A method for co-processing waste power generation in cement plants

A technology of co-processing and waste-to-energy, which is applied in steam generation method, combustion method, cement production, etc. using heat carrier, can solve the problems of high dioxin standard, affecting the quality of finished cement products, and untreated odor in garbage storage pits, etc. Achieve the effect of saving investment, reducing one-time investment and operating costs, and improving the local environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the drawings and specific embodiments.

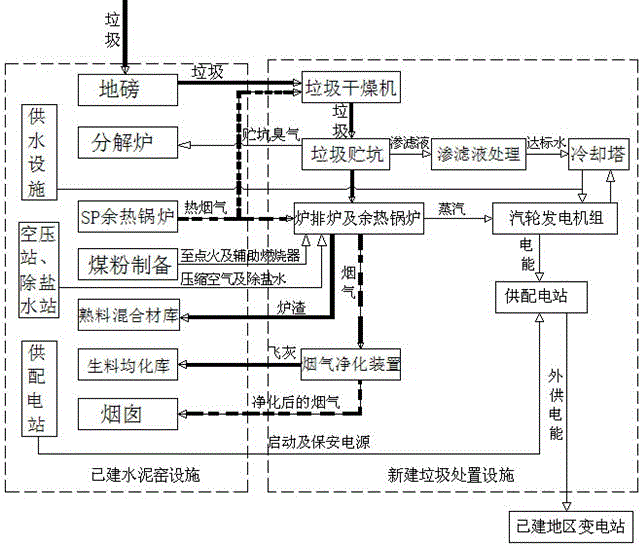

[0028] A method for co-processing waste to generate electricity in a cement plant. The method includes the following steps (such as figure 1 Shown):

[0029] 1) The garbage is weighed by a floor scale and sent to the garbage dryer, where it is dried.

[0030] 2) Place the dried garbage in the garbage storage pit. After 3 to 5 days, pass the odor in the garbage storage pit into the decomposition furnace in the built cement kiln facility, and infiltrate the garbage in the garbage storage pit to reach the standard Treatment, the treatment of leachate up to standard refers to the use of biofilm fermentation, decomposition and filtration treatment. The filtered water is connected to the cooling tower for reuse; the garbage in the garbage storage pit is sent to the grate furnace for combustion.

[0031] 3) The hot flue gas produced by the SP waste heat boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com