Plastic winnowing device

A kind of winnowing equipment and plastic technology, which is applied in the direction of plastic recycling, separating solids from solids with airflow, solid separation, etc., can solve the problems of difficult utilization of waste plastics, achieve wide application range, improve separation purity, improve The effect of resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

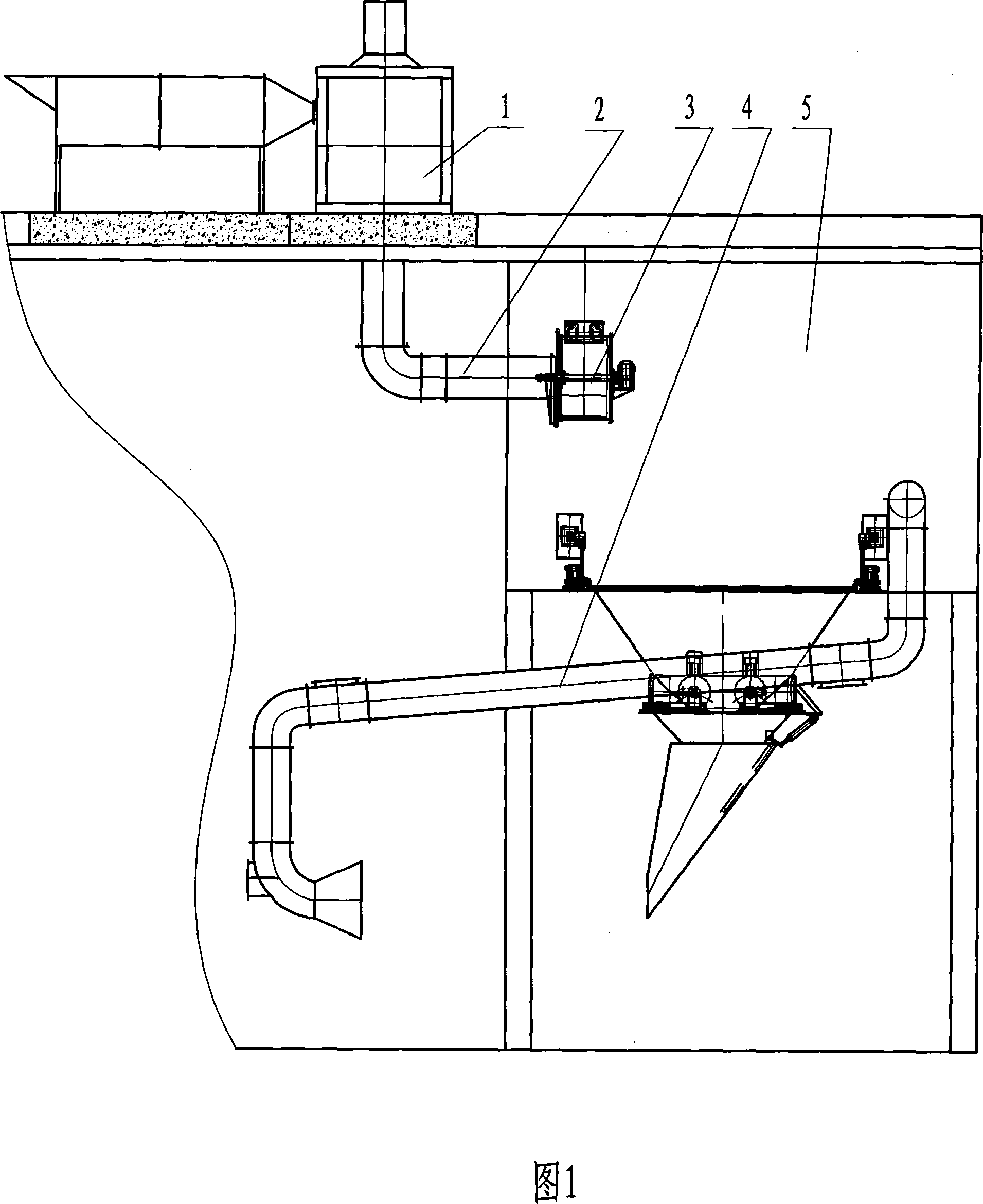

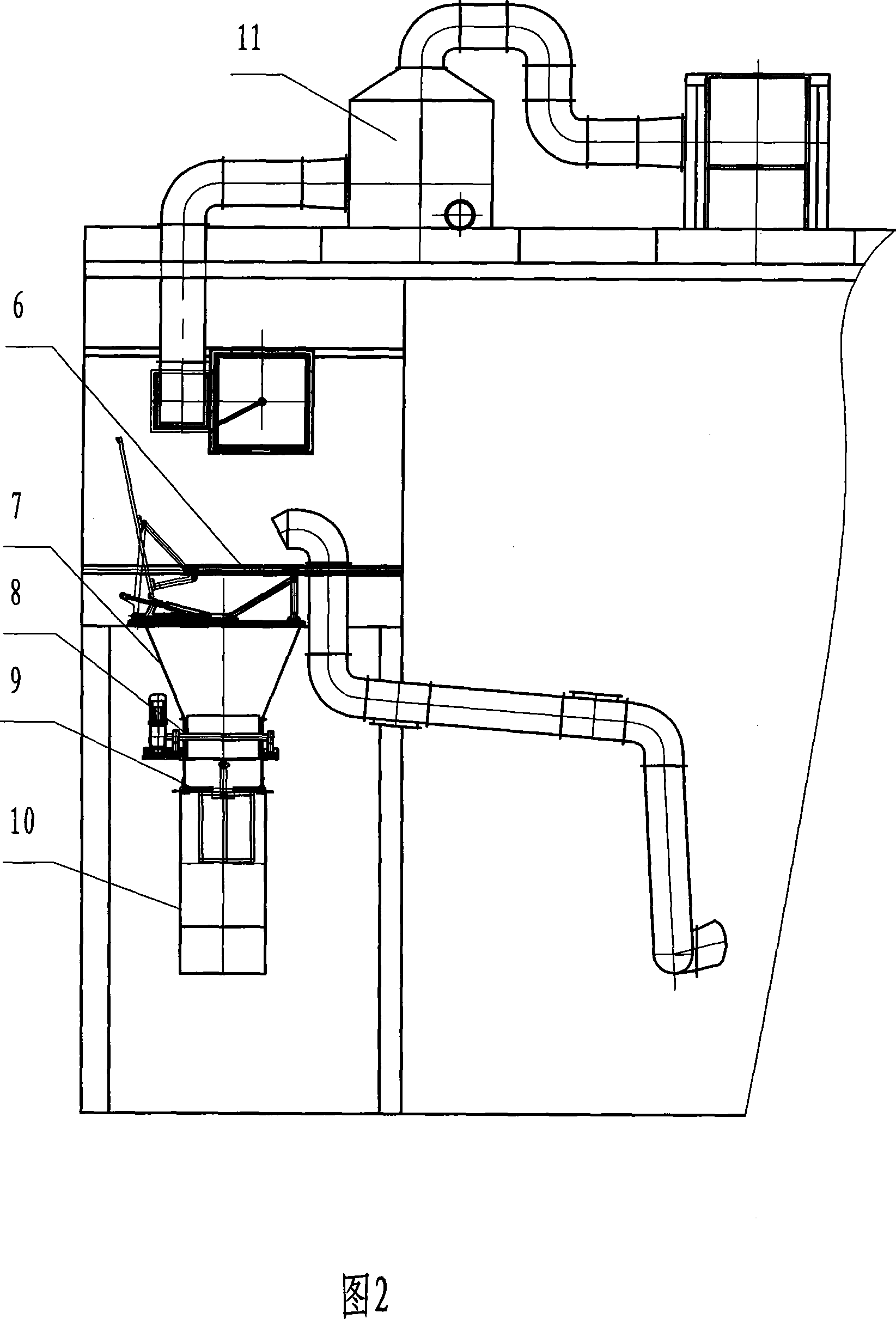

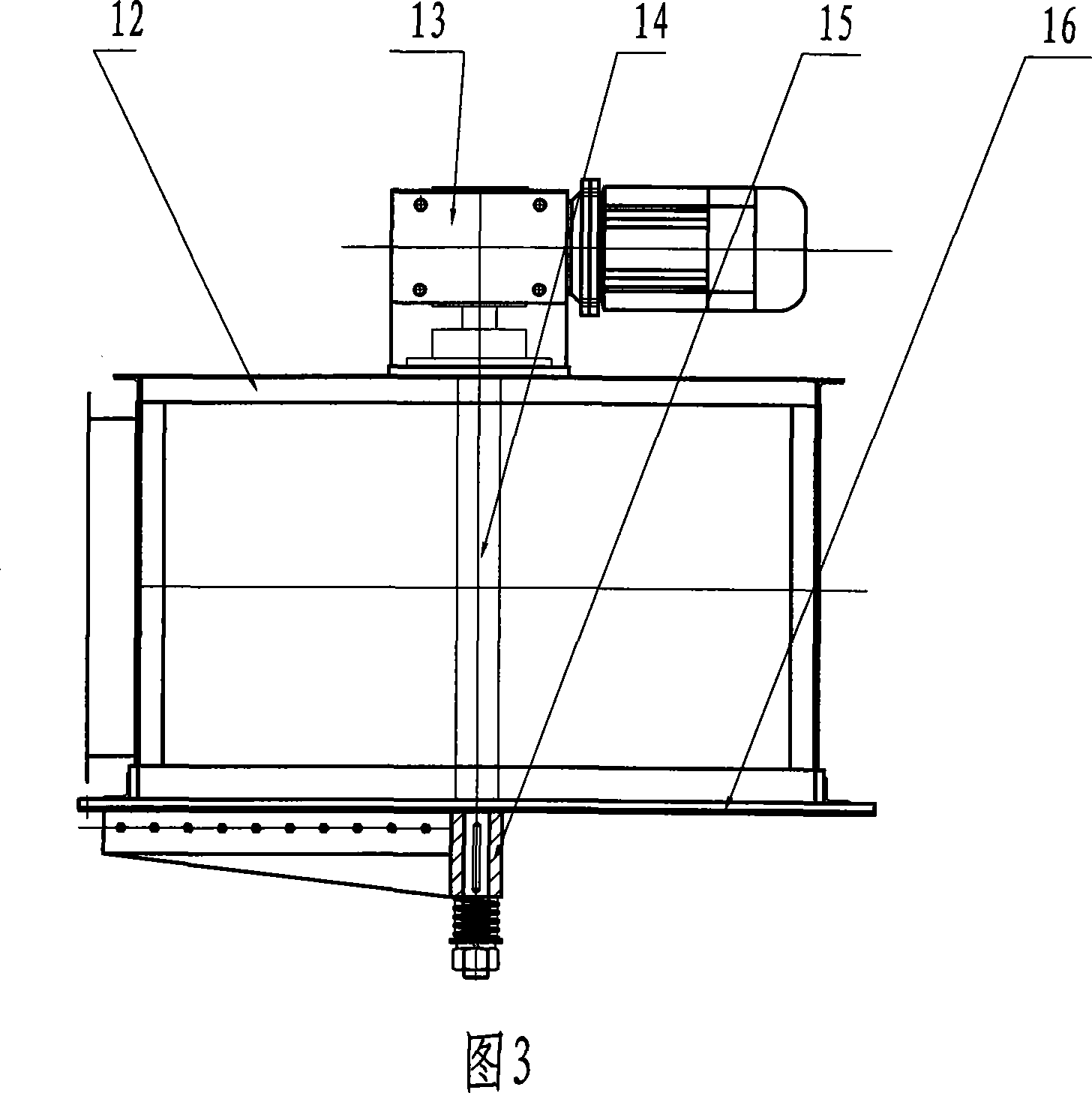

[0021] Referring to Fig. 1 and Fig. 2, the plastic winnowing equipment of the present invention, comprises settling chamber 5, is installed in the blower fan outside settling room and its sound attenuation and damping device 1, in settling chamber 5, above it is provided with through blower fan suction The material cleaning device 3 connected to the air duct 2 and the fan and its noise reduction and vibration reduction device 1 is provided with an upper sealing device 6, a material bin 7, a material guide device 8 and a lower sealing device 9 in sequence from top to bottom. A material suction pipe 4 is arranged above the upper sealing device 6 , and a material guide chute 10 is connected to the lower part of the lower sealing device. During use, the other end of the suction pipe 4, namely the suction port, leads to the output end or storage place of the waste plastic mixture of the garbage automatic crushing and sorting machine, and its function is to suck the waste plastic int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com