Method and process for extracting shale oil and gas by fracturing and chemical retorting in oil shale in-situ vertical well

a technology of oil shale and vertical well, which is applied in the direction of fluid removal, borehole/well accessories, insulation, etc., can solve the problems of large excavation cost of on-ground retorting, secondary pollution, and difficulty in treatment, and achieves small environmental pollution, low operating cost, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0047]Fuyu-Changchun Mountain Oil Shale Mine, in which a total reserves is of 45.274 billion tons, is taken as an implementation base. The oil shale has an average grade of 5.53%, an industrially developable resources total amount of 18 billions, an embedded depth of 160-800 meters with top and bottom strata of mousey shale, and an average thickness of 5 meters.

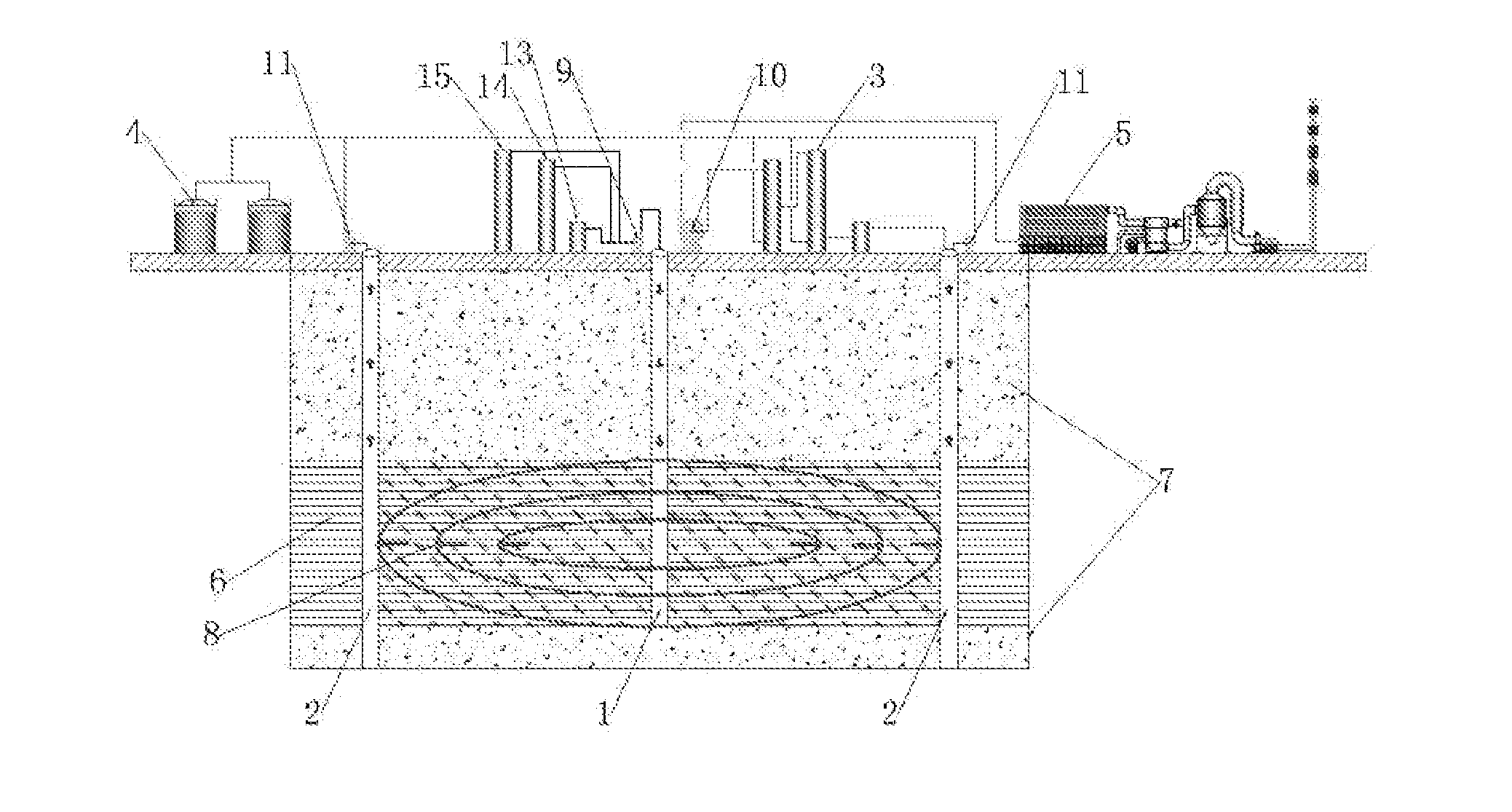

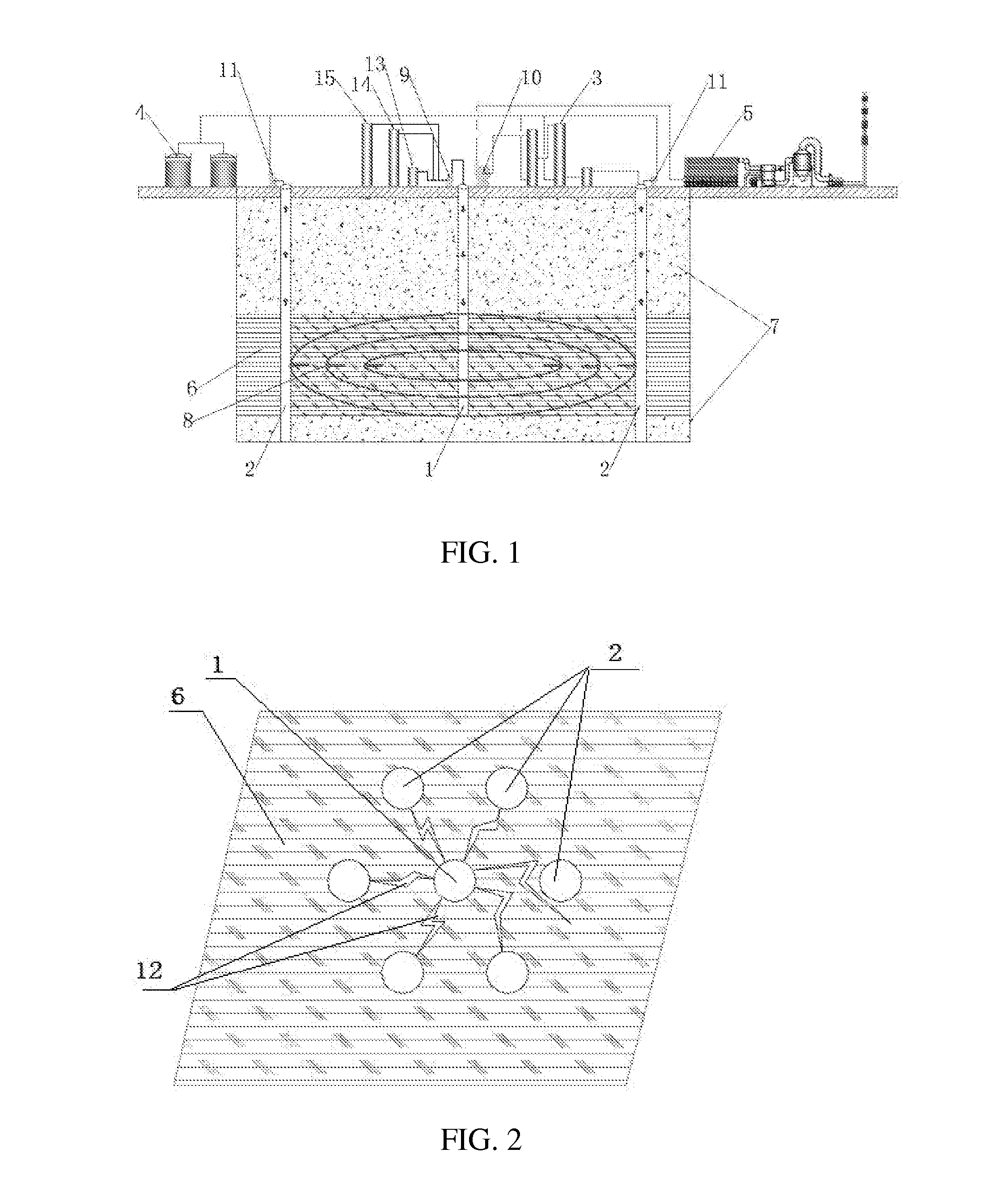

[0048]As shown in FIG. 1, depending on distribution and strike of an oil shale stratum, specific locations of a fractured burning well and export production wells are selected, a fractured burning well 1 (a head of which has a diameter of 200 mm) and six export production wells 2 (a head of each of which has a diameter of 200 mm) are drilled from a underground rock stratum 7 to a underground oil shale stratum 6 (which is distanced from the ground at 380 meters). As shown in FIG. 2, the six export production wells 2 are distributed in a honeycombed manner around the fractured burning well 1 as a center. The fractured burning w...

embodiment 2

[0069]Qiangguo Oil Shale Mine, in which a total mining area is of 675.5 km2, the total resources is of 6.172 billion tons and the exploitable total resources is of 4.94 billion tons, is taken as an implementation base. The oil shale has an average grade of 5%, an embedded depth of 160-800 meters with top and bottom strata of mousey shale, and an average thickness of 6 meters.

