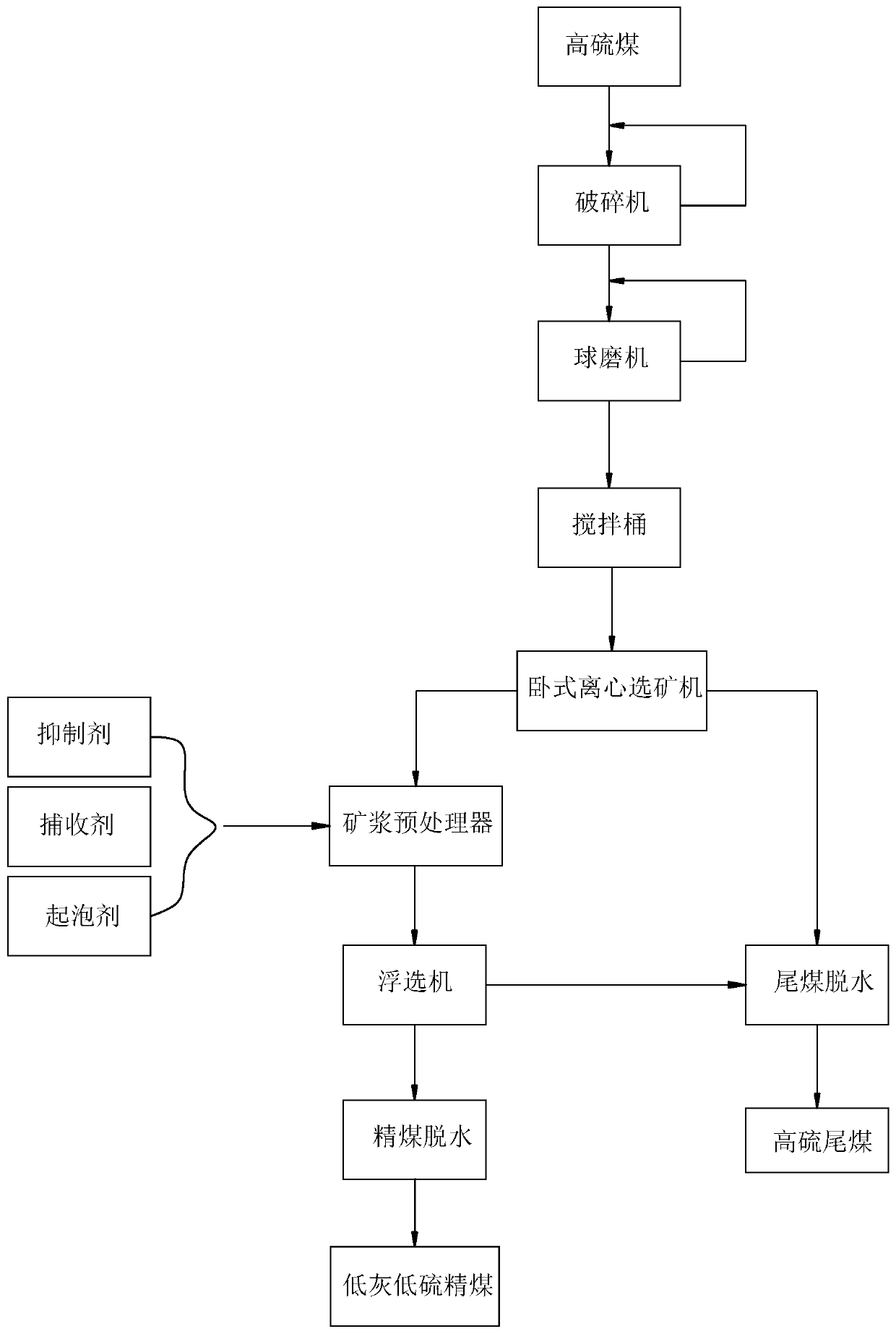

[0032] Such as figure 1 As shown, the comprehensive utilization process for reducing the sulfur content of high-sulfur coal ash in this embodiment includes the following steps:

[0033] Step 1. Feed the high-sulfur coal into the crusher for crushing to obtain crushed products; classify the crushed products to obtain coarsely crushed products and finely crushed products, and return the coarsely crushed products to the crusher again Carrying out crushing until the coarsely crushed product is broken into a finely crushed product, and the particle size of the finely crushed product is 2mm;

[0034] Step 2: Feed the finely crushed product obtained in step 1 into a ball mill for ball milling to obtain a ball mill product; after the ball mill product is classified, a coarse ball mill product and a fine ball mill product are obtained, and the coarse ball mill product is returned to the Described ball mill carries out ball milling again, until the ball milling of coarse ball milling p...

Embodiment 2

[0043] Such as figure 1 As shown, the comprehensive utilization process for reducing the sulfur content of high-sulfur coal ash in this embodiment includes the following steps:

[0044] Step 1. Feed the high-sulfur coal into the crusher for crushing to obtain crushed products; classify the crushed products to obtain coarsely crushed products and finely crushed products, and return the coarsely crushed products to the crusher again Carrying out crushing until the coarsely crushed product is broken into a finely crushed product, and the particle size of the finely crushed product is 6mm;

[0045] Step 2: Feed the finely crushed product obtained in step 1 into a ball mill for ball milling to obtain a ball mill product; after the ball mill product is classified, a coarse ball mill product and a fine ball mill product are obtained, and the coarse ball mill product is returned to the Described ball mill carries out ball milling again, until the ball milling of coarse ball milling p...

Embodiment 3

[0054] Such as figure 1 As shown, the comprehensive utilization process for reducing the sulfur content of high-sulfur coal ash in this embodiment includes the following steps:

[0055] Step 1. Feed the high-sulfur coal into the crusher for crushing to obtain crushed products; classify the crushed products to obtain coarsely crushed products and finely crushed products, and return the coarsely crushed products to the crusher again Carrying out crushing until the coarsely crushed product is broken into a finely crushed product, the particle size of the finely crushed product is 1mm;

[0056] Step 2: Feed the finely crushed product obtained in step 1 into a ball mill for ball milling to obtain a ball mill product; after the ball mill product is classified, a coarse ball mill product and a fine ball mill product are obtained, and the coarse ball mill product is returned to the The ball mill is again ball milled until the coarse ball milled product is a fine ball milled product, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com