[0070]As shown in FIG. 1, depending on distribution and strike of an oil shale stratum, specific locations of a fractured burning well 1 and export production wells 2 are selected, a fractured burning well 1 (a head of which has a diameter of 200 mm) and six export production wells 2 (a head of each of which has a diameter of 200 mm) are drilled from a underground rock stratum 7 to a underground oil shale stratum 6 (which is distanced from the ground at 380 meters). As shown in FIG. 2, the six export production wells 2 are distributed in a honeycombed manner around the fractured burning well 1 as a center. The f...

embodiment 3

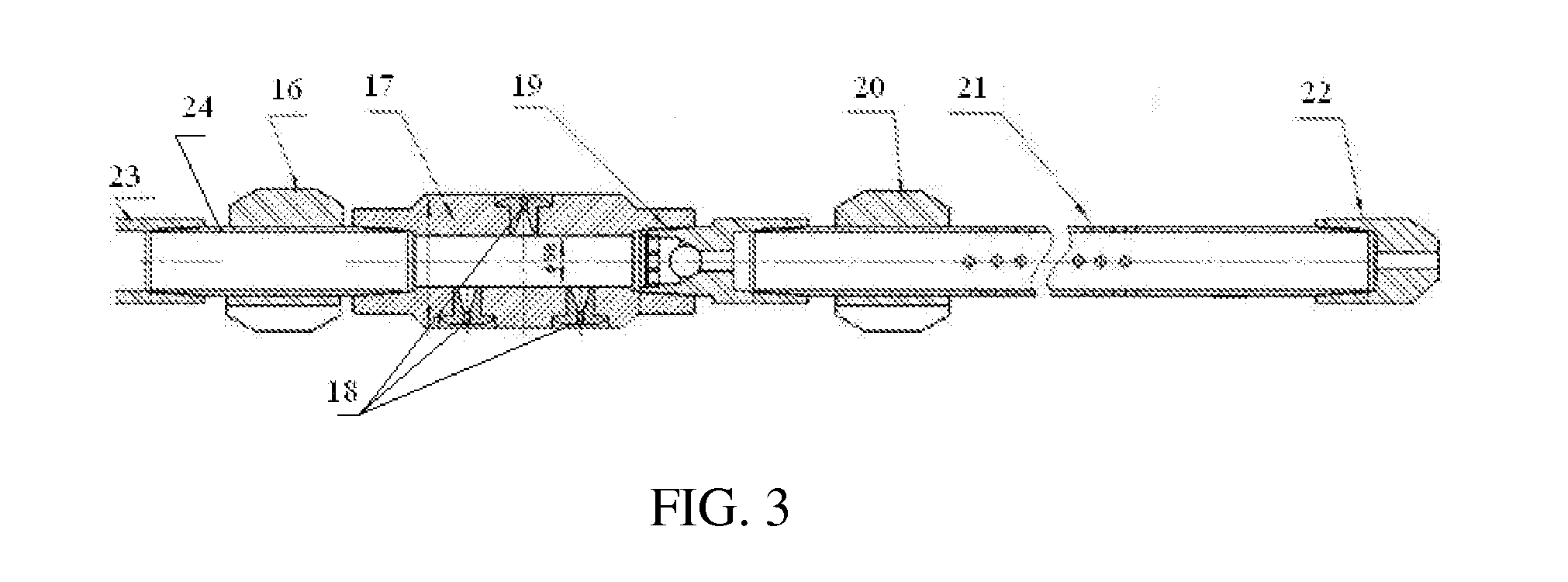

[0091]Referring to FIG. 3, there discloses a hydraulic casing nozzle involved in embodiments 1 and 2, it mainly comprises an upper centralizer 16, an ejection gun 17, a check valve 19, a lower centralizer 20, a screen pipe 22, a guide shoe 23, a casing 23 and a nipple 24, wherein a surface of the ejection gun 17 is provided with an ejection nozzle 18, the ejection nozzle 17 has one end communicated with the casing 23 by a nipple 24 and the other end communicated with the screen pipe 21 by the check valve 19, an outside of the nipple 24 is cased with the upper centralizer 16, pipe wall of the screen pipe 21 is uniformly distributed with several screen meshes, the lower centralizer 20 is cased over the screen pipe 21, and, the guide shoe 22 is secured to a top of the screen pipe 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com